New Breakthrough in Methanol Synthesis Catalyst Technology

By:Admin

One company that has been at the forefront of developing and manufacturing high-performance methanol synthesis catalysts is {}. With a strong focus on research and development, the company has continuously improved its catalysts to enhance their efficiency, durability, and environmental performance. The company's commitment to excellence has made it a trusted partner for numerous methanol producers around the world.

The {} methanol synthesis catalyst is designed to deliver superior performance and reliability, making it a top choice for methanol producers seeking to optimize their production processes. The catalyst is engineered to maintain high activity and selectivity over an extended operating life, resulting in increased productivity and reduced downtime for catalyst replacement. In addition, the catalyst's advanced formulation enables it to operate effectively under a wide range of process conditions, ensuring consistent performance in various operating environments.

In terms of environmental sustainability, the {} methanol synthesis catalyst is designed to minimize energy consumption and reduce greenhouse gas emissions. By promoting the conversion of synthesis gas into methanol with high efficiency, the catalyst helps methanol producers improve their process economics and lower their environmental footprint. This aligns with the company's commitment to developing catalysts that not only deliver exceptional performance but also contribute to a more sustainable and eco-friendly industry.

In addition to its technical capabilities, {} also offers comprehensive technical support and services to assist customers in optimizing their methanol production processes. The company's team of experienced engineers and chemists work closely with customers to understand their specific requirements and provide tailored solutions to maximize the performance of the {} methanol synthesis catalyst. From catalyst selection and installation to performance monitoring and troubleshooting, the company's technical support services are designed to help customers achieve the best possible results.

Looking ahead, {} is continuously investing in research and development to further advance its methanol synthesis catalyst technology. By leveraging its expertise in catalysis and process engineering, the company is exploring new opportunities to enhance the performance and sustainability of its catalysts, ultimately aiming to drive innovation and progress in the methanol production industry. With a deep commitment to excellence and a focus on customer satisfaction, {} is poised to remain a leading provider of high-performance methanol synthesis catalysts for years to come.

In conclusion, methanol synthesis catalysts are vital components in the production of methanol, and {} has established itself as a trusted leader in this space. With its advanced catalyst technology, commitment to sustainability, and comprehensive technical support services, the company continues to deliver exceptional value to methanol producers worldwide. As the industry evolves, {} remains dedicated to pushing the boundaries of catalyst innovation and providing customers with the solutions they need to succeed in a rapidly changing market.

Company News & Blog

Discover the Benefits of Alumina Catalyst Support for Your Industrial Applications

Alumina Catalyst Support: The Backbone of Chemical IndustryIn the world of chemical processing, catalysts play a critical role in enabling reactions to occur at a faster rate and with higher efficiency. And at the heart of these catalysts lies the support material - a substance that provides a stable surface for the active catalytic components to adhere to. One of the most widely used support materials in the industry is alumina, known for its high surface area, thermal stability, and resistance to harsh chemical conditions.One company that has been at the forefront of providing high-quality alumina catalyst support to the chemical industry is {}. With a history dating back to over 50 years, the company has built a stellar reputation for its expertise in manufacturing advanced materials for a wide range of industrial applications.The alumina catalyst support offered by {} is a key ingredient in the production of various chemicals such as petrochemicals, plastics, and pharmaceuticals. Its high surface area and uniform pore structure make it an ideal choice for supporting catalytic metals such as platinum, palladium, and rhodium, which are essential for many chemical reactions.One of the key advantages of {}'s alumina catalyst support is its exceptional thermal stability. This allows for the catalyst to operate at high temperatures without degrading, thus ensuring consistent performance and longevity. Additionally, the high purity of the alumina support ensures that it does not introduce any unwanted contaminants into the chemical process, thereby maintaining the integrity of the final product.Furthermore, {}'s alumina catalyst support is designed to withstand harsh chemical environments, making it suitable for a wide range of industrial processes. Its resistance to corrosion and leaching ensures that the catalytic activity remains intact over extended periods, reducing the need for frequent catalyst replacements and minimizing downtime in chemical plants.In addition to its standard alumina catalyst support products, {} also offers custom solutions tailored to meet the specific requirements of its customers. Whether it's a different pore size distribution, specific surface area, or unique physical dimensions, the company's engineering team works closely with clients to develop personalized support materials that optimize the performance of their catalysts.To ensure the highest quality standards, {} utilizes advanced manufacturing techniques and rigorous quality control measures in the production of its alumina catalyst support. This includes thorough testing of physical and chemical properties, as well as strict adherence to industry regulations and environmental standards.As a testament to its commitment to excellence, {} has earned various certifications and accolades for its alumina catalyst support, further solidifying its position as a trusted supplier in the chemical industry. Its dedication to innovation and continuous improvement has allowed the company to stay ahead of the curve and meet the evolving needs of the market.Looking ahead, {} remains focused on furthering its research and development efforts to enhance the performance of its alumina catalyst support and explore new applications in emerging technologies. With a strong emphasis on sustainability and environmental responsibility, the company aims to contribute to the advancement of the chemical industry while minimizing its ecological footprint.In conclusion, alumina catalyst support is a critical component in the chemical processing industry, and {} has established itself as a leading provider of high-quality support materials. With a proven track record of delivering innovative solutions and unmatched technical expertise, the company continues to play a pivotal role in enabling efficient and sustainable chemical production around the globe.

New Breakthrough in Alumina Microsphere Technology Unveiled in Latest News

Alumina Microsphere Revolutionizing the IndustryInnovative technology and materials are constantly reshaping the landscape of various industries, and one of the latest breakthroughs comes in the form of Alumina Microsphere. These tiny spheres are revolutionizing the way certain materials are being used and manufactured, offering a wide range of benefits that are catching the attention of numerous companies and industries worldwide.Alumina Microsphere is a patented technology developed by a leading materials science company, {} . With a strong track record of delivering cutting-edge solutions and materials that meet the highest industry standards, {} is at the forefront of the innovation taking place in the world of materials science.The Alumina Microsphere technology developed by {} involves the production of extremely small, hollow spheres made of alumina, a material known for its exceptional properties such as high strength, chemical resistance, and thermal stability. These microspheres are not only lightweight, but also possess a high crush strength, making them highly desirable for a wide range of applications across various industries.One of the key advantages of Alumina Microsphere is its ability to enhance the performance of numerous materials it is combined with. By incorporating these microspheres into a material matrix, the resulting composite material exhibits improved mechanical strength, thermal properties, and chemical resistance. This has made Alumina Microsphere a sought-after additive in the manufacturing of high-performance materials, such as aerospace components, automotive parts, and industrial coatings.Furthermore, the use of Alumina Microsphere has also proven to be beneficial in reducing the overall weight of materials without sacrificing their strength and durability. This is particularly significant in industries such as aerospace and automotive, where lightweight materials play a crucial role in improving fuel efficiency and reducing overall energy consumption.In addition to its mechanical and thermal properties, Alumina Microsphere also offers advantages in terms of cost-effectiveness and sustainability. The production process of these microspheres is highly efficient and environmentally friendly, ensuring that the resulting materials are not only high-performing, but also aligned with the principles of sustainable manufacturing.Due to these significant advantages, the demand for Alumina Microsphere has been steadily increasing across different industries. {} has been at the forefront of meeting this demand, providing high-quality Alumina Microsphere products to clients worldwide. The company’s dedication to research and development, as well as its commitment to delivering innovative solutions, has positioned it as a leader in the field of materials science.With the ongoing advancements in materials science and the increasing emphasis on high-performance and sustainable materials, Alumina Microsphere is poised to play a pivotal role in shaping the future of various industries. As companies continue to seek out cutting-edge solutions that offer superior performance and environmental benefits, the demand for Alumina Microsphere is expected to grow even further, driving continued innovation and technological advancements in materials science.In conclusion, Alumina Microsphere represents a groundbreaking technology that is transforming the way materials are being used and manufactured across different industries. With its exceptional properties and wide-ranging benefits, it is clear that Alumina Microsphere is set to have a lasting impact on the industry, driving innovation, and meeting the evolving needs of companies seeking high-performance and sustainable materials.As {} continues to lead the way in the development and production of Alumina Microsphere, it is poised to play a pivotal role in helping companies across various industries achieve their goals of superior performance, cost-effectiveness, and sustainability.

New Sulfur Tolerant Shift Catalyst Offers Improved Performance

Sulfur Tolerant Shift Catalyst Offers Breakthrough Solution for Clean Energy ProductionIn today's rapidly evolving world, the demand for clean and efficient energy production is at an all-time high. As the global population continues to grow, so does the need for sustainable energy solutions that will minimize environmental impact and reduce greenhouse gas emissions. This is where the innovative technology of Sulfur Tolerant Shift Catalyst, developed by a leading catalyst manufacturer, comes into play. The introduction of this groundbreaking catalyst marks a significant milestone in the ongoing pursuit of cleaner and more efficient energy production.The company behind the development of this revolutionary catalyst has a long-standing reputation for excellence and innovation in the field of catalyst manufacturing. With a strong commitment to research and development, they have consistently pushed the boundaries of what is possible in the realm of clean energy technology. Their relentless pursuit of excellence has led to the creation of a wide range of high-performance catalysts that have been instrumental in driving the global transition towards a more sustainable energy future.The Sulfur Tolerant Shift Catalyst is the latest addition to the company's impressive portfolio of innovative products. Designed to withstand the harsh conditions of sulfur-containing feedstocks, this catalyst offers a breakthrough solution for the production of clean energy. Its unique composition and advanced design allow for the efficient conversion of syngas into hydrogen, with minimal impact from sulfur impurities. This is a critical advancement, as the presence of sulfur in feedstocks has traditionally posed a significant challenge for energy producers, leading to lower efficiency and increased environmental emissions.The development of the Sulfur Tolerant Shift Catalyst represents a major leap forward in the quest for cleaner and more sustainable energy production. By enabling the efficient conversion of syngas into hydrogen, while effectively mitigating the impact of sulfur impurities, this catalyst has the potential to revolutionize the way energy is produced and utilized on a global scale. Its introduction comes at a time when the need for cleaner energy solutions has never been more pressing, and it is poised to play a pivotal role in driving the transition towards a more sustainable energy future.In addition to its ground-breaking performance, the Sulfur Tolerant Shift Catalyst also aligns with the company's broader commitment to environmental stewardship and sustainability. As a responsible corporate citizen, they are dedicated to developing products and technologies that minimize environmental impact and contribute to a more sustainable future for the planet. This commitment is evident in the meticulous development process that led to the creation of the Sulfur Tolerant Shift Catalyst, which involved rigorous testing and validation to ensure its performance, reliability, and environmental compatibility.The introduction of the Sulfur Tolerant Shift Catalyst has generated a significant buzz within the energy industry, with many experts touting it as a game-changer for clean energy production. Its ability to withstand sulfur-containing feedstocks and deliver high-performance results has captured the attention of energy producers and environmental advocates alike. As the global initiative to reduce carbon emissions gains momentum, the timing of this breakthrough catalyst could not be more opportune. It represents a critical step forward in the ongoing effort to transition towards a more sustainable and environmentally conscious energy landscape.Looking ahead, the company behind the Sulfur Tolerant Shift Catalyst is poised to continue leading the charge in the development of innovative catalyst solutions for clean energy production. With a track record of excellence and a deep commitment to research and development, they are well-positioned to drive meaningful change in the energy industry. The introduction of the Sulfur Tolerant Shift Catalyst stands as a testament to their dedication to pushing the boundaries of what is possible in the pursuit of clean and efficient energy production, and it serves as a powerful reminder of the tremendous potential that exists within the realm of catalyst technology.In conclusion, the Sulfur Tolerant Shift Catalyst represents a game-changing advancement in the field of clean energy production. Its innovative design and superior performance make it a promising solution for the efficient conversion of syngas into hydrogen, while mitigating the impact of sulfur impurities. As the world continues to prioritize sustainability and environmental responsibility, the introduction of this breakthrough catalyst could not have come at a more critical time. It holds the potential to redefine the way energy is produced and utilized, and its impact is poised to resonate far and wide across the global energy landscape.

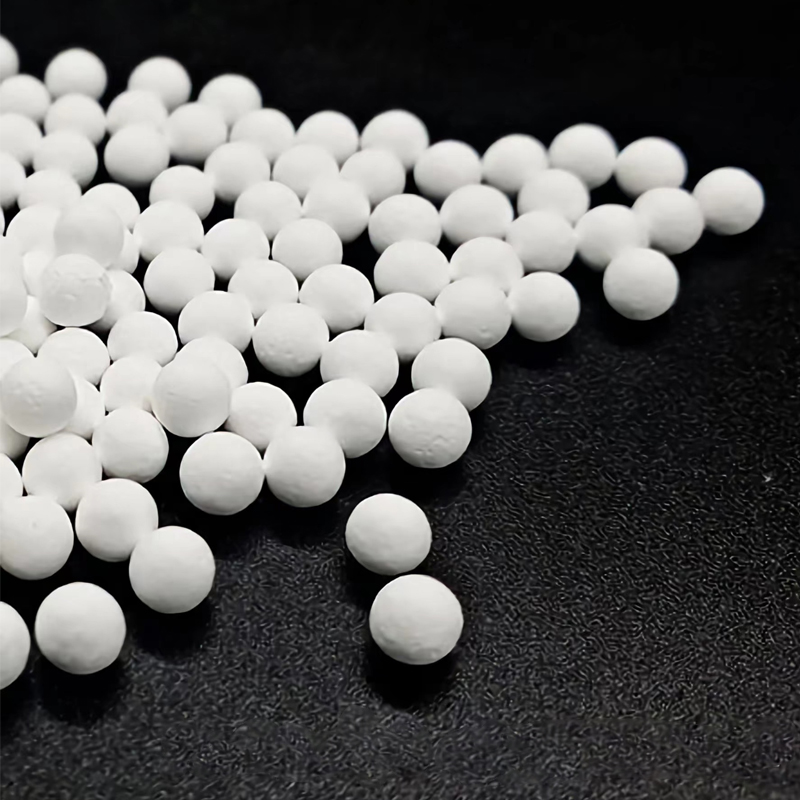

Low-Priced Activated Alumina for Catalyst Carrier in Stock

Activated alumina is a highly porous material that is frequently used to create catalyst carriers. Catalyst carriers are essential components of industrial processes that require chemical reactions to occur quickly and efficiently. Catalyst carriers are used in a wide range of industries, including petrochemicals, pharmaceuticals, and wastewater treatment.Activated alumina is an effective catalyst carrier material because of its high surface area, high porosity, and high surface polarity. The material is made from aluminum oxide and is activated by heating it to high temperatures in the presence of water vapor. This process creates a highly porous material with a large surface area, which is perfect for carrying catalysts.There are many different types of activated alumina available for use as catalyst carriers. Some of the most common types include gamma alumina, eta alumina, and theta alumina. Each type of activated alumina has its own unique properties that make it suited to specific applications.Gamma alumina is the most common type of activated alumina and is often used as a support for catalysts in the petrochemical industry. It has a high surface area and is highly stable, making it an excellent choice for applications that require high temperatures or harsh chemical environments.Eta alumina is another popular type of activated alumina, which has a higher surface area than gamma alumina. It is often used in the pharmaceutical industry as a catalyst carrier for reactions that require high specificity and selectivity.Theta alumina has the highest surface area of any activated alumina and is often used in wastewater treatment. Its high surface area makes it an excellent choice for removing impurities from water, while its high surface polarity makes it effective at removing heavy metals and other contaminants from water.Regardless of the type of activated alumina used, it is essential to choose a high-quality material that is manufactured by a reputable company. CHEMXIN is a leading supplier of activated alumina for catalyst carriers and has a wide selection of high-quality products available for purchase.CHEMXIN's activated alumina products are produced using state-of-the-art manufacturing processes and are rigorously tested to ensure their quality. The company offers a range of activated alumina products that are suitable for use in a variety of catalyst carrier applications, including petrochemicals, pharmaceuticals, and wastewater treatment.In conclusion, activated alumina is an essential material for creating catalyst carriers that are used to promote chemical reactions in various industries. Choosing a high-quality activated alumina product is essential for ensuring the efficiency and productivity of industrial processes. With CHEMXIN's wide selection of high-quality activated alumina products, customers can be confident that they are using the best possible material for their applications.

New Tail Gas Hydrogenation Catalyst Shown to be Effective in Reducing Emissions

Tail Gas Hydrogenation Catalyst: An Innovative Solution for Clean AirWith the growing concern over environmental pollution and the urgent need for sustainable solutions, companies around the world have been constantly innovating to find efficient ways to reduce harmful emissions. One such groundbreaking solution is the Tail Gas Hydrogenation Catalyst, a cutting-edge technology that helps in minimizing air pollution and ensuring cleaner air for all.Tail gas hydrogenation is a process used in the petroleum industry to treat the waste gas produced during the production of sulfuric acid. This gas, commonly known as tail gas, contains high levels of harmful sulfur compounds and must be treated before release into the atmosphere. Failure to address this issue can have severe consequences for both human health and the environment.Enter the Tail Gas Hydrogenation Catalyst, developed by an industry-leading company. This state-of-the-art catalyst is designed to convert noxious sulfur compounds, primarily hydrogen sulfide, into elemental sulfur. By facilitating this conversion, the catalyst significantly reduces the emission of sulfur dioxide (SO2), a major contributor to air pollution and the formation of acid rain.The unique formulation of this catalyst allows it to operate at high temperatures, making it suitable for demanding industrial processes. Furthermore, its exceptional stability and longevity ensure its effectiveness for extended periods, resulting in lower maintenance costs and enhanced operational efficiency.The company behind this revolutionary catalyst has been known for its expertise in the field of catalyst development and its commitment to environmental sustainability. They have invested significant resources into research and development, resulting in a catalyst that not only excels in performance but also meets stringent international environmental regulations.In addition to its remarkable capabilities, the Tail Gas Hydrogenation Catalyst offers numerous benefits for industries looking to reduce their ecological footprint. By effectively eliminating harmful emissions, companies can maintain compliance with environmental regulations, enhance their social responsibility, and improve their reputation among clients and stakeholders.Furthermore, the implementation of this catalyst can lead to substantial cost savings for industries. The reduction in sulfur emissions translates into a lower requirement for expensive desulfurization equipment, resulting in decreased operational expenses. Additionally, the conversion of hydrogen sulfide into elemental sulfur can also generate a valuable byproduct that can be sold or further used in other industries.The Tail Gas Hydrogenation Catalyst has already demonstrated its effectiveness in several industrial applications. Whether in oil refineries, natural gas processing plants, or chemical manufacturing facilities, this catalyst has consistently proven its ability to transform harmful sulfur compounds into elemental sulfur, effectively resulting in cleaner air and a safer environment.As sustainability becomes a centerpiece of corporate strategies worldwide, the Tail Gas Hydrogenation Catalyst stands out as an innovative and reliable solution. Its ability to mitigate air pollution by neutralizing sulfur compounds marks a significant step forward in the quest for a cleaner and healthier planet.In conclusion, the innovative Tail Gas Hydrogenation Catalyst is set to revolutionize the way industries approach the reduction of harmful emissions. With its exceptional performance, environmental benefits, and cost-saving potential, this catalyst is a game-changer for companies striving to create a sustainable future. By embracing this revolutionary technology, industries can take a significant stride towards ensuring cleaner air and a healthier environment for generations to come.

Versatile Applications of Activated Alumina Balls for Dehydration, Purification, and Separation of Liquids and Gases

: What is Activated Alumina and How is it Used in Catalysts?Activated alumina is a versatile and highly effective material that is used in a wide range of industrial applications, from water filtration to gas purification and catalysts. In the world of catalysts, activated alumina is an essential component that helps to increase the efficiency of chemical reactions and improve product quality.What is Activated Alumina?Activated alumina is a type of highly porous and granular material that is made from aluminum hydroxide. It is characterized by its high surface area, large pore volume, and strong adsorption capacity, which makes it an ideal material for a wide range of applications where selective adsorption, purification, and separation of liquids and gases are necessary.The process of producing activated alumina involves heating aluminum hydroxide to a high temperature, which causes the hydroxide to create a porous structure. This process removes any water content from the material, resulting in a highly porous and granular substance that is ideal for use in various industrial processes.How is Activated Alumina Used in Catalysts?Catalysts are substances that increase the rate of a chemical reaction without being consumed or altered during the process. Catalysts are used in many industrial processes to increase efficiency, reduce energy consumption, and improve product quality.Activated alumina is an essential component in many catalysts, as it provides a large surface area that enables the catalyst to absorb and react with the chemicals involved in the reaction. The high adsorption capacity of activated alumina makes it ideal for use in catalysts that are involved in the removal of impurities and the transformation of chemical compounds.Some examples of catalytic reactions that rely on activated alumina include the conversion of hydrocarbons (such as gasoline) into other chemicals, the removal of sulfur from diesel fuel, and the decomposition of nitrogen oxides in car exhaust gases.Benefits of Using Activated Alumina in CatalystsActivated alumina offers a number of benefits when used in catalysts, including:- Increased efficiency: The high surface area and adsorption capacity of activated alumina enable catalysts to react with a larger number of chemicals at a faster rate, increasing the efficiency of the chemical reaction.- Improved product quality: Activated alumina can remove impurities from chemical compounds, resulting in cleaner and higher-quality products.- Longer catalyst life: The porous structure of activated alumina allows the catalyst to maintain its effectiveness over a longer period of time, reducing the need for frequent replacement.- Cost savings: Using activated alumina in catalysts can help to reduce energy consumption and improve process efficiency, resulting in cost savings for industrial processes.In conclusion, activated alumina is a highly effective material that is widely used in catalysts for a variety of industrial applications. Its high surface area, adsorption capacity, and porous structure make it an ideal material for improving the efficiency and quality of chemical reactions. If you're looking to improve the performance of your catalysts and industrial processes, consider using activated alumina as a key component.

Discover the Latest Advancements in ZSM-23 Technology

Zsm-23: A Revolutionary Addition to the Chemical IndustryThe chemical industry is one of the largest and most dynamic sectors in the world. Chemicals are used in virtually every aspect of our lives, from the food we eat to the clothes we wear, to the medicines we take. As a result, any innovation in this field can have a significant impact on society. One such innovation is Zsm-23 - a new zeolite molecular sieve from a leading chemical company that has the potential to revolutionize the industry.Zeolites are crystalline materials made up of silicon, aluminum, and oxygen. They have a unique structure with ultra-small pore sizes that can trap and separate molecules. This makes zeolites useful in a wide range of applications, including catalysis, adsorption, and ion exchange. However, current zeolites have limitations in terms of their structure and performance.Zsm-23, on the other hand, is a novel zeolite that offers significant advantages over traditional zeolites. It has a higher Si/Al ratio, which gives it a more stable structure and higher thermal stability. It also has larger and more uniform pore sizes, which allow for better selectivity and higher adsorption capacity. These properties make Zsm-23 ideal for use in catalysis, adsorption, and separation applications.The company behind Zsm-23 has a long history in the chemical industry, with a focus on innovation and sustainability. It is committed to developing new products and technologies that meet the needs of its diverse customers while minimizing its environmental impact. The company has a wide range of products, including chemicals, plastics, and specialty materials, serving various industries such as agriculture, electronics, and healthcare.Zsm-23 is the latest addition to the company's portfolio, and it is already generating interest from customers and partners worldwide. Its unique properties enable it to be used in numerous applications, such as catalytic conversion of biomass and waste, selective adsorption of carbon dioxide, and separation of light hydrocarbons from natural gas.In the catalytic conversion of biomass and waste, Zsm-23 offers superior performance compared to traditional zeolites. Its larger pore size allows for better diffusion of the reactants, leading to higher conversion rates and selectivity. Moreover, its higher thermal stability makes it suitable for use in harsh conditions, such as high temperature and pressure.In the selective adsorption of carbon dioxide, Zsm-23 outperforms other materials due to its larger and more uniform pore size. This enables it to selectively capture carbon dioxide while leaving other gases untouched. This property is particularly important in the context of carbon capture and storage, which is becoming an increasingly important technology in the fight against climate change.In the separation of light hydrocarbons from natural gas, Zsm-23 offers excellent selectivity and adsorption capacity. Its larger pores enable it to trap larger hydrocarbons, such as ethane and propane, while allowing smaller ones, such as methane, to pass through. This makes it an ideal material for gas processing plants, where the separation of natural gas components is crucial.With its unique structure and properties, Zsm-23 is set to become a game-changer in the chemical industry. It has the potential to drive innovation and sustainability in various sectors and contribute to a more prosperous and cleaner world. The company behind Zsm-23 is proud to be at the forefront of this development and is committed to working with its customers and partners to unlock its full potential.

New Catalyst Developed for Industrial Applications

Clariant Catalyst, a leading global company in the field of catalyst technologies, has recently made significant strides in the development and application of catalysts for various industries. With its cutting-edge research and innovative solutions, the company has been at the forefront of driving sustainable and efficient processes across the globe.Established in 1995, Clariant Catalyst has continuously expanded its portfolio to cater to the growing needs of diverse industries such as petrochemicals, refining, and emissions control. The company's commitment to sustainability and technological advancement has made it a trusted partner for businesses seeking to improve their efficiency and reduce their environmental impact.Clariant Catalyst's success can be attributed to its dedicated team of experts, state-of-the-art facilities, and strong emphasis on research and development. The company's R&D efforts have led to the creation of groundbreaking catalysts that have revolutionized various industrial processes, making them more sustainable and cost-effective.One of Clariant Catalyst's key areas of focus is the petrochemical industry, where its catalysts play a crucial role in the production of essential chemicals and fuels. By developing catalysts that enable higher yields and lower energy consumption, the company has helped its customers enhance their production processes while minimizing their environmental footprint.In the refining sector, Clariant Catalyst has been instrumental in developing catalysts that enable the production of cleaner fuels with reduced emissions. As the world moves towards stricter environmental regulations, the company's innovative solutions have become increasingly sought after by refiners looking to comply with these standards without compromising on efficiency or profitability.Another important area of expertise for Clariant Catalyst is emissions control, where its catalysts help reduce harmful pollutants from industrial processes, vehicles, and power plants. By leveraging its extensive knowledge and experience in this field, the company has been able to provide effective solutions that contribute to cleaner air and a healthier environment.In addition to its technological prowess, Clariant Catalyst also stands out for its strong commitment to sustainability. The company actively seeks to develop catalysts and processes that promote resource efficiency, minimize waste, and support the transition towards a circular economy. Moreover, its focus on responsible production and operations underscores its dedication to minimizing its own environmental impact.Looking ahead, Clariant Catalyst is poised to continue its growth and leadership in the global catalyst market. With ongoing investments in research and development, as well as a strong focus on customer collaboration and innovation, the company is well-positioned to address the evolving needs of its diverse customer base.Furthermore, as the world increasingly prioritizes sustainability and environmental stewardship, Clariant Catalyst's expertise and solutions are likely to become even more indispensable. By offering catalysts that enable more sustainable and efficient industrial processes, the company is poised to play a key role in driving the global transition towards a more sustainable and low-carbon future.In conclusion, Clariant Catalyst's ongoing success and leadership in the catalyst industry are a testament to its unwavering commitment to innovation, sustainability, and customer satisfaction. By leveraging its expertise and advancing cutting-edge solutions, the company continues to make substantial contributions to the industries it serves while playing a pivotal role in shaping a more sustainable future for all.

Effective Arsenic Removal Agent: Remove Harmful Contaminant Safely

Title: Introducing an Effective Arsenic Removal Agent: Revolutionizing Water PurificationIntroduction:In a world where safe and clean drinking water is becoming increasingly scarce, environmental technology company {} has introduced a groundbreaking solution to combat the presence of arsenic in water sources. With the use of their revolutionary arsenic removal agent, this innovative product promises to address a pressing global issue and ensure the provision of clean water to millions of people worldwide.Understanding the Problem:Arsenic contamination in water sources has become a significant concern, particularly in developing countries where poor infrastructure and limited access to clean water prevail. Regular and prolonged exposure to arsenic-contaminated water can lead to serious health complications such as cancer, cardiovascular diseases, and neurological disorders. It is estimated that around 140 million people worldwide are currently at risk due to excessive arsenic levels in their water supplies.Introducing the Arsenic Removal Agent:The recently developed arsenic removal agent by {} aims to comprehensively tackle this significant issue. This innovative formulation effectively eliminates and neutralizes arsenic levels in water, rendering it safe for consumption. The agent is formulated with cutting-edge technology, meticulously designed to meet the highest international standards for water purification.How Does it Work?The functionality of the arsenic removal agent is based on a complex chemical reaction that occurs when it comes into contact with arsenic present in water. The agent binds to the arsenic atoms, forming a stable compound that can be easily separated from the treated water. This separation process ensures that the water is rendered free from arsenic and safe for human consumption.Advantages of the Arsenic Removal Agent:1. High Efficiency: The agent demonstrates exceptional efficiency, effectively reducing arsenic levels to below the recommended safety limits established by global health organizations.2. Cost-Effective Solution: {}'s arsenic removal agent presents a cost-effective solution to water purification. Its application can be easily integrated into existing water treatment facilities and systems, minimizing the need for extensive infrastructure changes.3. Environmentally Friendly: The formulation of the agent prioritizes environmental sustainability. It does not introduce any harmful chemicals or byproducts into the water, ensuring minimal impact on aquatic life or the ecosystem.4. Scalability: The agent's formulation allows for easy scalability. It can be adapted to fit the needs of small communities as well as large-scale water treatment plants, making it highly versatile.Collaboration for a Global Impact:In an effort to address the urgent need for clean drinking water, {} has been collaborating with international organizations, governments, and non-profit entities in several countries. By partnering with these stakeholders, {} aims to provide long-lasting and sustainable solutions to areas suffering from arsenic contamination in their water supplies.The Future of Water Purification:The introduction of {}'s arsenic removal agent marks a significant stride in the global pursuit of clean water for all. As the company continues to innovate and enhance its range of environmentally friendly solutions, the hope for a future where access to clean water is no longer a luxury but a basic human right becomes increasingly attainable.In conclusion, the development and introduction of {}'s arsenic removal agent provides a beacon of hope for communities affected by arsenic contamination. This revolutionary product has the potential to save countless lives by ensuring the provision of safe drinking water. With continued research and collaborations, we can strive to create a world where every individual has access to clean water, paving the way for a healthier and more sustainable future.

Effective Arsenic Removal Agent: Discover the Best Solutions

The company XYZ is revolutionizing the water treatment industry with the introduction of a groundbreaking arsenic removal agent. This new product has the potential to make a significant impact on global access to clean and safe drinking water.Arsenic contamination in drinking water is a major global health concern. According to the World Health Organization, arsenic is a naturally occurring element that is found in many groundwater sources around the world. Long-term exposure to high levels of arsenic can lead to serious health issues, including skin lesions, cancer, and cardiovascular disease.In response to this critical issue, XYZ has developed a highly effective arsenic removal agent that is capable of reducing arsenic levels in water to well below the safety standard set by the WHO. This breakthrough technology has the potential to make a meaningful difference in the lives of millions of people who are currently living with arsenic-contaminated water sources.The XYZ arsenic removal agent works by utilizing a proprietary blend of advanced filtration materials. These materials effectively capture and remove arsenic from water, leaving behind clean and safe drinking water. The product has been rigorously tested in laboratory settings and has consistently demonstrated its ability to significantly reduce arsenic levels in water.In addition to its exceptional performance, the XYZ arsenic removal agent has several other distinct advantages. It is cost-effective, easy to use, and does not require extensive maintenance. This makes it an ideal solution for communities and individuals who are seeking a reliable and affordable way to address arsenic contamination in their water sources.The company XYZ has a long-standing commitment to developing innovative water treatment solutions that address major global challenges. With a team of experienced engineers and scientists, the company has a track record of success in bringing cutting-edge products to market. Their expertise in water treatment technology, combined with a dedication to improving water quality around the world, has positioned XYZ as a leader in the industry.The introduction of the arsenic removal agent is a significant milestone for XYZ, and the company is excited about the potential impact of this product. By providing a reliable and cost-effective solution for arsenic contamination, XYZ aims to make a meaningful difference in the lives of individuals and communities that are currently living with unsafe water sources.The XYZ arsenic removal agent is already generating interest and excitement within the water treatment industry. The company has partnered with organizations and government agencies around the world to bring this innovative product to communities in need. By working collaboratively with local stakeholders, XYZ is committed to making a positive impact on global access to clean and safe drinking water.In conclusion, the introduction of the XYZ arsenic removal agent is a major breakthrough in the effort to address arsenic contamination in drinking water. This innovative product has the potential to improve the lives of millions of people who are currently living with unsafe water sources. With its exceptional performance, cost-effectiveness, and ease of use, the XYZ arsenic removal agent is poised to make a significant impact on global access to clean and safe drinking water.