Catalyst for Isomerization: What You Need to Know

By:Admin

The global oil and gas industry is constantly evolving, and new technologies are continually being developed to optimize the production and refining processes. One such innovation is the development of state-of-the-art Isomerization Catalysts, which have the potential to revolutionize the industry.

Isomerization Catalysts are a crucial component in the refining process, as they play a vital role in the production of high-octane gasoline. By utilizing advanced catalyst technologies, oil and gas companies can enhance their refining processes, resulting in improved fuel quality and increased production efficiency. These catalysts are designed to convert low-octane hydrocarbons into high-octane isomers, which are essential for the production of premium gasoline products.

One of the leading companies in the development and manufacturing of Isomerization Catalysts is {}. With extensive experience and expertise in the field of catalyst technology, {} has consistently been at the forefront of innovation in the oil and gas industry. The company's commitment to research and development has led to the creation of advanced catalyst solutions that have redefined the refining process, setting new standards for fuel quality and production efficiency.

{} operates with a clear mission to provide sustainable and cutting-edge solutions to the oil and gas industry. With a focus on technological innovation and environmental responsibility, the company has established itself as a trusted partner for oil and gas companies worldwide. Through its dedicated team of scientists, engineers, and industry experts, {} has developed a comprehensive portfolio of Isomerization Catalysts that have set new benchmarks for performance and reliability.

The key to {}'s success lies in its relentless pursuit of excellence and its unwavering commitment to delivering superior products and services to its customers. With a strong emphasis on research and development, {} continuously seeks to push the boundaries of catalyst technology, with a focus on creating solutions that are not only efficient but also environmentally sustainable. This dedication to innovation has enabled {} to stay ahead of the curve in an industry that is constantly evolving and adapting to new challenges.

One of the company's flagship products is its advanced Isomerization Catalyst, which has been engineered to deliver outstanding performance in the production of high-quality gasoline. The catalyst is designed to maximize the conversion of low-octane hydrocarbons into high-octane isomers, resulting in a significant enhancement in fuel quality. By utilizing {}'s Isomerization Catalyst, oil and gas companies can achieve higher yields of high-octane gasoline, while also reducing energy consumption and maximizing the efficiency of their refining processes.

In addition to its technical expertise, {} is also committed to providing unparalleled customer support and service. The company works closely with its clients to understand their specific needs and challenges, offering tailored solutions that address their unique requirements. By fostering strong partnerships with its customers, {} has earned a reputation for integrity, professionalism, and reliability, making it the go-to partner for Isomerization Catalyst solutions.

Looking ahead, the future of Isomerization Catalysts looks promising, with continued advancements in catalyst technology and innovations in the refining process. As the demand for high-quality gasoline continues to grow, the role of Isomerization Catalysts in the oil and gas industry will become even more critical. With its proven track record of excellence and its unwavering commitment to innovation, {} is well-positioned to play a leading role in shaping the future of catalyst technology in the oil and gas industry.

In conclusion, Isomerization Catalysts have emerged as a game-changing technology in the oil and gas industry, with the potential to drive significant advancements in fuel quality and production efficiency. As a pioneer in the field of catalyst technology, {} continues to lead the way with its cutting-edge Isomerization Catalysts, offering unparalleled performance and reliability to its customers. With its steadfast dedication to innovation and sustainability, {} is poised to remain at the forefront of catalyst technology, shaping the future of the oil and gas industry for years to come.

Company News & Blog

New Arsenic Removal Agent Shows Promising Results for Clean Drinking Water

Arsenic Removal Agent Proving to be Revolutionary in Water Treatment In today's society, access to clean and safe drinking water is essential for the health and well-being of people all over the world. Unfortunately, many communities are facing the challenge of dealing with high levels of arsenic in their water sources, posing significant health risks to the population. However, a revolutionary solution has emerged in the form of a groundbreaking Arsenic Removal Agent, developed by a leading environmental technology company, {company name}.{Company name} has been at the forefront of developing innovative solutions for water treatment and environmental remediation for over a decade. Their team of researchers and scientists have dedicated themselves to creating effective and sustainable solutions to address the pressing environmental challenges facing our world today. Their latest breakthrough in the form of the Arsenic Removal Agent has already shown great promise in effectively removing arsenic from water sources, making it safe for consumption and use in various applications.The Arsenic Removal Agent developed by {company name} is a proprietary blend of advanced materials and technologies that have been specifically engineered to target and remove arsenic from water. The agent works by effectively binding to arsenic molecules and removing them from the water, resulting in a significant reduction in arsenic levels that surpasses current industry standards. This innovative approach has the potential to transform the way communities and industries tackle the issue of arsenic contamination in their water sources.One of the key advantages of the Arsenic Removal Agent is its versatility and scalability. It can be easily integrated into existing water treatment systems, making it a practical and cost-effective solution for communities and industrial facilities dealing with arsenic contamination. The agent is also capable of handling high volumes of water, making it suitable for large-scale applications such as municipal water treatment plants and industrial facilities.Furthermore, {company name} has placed a strong emphasis on ensuring that their Arsenic Removal Agent is environmentally friendly and sustainable. The materials used in the agent are non-toxic and biodegradable, minimizing any potential impact on the environment. This commitment to environmental responsibility aligns with {company name}'s broader mission of developing solutions that not only address pressing environmental challenges but also do so in a way that is responsible and sustainable.The impact of the Arsenic Removal Agent developed by {company name} is already being felt in communities and industries grappling with arsenic contamination. In a recent pilot program conducted in a rural community affected by high levels of arsenic in their drinking water, the use of the agent resulted in a dramatic reduction in arsenic levels, providing the residents with access to safe and clean drinking water for the first time in years. The success of this pilot program has garnered attention from government agencies and non-profit organizations, positioning the Arsenic Removal Agent as a viable solution for addressing arsenic contamination in water sources.As {company name} continues to advance their efforts in promoting the Arsenic Removal Agent, they are actively collaborating with various stakeholders, including government agencies, non-profit organizations, and industry partners. These partnerships are essential in furthering the adoption and implementation of the agent in communities and industries affected by arsenic contamination, ultimately leading to a positive impact on public health and environmental sustainability.Looking ahead, {company name} is committed to furthering the development of their Arsenic Removal Agent and expanding its use to address arsenic contamination on a global scale. With a strong track record of delivering innovative environmental solutions, {company name} is well-positioned to play a pivotal role in addressing the pressing issue of arsenic contamination in water sources, offering hope and relief to communities and industries affected by this widespread problem.

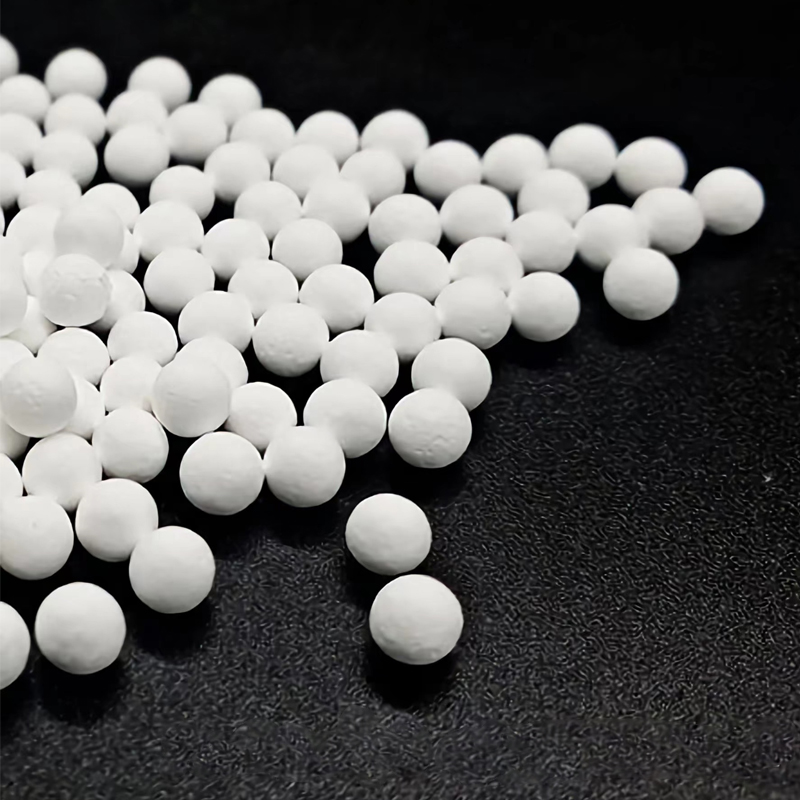

High-Quality Alumina Carrier for Catalysts: What You Need to Know

Alumina Carrier For Catalysts enhances company's position in the marketThe global demand for catalysts is on the rise, driven by the increasing emphasis on sustainable environmental practices and the growing need for cleaner energy sources. In line with this trend, {} is proud to introduce its latest product, Alumina Carrier For Catalysts, to the market. This new addition to the company's extensive product portfolio is set to further enhance its position as a leading provider of high-quality catalyst support materials.{} has been a key player in the catalyst industry for several years, offering a wide range of products that are widely used in various industrial processes. With the introduction of Alumina Carrier For Catalysts, the company is poised to bolster its market presence and meet the evolving needs of its customers.Alumina Carrier For Catalysts is a versatile product that offers excellent thermal stability, high surface area, and superior mechanical strength. These properties make it an ideal choice for supporting a wide range of catalysts, including those used in refining, petrochemical, and environmental applications. Moreover, the product's customizable particle size and pore structure enable it to be tailored to meet specific process requirements, further enhancing its versatility and applicability.The introduction of Alumina Carrier For Catalysts underscores {}'s commitment to innovation and excellence. The company continuously invests in research and development to bring new, advanced products to the market, and this latest offering is a testament to its dedication to meeting the technological demands of the industry.In addition to its technical capabilities, {}'s commitment to sustainability and responsible manufacturing practices sets it apart in the market. The production of Alumina Carrier For Catalysts adheres to rigorous environmental and quality standards, ensuring that the product not only meets the performance requirements of its customers but also aligns with their sustainability goals.As a trusted partner to its customers, {} provides comprehensive technical support and solutions to assist them in optimizing the performance of Alumina Carrier For Catalysts in their applications. The company's team of experienced engineers and technical specialists work closely with customers to understand their specific needs and recommend customized solutions that deliver the best results.With its extensive global network, {} is well-positioned to serve the catalyst industry and support customers across different regions. The company's expansive distribution and logistics capabilities ensure efficient and reliable delivery of Alumina Carrier For Catalysts to customers worldwide, enabling them to benefit from its exceptional performance and quality.In conclusion, the introduction of Alumina Carrier For Catalysts represents a significant milestone for {}. The product's exceptional properties, coupled with the company's commitment to innovation and sustainability, will undoubtedly reinforce its position as a leading provider of catalyst support materials. As the demand for high-performance catalysts continues to grow, {} is well-prepared to meet the evolving needs of the market and contribute to the advancement of sustainable and efficient industrial processes.

Innovative Catalyst Carrier: Spheralite - A Game-Changer in the Industry

Catalyst Carrier Spheralite, a highly innovative and effective solution for the chemical industry, is making waves with its cutting-edge technology and impressive results. With a focus on sustainability and efficiency, Spheralite is quickly becoming the go-to choice for companies looking to optimize their catalyst systems and improve their overall performance.Spheralite is a unique catalyst carrier that offers numerous advantages over traditional systems. Its spherical shape and highly porous structure provide a greater surface area for catalyst deposition, resulting in improved activity and selectivity. This allows for more efficient use of catalyst materials, ultimately reducing costs and minimizing environmental impact. In addition, Spheralite's uniform size and shape enable better fluidization and distribution within reactors, leading to more consistent and predictable results.One of the key factors that sets Spheralite apart from other catalyst carriers is its proprietary manufacturing process. This process allows for precise control over the properties of the carrier, ensuring optimal performance in a wide range of chemical processes. The result is a highly versatile and customizable product that can be tailored to meet the specific needs of each customer.Spheralite is also focused on sustainability, with a commitment to reducing waste and energy consumption. By optimizing catalyst performance, Spheralite helps companies minimize their environmental footprint and improve their overall sustainability. This aligns with the growing demand for eco-friendly solutions in the chemical industry, making Spheralite an attractive option for companies looking to meet and exceed environmental regulations.In addition to its impressive technical capabilities, Spheralite is backed by a team of experts who are dedicated to providing exceptional customer service. From initial consultation to ongoing support, the Spheralite team works closely with customers to ensure that their specific needs are met and their expectations are exceeded. This level of commitment and attention to detail has earned Spheralite a reputation for reliability and excellence in the industry.With its focus on innovation, sustainability, and customer satisfaction, Spheralite is well-positioned to continue its rapid growth in the chemical industry. The company's forward-thinking approach to catalyst carriers has already garnered significant attention from a wide range of customers, and its reputation for quality and performance is only expected to grow in the coming years.One of the key benefits of Spheralite is its ability to improve the performance of a wide range of chemical processes. Whether it's in gas-phase, liquid-phase, or multiphase reactions, Spheralite has been proven to enhance catalyst activity, selectivity, and stability. This makes it an ideal choice for companies looking to improve the efficiency and reliability of their operations.Moreover, Spheralite's versatility and customizable nature allow for seamless integration into existing catalyst systems, minimizing downtime and disruption. This makes it easy for companies to adopt Spheralite and start reaping the benefits of its superior performance without significant investment or retooling.As the demand for more sustainable and efficient solutions continues to grow, Spheralite is poised to become an indispensable asset for the chemical industry. Its ability to improve performance, reduce environmental impact, and provide exceptional customer service make it a clear choice for companies looking to stay ahead of the curve.In conclusion, Catalyst Carrier Spheralite is revolutionizing the chemical industry with its innovative technology, sustainability focus, and exceptional customer service. With its impressive technical capabilities and commitment to excellence, Spheralite is quickly becoming the catalyst carrier of choice for companies looking to optimize their operations and achieve long-term success. As the industry continues to evolve, Spheralite is well-positioned to lead the way with its groundbreaking solutions and unwavering dedication to customer satisfaction.

Advanced New Material Zsm-22 Shows Promise in Various Applications

ZSM-22 is a newly developed material that has shown impressive potential in various applications. The material is a form of zeolite, a crystalline structure that has a porous and cage-like framework, making it useful in a wide range of industrial processes, such as catalysis, gas separation, and ion exchange.Zeolites are aluminosilicate minerals that have a unique ability to exchange one cation for another. The structure of zeolites allows them to act as molecular sieves, selectively separating and capturing molecules based on their size and shape. This makes zeolites a valuable material in the fields of petrochemistry, environmental protection, and energy production.ZSM-22, in particular, has garnered significant attention due to its exceptional properties. The material has a unique pore structure, which gives it a high surface area and acidity. These characteristics make ZSM-22 an excellent candidate for catalytic applications, as it can effectively facilitate chemical reactions and improve reaction selectivity.Furthermore, ZSM-22's high silicon-to-aluminum ratio makes it particularly stable under harsh conditions, such as high temperatures and corrosive environments. This stability makes ZSM-22 a reliable and long-lasting material for industrial processes.The company {} specializes in the production and development of advanced materials, with a particular focus on zeolites and their applications. With a team of experienced scientists and engineers, the company has been at the forefront of research and development in the field of zeolite-based materials.{} has invested heavily in the synthesis and characterization of ZSM-22, aiming to harness its unique properties for various industrial applications. The company's state-of-the-art research facilities and expertise in material science have enabled them to produce high-quality ZSM-22 with tailored properties to meet specific industry requirements.The potential applications of ZSM-22 are vast and varied. In the petrochemical industry, ZSM-22 can be used as a catalyst for the conversion of hydrocarbons into valuable products, such as gasoline and diesel. The material's high activity and selectivity make it a promising candidate for improving the efficiency of these processes.In the field of gas separation, ZSM-22's molecular sieving properties can be utilized to selectively capture specific gases from a mixture, such as removing carbon dioxide from natural gas or separating oxygen from air. This can have significant implications for environmental protection and energy production.Moreover, ZSM-22 can also be employed in ion exchange applications, where it can selectively remove or release ions from a solution, making it useful in water purification and wastewater treatment processes. Its high stability and resistance to chemical degradation make ZSM-22 a reliable material for such demanding applications.The development of ZSM-22 represents a significant advancement in the field of zeolite-based materials, offering new possibilities for improving industrial processes and addressing environmental challenges. With the expertise and dedication of companies like {}, the potential of ZSM-22 is likely to be fully realized, leading to the creation of innovative and sustainable solutions across various industries.

Catalysts in Hydrofining Offer Better Fuel Quality and Efficiency

Title: Revolutionary Hydrofining Catalyst Promises Enhanced Performance and Sustainability in Oil Refining ProcessIntroduction:In a bid to further revolutionize the oil refining industry, a leading chemical manufacturing company has developed an innovative Hydrofining Catalyst. Designed to enhance the performance, efficiency, and sustainability of oil refining processes, this cutting-edge catalyst is poised to redefine the global energy landscape.Company Background:Founded in [Company Founding Year], [Company Name] is a renowned chemical manufacturing company at the forefront of developing revolutionary catalyst technologies. With a strong commitment to sustainable solutions, the company has consistently pushed the boundaries of innovation in order to meet the evolving demands of various industries worldwide. Combining state-of-the-art research facilities with a team of expert chemists and engineers, [Company Name] has successfully developed numerous catalysts that have redefined industry standards.Hydrofining Catalyst: Redefining Oil Refining ProcessesThe newly developed Hydrofining Catalyst is poised to transform the oil refining landscape by offering unparalleled performance and sustainability advantages. Its unique formulation and structure enable it to effectively remove impurities, such as sulfur, nitrogen, and aromatic components, from crude oil. This results in higher quality end-products, lower emission levels, and improved energy efficiency, all while meeting increasingly stringent environmental regulations.Enhanced Performance and Efficiency:The Hydrofining Catalyst brings a host of benefits to oil refineries, including optimized performance and greater operational efficiency. By selectively targeting harmful contaminants, it ensures cleaner and purer refining processes, leading to higher yields of valuable products, such as gasoline, diesel, and jet fuel. This translates into increased profitability for refineries, as well as a reduced environmental impact.Furthermore, the Hydrofining Catalyst's innovative design offers exceptional stability and longevity, minimizing catalyst deactivation and extending the catalyst's lifespan. By reducing the frequency of catalyst replacement, refineries can significantly reduce downtime and maintenance costs, enhancing overall productivity and profitability.Sustainability Advantages:In an era of increased environmental consciousness, the Hydrofining Catalyst takes center stage by promoting sustainable practices within the oil refining industry. By substantially lowering the sulfur content in refined products, it aids in the reduction of harmful emissions, including sulfur dioxide and nitrogen oxides, which contribute to air pollution and acid rain.Furthermore, the Hydrofining Catalyst's selective removal of aromatic compounds results in cleaner and less toxic end-products. This not only benefits the environment but also improves the overall quality and safety of refined fuels.Market Impact and Future Outlook:The introduction of the Hydrofining Catalyst marks a significant milestone in the oil refining industry, offering a more sustainable and efficient oil refining process. As the global demand for cleaner fuels continues to rise, this catalyst provides refineries with a competitive edge, allowing them to meet stringent emission standards while maximizing their operational profitability.With the increasing pressure from regulatory bodies and consumers to reduce environmental impact, the Hydrofining Catalyst is set to become a catalyst of change within the industry. Its widespread adoption has the potential to transform the landscape of oil refining, prioritizing sustainability without compromising operational efficiency.In conclusion, the Hydrofining Catalyst, developed by [Company Name], is a game-changer for the oil refining industry. With its ability to enhance performance, efficiency, and sustainability, this innovative catalyst promises to redefine the standards for oil refining processes worldwide. As we move towards a more sustainable future, this breakthrough technology sets a new benchmark for the industry while empowering refineries to meet the demands of a rapidly evolving energy landscape.

Discover the Latest Innovations in Alumina Microsphere Technology

Alumina Microsphere, a groundbreaking material that has taken the industry by storm, is making waves in the market. Developed by a leading materials technology company, this innovative product is set to revolutionize various industries, including automotive, aerospace, and electronics.The Alumina Microsphere is a lightweight and high-strength material with excellent thermal and chemical stability. It is also highly resistant to corrosion, making it an ideal choice for applications that require durability and reliability. The material’s unique properties make it suitable for a wide range of uses, such as in lightweight structural components, thermal insulating materials, and high-performance coatings.One of the key advantages of Alumina Microsphere is its ability to significantly reduce the weight of components without compromising on strength and performance. This makes it an attractive option for industries looking to enhance fuel efficiency and reduce carbon emissions. Additionally, its thermal insulation properties make it an excellent choice for heat management in automotive and aerospace applications, where maintaining optimal temperatures is crucial for efficient operation.The company behind the development of Alumina Microsphere has a strong track record in materials technology, with a focus on creating innovative solutions that address the evolving needs of modern industries. With extensive expertise in materials science and engineering, the company has been at the forefront of research and development in advanced materials, pushing the boundaries of what is possible in the field.The company's commitment to quality and innovation has been a driving force behind the success of Alumina Microsphere. Through rigorous testing and validation, the company has ensured that the material meets the highest standards of performance and reliability. This dedication to excellence has earned the company a reputation as a trusted partner for industries seeking cutting-edge materials solutions.In addition to its technical capabilities, the company also places a strong emphasis on sustainability and environmental responsibility. The development of Alumina Microsphere takes into consideration the importance of reducing the environmental impact of industrial processes. By offering a material that enables lightweighting and fuel efficiency, the company is helping its customers achieve their sustainability goals.The introduction of Alumina Microsphere comes at a time when industries are increasingly seeking innovative solutions to address the challenges of the modern world. The material's versatility and performance make it an attractive option for a wide range of applications, from automotive and aerospace to electronics and renewable energy. Its potential to drive meaningful advancements in these sectors is generating significant interest and excitement among industry leaders and experts.Looking ahead, the company is focused on further developing and refining Alumina Microsphere to unlock its full potential. With ongoing research and development efforts, the company is committed to exploring new applications and continuously improving the material's performance and properties. By doing so, it aims to establish Alumina Microsphere as a premier choice for industries looking to enhance their products and processes.In conclusion, Alumina Microsphere is a game-changing material that is set to redefine the possibilities for various industries. Backed by a company with a proven track record in materials technology, it promises to deliver significant advancements in lightweighting, thermal management, and durability. With its potential to drive innovation and sustainability, Alumina Microsphere is poised to shape the future of materials technology and industrial applications.

How Catalyst Carriers are Shaping the Future of the Industry

Catalyst Carrier Introduces Innovative Solution for Efficient Chemical ReactionsCatalyst Carrier, a leading chemical industry solution provider, has announced the launch of their latest innovation designed to improve the efficiency of chemical reactions. The company, which has a proven track record in delivering high-quality catalysts and catalytic solutions, has introduced a new carrier that promises to revolutionize the way chemical processes are carried out.The Catalyst Carrier is a versatile and efficient material that is designed to support catalysts and facilitate chemical reactions in a wide range of industrial applications. Its unique properties make it an ideal choice for a variety of reactions, including hydrogenation, oxidation, and hydrocracking, among others. The carrier is designed to provide optimal support for catalysts, ensuring maximum surface area exposure and improved reaction kinetics.One of the key features of the Catalyst Carrier is its high thermal stability, which allows it to maintain its structural integrity and performance under extreme temperature and pressure conditions. This makes it suitable for use in a wide range of operating environments, from ambient conditions to high-temperature industrial processes. Additionally, the carrier's high surface area and porosity enable effective mass transfer and diffusion of reactants, resulting in enhanced catalytic efficiency.In addition to its superior performance characteristics, the Catalyst Carrier is also designed to be highly customizable, allowing for tailored solutions to meet specific process requirements. With a variety of shapes, sizes, and compositions available, customers can select the most suitable carrier for their particular application, ensuring the best possible outcome for their chemical processes.The introduction of the Catalyst Carrier reflects Catalyst Carrier's commitment to providing innovative and sustainable solutions for the chemical industry. By offering a highly efficient and customizable material for catalytic processes, the company aims to help its customers improve their operational efficiency, reduce energy consumption, and minimize environmental impact."We are excited to introduce the Catalyst Carrier as a game-changing solution for the chemical industry," said a spokesperson for Catalyst Carrier. "With its exceptional performance and versatility, we believe that this innovative material will help our customers achieve significant advancements in their chemical processes, leading to improved productivity and cost savings."Catalyst Carrier has a long-standing reputation for delivering high-quality catalysts and catalytic solutions to a wide range of industries, including petrochemical, pharmaceutical, and fine chemical manufacturing. With a strong focus on research and development, the company is dedicated to continuous innovation and improvement, ensuring that their products remain at the forefront of technological advancements in the chemical industry.The introduction of the Catalyst Carrier further solidifies Catalyst Carrier's position as a leading provider of innovative and sustainable solutions for chemical processes. With a proven track record of delivering reliable and high-performance materials, the company is well-equipped to meet the evolving needs of the chemical industry and help its customers achieve their operational goals.As the global chemical industry continues to evolve and demand for more efficient and sustainable solutions grows, the introduction of the Catalyst Carrier represents a significant step forward in the quest for improved catalytic processes. With its unique combination of performance, versatility, and customizability, the Catalyst Carrier is set to drive innovation and efficiency in chemical reactions for years to come.

Revolutionizing Industrial Processes: Unveiling the Power of Activated Alumina Catalysts

**Headline: Activated Alumina Catalyst Revolutionizes Industrial Processes for Enhanced Efficiency and Sustainability****Introduction:**In an era where sustainable and efficient industrial processes take center stage, the introduction of Activated Alumina Catalyst by a groundbreaking company marks a significant milestone. The advanced catalyst offers unmatched potential to revolutionize numerous industries by enhancing efficiency, reducing environmental impact, and optimizing outcomes. Its unique properties and applications have ignited excitement among experts and industry leaders, steering us towards a greener and more sustainable future.**Breaking Ground: An Introduction to the Company Behind the Innovation**(Company Name) - An industry-leading provider of innovative solutions, (Brand Name) is at the forefront of pioneering research and development. With a vision to reshape traditional practices, they specialize in the creation of cutting-edge catalysts that address pressing challenges across various sectors. Their commitment to sustainability has garnered widespread recognition, pushing them to develop Activated Alumina Catalyst, the latest game-changing innovation designed to transform industries worldwide.**Features and Properties of Activated Alumina Catalyst:**Activated Alumina Catalyst is a highly porous and versatile material that exhibits exceptional surface area and sorption characteristics. The catalyst's unique properties stem from its carefully engineered structure, which provides maximum surface area to facilitate chemical reactions and adsorption processes. Its rigid framework ensures excellent mechanical strength, enabling its effectiveness even in the most demanding industrial applications.The composition of the Activated Alumina Catalyst includes aluminum oxide (Al2O3), which acts as the primary active component. This ingredient imparts remarkable catalytic properties and chemical stability to the material. The catalyst's surface chemistry can be tailored and enhanced further by incorporating trace metals or promoters, allowing it to selectively target specific reactions, making it highly efficient and versatile across a wide range of applications.**Applications and Impact Across Industries:**1. Petrochemical Industry: Activated Alumina Catalyst finds extensive use in the petroleum and gas refining sector. It plays a pivotal role in the removal of impurities, such as sulfur compounds, from fuels, ensuring compliance with stringent environmental regulations. The catalyst's high surface area and reactivity enable efficient desulfurization while minimizing undesirable byproducts.2. Water Purification: Addressing the global challenge of water scarcity, Activated Alumina Catalyst proves invaluable in the removal of contaminants, including fluoride, arsenic, and heavy metals, from drinking water. Its outstanding adsorption capacity and mechanical robustness make it an ideal choice for water treatment plants, contributing to providing safe and clean drinking water to communities worldwide.3. Pharmaceuticals and Chemical Manufacturing: The pharmaceutical and chemical industries benefit greatly from Activated Alumina Catalyst's ability to facilitate chemical reactions and separation processes. The catalyst assists in the production of various chemicals, pharmaceutical intermediates, and the purification of active ingredients, promoting efficiency and reducing environmental impact.4. Air and Gas Drying: Activated Alumina Catalyst offers an efficient solution for drying air and various gases, preventing the formation of moisture-induced corrosion and ensuring the longevity of equipment and infrastructure. Industries, such as natural gas processing, cryogenics, and compressed air, rely on Activated Alumina Catalyst for efficient and reliable gas drying applications.**A Sustainable Future with Activated Alumina Catalyst:**The introduction of Activated Alumina Catalyst marks a significant step towards achieving sustainability and efficiency in various industries worldwide. By providing unparalleled performance in desulfurization, water purification, chemical manufacturing, and gas drying applications, this groundbreaking catalyst ensures a cleaner environment, reduced waste, and increased energy efficiency. With (Brand Name) at the helm of this technological advancement, we embark on a greener, more sustainable future, where innovation meets environmental stewardship.

Highly Effective Alumina Catalyst for Improved Chemical Reactions

Al2O3 Catalyst: The Best Choice for Environmental ProtectionIn today's world, the need for environmental protection and sustainability has become more important than ever. With the constant threat of climate change and the depletion of natural resources, companies and individuals are constantly looking for ways to minimize their environmental impact. This is where Al2O3 catalyst comes into play. The use of Al2O3 catalyst has been proven to be an effective method for reducing pollution and promoting sustainability in various industries.Al2O3, also known as aluminum oxide, is a versatile and widely used catalyst in the industry. It is a key component in many industrial processes, including the production of chemicals, petrochemicals, and environmental protection applications. The use of Al2O3 catalyst has been shown to improve the efficiency of various chemical reactions, leading to reduced energy consumption and lower emissions of harmful pollutants.One of the leading companies in the production and application of Al2O3 catalyst is {}. With years of experience in the industry, {} has established itself as a reliable and innovative supplier of high-quality catalyst materials. The company's commitment to research and development has led to the creation of advanced Al2O3 catalyst products that meet the strictest environmental standards and deliver exceptional performance.The unique properties of Al2O3 catalyst make it an ideal choice for a wide range of environmental protection applications. Its high surface area and porosity make it an effective adsorbent for removing pollutants from air and water. It is also used in catalytic converters to reduce harmful emissions from vehicles, helping to improve air quality and protect the environment.In addition to its environmental benefits, the use of Al2O3 catalyst also offers significant economic advantages. By improving the efficiency of industrial processes, it helps companies save on energy and raw material costs. Moreover, the reduction of pollutants leads to lower regulatory compliance costs and promotes a positive public image for businesses.With the growing demand for sustainable and eco-friendly solutions, the market for Al2O3 catalyst is experiencing rapid growth. Companies across various industries are increasingly turning to this versatile catalyst to meet their environmental goals and regulatory requirements. As a result, the demand for high-quality Al2O3 catalyst products from companies like {} is on the rise.To meet this demand, {} continues to invest in research and development to further enhance the performance and applications of its Al2O3 catalyst products. The company's team of skilled engineers and scientists is dedicated to developing innovative solutions that address the evolving needs of its customers and contribute to a cleaner and healthier environment.In conclusion, the use of Al2O3 catalyst is an effective and sustainable solution for addressing environmental challenges in the industry. As a leading supplier of high-quality catalyst materials, {} is well-positioned to meet the growing demand for Al2O3 catalyst products and support the efforts of companies to protect the environment. With its commitment to innovation and excellence, {} is driving positive change and helping to create a more sustainable future for all.

Discover the Latest Innovation in Alumina Microsphere Technology

Alumina Microsphere, a leading company in the field of advanced materials, has recently made significant advancements in the development and production of alumina microspheres. These microspheres have a wide range of applications in various industries, including cosmetics, electronics, and automotive.The alumina microspheres produced by Alumina Microsphere are known for their high purity, excellent dispersion, and uniform particle size distribution. These unique properties make them ideal for use in a wide range of applications, such as fillers in polymer composites, additives in coatings and paints, and as additives in skincare and personal care products.One of the key advantages of alumina microspheres is their ability to improve the mechanical properties of composites and coatings while maintaining low density. This makes them an ideal choice for manufacturers looking to enhance the performance and durability of their products without adding extra weight.In the cosmetics industry, alumina microspheres are used as gentle exfoliants in skincare products, providing a smooth and even texture to the skin. Their high purity and inert nature also make them suitable for use in sensitive and hypoallergenic formulations.Furthermore, the electronic industry has also benefitted from the properties of alumina microspheres. These microspheres are used as fillers in electronic materials to enhance the thermal conductivity and mechanical strength of the final products. This helps in prolonging the lifespan and improving the overall performance of electronic devices.In the automotive industry, alumina microspheres are used as lightweight fillers in polymer composites, contributing to the reduction of overall vehicle weight. This not only improves fuel efficiency but also helps in lowering emissions and enhancing the overall sustainability of the automotive industry.Alumina Microsphere takes pride in its state-of-the-art production facilities and its commitment to quality and innovation. The company continuously invests in research and development to further enhance the properties and applications of alumina microspheres. Additionally, Alumina Microsphere places a strong emphasis on sustainability and environmental responsibility, ensuring that its manufacturing processes are in line with the highest industry standards.The company's team of experienced scientists and engineers are dedicated to providing customized solutions to meet the specific needs of its customers. Whether it's developing new formulations or improving existing products, Alumina Microsphere collaborates closely with its clients to deliver high-performance materials that meet the strictest quality standards.Through its dedication to innovation and customer satisfaction, Alumina Microsphere has earned a reputation as a trusted and reliable partner in the advanced materials industry. The company's alumina microspheres have gained recognition for their superior quality and performance, making them the preferred choice for a wide range of applications across various industries.As the demand for high-performance materials continues to grow, Alumina Microsphere is well-positioned to meet the evolving needs of its customers. With its cutting-edge technology and unwavering commitment to excellence, the company is poised to remain at the forefront of the advanced materials industry for years to come.