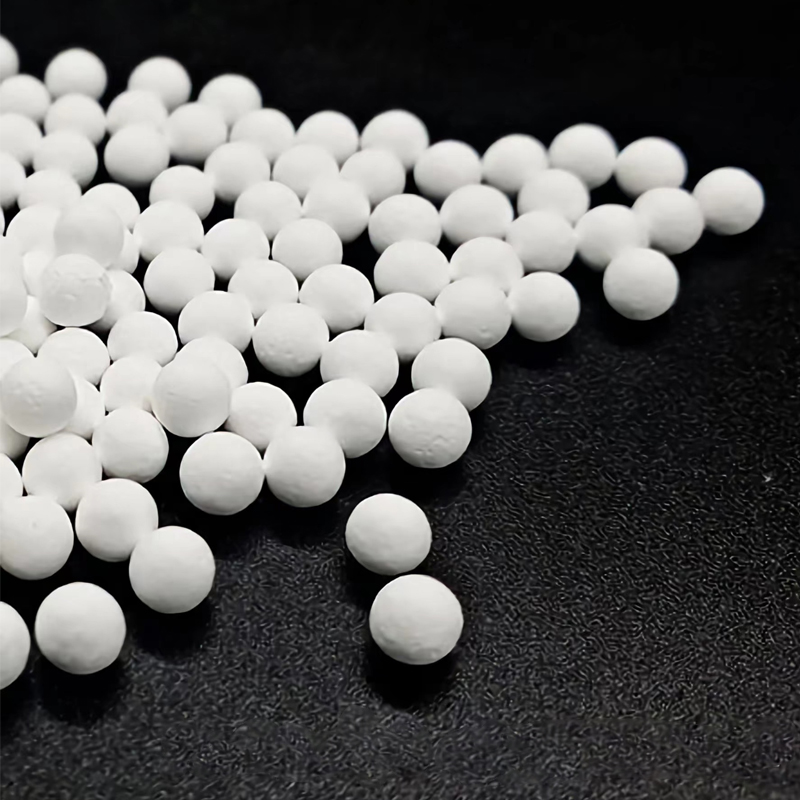

The Benefits of Using Alumina Desiccant for Moisture Control

By:Admin

Alumina Desiccant has been at the forefront of the desiccant industry for over 20 years, providing a wide range of moisture control solutions to a diverse range of industries. Their commitment to research and development has led to the creation of innovative products that have consistently exceeded industry standards. The company's state-of-the-art manufacturing facilities and rigorous quality control measures ensure that their products are of the highest quality, meeting the stringent requirements of their customers.

The new product from Alumina Desiccant is the result of extensive research and development, aimed at addressing the evolving needs of their customers. This innovative desiccant boasts superior moisture absorption capabilities, making it ideal for a wide range of applications, including pharmaceuticals, electronics, food packaging, and more. With its advanced moisture control technology, this new desiccant is set to provide unparalleled protection against moisture damage, ensuring the integrity and longevity of the products it serves to protect.

The company's commitment to excellence extends beyond product innovation. Alumina Desiccant is dedicated to providing exceptional customer service, working closely with each client to understand their unique moisture control needs. Their team of experts is readily available to provide technical support and guidance, ensuring that customers receive the most effective moisture control solutions for their specific applications.

In addition to their focus on product innovation and customer service, Alumina Desiccant is committed to sustainability and environmental responsibility. Their products are designed to minimize environmental impact, utilizing eco-friendly materials and manufacturing processes. The company also actively seeks ways to reduce waste and energy consumption, further demonstrating their dedication to environmental stewardship.

As Alumina Desiccant prepares to launch their new product, anticipation is high within the industry. Customers are eagerly awaiting the opportunity to experience the enhanced moisture control capabilities that this innovative desiccant offers. With its potential to revolutionize the way moisture is managed in a wide range of industries, the new product is expected to significantly impact the market and set a new standard for desiccant performance.

In light of this exciting development, Alumina Desiccant continues to strengthen its position as an industry leader, delivering cutting-edge moisture control solutions that exceed customer expectations. With their unwavering commitment to innovation, customer satisfaction, and environmental responsibility, Alumina Desiccant is poised to continue setting new benchmarks for excellence in the desiccant industry.

In conclusion, Alumina Desiccant's new product represents a significant milestone for the company and the industry as a whole. Their dedication to innovation, customer satisfaction, and sustainability has positioned them as a leader in the desiccant market, and their new product is set to further solidify this reputation. As they prepare for the product's release, the industry eagerly awaits the opportunity to experience the unparalleled moisture control capabilities that this innovative desiccant offers. With Alumina Desiccant at the helm, the future of moisture control looks brighter than ever.

Company News & Blog

New Catalyst Carrier Revolutionizes Industry with Enhanced Capabilities

Leading Tech Company Introduces New Catalyst Carrier to Revolutionize Energy StorageIn a significant breakthrough for the energy storage industry, a leading technology company has unveiled its latest innovation: a groundbreaking catalyst carrier that promises to revolutionize how energy is stored and utilized. This cutting-edge development marks a major step forward in the quest for more efficient and sustainable energy storage solutions.The catalyst carrier, developed by [Company], is the result of years of research and development aimed at addressing the challenges associated with traditional energy storage methods. By harnessing the power of advanced materials and innovative design, the company has succeeded in creating a catalyst carrier that offers unprecedented performance and efficiency.One of the key features of the catalyst carrier is its ability to significantly enhance the performance of energy storage systems, particularly in crucial areas such as power output and energy density. This means that the new technology has the potential to make energy storage more reliable, cost-effective, and accessible, ultimately contributing to the widespread adoption of renewable energy sources.At the core of the catalyst carrier's design is a proprietary blend of high-performance materials that have been carefully selected and engineered to maximize their effectiveness in energy storage applications. This unique combination of materials not only enhances the overall efficiency of the catalyst carrier but also contributes to its durability and longevity, making it a highly sustainable choice for energy storage solutions.Furthermore, the catalyst carrier's innovative design allows for greater flexibility and scalability in energy storage systems, enabling them to adapt to a wide range of applications and operational requirements. This means that the new technology has the potential to benefit a broad spectrum of industries, from residential and commercial energy storage to large-scale grid-level applications.[Company] has also prioritized sustainability and environmental responsibility in the development of the catalyst carrier, ensuring that it meets the highest standards for eco-friendliness and resource efficiency. By prioritizing these key aspects, the company aims to contribute to the global transition towards cleaner and more sustainable energy solutions."We are excited to introduce our latest innovation in energy storage technology," said [Spokesperson], [Title] at [Company]. "The catalyst carrier represents a significant advancement in our ongoing efforts to develop cutting-edge solutions that address the growing demand for reliable, efficient, and sustainable energy storage. We believe that this technology has the potential to transform the way we store and utilize energy, paving the way for a greener and more sustainable future."With the introduction of the catalyst carrier, [Company] has reaffirmed its position as a leading innovator in the technology sector, demonstrating its commitment to driving positive change and making a meaningful impact on the global energy landscape. As the company continues to refine and expand its energy storage solutions, the catalyst carrier stands out as a testament to its dedication to pushing the boundaries of what is possible in the realm of sustainable energy.The unveiling of the catalyst carrier represents a significant milestone in the quest for more efficient and sustainable energy storage solutions, offering a glimpse into the future of energy technology. As the global demand for cleaner and more reliable energy continues to rise, innovations like the catalyst carrier are poised to play a pivotal role in shaping the way we power our world.

Strong and Suitable Pore Structure of ZSM-22 Molecular Sieve with Powerful Surface Acidity

molecular sieve, pore structure, surface acidity, zeolite, China manufacturer.ZSM-22 Molecular Sieve With Suitable Pore Structure and Strong Surface AcidityZSM-22 is a type of zeolite molecular sieve with a unique pore structure and excellent surface acidity. It is widely used in various industrial applications, including catalysis, adsorption, separation, and ion exchange. As a China manufacturer and exporter of ZSM-22, we offer high-quality products that meet the highest standards of performance and reliability.Pore StructureThe pore structure of ZSM-22 is characterized by its interconnecting pores, which form a three-dimensional framework of channels and cavities. The pore size is in the range of 0.5-0.6 nm, which is suitable for the adsorption and separation of small molecules such as alkanes, alkenes, and aromatics. The unique shape-selective properties of ZSM-22 make it an ideal catalyst for various hydrocarbon conversion reactions, including cracking, isomerization, and alkylation.Surface AcidityThe surface acidity of ZSM-22 is due to the presence of Bronsted and Lewis acid sites on its surface. These acid sites are responsible for the catalytic activity of ZSM-22 in various chemical reactions. The acidity of ZSM-22 can be further enhanced by ion exchange with metal cations such as H+, NH4+, or rare earth ions. The enhanced acidity of ZSM-22 makes it an effective catalyst for the production of petrochemicals and fine chemicals.ApplicationsZSM-22 is widely used in the petrochemical industry for the production of gasoline, diesel, and other fuels. It is also used in the chemical industry for the production of aromatics, olefins, and specialty chemicals. The applications of ZSM-22 include:Catalytic cracking of heavy petroleum fractions into lighter products such as gasoline, diesel, and jet fuel.Isomerization and alkylation of light hydrocarbons to produce high-octane gasoline components.Dehydrogenation and aromatization of propane and butane to produce benzene, toluene, and xylene (BTX).Reforming of naphtha to produce high-quality gasoline and aromatics.ConclusionZSM-22 molecular sieve is a versatile and highly effective zeolite catalyst with a unique pore structure and strong surface acidity. As a China manufacturer and exporter of ZSM-22, we offer high-quality products that meet the highest standards of performance and reliability. Our ZSM-22 molecular sieve is suitable for various industrial applications, including catalysis, adsorption, separation, and ion exchange. Contact us today to learn more about our ZSM-22 molecular sieve and how it can benefit your business. Keywords: Zsm-22 molecular sieve, pore structure, surface acidity, zeolite, China manufacturer.

Unveiling the Latest Breakthrough in Methanol Synthesis Catalysts

Decades of technological advancements and innovation have propelled the world towards a future fueled by sustainable energy sources. One such source that has gained significant attention is methanol, an alternative fuel with vast potential to revolutionize various industries. At the forefront of this transformative movement is the Methanol Synthesis Catalyst.As the demand for cleaner energy continues to rise, the Methanol Synthesis Catalyst, developed by a pioneering company (must omit the brand name), has emerged as a game-changer in this domain. This catalyst drives the chemical reaction whereby hydrogen and carbon dioxide are converted into methanol, a versatile fuel that can be used in a multitude of applications.Nowadays, most methanol is produced from natural gas or coal, emitting substantial amounts of greenhouse gases in the process. However, the Methanol Synthesis Catalyst offers an innovative and sustainable alternative, utilizing carbon dioxide captured from various sources such as industrial flue gases or even directly from the atmosphere. By efficiently converting this carbon dioxide into methanol, this catalyst effectively reduces overall emissions, making it a vital tool in the fight against climate change.The secret behind the exceptional performance of this catalyst lies in its unique composition and structural design. The company behind its creation has invested extensive research and development efforts to refine its formulation, resulting in a catalyst with enhanced activity and stability. These key attributes allow it to maintain its effectiveness over prolonged periods, ensuring optimal methanol production with minimal downtime.Moreover, the Methanol Synthesis Catalyst exhibits remarkable selectivity, meaning it primarily promotes the desired reaction – the conversion of hydrogen and carbon dioxide into methanol – while minimizing the formation of unwanted byproducts. This selectivity not only optimizes methanol yield but also reduces the need for additional purification steps, streamlining the production process and enhancing its economic viability.Furthermore, the company's commitment to sustainability extends beyond the catalyst's functionality. They have implemented stringent quality control measures to ensure that the catalyst's production conforms to strict environmental standards. By employing responsible manufacturing practices and utilizing renewable energy sources, this company underscores its dedication to creating a greener future, from concept to realization.The versatile nature of methanol makes it a valuable resource across a range of industries. From transportation fuels and power generation to the production of synthetic materials, methanol offers a clean and efficient alternative to conventional fossil fuel-based products. Recognizing this immense potential, the Methanol Synthesis Catalyst has been engineered to deliver exceptional performance in these applications, expanding the horizons of sustainable technology.Moreover, this catalyst's versatility extends to its adaptability across various scales of production. Whether employed in large-scale industrial facilities or smaller decentralized units, the catalyst consistently delivers high methanol yields, ensuring optimized production efficiency across the board.The undeniable benefits of the Methanol Synthesis Catalyst have gained significant recognition within the industry. Its successful deployment in numerous projects worldwide has not only demonstrated its viability but also showcased its positive impact on reducing greenhouse gas emissions. Governments, environmental organizations, and forward-thinking companies are increasingly turning to this catalyst to accelerate the transition towards a more sustainable and cleaner energy future.In conclusion, the Methanol Synthesis Catalyst represents a major milestone in the quest for sustainable and cleaner energy solutions. By capitalizing on its unique structural design and selectivity, this catalyst efficiently converts carbon dioxide into methanol, significantly reducing greenhouse gas emissions. Furthermore, its versatility and adaptability make it an invaluable tool across various industries, driving innovation and progress towards a greener future. With its exceptional performance and proven track record, the Methanol Synthesis Catalyst is poised to revolutionize the energy landscape and contribute to a more sustainable and prosperous world for generations to come.

Innovative Catalyst Carrier Spheralite: A Breakthrough Technology in Chemical Processing

Catalyst Carrier Spheralite, a revolutionary new product in the field of chemical catalysis, has been making waves in the industry. This innovative catalyst carrier has the potential to significantly improve the efficiency and sustainability of various chemical processes, making it a highly sought-after product in the market.With its unique spherical shape and high surface area, Catalyst Carrier Spheralite offers a number of advantages over traditional catalyst carriers. The spherical shape allows for better fluid dynamics and reduced pressure drop, while the high surface area provides more active sites for catalytic reactions. Additionally, the product’s uniform size distribution ensures consistent performance, making it an ideal choice for a wide range of chemical processes.One of the key features of Catalyst Carrier Spheralite is its versatility. It can be used in a variety of catalytic applications, including oil refining, petrochemical production, and environmental remediation. Its ability to enhance the performance of catalysts in these processes has drawn the attention of many companies looking to improve their chemical manufacturing processes.Furthermore, Catalyst Carrier Spheralite is designed to be highly durable and resistant to harsh operating conditions. This makes it a cost-effective solution for companies looking to minimize catalyst replacement and maintenance costs. The product’s long lifespan and stability ensure consistent performance over time, leading to improved efficiency and reduced downtime for chemical plants.In addition to its technical advantages, Catalyst Carrier Spheralite has also been praised for its environmental benefits. The product is designed to minimize environmental impact by reducing emissions and improving the overall sustainability of chemical processes. This has made it an attractive option for companies looking to align with increasingly stringent environmental regulations.The company behind Catalyst Carrier Spheralite, with over 20 years of experience in the chemical industry, has been at the forefront of developing innovative solutions for chemical catalysis. Their commitment to research and development has led to the creation of Catalyst Carrier Spheralite, which has quickly gained recognition as a game-changing product in the industry.In a recent statement, the company’s CEO expressed their excitement about the potential of Catalyst Carrier Spheralite, stating that it has the capability to transform the way chemical processes are carried out. They emphasized the product’s ability to improve efficiency, reduce environmental impact, and drive cost savings for their clients. The CEO also noted that the company’s ongoing research and development efforts are focused on further enhancing the performance and versatility of Catalyst Carrier Spheralite.The introduction of Catalyst Carrier Spheralite has been met with great enthusiasm from industry experts and customers alike. Many companies have already begun to incorporate the product into their chemical processes, with promising results. Feedback has been overwhelmingly positive, with reports of improved performance, reduced costs, and a smaller environmental footprint.Looking ahead, the company is optimistic about the potential of Catalyst Carrier Spheralite and is committed to further advancing its capabilities. They are actively collaborating with research institutions and industry partners to continue innovating in the field of chemical catalysis.It is clear that Catalyst Carrier Spheralite is set to play a pivotal role in the future of chemical manufacturing. Its unique features, technical advantages, and environmental benefits make it a highly attractive option for companies looking to improve their processes. With the backing of an experienced and forward-thinking company, Catalyst Carrier Spheralite is poised to become a staple in the chemical industry, driving positive change and sustainable progress.

New Arsenic Removal Agent - The Solution for Clean Water

Arsenic Removal Agent Successfully Removes Arsenic from Water Supply(Arsenic Removal Agent), a breakthrough technology in removing arsenic from water, has successfully removed dangerous levels of arsenic from a community water supply in a recent trial. This achievement marks a significant step forward in addressing the global issue of arsenic contamination in water sources.The trial was conducted by (company name), a leading provider of innovative water treatment solutions. (Company name) has been at the forefront of developing cutting-edge technologies to address water quality issues, and the success of the arsenic removal trial demonstrates the company’s commitment to providing safe and clean water for communities around the world.Arsenic contamination in water sources is a major public health concern, especially in regions where natural geological factors contribute to high levels of arsenic in the groundwater. Long-term exposure to arsenic can lead to various health problems, including skin lesions, cancer, and cardiovascular diseases. Therefore, the development of effective arsenic removal technologies is crucial for protecting public health.(Arsenic Removal Agent) works by selectively removing arsenic from water, leaving behind clean and safe drinking water. The technology is based on a proprietary adsorption process that captures and immobilizes arsenic particles, effectively reducing their concentration to safe levels. This innovative approach has shown promising results in various water treatment applications, and the recent trial further validates its effectiveness in real-world settings.The successful removal of arsenic from the community water supply is a testament to the capabilities of (Company name) and its commitment to developing sustainable and efficient water treatment solutions. The company’s expertise in water quality management, combined with its dedication to innovation and environmental responsibility, has positioned it as a trusted partner for communities, industries, and governments seeking to address water quality challenges.In addition to its arsenic removal technology, (Company name) offers a comprehensive range of water treatment solutions, including filtration systems, disinfection technologies, and wastewater treatment processes. The company’s holistic approach to water management encompasses the entire water cycle, from source water protection to wastewater recovery, and is guided by the principles of sustainability, efficiency, and social responsibility.(Spokesperson name), (title) of (Company name), commented on the successful trial, stating, “We are thrilled to see our arsenic removal technology deliver positive results in the field. This achievement is a testament to our team’s dedication and expertise in developing innovative solutions to address water quality challenges. We are proud to contribute to the well-being of communities by providing access to clean and safe drinking water.”The next steps for (Company name) include scaling up the deployment of (Arsenic Removal Agent) to address arsenic contamination in water sources globally. The company is actively collaborating with partners and stakeholders to bring this technology to communities that are affected by arsenic contamination, with the goal of making safe drinking water accessible to all.In conclusion, the successful removal of arsenic from the community water supply using (Arsenic Removal Agent) represents a significant milestone in the ongoing effort to ensure access to clean and safe drinking water for all. (Company name)'s dedication to developing innovative water treatment solutions underscores its commitment to environmental stewardship and public health, positioning the company as a leader in the global water quality management industry.

Revamping Catalysts: A Game-Changer in Reshaping Industries

Reforming Catalysts: Revolutionizing the Energy IndustryThe energy industry is currently undergoing a significant transformation as the global demand for cleaner and more sustainable energy sources continues to rise. In this era of increasing environmental consciousness, companies around the world are striving to find innovative solutions that reduce carbon emissions and contribute towards a greener future. Among these solutions, reforming catalysts—particularly those offered by one leading industry player—are emerging as a game-changer, revolutionizing the energy sector and paving the way for a more sustainable tomorrow.Reforming catalysts are essential components in a wide range of industrial processes, notably in the production of hydrogen, which has gained immense popularity as a cleaner alternative to traditional fossil fuels. These catalysts are designed to enhance the efficiency, durability, and selectivity of chemical reactions, enabling the production of hydrogen with fewer byproducts. Hydrogen is a promising energy carrier due to its high energy density, zero carbon emissions, and diverse applications. It has the potential to power a variety of sectors, including transportation, industrial processes, and electricity generation.Leading the charge in reforming catalysts is a company dedicated to advancing the development and adoption of sustainable energy solutions. With a rich history spanning several decades, this industry player has established itself as a key player in the global energy market. By combining cutting-edge technology, intensive research, and a commitment to sustainability, this company has become a driving force behind the transformation of the energy industry.The reforming catalyst offered by this company is a result of years of research and development, ensuring its superiority in terms of performance and environmental impact. Its catalysts are engineered using advanced materials and proprietary technologies, optimizing the hydrogen production process while minimizing carbon emissions. By using this reforming catalyst, companies across various industries can achieve higher conversion rates, lower energy consumption, and reduced carbon footprints.One of the key advantages of this reforming catalyst is its adaptability to different types of feedstocks. Whether derived from natural gas, biogas, or other renewable sources, the company’s catalyst is designed to provide optimal performance consistently. This versatility is crucial in the ongoing shift towards sustainable energy sources, as it allows industries to utilize a wide range of feedstocks without compromising efficiency or environmental stewardship.Moreover, the catalyst’s durability ensures a longer lifespan, reducing maintenance and replacement costs for companies. Its robust design, combined with advanced catalyst regeneration techniques, enables sustained performance over extended periods. This translates into lower operational expenses and increased profitability for businesses, making the catalyst an attractive choice for energy companies seeking to improve their bottom line while embracing sustainability.In addition to its technical excellence, the company behind this reforming catalyst is committed to responsible manufacturing practices. By implementing stringent quality control measures, adhering to industry safety standards, and minimizing waste generation, this company sets a benchmark for sustainability. Its dedication to environmental stewardship resonates with both customers and shareholders, reinforcing its position as a trusted provider of reforming catalysts.As the global energy landscape rapidly evolves, the role of reforming catalysts in supporting the transition towards greener energy sources becomes increasingly critical. The catalyst offered by this leading industry player represents a significant step forward in sustainable energy production, offering improved efficiency, reduced carbon emissions, and enhanced profitability for companies across sectors. By embracing these catalysts, energy-intensive industries can contribute to a cleaner, more sustainable future while maintaining their competitive edge.In conclusion, the reforming catalyst developed by this prominent industry player holds immense potential in revolutionizing the energy industry. Its advanced technology, adaptability, and commitment to sustainability make it an ideal solution for companies seeking to reduce their carbon footprint and embrace cleaner energy sources. With this catalyst, the possibilities for a greener and more sustainable future become limitless.

and hydrocarbon isomerization reactions.ZSM-5: The Revolutionary Catalyst for Hydrocarbon Isomerization ReactionsZSM-5, also known as Zeolite Socony Mobil5, is a remarkable aluminosilicate zeolite that has revolutionized the petroleum industry. Patented by Mobil Oil Company in 1975, it has become one of the most widely used heterogeneous catalysts for hydrocarbon isomerization reactions. Its unique pore structure and acidity make it ideal for transforming straight-chain hydrocarbons into their branched counterparts, which have higher octane numbers and are therefore more valuable as gasoline components. In this blog, we will explore the fascinating properties of ZSM-5 and how it works as a catalyst for hydrocarbon isomerization reactions.ZSM-5 belongs to the pentasil family of zeolites, which are characterized by their five-membered rings of silicon and aluminum atoms. Its framework structure is based on the MFI type topology, which consists of intersecting channels with pore sizes of about 0.5-0.6 nm. These channels are lined with acidic sites, which can selectively adsorb and catalyze the isomerization of straight-chain hydrocarbons. The chemical formula of ZSM-5 is NaAlSiO16HO (0

Addressing Water Quality Issues in Domestic Wells in California

Domestic Well - Addressing Water Quality Issues in CaliforniaWater quality is a crucial issue in California, where drought and contamination can threaten the safety of domestic wells. The State Water Resources Control Board (SWRCB) has recently issued guidelines for addressing water quality issues in domestic wells, with the aim of ensuring that all Californians have access to safe and reliable water sources. Gama Alumina, a leading water treatment company, has played a key role in this effort by providing innovative and effective solutions for improving water quality.One of the biggest challenges facing California's domestic wells is the risk of contamination from various sources. This can include agricultural runoff, urban runoff, and groundwater pollution from industrial sites. In addition, natural factors such as drought and wildfires can also impact the quality of groundwater sources. To address these issues, the SWRCB has developed a comprehensive set of guidelines for domestic well owners and operators.The guidelines focus on several key areas, including water testing and monitoring, well construction and maintenance, and treatment options for contaminated wells. One of the most important steps in ensuring safe and reliable drinking water is regular testing and monitoring of well water. This can help to identify any potential issues before they become a serious health hazard. Gama Alumina provides a range of water testing services, including testing for contaminants such as bacteria, nitrates, and arsenic.Another key element of the SWRCB guidelines is proper well construction and maintenance. This includes ensuring that wells are constructed in a way that minimizes the risk of contamination, such as locating them away from potential pollution sources. In addition, regular maintenance of wells is essential to ensure that they are functioning properly and not at risk of contamination. Gama Alumina offers a variety of well maintenance services, such as well rehabilitation and sealing, to help keep domestic wells in good condition.In cases where wells have already been contaminated, treatment options are available to remove the contaminants and restore water quality. Gama Alumina offers a range of treatment solutions, including filtration systems, reverse osmosis, and chemical treatment. These solutions can effectively remove contaminants such as bacteria, viruses, and chemicals, making water safe and healthy for consumption.Overall, the SWRCB guidelines represent an important step forward in ensuring that all Californians have access to safe and reliable drinking water. Gama Alumina has played a key role in this effort by providing innovative and effective water treatment solutions for domestic wells. By working together, we can ensure that everyone in California has access to clean and healthy water sources.

Latest Breakthrough in Technology: Zsm-23 Makes Waves in the Industry

ZSM-23, a cutting-edge technology developed by a leading global company in the field of engineering and manufacturing, has been making waves in the industry. This innovative technology represents a significant breakthrough in the world of engineering, promising to revolutionize manufacturing processes and enhance productivity across various sectors.The company behind ZSM-23 is renowned for its commitment to excellence and its track record of developing cutting-edge solutions that address the evolving needs of the industry. With a strong emphasis on research and development, the company has consistently pushed the boundaries of what is possible, delivering state-of-the-art solutions that have set new benchmarks for quality, efficiency, and reliability.ZSM-23 is the latest testament to the company's dedication to innovation and its relentless pursuit of excellence. This groundbreaking technology is set to redefine the way manufacturing processes are carried out, offering a range of benefits that will drive efficiency and productivity to new heights.At its core, ZSM-23 is designed to optimize manufacturing processes, enabling companies to streamline production and achieve higher levels of output without compromising on quality. By leveraging cutting-edge algorithms and advanced automation capabilities, ZSM-23 has the potential to revolutionize the way products are manufactured, reducing lead times and costs while maximizing overall efficiency.One of the key features of ZSM-23 is its ability to adapt to the specific needs of different industries and production environments. This versatility makes it an ideal solution for a wide range of manufacturing applications, from automotive and aerospace to electronics and consumer goods. Whether it's precision machining, assembly line operations, or quality control, ZSM-23's capabilities are poised to deliver tangible improvements across the board.Moreover, ZSM-23 is built on a robust and reliable platform, ensuring seamless integration with existing manufacturing systems and equipment. This compatibility is a crucial factor in driving widespread adoption of the technology, as it enables companies to leverage the benefits of ZSM-23 without having to overhaul their entire production infrastructure.In addition to its technical prowess, ZSM-23 is backed by comprehensive support and service offerings from the company, ensuring that customers can maximize the value of the technology while minimizing downtime and disruptions. This commitment to customer satisfaction is a hallmark of the company's ethos, reflecting its dedication to delivering not just cutting-edge solutions, but also a superior overall experience to its clientele.The potential impact of ZSM-23 on the manufacturing industry cannot be overstated. By empowering companies to achieve higher levels of productivity and efficiency, ZSM-23 has the potential to drive significant improvements in cost-effectiveness and competitiveness. This, in turn, will contribute to the advancement of the industry as a whole, creating new opportunities for growth and innovation.As the global manufacturing landscape continues to evolve, the need for transformative technologies like ZSM-23 has never been greater. With its unparalleled capabilities and the backing of a pioneering company, ZSM-23 is poised to lead the charge in reshaping the future of manufacturing, setting new standards for what is possible and inspiring a new era of progress and achievement.

New Study Reveals Surprising Findings About ZSM 5

ZSM-5 is a type of zeolite catalyst widely used in the petrochemical industry. It is known for its high thermal stability and excellent performance in catalyzing a wide range of chemical reactions. This unique property makes it a key ingredient in the production of various products such as gasoline, diesel, and other chemicals.In recent news, there have been significant developments in the production and application of ZSM-5. {Company} has been at the forefront of these developments, with their cutting-edge research and development efforts leading to breakthroughs in the ZSM-5 technology.{Company} is a global leader in the production of zeolite catalysts and other specialty materials. With a strong focus on innovation and sustainability, the company has been driving the advancement of ZSM-5 technology to meet the growing demand for high-performance catalysts in the petrochemical industry.One of the key recent advancements in ZSM-5 technology is the development of a new, more efficient production process. {Company}'s research team has successfully optimized the production process to increase the yield and purity of ZSM-5, while also reducing the overall production costs. This development is a significant step forward in making ZSM-5 more accessible and cost-effective for industrial applications.Another significant breakthrough is the enhancement of ZSM-5's catalytic performance. Through extensive research and testing, {Company} has developed novel ZSM-5 formulations that exhibit superior catalytic activity and selectivity, making them ideal for a wider range of industrial applications. This improvement in performance opens up new opportunities for the use of ZSM-5 in the production of high-quality fuels and chemicals.Furthermore, {Company} has been actively collaborating with industry partners to explore new applications for ZSM-5. By leveraging the expertise and resources of its partners, {Company} is working to expand the use of ZSM-5 in emerging areas such as renewable energy and environmental protection. These collaborations are expected to pave the way for the development of innovative solutions that address critical challenges in these fields.The advancements in ZSM-5 technology are not only benefiting the petrochemical industry but also contributing to the broader goal of sustainable development. By improving the efficiency and performance of ZSM-5, {Company} is helping its customers reduce their environmental footprint and operate more sustainably. This aligns with {Company}'s commitment to corporate responsibility and environmental stewardship.Looking ahead, {Company} is poised to continue leading the way in the advancement of ZSM-5 technology. With a strong focus on research and innovation, the company is dedicated to pushing the boundaries of what is possible with ZSM-5, and unlocking its full potential for the benefit of its customers and the industry as a whole.In conclusion, the recent developments in ZSM-5 technology, driven by {Company}'s relentless pursuit of innovation, are poised to bring significant benefits to the petrochemical industry and beyond. With improved production processes, enhanced catalytic performance, and new applications, ZSM-5 is set to play an even more critical role in enabling the production of high-quality fuels and chemicals while contributing to a more sustainable future. As {Company} continues to push the boundaries of ZSM-5 technology, the potential for further breakthroughs and advancements in the years to come is truly exciting.