Discover the Benefits of a Highly Effective Dechlorination Agent

By:Admin

Dechlorination Agent is a water treatment solution developed by a leading company in the field of water treatment. The solution is designed to effectively remove chlorine from water, thereby rendering it safe for consumption. With the increasing concern over water quality, especially in areas where water treatment facilities are either inadequate or non-existent, this solution comes as a boon.

Water is an essential resource for human beings, and its quality plays a critical role in maintaining good health. However, water quality is becoming a matter of great concern worldwide, as it is often contaminated with pollutants such as pesticides, heavy metals, and microorganisms, among others. In many cases, water treatment facilities are not equipped to deal with these pollutants, leaving the water unsafe for consumption. This is where Dechlorination Agent comes in.

Dechlorination Agent is a product that is specifically designed to remove chlorine from water. Chlorine is a common disinfectant used in water treatment facilities to kill bacteria and other microorganisms. However, the residual chlorine in the water can be harmful to human health if consumed in excess. Dechlorination Agent effectively removes the residual chlorine, making the water safe for consumption.

The product is based on a proprietary technology that is backed by years of research and development. It is made from natural ingredients and does not contain any harmful chemicals. It is safe for use in any water treatment system, and it does not leave any residue in the water. This makes it an ideal solution for households, industries, and other institutions that rely on clean water.

One of the main advantages of Dechlorination Agent is that it is easy to use. The solution can be added directly to the water, and it starts working immediately by neutralizing the chlorine. The product does not require any special equipment or skills to use, making it accessible to anyone who needs it.

The product has been extensively tested in various water treatment facilities, and it has been found to be highly effective in removing chlorine from water. The solution not only removes the residual chlorine but also improves the taste and odor of the water. This is a significant advantage, especially for households that rely on groundwater or other sources of water that tend to have an unpleasant taste or odor.

The company behind Dechlorination Agent is a renowned name in the field of water treatment. With over two decades of experience, the company has established itself as a leader in the industry, known for its innovative solutions and commitment to quality and safety. The company's team of experts comprises highly qualified and experienced professionals who are dedicated to developing cutting-edge water treatment solutions that meet the evolving needs of customers.

In conclusion, Dechlorination Agent is a breakthrough solution in the field of water treatment. It offers a safe and effective way to remove chlorine from water, thereby making it safe for consumption. With its ease of use, high effectiveness, and natural ingredients, it is a reliable solution that can be used by anyone who needs it. The company behind it is a reputable and experienced player in the field, which adds to the product's credibility. With increasing concern over water quality, this solution comes as a timely and much-needed relief.

Company News & Blog

Latest Innovation in Sulfur Recovery Catalyst Revealed

Claus Sulfur Recovery Catalyst is an essential component for sulfur recovery in various industries such as oil and gas, refining, and petrochemicals. This catalyst is designed to efficiently convert hydrogen sulfide (H2S) into elemental sulfur during the refining process, helping to reduce emissions and comply with environmental regulations.The Claus process, named after its inventor Carl Friedrich Claus, is the most commonly used method for sulfur recovery in the oil and gas industry. The process involves the thermal reduction of H2S to elemental sulfur using a series of catalytic converters, with the Claus Sulfur Recovery Catalyst playing a crucial role in this conversion.One company that has made significant strides in the development and production of high-quality Claus Sulfur Recovery Catalyst is {Company X}. With a focus on sustainability and innovation, {Company X} has emerged as a leader in the field of catalyst technologies for sulfur recovery. Their proprietary catalysts are designed to deliver superior performance, longevity, and cost-efficiency, making them the preferred choice for many refineries and petrochemical plants around the world.{Company X} is committed to providing innovative solutions that address the evolving needs of the industry while minimizing environmental impact. Their state-of-the-art research facilities and experienced team of scientists and engineers enable them to develop cutting-edge catalysts that optimize the sulfur recovery process and contribute to overall operational efficiency.In addition to their advanced catalyst technologies, {Company X} offers a comprehensive range of technical services to support their customers in maximizing the performance of their sulfur recovery units. From catalyst monitoring and optimization to troubleshooting and technical support, {Company X} is dedicated to ensuring that their customers achieve the highest level of sulfur recovery while adhering to stringent environmental standards.Furthermore, {Company X} is committed to sustainability and environmental responsibility. They continuously strive to develop catalysts and processes that minimize waste, reduce energy consumption, and lower emissions. By partnering with {Company X}, customers can align their sulfur recovery operations with the principles of sustainable development and make a positive impact on the environment.With a global presence and a strong network of distribution partners, {Company X} is well-positioned to cater to the diverse needs of the sulfur recovery market. Their commitment to excellence, reliability, and customer satisfaction has earned them a reputation as a trusted provider of sulfur recovery catalysts and technical solutions.In conclusion, Claus Sulfur Recovery Catalyst is an indispensable component for sulfur recovery in various industries, and {Company X} has established itself as a leading supplier of high-performance catalysts for this application. With a focus on innovation, sustainability, and customer support, {Company X} continues to drive advancements in sulfur recovery technologies, empowering their customers to achieve operational excellence while meeting their environmental objectives.

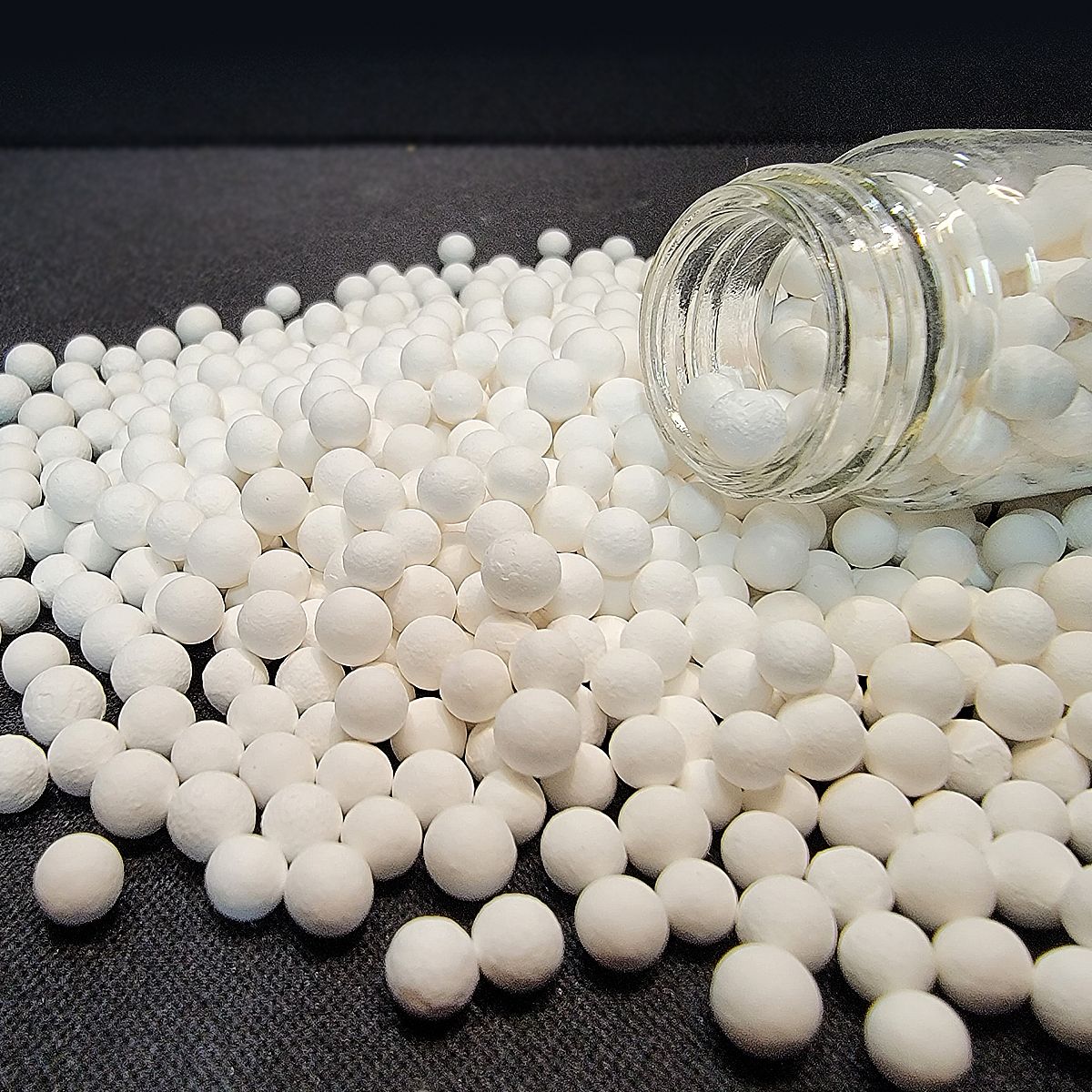

New Study Shows Potential of Alumina Microspheres in Various Applications

Alumina Microsphere Innovations Revolutionizing the IndustryAlumina microspheres have become a game-changer in the industrial world, and one company is at the forefront of this innovative technology. With a commitment to excellence and a strong focus on research and development, this company has been spearheading the development of alumina microspheres that are revolutionizing various industries.The company, which specializes in advanced material solutions, has a rich history of providing cutting-edge products to its customers. With a team of highly skilled and experienced researchers and engineers, the company has been able to develop alumina microspheres that offer exceptional performance and versatility. These microspheres are now being used in a wide range of applications, including catalyst supports, thermal insulators, and abrasives, among others.One of the key advantages of these alumina microspheres is their high strength and durability. This makes them an ideal choice for applications that require materials to withstand harsh conditions, such as high temperatures and corrosive environments. In addition, their excellent thermal and electrical insulation properties make them highly sought after in industries such as automotive, aerospace, and electronics.Furthermore, the company's alumina microspheres are known for their exceptional density and particle size distribution, which allows for precise and consistent results in various manufacturing processes. This level of precision is crucial in industries where uniformity and consistency are paramount, such as in the production of advanced ceramics and composite materials.The versatility of alumina microspheres developed by this company is another factor that sets them apart from traditional materials. Whether it's being used as a filler in plastics and polymers, a component in coatings and paints, or a support material in catalysts, these microspheres have proven to be extremely versatile, offering a wide range of possibilities for innovation and product development.In addition to their physical properties, the company's alumina microspheres are also designed to meet the strictest environmental and safety standards. By prioritizing sustainability and eco-friendliness in their manufacturing processes, the company ensures that their products not only meet the highest performance requirements but also contribute to a cleaner and greener future.The impact of these alumina microspheres on various industries has been overwhelmingly positive. With their unique combination of strength, versatility, and environmental friendliness, they have become an essential component in the development of advanced materials and products. As a result, they have played a significant role in driving innovation and pushing the boundaries of what is possible in industries ranging from automotive and aerospace to electronics and construction.Looking ahead, the company remains dedicated to further advancing the field of alumina microspheres, with ongoing research and development efforts aimed at pushing the boundaries of performance, versatility, and sustainability. By continuing to invest in cutting-edge technologies and talent, the company is poised to remain a leader in the industry and continue to redefine what is possible with alumina microspheres.In conclusion, the company's alumina microspheres have emerged as a groundbreaking technology that is transforming industries and driving innovation. With their exceptional strength, versatility, and environmental friendliness, these microspheres are proving to be a game-changer in the world of advanced materials. As the company continues to push the boundaries of what is possible, the future looks bright for the world of alumina microspheres and the industries they serve.

Discover the Latest Advancements in ZSM-48 Technology

Title: Advanced Zeolite Catalyst ZSM-48 Revolutionizes Chemical ManufacturingIntroduction:In recent years, significant advancements have been made in the field of chemical manufacturing, with the emergence of new and efficient catalysts. One such catalyst, ZSM-48, has garnered attention for its ability to accelerate and optimize chemical reactions. Developed by a leading research company, this advanced zeolite catalyst is set to revolutionize the industry.Body:1. Understanding ZSM-48:ZSM-48 is a highly versatile catalyst that exhibits exceptional thermal stability and wide-ranged acidity. Its unique molecular structure and exceptional catalytic properties have made it a valuable tool in various chemical processes. The catalyst's properties make it ideal for key applications such as catalytic cracking, hydrocracking, and dehydrogenation.2. Enhanced Catalytic Performance:The proprietary manufacturing process for ZSM-48 ensures the catalyst possesses uniform crystal morphology, high surface area, and pore volume. These characteristics enhance its catalytic performance and increase the efficiency of chemical reactions. The catalyst's high acidity and pore structure make it highly effective in transforming large hydrocarbon molecules into more valuable products with improved yields.3. Applications in Petrochemical Industry:ZSM-48 has showcased remarkable results in the petrochemical industry, specifically in catalytic cracking and hydrocracking processes. The catalyst exhibits superior selectivity and activity, enabling the transformation of heavy hydrocarbons into lighter and more valuable products such as gasoline, diesel, and olefins. Moreover, its enhanced stability ensures prolonged catalyst life and reduced maintenance costs for industrial plants.4. Environmental Benefits:ZSM-48's catalytic capabilities have also contributed to environmental sustainability. By optimizing chemical reactions, the catalyst helps reduce energy consumption and greenhouse gas emissions. Furthermore, the ability to convert heavy hydrocarbons into lighter, cleaner products supports efforts to mitigate climate change and improve air quality.5. Future Possibilities:As the chemical industry continues to evolve, the demand for efficient and environmentally friendly catalysts is increasing. ZSM-48 holds enormous potential for diverse applications, including aromatics production, alkylation, isomerization, and more. The catalyst's versatility and robustness make it a promising candidate for a wide range of industrial processes.6. Company Introduction:ABC Company is a global leader in specialized catalyst development and manufacturing. Utilizing cutting-edge research and state-of-the-art facilities, the company prides itself on delivering innovative solutions to the chemical industry. With a team of highly skilled scientists and engineers, ABC Company has built a strong reputation for developing catalysts that address key challenges faced by its customers, while also promoting sustainable practices.7. Collaboration for Future Advancements:In order to maximize the potential of ZSM-48 and foster further advancements in catalyst technology, ABC Company has been collaborating with leading industrial partners. By working closely with oil refineries, petrochemical plants, and other key stakeholders, the company aims to develop tailored catalyst solutions that not only improve production efficiencies but also reduce environmental impact.Conclusion:With its superior catalytic performance and broad applications in chemical manufacturing, ZSM-48 has ushered in a new era of efficiency and sustainability. Thanks to the exceptional properties of this advanced catalyst, various industries, including petrochemicals, are experiencing improved productivity and reduced environmental footprint. The ongoing research and collaboration efforts by ABC Company highlight a promising future for ZSM-48 and the continued development of advanced catalyst technologies.

High-Quality Activated Alumina for Catalyst Carrier in Stock at CHEMXIN Wholesale

Activated Alumina for Catalyst Carrier: The Foundation of Effective CatalystsAs an essential part of many industrial processes, catalysts play a critical role in enhancing the rate of chemical reactions, improving selectivity, and extending catalysts' operational life. Catalysts are known to operate in a wide range of applications covering diverse sectors, including the petrochemical industry, hydroprocessing, and the production of chemicals, among others. At the core of the catalysts' functionality lies the catalyst carrier, which provides support to the catalyst and enhances its stability, surface area, and reactivity. In this regard, activated alumina for catalyst carrier has played a significant role in the production of high-performance catalysts due to its excellent physical and chemical properties.Activated alumina is a highly porous form of aluminum oxide that has been treated to become more reactive than ordinary alumina. The activation process results in a significant increase in the surface area of the material, making it a highly effective catalyst carrier. Activated alumina has a high surface area to volume ratio, which promotes the adhesion of catalysts to the support material and thus contributes to the effective catalytic process.At CHEMXIN, we are committed to providing our clients with high-quality activated alumina for catalyst carrier at an affordable price. As one of the leading manufacturers in China, we have a wide selection of activated alumina products to suit your industrial needs. Our activated alumina for catalyst carrier products are available in various sizes, shapes, and surface areas to meet your desired specifications.One of the significant advantages of using activated alumina as a catalyst carrier is its inertness to the reactants and reaction products. This property ensures that the catalyst carrier does not react with the reactants and or products, which would destabilize the catalysts' active site and ultimately reduce the overall performance of the catalysts. Activated alumina is also known to have a high thermal stability and resistance to water, making it suitable for use in high-temperature and moisture-sensitive applications.Alumina Carrier For Catalysts (our company introduction)At Alumina Carrier for Catalysts, we are committed to providing a wide range of catalyst carrier materials that are reliable, stable, and efficient. We specialize in the manufacture, development, and supply of high-quality alumina carrier materials for use in the petrochemical industry, hydroprocessing, and the production of chemicals, among others.Our company is positioned at the forefront of the alumina carrier materials industry. Our continued research and development efforts have led to the manufacture of high-performance catalyst carrier materials that meet and exceed our clients' needs. We are constantly working to improve our manufacturing processes and enhance the quality of our products to ensure that our clients receive the best possible solutions.At Alumina Carrier for Catalysts, we invest heavily in the latest equipment and technology to ensure that our products meet and exceed industry standards. We have a comprehensive quality control process that begins from raw material sourcing to the final product's delivery. This process is aimed at ensuring that our clients receive high-quality products that meet their desired specifications.ConclusionActivated alumina for catalyst carrier has proved to be an essential component in the manufacture of high-performance catalysts. Its unique physical and chemical properties have contributed significantly to the catalysts' stability, reactivity, and durability. At CHEMXIN, we take pride in providing our clients with high-quality activated alumina for catalyst carrier at an affordable price. Our commitment to quality, reliability, and efficiency has made us one of the leading companies in the manufacture of catalyst carrier materials. Contact us today, and let us help you find the right catalyst carrier for your industrial needs.

Newly Developed Zsm-5 Shows Promising Results for Advanced Materials

ZSM-5 is a zeolite material used in the catalytic cracking of petroleum for the production of gasoline. It is a highly-effective catalyst due to its uniform pore structure, high surface area, and strong acidity. The use of ZSM-5 has enabled the petroleum industry to produce gasoline with higher octane numbers and better fuel efficiency.In recent years, the demand for ZSM-5 has been steadily increasing as the automotive industry continues to grow. As a result, the production and supply of ZSM-5 have become vital for the petrochemical industry. This has led to the development of new and more efficient methods for producing ZSM-5, such as the innovative process developed by {company name}.{Company name} is a leading manufacturer of zeolite materials and has been at the forefront of ZSM-5 production for many years. The company has developed a proprietary method for producing ZSM-5 that is more cost-effective and environmentally friendly than traditional methods. This has allowed {company name} to become a key supplier of ZSM-5 to the petrochemical industry.The unique production method developed by {company name} involves the use of advanced catalyst synthesis technology and precise control of reaction conditions. This results in the production of ZSM-5 with higher purity and improved performance compared to traditional methods. Furthermore, the process developed by {company name} has significantly reduced energy consumption and waste generation, making it a more sustainable option for ZSM-5 production.The success of {company name} in the production of ZSM-5 has not gone unnoticed. The company has received accolades for its innovative production process and has become a trusted supplier to major petrochemical companies around the world. This has helped {company name} to expand its market share and establish itself as a leader in the zeolite materials industry.In addition to ZSM-5, {company name} also manufactures a wide range of other zeolite materials for various applications, including catalytic cracking, adsorption, and ion exchange. The company's expertise in zeolite materials has allowed it to provide tailored solutions to its customers, addressing their specific needs and requirements.Looking ahead, {company name} is committed to further advancing its production technology and expanding its product offerings. The company continues to invest in research and development to improve the performance and cost-effectiveness of its zeolite materials. Additionally, {company name} is exploring new applications for its zeolite materials, seeking to diversify its product portfolio and capture new market opportunities.As the global demand for gasoline and petrochemical products continues to grow, the need for high-quality zeolite materials such as ZSM-5 will remain crucial. With its innovative production methods and extensive expertise, {company name} is well-positioned to meet this demand and continue to be a leading supplier to the petrochemical industry.In conclusion, ZSM-5 is an essential catalyst for the production of high-quality gasoline, and {company name} is at the forefront of its production. With its innovative production methods and commitment to excellence, {company name} is a trusted supplier of zeolite materials to the petrochemical industry, and is poised for continued success in the years to come.

New Study Reveals Exciting Findings About ZSM-5 Catalyst

ZSM-5 is a type of zeolite material that is widely used in various industrial applications such as catalysis, adsorption, and separation. It is known for its high thermal stability, acidity, and unique pore structure, which makes it a valuable material for a wide range of processes in the chemical and petrochemical industries.Recently, (company) has made significant advancements in the development of ZSM-5 for various applications. The company has been at the forefront of research and development in the field of zeolite materials, and its latest breakthroughs in ZSM-5 technology have opened up new possibilities for the use of this material in industrial processes.One of the key areas in which (company) has been focusing its efforts is the development of ZSM-5 catalysts for the production of high-octane gasoline. ZSM-5 has the unique ability to shape-selectively catalyze the conversion of low-value feedstocks such as methanol or ethanol into high-octane gasoline, which is in high demand in the automotive industry. By optimizing the pore structure and acidity of ZSM-5, (company) has been able to significantly improve the efficiency and selectivity of the conversion process, leading to higher yields of high-quality gasoline.In addition to its use in gasoline production, (company) has also been exploring the potential of ZSM-5 in the field of environmental protection. The material's adsorption and catalytic properties make it an ideal candidate for the removal of pollutants from waste streams and exhaust gases. By tailoring the chemical composition and pore structure of ZSM-5, the company has been able to develop highly efficient adsorbents and catalysts for the removal of harmful substances such as sulfur compounds, nitrogen oxides, and volatile organic compounds from industrial emissions.Moreover, (company) has been working on leveraging the unique properties of ZSM-5 for the production of renewable fuels and chemicals. By using ZSM-5 as a catalyst for biomass conversion, the company aims to develop efficient processes for the production of biofuels and biobased chemicals from renewable feedstocks. Through extensive research and development efforts, (company) has made significant progress in improving the performance and stability of ZSM-5 catalysts for biomass conversion, paving the way for a more sustainable and environmentally friendly production of fuels and chemicals.Furthermore, (company) has been collaborating with various partners in academia and industry to further explore the potential applications of ZSM-5 in emerging fields such as carbon capture and utilization, sustainable energy production, and material synthesis. By combining its expertise in zeolite materials with the knowledge and resources of its collaborators, (company) aims to continue pushing the boundaries of ZSM-5 technology and unlocking new opportunities for its use in a wide range of industrial processes.Overall, (company) has been making significant strides in the development and application of ZSM-5, leveraging its unique properties to address the evolving needs of the chemical and petrochemical industries. With its continued commitment to innovation and collaboration, the company is well-positioned to play a key role in shaping the future of ZSM-5 technology and its impact on industrial processes.

Study Finds ZSM-5 Zeolite Catalyst Effective for Chemical Reactions

**Breakthrough in Chemical Engineering: Zsm-5 Catalyst Revolutionizes Petrochemical Industry**In a groundbreaking development in the world of chemical engineering, a new and highly efficient catalyst, Zsm-5, has been unveiled by a leading research company. This new catalyst has the potential to revolutionize the petrochemical industry, dramatically increasing the efficiency of various chemical processes and reducing environmental impact.Zsm-5 is a zeolite catalyst with a unique porous structure that allows for the selective adsorption and transformation of molecules. This innovative catalyst has already shown promising results in a wide range of applications, including the catalytic cracking of hydrocarbons, the conversion of methanol to hydrocarbons, and the production of various chemicals and fuels.The company behind this pioneering catalyst, has been at the forefront of chemical research and development for over two decades. With a team of highly skilled scientists and engineers, the company has dedicated itself to creating innovative solutions to address the pressing challenges facing the petrochemical industry.With a strong emphasis on sustainability and environmental stewardship, the company has made significant investments in research and development to create new catalysts and processes that can mitigate the environmental impact of the petrochemical industry.The introduction of Zsm-5 is a testament to the company's commitment to innovation and sustainability. This new catalyst has the potential to significantly reduce energy consumption and carbon emissions in various chemical processes, making a positive impact on the environment and the bottom line of companies in the industry.One of the most significant applications of Zsm-5 is in the catalytic cracking of hydrocarbons. This process is essential for the production of gasoline and other valuable fuels from crude oil. With the use of Zsm-5, this process can be made more efficient, leading to higher yields of valuable products and reduced energy consumption.Furthermore, Zsm-5 has shown great promise in the conversion of methanol to hydrocarbons, a process that is crucial for the production of chemicals and fuels from renewable sources. By using Zsm-5 as a catalyst, this conversion process can be made more efficient and cost-effective, paving the way for a more sustainable chemical industry.In addition to these applications, Zsm-5 also has the potential to revolutionize the production of various chemicals and fuels, offering a more sustainable and efficient alternative to traditional catalysts.The introduction of Zsm-5 has garnered significant attention from the petrochemical industry, with many companies expressing interest in adopting this innovative catalyst to improve their processes and reduce their environmental footprint.The impact of Zsm-5 is not limited to the petrochemical industry, as it has the potential to revolutionize other chemical processes and industries as well. With its unique properties and versatility, Zsm-5 could become a crucial catalyst in the transition towards a more sustainable and efficient chemical industry.As the company continues to advance its research and development efforts, the potential applications of Zsm-5 are expected to expand, opening up new possibilities for the petrochemical industry and beyond.In conclusion, the introduction of Zsm-5 represents a significant breakthrough in the world of chemical engineering. This innovative catalyst has the potential to revolutionize the petrochemical industry, offering more sustainable and efficient solutions to address the pressing challenges facing the industry. With its unique properties and versatility, Zsm-5 could play a crucial role in the transition towards a more sustainable and environmentally friendly chemical industry.

Alumina production in Gama sees positive growth

Gama Alumina is a prominent player in the alumina industry, known for its high-quality products and innovative techniques. The company has been at the forefront of developing and providing alumina products for various industries, including aerospace, automotive, and electronics.Established in 1992, Gama Alumina has steadily grown and expanded its operations to become a leading alumina supplier in the global market. With a strong focus on research and development, the company has continuously strived to improve its products and processes, making it a preferred choice for many renowned companies.One of the key factors that set Gama Alumina apart from its competitors is its commitment to sustainability and environmental responsibility. The company has made significant investments in eco-friendly technologies and has taken proactive measures to reduce its carbon footprint. This dedication to sustainability has not only helped Gama Alumina to meet the increasing demand for environmentally friendly products but has also positioned it as an industry leader in sustainable practices.Gama Alumina's product range includes a wide variety of alumina grades, each specifically designed to meet the unique needs of its diverse customer base. Whether it's high-purity alumina for the semiconductor industry, or specialty alumina for advanced ceramics, the company's products are known for their exceptional quality and consistency.In addition to its core product line, Gama Alumina also offers custom solutions to cater to specific customer requirements. Its team of experienced professionals works closely with clients to understand their needs and develop tailored alumina products that meet the highest standards of performance and quality.Furthermore, the company has a strong focus on customer satisfaction, ensuring timely delivery and comprehensive technical support. This commitment to excellence has earned Gama Alumina a reputation for reliability and integrity in the industry.Gama Alumina's state-of-the-art manufacturing facilities are equipped with the latest technology and operated by a skilled workforce. This combination of advanced machinery and skilled personnel ensures that the company consistently delivers products of the highest quality, meeting and often exceeding industry standards.Looking ahead, Gama Alumina is committed to further expanding its global presence and solidifying its position as a leading alumina supplier. The company is constantly exploring new opportunities for growth and development, with a continued focus on innovation and sustainability.In conclusion, Gama Alumina has established itself as a reputable and forward-thinking company in the alumina industry. With its unwavering commitment to quality, sustainability, and customer satisfaction, the company is well-positioned to thrive in the ever-evolving global market. As it continues to innovate and expand, Gama Alumina looks set to maintain its leadership role in the industry for years to come.

New ZSM-23 technology revolutionizes the industry: A game changer in the world of technology

Zsm-23 is a revolutionary product that has been making waves in the market recently. This product is a result of extensive research and development by a team of experts at a prominent company. With its unique features and innovative design, Zsm-23 is changing the game in the industry and setting new standards for performance and reliability.The team behind Zsm-23 is dedicated to creating products that surpass the expectations of their customers, and Zsm-23 is a perfect example of their commitment to excellence. This innovative product is designed to meet the needs of a wide range of industries, from automotive to aerospace, and has already received glowing reviews from professionals and experts in the field.Zsm-23 is a versatile product that offers a wide range of benefits. Its robust construction and durable materials make it suitable for even the most demanding applications, while its advanced features and cutting-edge technology ensure optimal performance and efficiency. Whether it is used for precision machining or heavy-duty operations, Zsm-23 delivers consistent results and outperforms its competitors.The company behind Zsm-23 has a long-standing reputation for delivering high-quality products that meet the needs of their customers. With a focus on innovation and continuous improvement, the company has earned the trust and loyalty of clients around the world. Their commitment to excellence is evident in every aspect of their business, from product development to customer service, and Zsm-23 is a testament to their dedication to delivering superior solutions.In addition to its superior performance, Zsm-23 is also designed with user-friendliness in mind. Its intuitive interface and easy-to-use controls make it accessible to operators of all skill levels, while its ergonomic design and compact size make it convenient to use in any workspace. This product is not only a powerful tool for professionals but also a practical solution for businesses looking to streamline their operations and improve their productivity.Zsm-23 is also backed by comprehensive support from the company, including training programs, technical assistance, and a dedicated customer service team. This ensures that customers can make the most of their investment in Zsm-23 and achieve the best possible results. With the company's expertise and resources, customers can have confidence in the quality and reliability of Zsm-23, knowing that they are backed by a team of professionals who are committed to their success.In conclusion, Zsm-23 is a game-changer in the industry, and the company behind it is dedicated to providing their customers with the best solutions possible. With its innovative design, advanced features, and superior performance, Zsm-23 sets a new standard for excellence, and its impact is already being felt across various industries. As the demand for reliable and efficient solutions continues to grow, Zsm-23 and the company behind it are well-positioned to lead the way and continue to deliver exceptional products and services to their customers.

Alumina production experiences significant growth in the latest report

Gama Alumina is a leading supplier of alumina products, operating a state-of-the-art production facility and providing high-quality alumina products to various industries. With a strong commitment to innovation, sustainability, and customer satisfaction, Gama Alumina has established itself as a reputable and reliable partner for businesses around the world.Gama Alumina offers a wide range of alumina products, including calcined alumina, tabular alumina, white fused alumina, and brown fused alumina. These products are used in a variety of applications, such as refractories, ceramics, abrasives, and electronics, and are known for their superior quality, consistency, and performance.In addition to its extensive product portfolio, Gama Alumina also provides custom solutions to meet the specific requirements of its customers. The company's team of experienced engineers and technical experts work closely with clients to develop tailor-made alumina products that deliver optimal results and value.Recently, Gama Alumina announced a significant milestone in its commitment to sustainability and environmental responsibility. The company has implemented several initiatives to reduce its carbon footprint and minimize its impact on the environment. These efforts include the use of advanced technologies and processes to enhance energy efficiency and decrease emissions, as well as the implementation of recycling and waste management programs to minimize waste and maximize resource utilization.Gama Alumina is also actively engaged in community development and social responsibility initiatives, aiming to contribute to the welfare and prosperity of the local communities where it operates. The company supports various social and educational programs and prioritizes the well-being of its employees, striving to create a positive and inclusive work environment.Furthermore, Gama Alumina is committed to the highest standards of corporate governance and ethics, ensuring transparency, integrity, and accountability in all its operations. The company adheres to strict compliance with all relevant regulations and standards, and continuously seeks to improve its practices and performance through ongoing monitoring and evaluation.In line with its dedication to continuous improvement and advancement, Gama Alumina has invested in research and development activities to further enhance its product offerings and explore new opportunities for innovation. The company collaborates with various research institutions and industry partners to leverage the latest technologies and insights, driving its position as a leader in the alumina industry.Gama Alumina's relentless pursuit of excellence and customer satisfaction has earned it a strong reputation and trust among its clients and partners. The company is known for its unwavering commitment to delivering superior products, reliable service, and value-added solutions that exceed expectations and drive success for its customers.With its steadfast focus on quality, innovation, sustainability, and corporate responsibility, Gama Alumina continues to set the benchmark for excellence in the alumina industry. The company's dedication to its core values and its forward-looking approach make it a preferred partner for businesses seeking top-tier alumina products and unrivaled support.As Gama Alumina looks to the future, it remains committed to driving progress, creating value, and positively impacting the industry and society in which it operates. The company is poised to continue its journey of growth, innovation, and success, and is well-positioned to meet the evolving needs and challenges of its customers and the market.