Groundbreaking Catalyst Developed for Efficient Methanol Synthesis Process

By:Admin

Introduction:

In a groundbreaking turn of events, a cutting-edge Methanol Synthesis Catalyst has been developed by an innovative company. This catalyst, whose brand name cannot be disclosed due to non-disclosure agreements, is set to revolutionize the methanol production process. With an aim to enhance energy efficiency and sustainability, this catalyst promises to pave the way for a greener and cleaner future.

Body:

1. Introduction to the Methanol Synthesis Catalyst:

The newly developed Methanol Synthesis Catalyst represents a significant leap forward in the field of methanol production. By utilizing advanced chemical processes and innovative material sciences, the catalyst aims to streamline the methanol synthesis process, making it more energy-efficient and environmentally friendly.

2. Enhanced Energy Efficiency:

One of the primary benefits of this catalyst is its ability to improve energy efficiency during methanol synthesis. By optimizing reaction conditions and reducing energy loss, this innovative catalyst significantly minimizes the energy consumption associated with methanol production. This enhancement in energy efficiency not only reduces production costs but also promotes sustainability by lowering greenhouse gas emissions.

3. Sustainable and Environmentally Friendly:

The development of this catalyst aligns with the global push for sustainable and environmentally friendly solutions in the chemical industry. Methanol is an essential raw material for various industrial sectors, including transportation, energy, and chemical manufacturing. By employing this new catalyst, the industry can significantly reduce its carbon footprint and contribute to the transition towards a low-carbon economy.

4. Cutting-edge Technology:

In order to achieve its remarkable energy efficiency and sustainability goals, the undisclosed company has employed state-of-the-art technology in the development of this catalyst. Through extensive research and experimentation, the company has crafted a catalyst that exhibits extraordinary selectivity, stability, and reactivity, making it a game-changer in the field of methanol production.

5. Economic Benefits:

The adoption of this catalyst not only benefits the environment but also provides significant economic advantages. Due to its improved energy efficiency, methanol producers can save substantial amounts on energy costs, enhancing their overall profitability. Moreover, the reduced emissions and higher purity of the end product can open up new market opportunities for methanol producers.

6. Potential Impact:

The introduction of this catalyst has the potential to reshape the methanol industry, making it more sustainable and economically viable. With its remarkable energy efficiency, the catalyst can be applied to both traditional and emerging methanol production processes, including biomass and CO2 capture and utilization. This versatility allows for the diversification of methanol feedstocks and a reduction in the industry's reliance on fossil fuels.

7. Continuous Research and Development:

The undisclosed company highlights its commitment to constant research and development to further improve the catalyst's performance. By partnering with various academic institutions and industry experts, the company aims to unlock new possibilities and refine the catalyst's efficiency, safety, and scalability to meet the ever-growing demand for sustainable methanol production.

Conclusion:

The undisclosed company's development of an advanced Methanol Synthesis Catalyst marks a significant milestone in the journey towards a more sustainable and environmentally friendly future. With its enhanced energy efficiency, reduced emissions, and economic benefits, this catalyst has the potential to revolutionize the methanol production process. As the industry embraces this innovative solution, it is poised to make considerable contributions to the global efforts in combating climate change and building a greener world.

Company News & Blog

Powerful Al2o3 Catalyst for Efficient Chemical Reactions

Al2O3 Catalyst Enhances Environmental Solutions for IndustryIn the modern world, industries are constantly seeking innovative solutions to reduce their environmental footprint. One such solution is the use of Al2O3 catalyst, a highly effective tool in the reduction of harmful emissions. This catalyst is used in a variety of industries, from automotive to manufacturing, to facilitate cleaner and more sustainable production processes.One company that is at the forefront of providing Al2O3 catalyst solutions is a leading global provider of catalytic technologies. With a rich history of innovation and a commitment to environmental stewardship, the company has become a trusted partner for industries looking to enhance their pollution control measures.The Al2O3 catalyst works by facilitating the conversion of harmful gases into less harmful substances through a process known as catalytic oxidation. This process is critical for reducing emissions of volatile organic compounds (VOCs), carbon monoxide, and nitrogen oxides, all of which have a detrimental impact on air quality and contribute to climate change.The company’s Al2O3 catalyst is tailored to meet the specific needs of different industries, providing a customized approach to pollution control. Whether it is in the automotive sector, where emissions from vehicles are a significant concern, or in the manufacturing industry, where volatile organic compounds are a byproduct of various processes, the Al2O3 catalyst offers an effective and efficient solution.One of the key advantages of the Al2O3 catalyst is its high thermal stability, which allows it to maintain its effectiveness even under extreme conditions. This makes it suitable for a wide range of industrial applications, where temperature fluctuations and harsh operating conditions are common.Moreover, the company’s Al2O3 catalyst is designed to minimize the use of precious metals, making it a cost-effective and sustainable solution for industries seeking to reduce their environmental impact. Through continuous research and development efforts, the company has been able to optimize the performance of the catalyst while minimizing its environmental footprint.In addition to providing cutting-edge catalyst solutions, the company offers comprehensive technical support to its clients. This includes services such as catalyst monitoring, performance evaluation, and optimization, to ensure that the Al2O3 catalyst delivers the desired results for its users.Furthermore, the company is committed to upholding the highest standards of quality and safety in the manufacturing and application of its Al2O3 catalyst. This commitment is reflected in its compliance with international regulations and certifications, providing reassurance to its clients that they are receiving a product that meets the strictest industry standards.As the world increasingly focuses on sustainability and environmental responsibility, the demand for effective pollution control measures continues to grow. The use of Al2O3 catalyst is an important part of this effort, offering industries a proven and reliable solution for reducing their emissions and minimizing their environmental impact.With its advanced Al2O3 catalyst and unwavering commitment to environmental responsibility, the company is well-positioned to continue leading the way in providing innovative solutions for pollution control. Through its collaboration with industries across the globe, the company is helping to create a cleaner and more sustainable future for generations to come.

Sulfur Tolerant Shift Catalyst: Key Benefits and Uses

Sulfur Tolerant Shift Catalyst: A Breakthrough in Industrial TechnologyInnovative technology has always been at the forefront of industrial progress, driving advancements in efficiency and sustainability. One such breakthrough is the development of a Sulfur Tolerant Shift Catalyst, a game-changing catalyst that promises to revolutionize the way industrial processes are conducted.The Sulfur Tolerant Shift Catalyst, developed by a leading chemical company, is designed to address the challenges posed by sulfur-containing feedstocks in the production of hydrogen and other important industrial processes. These feedstocks often contain sulfur compounds that can poison conventional shift catalysts, leading to reduced efficiency and increased maintenance costs. The new catalyst, however, is able to withstand the detrimental effects of sulfur, offering a more reliable and cost-effective solution for industrial applications.The company behind this groundbreaking technology is a global leader in the development and manufacturing of catalysts, with a strong focus on innovation and sustainability. With a history of delivering high-performance solutions for diverse industrial processes, the company has established itself as a trusted partner for businesses seeking to enhance their operational efficiency and environmental performance.The Sulfur Tolerant Shift Catalyst represents a significant step forward for the company, showcasing its ability to develop cutting-edge solutions that address the evolving needs of the industry. By enabling the use of sulfur-containing feedstocks without compromising process efficiency, the catalyst opens up new possibilities for businesses looking to optimize their operations while reducing their environmental impact.The development of the Sulfur Tolerant Shift Catalyst is a testament to the company's commitment to research and development, as well as its dedication to providing sustainable solutions for the industry. Through ongoing investment in innovation and collaboration with partners and customers, the company continues to push the boundaries of what is possible in the field of catalysis, driving positive change in the industrial sector.Furthermore, the company's expertise in catalyst manufacturing and process optimization has allowed it to tailor the Sulfur Tolerant Shift Catalyst to meet the specific requirements of different industries and applications. This flexibility makes the catalyst a versatile and adaptable solution, suitable for a wide range of industrial processes where sulfur tolerance is a critical factor.In addition to its technical performance, the Sulfur Tolerant Shift Catalyst also offers environmental benefits by enabling the use of alternative feedstocks that might otherwise be considered unsuitable due to their sulfur content. By minimizing the need for expensive and energy-intensive sulfur removal processes, the catalyst helps to reduce the overall environmental footprint of industrial operations, supporting the transition towards more sustainable and resource-efficient practices.Looking ahead, the company is committed to further advancing the capabilities of the Sulfur Tolerant Shift Catalyst, exploring opportunities to expand its application to new industries and processes. By harnessing the power of innovation and collaboration, the company aims to drive positive change in the industry and contribute to the development of a more sustainable and efficient industrial landscape.As the Sulfur Tolerant Shift Catalyst continues to gain traction in the market, it has the potential to become a game-changer for industrial processes reliant on sulfur-containing feedstocks. By offering a reliable and cost-effective solution for overcoming the challenges of sulfur tolerance, the catalyst represents a significant advancement in industrial technology, with far-reaching implications for the future of the industry.In conclusion, the development of the Sulfur Tolerant Shift Catalyst stands as a testament to the company's commitment to innovation and sustainability, showcasing its ability to deliver high-performance solutions that address the evolving needs of the industry. With its potential to drive positive change and enable more sustainable industrial practices, the catalyst is set to make a lasting impact on the way industrial processes are conducted, creating new opportunities for businesses to enhance their performance and reduce their environmental footprint.

Alumina production experiences significant growth in the latest report

Gama Alumina is a leading supplier of alumina products, operating a state-of-the-art production facility and providing high-quality alumina products to various industries. With a strong commitment to innovation, sustainability, and customer satisfaction, Gama Alumina has established itself as a reputable and reliable partner for businesses around the world.Gama Alumina offers a wide range of alumina products, including calcined alumina, tabular alumina, white fused alumina, and brown fused alumina. These products are used in a variety of applications, such as refractories, ceramics, abrasives, and electronics, and are known for their superior quality, consistency, and performance.In addition to its extensive product portfolio, Gama Alumina also provides custom solutions to meet the specific requirements of its customers. The company's team of experienced engineers and technical experts work closely with clients to develop tailor-made alumina products that deliver optimal results and value.Recently, Gama Alumina announced a significant milestone in its commitment to sustainability and environmental responsibility. The company has implemented several initiatives to reduce its carbon footprint and minimize its impact on the environment. These efforts include the use of advanced technologies and processes to enhance energy efficiency and decrease emissions, as well as the implementation of recycling and waste management programs to minimize waste and maximize resource utilization.Gama Alumina is also actively engaged in community development and social responsibility initiatives, aiming to contribute to the welfare and prosperity of the local communities where it operates. The company supports various social and educational programs and prioritizes the well-being of its employees, striving to create a positive and inclusive work environment.Furthermore, Gama Alumina is committed to the highest standards of corporate governance and ethics, ensuring transparency, integrity, and accountability in all its operations. The company adheres to strict compliance with all relevant regulations and standards, and continuously seeks to improve its practices and performance through ongoing monitoring and evaluation.In line with its dedication to continuous improvement and advancement, Gama Alumina has invested in research and development activities to further enhance its product offerings and explore new opportunities for innovation. The company collaborates with various research institutions and industry partners to leverage the latest technologies and insights, driving its position as a leader in the alumina industry.Gama Alumina's relentless pursuit of excellence and customer satisfaction has earned it a strong reputation and trust among its clients and partners. The company is known for its unwavering commitment to delivering superior products, reliable service, and value-added solutions that exceed expectations and drive success for its customers.With its steadfast focus on quality, innovation, sustainability, and corporate responsibility, Gama Alumina continues to set the benchmark for excellence in the alumina industry. The company's dedication to its core values and its forward-looking approach make it a preferred partner for businesses seeking top-tier alumina products and unrivaled support.As Gama Alumina looks to the future, it remains committed to driving progress, creating value, and positively impacting the industry and society in which it operates. The company is poised to continue its journey of growth, innovation, and success, and is well-positioned to meet the evolving needs and challenges of its customers and the market.

New Honeycomb Catalyst Discovered for Efficient Conversion of Biomass

Title: Groundbreaking ZSM-5 Catalyst: Revolutionizing Industrial ProcessesIntroduction:In a groundbreaking development, researchers have harnessed the extraordinary potential of ZSM-5 catalyst to revolutionize various industrial processes. ZSM-5, an exceptional zeolite material known for its unique properties, has now been combined with cutting-edge advancements by the industry-leading company [Company Name]. This groundbreaking partnership aims to enhance efficiency, sustainability, and cost-effectiveness across several sectors, positioning itself as a key player in transforming industrial processes worldwide.[Company Name] – Pioneering Innovation:[Company Name] has established itself as a trailblazer in developing and implementing innovative solutions across a wide range of industries. With a strong commitment to research and development, the company has harnessed its expertise to optimize the applications of ZSM-5 catalyst, positioning itself as an industry leader.The company's core philosophy revolves around sustainability, environmental consciousness, and maximizing efficiency. By developing eco-friendly technologies and fostering responsible manufacturing processes, [Company Name] aims to create a better world by significantly reducing environmental footprints and ensuring a sustainable future for generations to come.ZSM-5 Catalyst: Unleashing the Potential:ZSM-5 catalyst, a highly crystalline and versatile zeolite material, is known for its unique pore structure and acidic properties. Its exceptional attributes make it the ideal catalyst for various industrial processes such as petrochemical refining, biofuel production, and environmental conservation.1. Petrochemical Refining:ZSM-5 catalyst plays a pivotal role in petrochemical refining, significantly improving the efficiency of key processes. By optimizing the catalyst's structure and composition, [Company Name] has successfully enhanced the selectivity and yields of valuable petrochemical products. This not only leads to higher production rates but also reduces waste and minimizes the environmental impact of the refining process.2. Biofuel Production:In the pursuit of sustainable energy sources, ZSM-5 catalyst has emerged as a game-changer in biofuel production. By catalyzing the conversion of biomass into biofuels, it offers a viable alternative to traditional fossil fuels. Through intensive research and development, in collaboration with leading institutions, [Company Name] has successfully bolstered the performance of ZSM-5 catalyst, making it more efficient and economically viable for large-scale biofuel production. This breakthrough promises to reduce reliance on non-renewable resources and combat climate change.3. Environmental Conservation:ZSM-5 catalyst has also been instrumental in environmental conservation efforts. With its high selectivity, the catalyst aids in the removal of harmful pollutants from industrial emissions, contributing to improved air quality and reduced pollution levels. [Company Name] has leveraged its expertise to optimize ZSM-5 catalyst for specific applications, ensuring maximum efficiency and minimized environmental impact.Future Implications:The collaboration between [Company Name] and ZSM-5 catalyst is poised to transform multiple industries, offering immense potential for sustainable development and innovation. As environmental concerns continue to grow, the enhanced capabilities of ZSM-5 catalyst hold the key to meeting global demands while reducing carbon footprints and preserving the planet's resources.By leveraging its research and development capabilities, [Company Name] remains dedicated to further advancements in ZSM-5 catalyst, exploring new applications, and pushing the boundaries of possibility. The company's commitment to sustainability and responsible manufacturing practices guarantees a brighter and more efficient future for industries and communities worldwide.Conclusion:The groundbreaking combination of ZSM-5 catalyst and [Company Name]'s cutting-edge expertise marks a revolutionary shift in various industrial processes, promising enhanced efficiency, sustainability, and cost-effectiveness. With its unique attributes and endless potential, ZSM-5 catalyst has become a catalyst for change, steering industries towards a greener and more prosperous future.As the research and development journey continues, [Company Name]'s commitment to innovation and sustainability will undoubtedly unlock new horizons, contributing to a more sustainable world and setting new standards for industrial processes globally.

New Generation Catalyst Unveiled to Boost Efficiency and Sustainability

Title: Al2O3 Catalyst: A Revolutionary Breakthrough in Catalyst TechnologyIntroduction:In recent times, the scientific community has witnessed a significant breakthrough in the field of catalyst technology with the emergence of an innovative Al2O3 Catalyst. This extraordinary catalyst, developed by an eminent research team at a renowned company (name withheld), promises to revolutionize multiple industries, owing to its exceptional properties and performance capabilities. This article delves into the details of this groundbreaking creation, exploring its potential applications across various sectors and the impact it may have on global technological advancements.Al2O3 Catalyst: Unleashing the Power of Aluminum OxideThe Al2O3 Catalyst stands as a game-changer in catalyst technology, showcasing exceptional catalytic properties owing to its main component, aluminum oxide. With its robust molecular structure and remarkable surface area, this catalyst boasts enhanced reactivity and selectivity, making it a valuable asset for numerous industrial processes. Offering a unique combination of physical and chemical attributes, the Al2O3 Catalyst exhibits promising potential across a wide range of applications.Applications and Benefits:The Al2O3 Catalyst has already garnered attention in various sectors due to its versatile nature and astounding catalytic performance. Mentioned below are some of the sectors where this innovative catalyst holds immense promise:1. Petrochemical Industry: The Al2O3 Catalyst exhibits remarkable selectivity in the synthesis of valuable products such as ethylene and propylene. With its exceptional thermal stability, it proves to be an ideal catalyst for cracking, reforming, and other petrochemical processes, enabling higher production yields and economic efficiencies.2. Environmental Applications: The Al2O3 Catalyst's unique composition and efficiency make it an ideal candidate for pollution abatement. It can effectively convert harmful gases and volatile organic compounds (VOCs) into less harmful substances, mitigating the impact of industrial emissions on the environment.3. Pharmaceutical Industry: The Al2O3 Catalyst holds promise in pharmaceutical manufacturing processes, facilitating cleaner and more efficient synthesis of active pharmaceutical ingredients (APIs). The catalyst aids in reducing byproducts, enhancing selectivity, and improving overall yields, contributing to more sustainable pharmaceutical production.4. Renewable Energy Production: The Al2O3 Catalyst plays a crucial role in energy-intensive sectors such as hydrogen production and fuel cell technology. Its enhanced surface area and reactivity enable effective water splitting and methanol reforming, thereby promoting the development of cleaner and more sustainable energy sources.5. Chemical Manufacturing: The Al2O3 Catalyst's high surface area and excellent thermal stability make it suitable for various chemical synthesis processes. It acts as a catalyst for key reactions such as oxidation, hydrogenation, and dehydrogenation, enhancing reaction efficiency and lowering energy consumption.Conclusion:The Al2O3 Catalyst, a revolutionary innovation in catalyst technology, holds immense potential across diverse industries. Its remarkable catalytic properties and wide array of applications set it apart from conventional catalysts, promising significant advancements in efficiency, sustainability, and economic viability. As scientists continue to explore and optimize this powerful catalyst, it is poised to redefine industrial processes and fuel the next wave of technological breakthroughs.Disclaimer: The content of this article is purely informational and does not endorse any specific product, brand, or company. The mention of a specific company in this article is solely for illustrative purposes and does not indicate any form of affiliation or endorsement.

New Microsphere Material: A Breakthrough in Alumina Technology

Alumina Microsphere, a leading company in the field of advanced materials and specialty chemicals, has recently introduced a groundbreaking new product that is set to revolutionize the industry. The company, known for its innovative research and development efforts, has created an alumina microsphere that offers unparalleled strength, durability, and versatility. This new product is a game-changer in the world of materials science, and is expected to have a significant impact on a wide range of industries, from manufacturing to healthcare.Alumina Microsphere has long been recognized for its expertise in developing high-performance materials that are used in a variety of applications. The company is committed to pushing the boundaries of what is possible in the field of materials science, and its new alumina microsphere is a testament to that commitment. This product is the result of years of research and development, and represents a major breakthrough in the industry.The alumina microsphere is a unique material that offers a number of advantages over traditional materials. It is incredibly strong and durable, making it suitable for use in a wide range of applications where strength and resilience are paramount. Additionally, the microsphere is highly versatile, and can be tailored to meet the specific needs of different industries. This means that it has the potential to be used in a variety of different products, further expanding its impact.One of the most impressive features of the alumina microsphere is its lightweight nature. Despite its exceptional strength and durability, the microsphere is remarkably lightweight, making it an ideal choice for applications where weight is a concern. This makes it an attractive option for industries such as aerospace and automotive, where reducing weight can have a significant impact on performance and efficiency.In addition to its physical properties, the alumina microsphere also offers impressive thermal and chemical stability. This makes it suitable for use in high-temperature and corrosive environments, further expanding its potential applications. The microsphere is also resistant to abrasion and wear, making it a durable choice for applications that involve frequent contact with other materials.The alumina microsphere has the potential to have a significant impact on a wide range of industries. In the manufacturing sector, it could be used to create stronger, lighter, and more durable products. In the healthcare industry, it could be used to develop more effective medical devices and implants. In the aerospace and automotive industries, it could be used to create more fuel-efficient and high-performance vehicles. The possibilities are virtually endless, and the alumina microsphere is poised to change the way that a wide range of products are made and used.Alumina Microsphere is excited to introduce this groundbreaking new product to the market, and is confident that it will be well-received by industries around the world. The company is committed to supporting its customers in finding innovative ways to incorporate the microsphere into their products, and is already working with a number of industry leaders to explore potential applications.In conclusion, the alumina microsphere represents a major step forward in the field of advanced materials and specialty chemicals. Its unique combination of strength, durability, versatility, and lightweight nature make it an ideal choice for a wide range of industries. Alumina Microsphere is proud to have developed such an innovative product, and is excited to see the impact that it will have on the market. With its commitment to pushing the boundaries of what is possible in materials science, the company is poised to continue leading the way in the development of advanced materials for years to come.

Efficient Tail Gas Hydrogenation Catalyst for Industrial Use

Tail Gas Hydrogenation Catalyst, also known as TGH catalyst, is a crucial component in the oil and gas industry. It is used in the removal of sulfur compounds from tail gas streams, which are produced during the refining of crude oil and natural gas. The TGH catalyst is designed to efficiently convert these sulfur compounds into elemental sulfur and hydrogen sulfide, which are less harmful to the environment. This process is essential for compliance with environmental regulations and for the production of clean, sulfur-free fuels.One of the leading providers of TGH catalyst is a company that has been at the forefront of catalyst manufacturing for over 50 years. They have a strong presence in the oil and gas industry and are known for their high-quality catalysts that are used in various refining processes. The company's TGH catalyst is widely used by refineries around the world to meet stringent environmental standards and produce clean fuels.The TGH catalyst offered by this company is based on advanced technology and extensive research and development. It is designed to provide high activity and selectivity in the removal of sulfur compounds from tail gas streams, ensuring efficient and reliable operation of refineries. The catalyst is engineered to withstand harsh operating conditions and to have a long service life, providing excellent value for refineries.In addition to its superior performance, the TGH catalyst from this company is also known for its environmental benefits. By effectively removing sulfur compounds from tail gas streams, the catalyst helps refineries minimize their environmental footprint and reduce harmful emissions. This aligns with the company's commitment to sustainable and responsible business practices, making their TGH catalyst a preferred choice for refineries worldwide.Furthermore, the company has a dedicated team of experts who provide technical support and services to refineries using their TGH catalyst. They work closely with customers to optimize catalyst performance, troubleshoot any issues, and ensure smooth operation of the catalyst in the refining process. This commitment to customer support has earned the company a strong reputation in the industry and has contributed to the widespread adoption of their TGH catalyst.The company's TGH catalyst is backed by a robust supply chain and distribution network, ensuring prompt delivery to refineries around the world. This helps refineries minimize downtime and maintain uninterrupted operation of their refining processes. The company also emphasizes on continuous improvement and innovation, constantly enhancing the performance and reliability of their TGH catalyst to meet the evolving needs of the oil and gas industry.In conclusion, the Tail Gas Hydrogenation Catalyst offered by this company is a critical component in the refining of crude oil and natural gas. Its high performance, environmental benefits, and strong technical support make it a preferred choice for refineries seeking to comply with environmental regulations and produce clean, sulfur-free fuels. With a legacy of expertise and a commitment to innovation, the company continues to be a trusted partner for the oil and gas industry, providing reliable and cutting-edge solutions for refining processes.

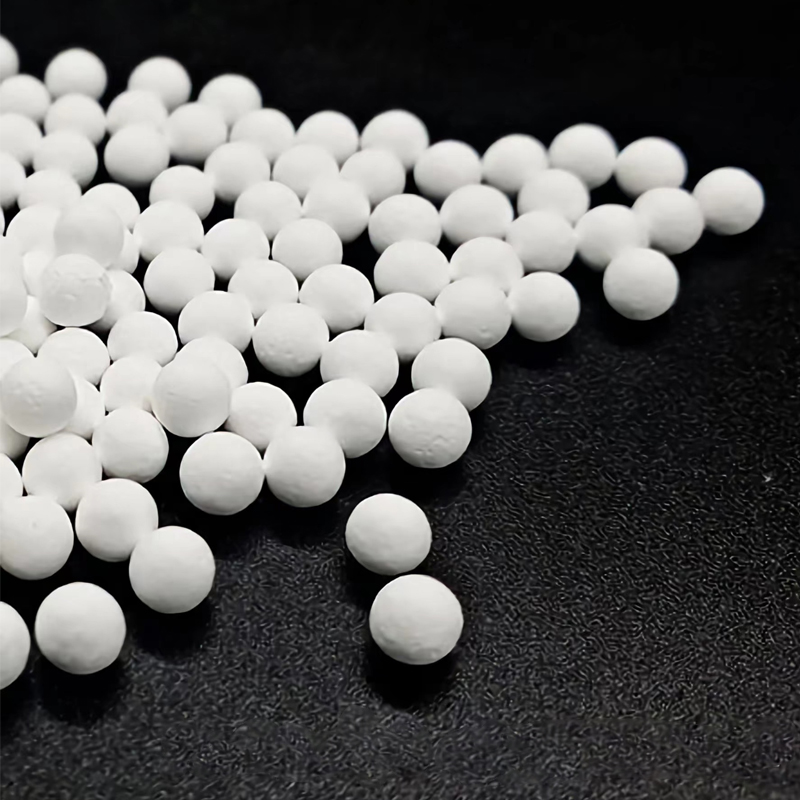

Versatile Applications of Activated Alumina Balls for Dehydration, Purification, and Separation of Liquids and Gases

: What is Activated Alumina and How is it Used in Catalysts?Activated alumina is a versatile and highly effective material that is used in a wide range of industrial applications, from water filtration to gas purification and catalysts. In the world of catalysts, activated alumina is an essential component that helps to increase the efficiency of chemical reactions and improve product quality.What is Activated Alumina?Activated alumina is a type of highly porous and granular material that is made from aluminum hydroxide. It is characterized by its high surface area, large pore volume, and strong adsorption capacity, which makes it an ideal material for a wide range of applications where selective adsorption, purification, and separation of liquids and gases are necessary.The process of producing activated alumina involves heating aluminum hydroxide to a high temperature, which causes the hydroxide to create a porous structure. This process removes any water content from the material, resulting in a highly porous and granular substance that is ideal for use in various industrial processes.How is Activated Alumina Used in Catalysts?Catalysts are substances that increase the rate of a chemical reaction without being consumed or altered during the process. Catalysts are used in many industrial processes to increase efficiency, reduce energy consumption, and improve product quality.Activated alumina is an essential component in many catalysts, as it provides a large surface area that enables the catalyst to absorb and react with the chemicals involved in the reaction. The high adsorption capacity of activated alumina makes it ideal for use in catalysts that are involved in the removal of impurities and the transformation of chemical compounds.Some examples of catalytic reactions that rely on activated alumina include the conversion of hydrocarbons (such as gasoline) into other chemicals, the removal of sulfur from diesel fuel, and the decomposition of nitrogen oxides in car exhaust gases.Benefits of Using Activated Alumina in CatalystsActivated alumina offers a number of benefits when used in catalysts, including:- Increased efficiency: The high surface area and adsorption capacity of activated alumina enable catalysts to react with a larger number of chemicals at a faster rate, increasing the efficiency of the chemical reaction.- Improved product quality: Activated alumina can remove impurities from chemical compounds, resulting in cleaner and higher-quality products.- Longer catalyst life: The porous structure of activated alumina allows the catalyst to maintain its effectiveness over a longer period of time, reducing the need for frequent replacement.- Cost savings: Using activated alumina in catalysts can help to reduce energy consumption and improve process efficiency, resulting in cost savings for industrial processes.In conclusion, activated alumina is a highly effective material that is widely used in catalysts for a variety of industrial applications. Its high surface area, adsorption capacity, and porous structure make it an ideal material for improving the efficiency and quality of chemical reactions. If you're looking to improve the performance of your catalysts and industrial processes, consider using activated alumina as a key component.

New Study Shows Potential of Alumina Microspheres in Various Applications

Alumina Microsphere Innovations Revolutionizing the IndustryAlumina microspheres have become a game-changer in the industrial world, and one company is at the forefront of this innovative technology. With a commitment to excellence and a strong focus on research and development, this company has been spearheading the development of alumina microspheres that are revolutionizing various industries.The company, which specializes in advanced material solutions, has a rich history of providing cutting-edge products to its customers. With a team of highly skilled and experienced researchers and engineers, the company has been able to develop alumina microspheres that offer exceptional performance and versatility. These microspheres are now being used in a wide range of applications, including catalyst supports, thermal insulators, and abrasives, among others.One of the key advantages of these alumina microspheres is their high strength and durability. This makes them an ideal choice for applications that require materials to withstand harsh conditions, such as high temperatures and corrosive environments. In addition, their excellent thermal and electrical insulation properties make them highly sought after in industries such as automotive, aerospace, and electronics.Furthermore, the company's alumina microspheres are known for their exceptional density and particle size distribution, which allows for precise and consistent results in various manufacturing processes. This level of precision is crucial in industries where uniformity and consistency are paramount, such as in the production of advanced ceramics and composite materials.The versatility of alumina microspheres developed by this company is another factor that sets them apart from traditional materials. Whether it's being used as a filler in plastics and polymers, a component in coatings and paints, or a support material in catalysts, these microspheres have proven to be extremely versatile, offering a wide range of possibilities for innovation and product development.In addition to their physical properties, the company's alumina microspheres are also designed to meet the strictest environmental and safety standards. By prioritizing sustainability and eco-friendliness in their manufacturing processes, the company ensures that their products not only meet the highest performance requirements but also contribute to a cleaner and greener future.The impact of these alumina microspheres on various industries has been overwhelmingly positive. With their unique combination of strength, versatility, and environmental friendliness, they have become an essential component in the development of advanced materials and products. As a result, they have played a significant role in driving innovation and pushing the boundaries of what is possible in industries ranging from automotive and aerospace to electronics and construction.Looking ahead, the company remains dedicated to further advancing the field of alumina microspheres, with ongoing research and development efforts aimed at pushing the boundaries of performance, versatility, and sustainability. By continuing to invest in cutting-edge technologies and talent, the company is poised to remain a leader in the industry and continue to redefine what is possible with alumina microspheres.In conclusion, the company's alumina microspheres have emerged as a groundbreaking technology that is transforming industries and driving innovation. With their exceptional strength, versatility, and environmental friendliness, these microspheres are proving to be a game-changer in the world of advanced materials. As the company continues to push the boundaries of what is possible, the future looks bright for the world of alumina microspheres and the industries they serve.

New Sulfur Tolerant Shift Catalyst Offers Improved Performance

Sulfur Tolerant Shift Catalyst Offers Breakthrough Solution for Clean Energy ProductionIn today's rapidly evolving world, the demand for clean and efficient energy production is at an all-time high. As the global population continues to grow, so does the need for sustainable energy solutions that will minimize environmental impact and reduce greenhouse gas emissions. This is where the innovative technology of Sulfur Tolerant Shift Catalyst, developed by a leading catalyst manufacturer, comes into play. The introduction of this groundbreaking catalyst marks a significant milestone in the ongoing pursuit of cleaner and more efficient energy production.The company behind the development of this revolutionary catalyst has a long-standing reputation for excellence and innovation in the field of catalyst manufacturing. With a strong commitment to research and development, they have consistently pushed the boundaries of what is possible in the realm of clean energy technology. Their relentless pursuit of excellence has led to the creation of a wide range of high-performance catalysts that have been instrumental in driving the global transition towards a more sustainable energy future.The Sulfur Tolerant Shift Catalyst is the latest addition to the company's impressive portfolio of innovative products. Designed to withstand the harsh conditions of sulfur-containing feedstocks, this catalyst offers a breakthrough solution for the production of clean energy. Its unique composition and advanced design allow for the efficient conversion of syngas into hydrogen, with minimal impact from sulfur impurities. This is a critical advancement, as the presence of sulfur in feedstocks has traditionally posed a significant challenge for energy producers, leading to lower efficiency and increased environmental emissions.The development of the Sulfur Tolerant Shift Catalyst represents a major leap forward in the quest for cleaner and more sustainable energy production. By enabling the efficient conversion of syngas into hydrogen, while effectively mitigating the impact of sulfur impurities, this catalyst has the potential to revolutionize the way energy is produced and utilized on a global scale. Its introduction comes at a time when the need for cleaner energy solutions has never been more pressing, and it is poised to play a pivotal role in driving the transition towards a more sustainable energy future.In addition to its ground-breaking performance, the Sulfur Tolerant Shift Catalyst also aligns with the company's broader commitment to environmental stewardship and sustainability. As a responsible corporate citizen, they are dedicated to developing products and technologies that minimize environmental impact and contribute to a more sustainable future for the planet. This commitment is evident in the meticulous development process that led to the creation of the Sulfur Tolerant Shift Catalyst, which involved rigorous testing and validation to ensure its performance, reliability, and environmental compatibility.The introduction of the Sulfur Tolerant Shift Catalyst has generated a significant buzz within the energy industry, with many experts touting it as a game-changer for clean energy production. Its ability to withstand sulfur-containing feedstocks and deliver high-performance results has captured the attention of energy producers and environmental advocates alike. As the global initiative to reduce carbon emissions gains momentum, the timing of this breakthrough catalyst could not be more opportune. It represents a critical step forward in the ongoing effort to transition towards a more sustainable and environmentally conscious energy landscape.Looking ahead, the company behind the Sulfur Tolerant Shift Catalyst is poised to continue leading the charge in the development of innovative catalyst solutions for clean energy production. With a track record of excellence and a deep commitment to research and development, they are well-positioned to drive meaningful change in the energy industry. The introduction of the Sulfur Tolerant Shift Catalyst stands as a testament to their dedication to pushing the boundaries of what is possible in the pursuit of clean and efficient energy production, and it serves as a powerful reminder of the tremendous potential that exists within the realm of catalyst technology.In conclusion, the Sulfur Tolerant Shift Catalyst represents a game-changing advancement in the field of clean energy production. Its innovative design and superior performance make it a promising solution for the efficient conversion of syngas into hydrogen, while mitigating the impact of sulfur impurities. As the world continues to prioritize sustainability and environmental responsibility, the introduction of this breakthrough catalyst could not have come at a more critical time. It holds the potential to redefine the way energy is produced and utilized, and its impact is poised to resonate far and wide across the global energy landscape.