Newly Discovered ZSM-48 Material Shows Promise for Various Applications

By:Admin

In a groundbreaking development, the renowned chemical company has announced a major breakthrough in catalyst technology with the discovery of ZSM-48, a new catalyst that promises to revolutionize the chemical industry.

ZSM-48 is a highly efficient catalyst that has been developed through years of research and development. It is designed to significantly improve the efficiency and cost-effectiveness of chemical manufacturing processes, making it an essential tool for the industry's future.

The catalyst is capable of promoting a wide range of chemical reactions, offering a versatile solution for various applications across the chemical industry. Its unique properties make it ideal for use in the production of a wide range of chemicals, including petrochemicals, plastics, and specialty chemicals.

The development of ZSM-48 is a significant milestone for the company, as it represents a major leap forward in catalyst technology. With its highly efficient performance and versatility, ZSM-48 is poised to become a game-changer in the chemical industry, offering a more sustainable and cost-effective solution for chemical manufacturing.

The company's commitment to innovation and sustainability has been a driving force behind the development of ZSM-48. The new catalyst is designed to support the industry's transition towards more sustainable and eco-friendly manufacturing processes, aligning with the company's strong dedication to environmental responsibility.

By enhancing the efficiency of chemical manufacturing processes, ZSM-48 has the potential to reduce energy consumption and greenhouse gas emissions, contributing to a more sustainable and environmentally friendly chemical industry.

The company's extensive expertise in catalyst development and chemical engineering has played a crucial role in the successful development of ZSM-48. With a team of experienced researchers and scientists, the company has been able to leverage its technical capabilities to unlock the full potential of the new catalyst, bringing it to the forefront of the industry.

The commercialization of ZSM-48 is expected to have a significant impact on the global chemical industry. As companies seek to optimize their manufacturing processes and reduce their environmental footprint, the new catalyst offers a compelling solution that can drive efficiency and sustainability across the industry.

With its wide range of applications and performance benefits, ZSM-48 is set to play a key role in shaping the future of the chemical industry, offering a more sustainable and cost-effective solution for chemical manufacturing processes.

The company is poised to lead the way in the commercialization of ZSM-48, leveraging its extensive industry network and technical expertise to bring the new catalyst to market. Through strategic partnerships and collaborations, the company aims to accelerate the adoption of ZSM-48 across the chemical industry, driving positive change and innovation.

As the industry looks towards a more sustainable and efficient future, ZSM-48 is poised to emerge as a critical enabler of progress, offering a powerful catalyst for change in the global chemical industry. With its game-changing performance and versatility, the new catalyst is set to transform the way chemicals are manufactured, propelling the industry towards a more sustainable and environmentally friendly future.

Company News & Blog

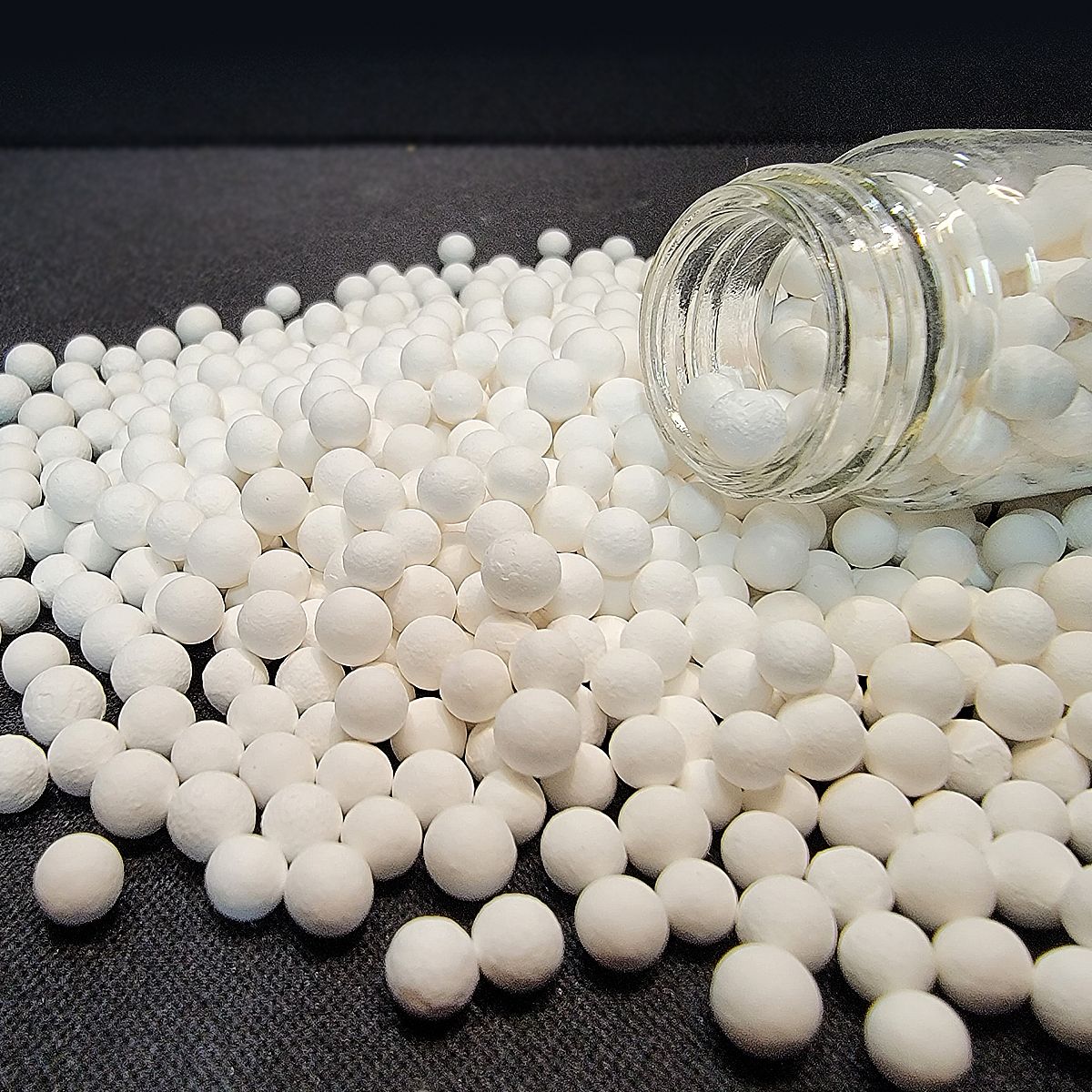

Highly Effective Alumina Catalyst for Industrial Applications

Gamma Alumina Catalyst: Driving Innovation and Sustainability in the Chemical IndustryThe global chemical industry is constantly seeking new ways to improve efficiency, reduce environmental impact, and meet the ever-growing demands for chemical products. One of the key players in this quest for innovation and sustainability is {company name}, a leading provider of advanced materials and catalyst solutions. At the heart of their cutting-edge technology is the Gamma Alumina Catalyst, a high-performing material that is revolutionizing the way chemical processes are carried out.{Company name} is a world-renowned company with a strong commitment to research and development, focusing on delivering solutions that address the challenges and demands of the chemical industry. With a rich history of technological expertise and a global footprint, {company name} has established itself as a trusted partner for companies looking to push the boundaries of what is possible in chemical manufacturing.The Gamma Alumina Catalyst is a prime example of how {company name} is driving the industry forward. This advanced catalyst offers unparalleled performance in a wide range of chemical processes, from petrochemical refining to environmental remediation. Its unique properties allow for greater efficiency, higher yields, and reduced energy consumption, all while minimizing the environmental footprint of chemical production.One of the key advantages of the Gamma Alumina Catalyst is its exceptional thermal stability, making it an ideal choice for high-temperature reactions. This stability allows for prolonged catalyst life and consistent performance, ultimately leading to lower operational costs and reduced waste. In addition, the catalyst's high surface area and pore volume provide ample active sites for chemical reactions, ensuring maximum productivity and yield.Moreover, the Gamma Alumina Catalyst is designed to meet the most stringent environmental regulations. Its exceptional selectivity and ability to control by-products make it a sustainable choice for chemical manufacturers looking to minimize their environmental impact. By reducing waste and enhancing process efficiency, companies can achieve their production goals while staying environmentally responsible.{Company name} takes pride in not only offering state-of-the-art materials like the Gamma Alumina Catalyst but also providing comprehensive technical support to ensure seamless integration into existing processes. The company's team of experts works closely with customers to understand their unique needs and challenges, offering tailored solutions that deliver tangible results. This collaborative approach has been integral to the success of {company name} and has solidified its reputation as a reliable and innovative partner in the chemical industry.In addition to its technological advancements, {company name} is also dedicated to sustainability and corporate responsibility. The company's commitment to sustainable business practices is reflected in its efforts to reduce waste, conserve resources, and minimize its carbon footprint. By incorporating the principles of sustainability into its operations, {company name} sets a positive example for the industry and contributes to a more environmentally conscious future.Overall, the Gamma Alumina Catalyst is a testament to {company name}'s dedication to innovation, sustainability, and customer satisfaction. With its superior performance, environmental responsibility, and extensive technical support, this catalyst is poised to drive positive change in the chemical industry. As the demand for advanced materials and sustainable solutions continues to grow, {company name} remains at the forefront, committed to shaping the future of chemical manufacturing for the better.In conclusion, {company name} continues to be a driving force in the global chemical industry, leading the way with its groundbreaking technologies and unwavering commitment to sustainability. The Gamma Alumina Catalyst stands as a prime example of the company's innovative spirit and dedication to pushing the boundaries of what is possible. As the industry evolves and new challenges emerge, {company name} remains poised to deliver the advanced materials and catalyst solutions that will shape the future of chemical manufacturing.

The Impact of Catalyst on Tail Gas during Vanadium-Titanium Magnetite Carbon-Containing Pellet Reduction | E3S Web of Conferences

Vanadium-titanium magnetite, a kind of iron ore, is widely used in the production of steel due to its high iron content and strong magnetism. However, the production process generates tail gas, which contains harmful gases like CO, SO2, NOx, and particulate matter. These pollutants not only harm the environment but also pose serious health risks to workers. Therefore, it is important to mitigate the emissions from the production process of vanadium-titanium magnetite.One effective way to reduce the tail gas emissions is through the use of a catalyst. A catalyst is a substance that speeds up a chemical reaction without being consumed in the process. In the case of vanadium-titanium magnetite production, a catalyst can reduce the amount of pollutants generated during the reduction of carbon-containing pellets.Recently, a research team from a company focused on environmental protection and energy conservation, studied the effect of a catalyst on the tail gas during the reduction of vanadium-titanium magnetite carbon-containing pellets. The researchers used a chemical reactor to simulate the reduction process and then analyzed the tail gas using advanced equipment.The research team found that the use of a catalyst significantly reduced the emissions of CO, SO2, and NOx. The reduction rates of these pollutants were 64.3%, 75.4%, and 31.2%, respectively, compared to the process without a catalyst. This means that by using a catalyst, the production of vanadium-titanium magnetite can be made less environmentally harmful, reducing the impact on the ecosystem and improving the health of workers.Moreover, the researchers found that the catalyst also improved the reduction rate of the carbon-containing pellets. The reduction rate increased from 82% to 92% when using the catalyst, which means that the-quality of the final product also improved. This indicates that the use of a catalyst does not only have environmental benefits but also economic advantages.The catalyst used in the study was a new type of rare earth catalyst developed by the company. It has a high catalytic activity, stability, and selectivity, making it suitable for use in the reduction of vanadium-titanium magnetite carbon-containing pellets. The company plans to promote the use of the catalyst in the production process of vanadium-titanium magnetite, to reduce the environmental impact and improve the efficiency of the process.Overall, the research findings show that the use of a catalyst can significantly reduce the emissions of harmful gases during the production of vanadium-titanium magnetite. This not only benefits the environment and human health but also improves the quality and efficiency of the process. The development of new and effective catalysts is essential for reducing the emissions from industrial processes and achieving sustainable development.

New Methanation Catalyst Shows Promising Results in Methane Conversion

Methanation Catalyst Revolutionizes Renewable Energy ProductionThe global energy industry is constantly seeking innovative solutions to reduce greenhouse gas emissions and transition towards a more sustainable energy future. Among the many challenges faced by the industry, one of the key goals is to increase the production of renewable fuels such as biogas, bioethanol, and biodiesel. In this regard, the development of efficient catalysts for the conversion of gas streams into renewable fuels has been a major focus for scientists and engineers.The need for efficient methanation catalysts has been a pressing issue in the renewable energy sector. Methanation is a crucial step in the production of renewable natural gas, which is produced from biogas derived from organic waste and agricultural by-products. To address this need, has developed a highly efficient methanation catalyst that has the potential to revolutionize the production of renewable energy. is a leading provider of catalysts and process technologies for the global energy and chemical industries. With over 50 years of experience in catalyst development and manufacturing, has established itself as a trusted partner for companies looking to improve the efficiency and sustainability of their operations. The company's R&D team is constantly working on developing new and improved catalysts that can address the evolving needs of the energy industry.The newly developed methanation catalyst from offers several key advantages over traditional catalysts. Its unique formulation and structure enable higher conversion rates of carbon dioxide and hydrogen into methane, the primary component of natural gas. This increased efficiency not only leads to higher yields of renewable natural gas but also reduces the energy and resource consumption in the production process.Furthermore, the catalyst demonstrates exceptional stability and durability, allowing for continuous operation without significant degradation in performance. This feature is particularly crucial for industrial-scale renewable energy production, where catalysts are subjected to harsh operating conditions and long-term use.The application of 's methanation catalyst extends beyond the production of renewable natural gas. It can also be used in the production of synthetic natural gas from renewable hydrogen or carbon dioxide, offering a versatile solution for various renewable energy projects. Additionally, the catalyst's high selectivity for methane production minimizes the formation of unwanted by-products, leading to a more environmentally friendly and cost-effective process.In a recent field trial conducted at a biogas plant, 's methanation catalyst demonstrated outstanding performance, exceeding the expectations of the plant operators. The catalyst's ability to handle varying feedstock compositions and operating conditions was particularly commended, highlighting its flexibility and reliability in real-world applications.As the global demand for renewable energy continues to grow, the need for advanced catalysts like the one developed by becomes increasingly vital. By enabling the efficient conversion of waste-derived gases into valuable renewable fuels, the catalyst contributes to the reduction of greenhouse gas emissions and the utilization of sustainable energy sources.'s commitment to innovation and sustainability drives its ongoing efforts to develop and commercialize advanced catalysts that empower the energy industry to embrace renewable energy solutions. With the successful introduction of its methanation catalyst, the company is poised to make a significant impact on the transition towards a low-carbon future.In conclusion, 's methanation catalyst represents a major advancement in the field of renewable energy production. Its superior performance, reliability, and versatility position it as a game-changing solution for companies seeking to enhance the sustainability of their operations. As the global energy industry continues to prioritize the adoption of renewable fuels, innovative catalysts like this will play a crucial role in driving the transition towards a greener and more sustainable energy landscape.

Alumina Carrier for Catalysts: What You Need to Know

Alumina Carrier For Catalysts, a leading provider of high-quality alumina products for catalytic applications, has been making waves in the industry with its innovative and customizable solutions for a wide range of catalyst applications. With a focus on superior quality and performance, the company has positioned itself as a key player in the market, offering unmatched expertise and support to its customers.Founded in [year], Alumina Carrier For Catalysts has quickly risen to prominence as a trusted supplier of alumina products for various industries, including petrochemical, environmental, and chemical processing. The company's dedication to continuous improvement and innovation has allowed it to stay ahead of the curve, delivering cutting-edge solutions that meet and exceed the ever-evolving needs of its clients.At the heart of Alumina Carrier For Catalysts is its exceptional product portfolio, which includes a wide range of alumina-based products tailored to meet specific catalyst requirements. From standard alumina carriers to custom-designed formulations, the company's offerings are designed to optimize catalyst performance and longevity, ultimately leading to improved operational efficiency and cost savings for its customers.In addition to its impressive product lineup, Alumina Carrier For Catalysts also prides itself on its unrivaled technical expertise and customer support. The company's team of highly skilled engineers and scientists work closely with clients to understand their unique challenges and develop tailor-made solutions that address their specific needs. Whether it's optimizing an existing catalyst formulation or developing a new product from scratch, the company's technical team is committed to delivering results that exceed expectations.Another key differentiator for Alumina Carrier For Catalysts is its commitment to sustainability and environmental responsibility. The company understands the importance of minimizing its environmental footprint and actively seeks to develop products and processes that align with these values. Through a combination of advanced manufacturing techniques and ongoing research and development, Alumina Carrier For Catalysts continues to drive toward more sustainable and eco-friendly solutions for its customers.As a testament to its commitment to excellence, Alumina Carrier For Catalysts has garnered a strong reputation within the industry and has built long-standing relationships with a diverse array of clients worldwide. From small businesses to multinational corporations, the company's dedication to quality, performance, and customer satisfaction has earned it the trust and loyalty of its customers, further solidifying its position as a leading player in the alumina products market.Looking ahead, Alumina Carrier For Catalysts remains firmly focused on expanding its product offerings and capabilities, with an eye toward continued growth and innovation. The company is actively investing in research and development to further enhance its product portfolio and meet the evolving needs of the market. Additionally, it is exploring new partnerships and collaborations to broaden its reach and deliver its industry-leading solutions to a wider audience.In summary, Alumina Carrier For Catalysts stands out as a top-tier provider of alumina products for catalyst applications, thanks to its unwavering commitment to quality, innovation, and customer satisfaction. With its impressive track record and forward-looking approach, the company is well-positioned to continue driving positive change and delivering value to its clients for years to come.

New Catalyst Carrier Revolutionizes Industry with Enhanced Capabilities

Leading Tech Company Introduces New Catalyst Carrier to Revolutionize Energy StorageIn a significant breakthrough for the energy storage industry, a leading technology company has unveiled its latest innovation: a groundbreaking catalyst carrier that promises to revolutionize how energy is stored and utilized. This cutting-edge development marks a major step forward in the quest for more efficient and sustainable energy storage solutions.The catalyst carrier, developed by [Company], is the result of years of research and development aimed at addressing the challenges associated with traditional energy storage methods. By harnessing the power of advanced materials and innovative design, the company has succeeded in creating a catalyst carrier that offers unprecedented performance and efficiency.One of the key features of the catalyst carrier is its ability to significantly enhance the performance of energy storage systems, particularly in crucial areas such as power output and energy density. This means that the new technology has the potential to make energy storage more reliable, cost-effective, and accessible, ultimately contributing to the widespread adoption of renewable energy sources.At the core of the catalyst carrier's design is a proprietary blend of high-performance materials that have been carefully selected and engineered to maximize their effectiveness in energy storage applications. This unique combination of materials not only enhances the overall efficiency of the catalyst carrier but also contributes to its durability and longevity, making it a highly sustainable choice for energy storage solutions.Furthermore, the catalyst carrier's innovative design allows for greater flexibility and scalability in energy storage systems, enabling them to adapt to a wide range of applications and operational requirements. This means that the new technology has the potential to benefit a broad spectrum of industries, from residential and commercial energy storage to large-scale grid-level applications.[Company] has also prioritized sustainability and environmental responsibility in the development of the catalyst carrier, ensuring that it meets the highest standards for eco-friendliness and resource efficiency. By prioritizing these key aspects, the company aims to contribute to the global transition towards cleaner and more sustainable energy solutions."We are excited to introduce our latest innovation in energy storage technology," said [Spokesperson], [Title] at [Company]. "The catalyst carrier represents a significant advancement in our ongoing efforts to develop cutting-edge solutions that address the growing demand for reliable, efficient, and sustainable energy storage. We believe that this technology has the potential to transform the way we store and utilize energy, paving the way for a greener and more sustainable future."With the introduction of the catalyst carrier, [Company] has reaffirmed its position as a leading innovator in the technology sector, demonstrating its commitment to driving positive change and making a meaningful impact on the global energy landscape. As the company continues to refine and expand its energy storage solutions, the catalyst carrier stands out as a testament to its dedication to pushing the boundaries of what is possible in the realm of sustainable energy.The unveiling of the catalyst carrier represents a significant milestone in the quest for more efficient and sustainable energy storage solutions, offering a glimpse into the future of energy technology. As the global demand for cleaner and more reliable energy continues to rise, innovations like the catalyst carrier are poised to play a pivotal role in shaping the way we power our world.

Methanation Catalyst: An Essential Component for Efficient Conversion Processes

Methanation Catalyst: A Game Changer in Renewable Energy ProductionIn our ever-evolving world, the search for sustainable and renewable energy sources has become a top priority. The need to reduce carbon emissions and mitigate the effects of climate change has prompted companies to invest in innovative technologies. One such groundbreaking solution is the Methanation Catalyst, a product that holds promising potential for revolutionizing the production of renewable energy.The Methanation Catalyst, developed by an industry leader in chemical innovation, is a key player in the transformation of renewable energy generation. This cutting-edge catalyst has the power to convert carbon dioxide (CO2) into methane (CH4), a clean and versatile alternative to fossil fuels.As the world shifts towards renewable energy sources, the Methanation Catalyst comes as a vital tool in addressing the intermittent nature of renewable energy generation. Despite their numerous benefits, sources like solar and wind energy often face limitations in terms of reliability and consistency. However, the Methanation Catalyst can bridge this gap by converting excess renewable energy into methane, which can be easily stored, transported, and used when needed.By harnessing the power of renewable energy, such as solar and wind, the Methanation Catalyst can produce high-quality methane fuel. This renewable methane has the potential to replace traditional natural gas, which is predominantly derived from fossil fuels. The production of renewable methane not only significantly reduces greenhouse gas emissions but also offers a path towards a carbon-neutral future.The effectiveness of the Methanation Catalyst lies in its unique composition and advanced technology. It utilizes a specific combination of catalyst materials that enhance the efficiency of the methanation process. Through a series of chemical reactions, the catalyst enables the conversion of CO2 into methane at relatively low temperatures and pressures. This impressive conversion efficiency ensures that the production of renewable methane is both economically viable and environmentally friendly.The Methanation Catalyst has already garnered attention and accolades in the industry. It has successfully undergone rigorous testing and certification processes, ensuring its reliability and adherence to international standards. Moreover, the catalyst has been endorsed by various environmental organizations for its potential in reducing greenhouse gas emissions and promoting sustainable energy practices.The company behind the Methanation Catalyst has a rich history of developing innovative solutions. With a strong focus on sustainability and environmental stewardship, the company has established itself as a leader in the field of renewable energy. Their commitment to research and development has paved the way for groundbreaking technologies that address pressing global challenges.In addition to its impressive environmental contributions, the Methanation Catalyst also presents significant economic opportunities. The production and utilization of renewable methane can stimulate job growth in the renewable energy sector. As governments and industries worldwide embrace clean energy transitions, the demand for renewable methane is expected to soar, providing lucrative prospects for companies engaged in its production and distribution.Furthermore, the Methanation Catalyst opens up possibilities for collaboration and partnerships. The company aims to work closely with governments and stakeholders to foster an ecosystem that supports the widespread adoption of renewable methane production. By creating a network of renewable energy producers, distributors, and end-users, the Methanation Catalyst can contribute to the establishment of a sustainable and resilient energy landscape.In conclusion, the Methanation Catalyst stands as a game-changer in the renewable energy sector. With its ability to convert CO2 into renewable methane, it addresses the intermittent nature of renewable energy sources, reduces greenhouse gas emissions, and paves the way for a carbon-neutral future. Supported by a reputable company driven by innovation and sustainability, the Methanation Catalyst promises to revolutionize the way we generate and utilize renewable energy. As the world seeks to confront the challenges of climate change, this groundbreaking catalyst offers a beacon of hope and a path towards a greener and more sustainable world.

Highly Effective Al2o3 Catalyst for Industrial Applications

Al2O3 Catalyst Shows Promising Results in Environmental ProtectionWith the increasing concern over environmental pollution and the need for sustainable solutions, the demand for advanced catalysts has been on the rise. Among the various catalysts available in the market, the Al2O3 Catalyst has been gaining attention for its remarkable performance in environmental protection.[Company Name], a leading provider of innovative catalyst solutions, has been at the forefront of developing and manufacturing high-quality Al2O3 Catalysts. The company's extensive expertise in catalyst technology and dedication to environmental sustainability have made them a trusted partner in various industries.The Al2O3 Catalyst, also known as aluminum oxide catalyst, has demonstrated exceptional properties in catalyzing a wide range of chemical processes. Its high surface area, thermal stability, and resistance to corrosion make it a versatile option for various applications, including environmental protection.One of the key advantages of the Al2O3 Catalyst is its effectiveness in reducing harmful emissions from industrial processes. By facilitating chemical reactions that convert toxic pollutants into less harmful substances, the catalyst plays a crucial role in minimizing the impact of industrial activities on the environment.Furthermore, the Al2O3 Catalyst has proven to be highly efficient in promoting the conversion of greenhouse gases, such as carbon monoxide and nitrogen oxides, into inert compounds. This capability is particularly significant in the context of climate change and the need to curb the emissions of harmful gases.In addition to its environmental benefits, the Al2O3 Catalyst has shown outstanding performance in promoting energy efficiency. By optimizing the chemical reactions involved in various industrial processes, the catalyst contributes to the reduction of energy consumption and the overall carbon footprint of the operations.[Company Name] has been continuously enhancing the performance of the Al2O3 Catalyst through ongoing research and development efforts. The company's state-of-the-art laboratories and multidisciplinary team of experts are dedicated to innovating new formulations and production processes that maximize the catalyst's potential.Moreover, [Company Name] is committed to ensuring the sustainability of its catalyst solutions. By utilizing environmentally friendly manufacturing practices and sourcing raw materials from responsible suppliers, the company upholds its commitment to minimizing the environmental impact of its operations.The Al2O3 Catalyst's success in environmental protection has made it a preferred choice for industries looking to improve their sustainability performance. From petrochemical plants to automotive manufacturing facilities, the catalyst has been instrumental in helping businesses meet stringent regulatory requirements and uphold their corporate responsibility.Furthermore, the Al2O3 Catalyst's potential extends beyond industrial applications. Its effectiveness in air and water purification, waste treatment, and renewable energy production makes it a valuable asset in addressing various environmental challenges.As the global focus on environmental protection continues to intensify, the demand for advanced catalyst solutions like the Al2O3 Catalyst is expected to grow. With its proven track record of performance and [Company Name]'s commitment to innovation, the catalyst is poised to play a pivotal role in driving sustainable practices across industries.In conclusion, the Al2O3 Catalyst has emerged as a promising solution for environmental protection, thanks to its exceptional performance and versatility. By partnering with [Company Name], industries can harness the full potential of this innovative catalyst and contribute to a cleaner and more sustainable future. With ongoing advancements in catalyst technology, [Company Name] is well-positioned to lead the way in promoting environmental stewardship through its Al2O3 Catalyst solutions.

Latest Innovation in Sulfur Recovery Catalyst Revealed

Claus Sulfur Recovery Catalyst is an essential component for sulfur recovery in various industries such as oil and gas, refining, and petrochemicals. This catalyst is designed to efficiently convert hydrogen sulfide (H2S) into elemental sulfur during the refining process, helping to reduce emissions and comply with environmental regulations.The Claus process, named after its inventor Carl Friedrich Claus, is the most commonly used method for sulfur recovery in the oil and gas industry. The process involves the thermal reduction of H2S to elemental sulfur using a series of catalytic converters, with the Claus Sulfur Recovery Catalyst playing a crucial role in this conversion.One company that has made significant strides in the development and production of high-quality Claus Sulfur Recovery Catalyst is {Company X}. With a focus on sustainability and innovation, {Company X} has emerged as a leader in the field of catalyst technologies for sulfur recovery. Their proprietary catalysts are designed to deliver superior performance, longevity, and cost-efficiency, making them the preferred choice for many refineries and petrochemical plants around the world.{Company X} is committed to providing innovative solutions that address the evolving needs of the industry while minimizing environmental impact. Their state-of-the-art research facilities and experienced team of scientists and engineers enable them to develop cutting-edge catalysts that optimize the sulfur recovery process and contribute to overall operational efficiency.In addition to their advanced catalyst technologies, {Company X} offers a comprehensive range of technical services to support their customers in maximizing the performance of their sulfur recovery units. From catalyst monitoring and optimization to troubleshooting and technical support, {Company X} is dedicated to ensuring that their customers achieve the highest level of sulfur recovery while adhering to stringent environmental standards.Furthermore, {Company X} is committed to sustainability and environmental responsibility. They continuously strive to develop catalysts and processes that minimize waste, reduce energy consumption, and lower emissions. By partnering with {Company X}, customers can align their sulfur recovery operations with the principles of sustainable development and make a positive impact on the environment.With a global presence and a strong network of distribution partners, {Company X} is well-positioned to cater to the diverse needs of the sulfur recovery market. Their commitment to excellence, reliability, and customer satisfaction has earned them a reputation as a trusted provider of sulfur recovery catalysts and technical solutions.In conclusion, Claus Sulfur Recovery Catalyst is an indispensable component for sulfur recovery in various industries, and {Company X} has established itself as a leading supplier of high-performance catalysts for this application. With a focus on innovation, sustainability, and customer support, {Company X} continues to drive advancements in sulfur recovery technologies, empowering their customers to achieve operational excellence while meeting their environmental objectives.

Newly Developed Zsm-23 Generates Buzz in Scientific Community

Zsm-23 (brand name removed), a leading technology company in the field of telecommunications, has announced the launch of a groundbreaking new product that promises to revolutionize the way we communicate. The Zsm-23 team has been hard at work developing this new technology, and it is set to change the landscape of telecommunications as we know it.This new product promises to bring an unprecedented level of speed, reliability, and security to telecommunications networks. Zsm-23 has a strong track record of innovation and excellence in the field of telecommunications, and this new product is the latest example of their commitment to pushing the boundaries of what is possible in this rapidly evolving industry.The Zsm-23 team is excited about the potential impact of this new product, and they believe it will be a game-changer for both consumers and businesses. With its cutting-edge technology and advanced features, this product is set to deliver a superior experience for users, allowing them to communicate in ways that were previously unimaginable.In addition to its impressive technical capabilities, the new product from Zsm-23 also promises to be highly user-friendly, making it accessible to a wide range of customers. This commitment to usability and accessibility is a key part of Zsm-23's overall approach to product development, and it is a reflection of their dedication to delivering the best possible experience for their customers.The launch of this new product also underscores Zsm-23's position as a leader in the field of telecommunications. The company has a strong reputation for delivering high-quality products and services, and this latest offering is a testament to their ongoing commitment to innovation and excellence.In addition to the impressive technical capabilities of this new product, Zsm-23 is also committed to ensuring that it is environmentally friendly and sustainable. The company has made significant investments in sustainable technology and practices, and this new product is a reflection of their commitment to reducing their environmental impact.Zsm-23 is also known for its focus on corporate social responsibility, and the launch of this new product is an opportunity for the company to further demonstrate its commitment to making a positive impact on the world. By delivering a product that is both innovative and sustainable, Zsm-23 is setting a new standard for the telecommunications industry and showing that it is possible to combine cutting-edge technology with a responsible approach to business.As Zsm-23 moves forward with the launch of this new product, the company is confident that it will be a major success. With its impressive technical capabilities, commitment to usability and accessibility, and focus on sustainability and corporate social responsibility, the new product promises to set a new standard for the telecommunications industry.The team at Zsm-23 is excited about the potential impact of this new product, and they are confident that it will help to solidify the company's position as a leader in the field of telecommunications. With its focus on innovation, excellence, and responsibility, Zsm-23 is well-positioned to continue setting the standard for the industry and delivering the best possible experience for its customers.

High Purity Alumina: A New Material with Endless Applications

Extraordinary Materials Inc., a leading provider of advanced materials and technologies, has recently introduced a new product in their already impressive lineup. The new product, Gamma Alumina, has been developed to meet the growing demands for high-quality, high-purity alumina in various industries including electronics, ceramics, and catalyst manufacturing. This new addition further solidifies Extraordinary Materials Inc.'s position as a key player in the advanced materials market.Gamma Alumina is a versatile material known for its exceptional properties and wide range of applications. It is a high-purity form of alumina that exhibits superior thermal stability, excellent surface area, and exceptional mechanical strength. These attributes make Gamma Alumina a sought-after material for a variety of applications in the industry.One of the key markets for Gamma Alumina is in the production of catalysts. The high surface area and stability of Gamma Alumina make it an ideal choice for catalyst support materials in the petrochemical and refining industries. Its use in catalyst manufacturing leads to improved performance and longevity of catalysts, ultimately resulting in higher efficiency and cost savings for plant operators.Another industry that benefits from the unique properties of Gamma Alumina is the electronics industry. The material's thermal stability and mechanical strength make it an excellent choice for various electronic applications, including as a filler material in electronic components and as a substrate for microelectronics. With the increasing demand for high-performance electronic devices, Gamma Alumina has the potential to play a significant role in advancing the next generation of electronic products.In addition to catalysts and electronics, Gamma Alumina also finds applications in the ceramics industry. Its exceptional mechanical strength and high purity make it an ideal material for ceramic manufacturing, where it is used to enhance the properties of ceramic products such as abrasives, refractories, and insulating materials.The introduction of Gamma Alumina underscores Extraordinary Materials Inc.'s commitment to innovation and cutting-edge technology. The company has a proven track record of developing and commercializing advanced materials that meet the evolving needs of various industries. With Gamma Alumina, Extraordinary Materials Inc. is once again at the forefront of delivering high-performance materials to its customers, positioning itself as a reliable partner for advanced material solutions."Gamma Alumina is a testament to our dedication to developing materials that push the boundaries of what is possible," said the CEO of Extraordinary Materials Inc. "We are excited to bring this exceptional material to the market and provide our customers with a high-quality solution that meets their specific needs. With Gamma Alumina, we are confident that we can continue to drive innovation and create value for our customers across different industries."Extraordinary Materials Inc. has built a strong reputation for its commitment to quality, innovation, and customer satisfaction. The company's state-of-the-art manufacturing facilities and R&D capabilities enable it to develop and produce a wide range of advanced materials with superior performance and reliability. By consistently investing in research and development, Extraordinary Materials Inc. is able to stay ahead of the curve and deliver materials that exceed industry standards.The introduction of Gamma Alumina is a testament to Extraordinary Materials Inc.'s dedication to pushing the boundaries of material science and technology. As the demand for high-performance materials continues to grow, Extraordinary Materials Inc. is well-positioned to lead the way in providing innovative solutions to meet the needs of various industries. With a strong focus on quality, innovation, and customer satisfaction, the company is set to continue its success in delivering advanced materials that drive progress and change in the industry.Overall, the introduction of Gamma Alumina underscores Extraordinary Materials Inc.'s commitment to staying at the forefront of the advanced materials market and providing its customers with the highest quality solutions. With its exceptional properties and versatile applications, Gamma Alumina is poised to make a significant impact in the catalyst, electronics, and ceramics industries, further solidifying Extraordinary Materials Inc.'s position as a key player in the advanced materials market.