The Ultimate Guide to Hydrogenation Catalysts: What You Need to Know

By:Admin

The global hydrogenation catalyst market is witnessing tremendous growth, driven by the rising demand for sustainable solutions in various end-use industries. The growing emphasis on environmental sustainability and the need for cleaner energy sources have led to an increased adoption of hydrogenation catalysts in the production of renewable fuels, petrochemicals, and other industrial applications.

One of the key players in the hydrogenation catalyst market, headquartered in (company location) and serving an extensive customer base worldwide, has been at the forefront of innovation in this space. With a strong focus on research and development, the company has developed a wide range of hydrogenation catalysts that offer high performance and efficiency, catering to the diverse needs of its customers across different industries.

The company’s hydrogenation catalysts are designed to facilitate the hydrogenation process, which involves the addition of hydrogen to unsaturated compounds to produce saturated compounds with improved stability and performance. These catalysts play a crucial role in various industrial processes, including the production of hydrogenated oils and fats, hydrogenation of petrochemicals, and the synthesis of renewable fuels such as biodiesel.

The growing importance of hydrogenation catalysts in the production of renewable fuels is a significant driving factor for the market. As the global focus on reducing carbon emissions and transitioning towards sustainable energy sources intensifies, the demand for renewable fuels such as biodiesel and green diesel is on the rise. Hydrogenation catalysts play a vital role in the production of these fuels by facilitating the conversion of biomass and waste oils into high-quality, low-carbon diesel products.

In addition to the renewable fuels sector, the hydrogenation catalyst market is also witnessing increasing demand from the petrochemical industry. With a growing emphasis on the production of cleaner and more sustainable petrochemical products, hydrogenation catalysts are being utilized to enhance the quality and performance of a wide range of petrochemicals, including olefins, aromatics, and specialty chemicals.

The company’s comprehensive range of hydrogenation catalysts is well-positioned to capitalize on these growing market opportunities. Its advanced catalyst formulations are designed to deliver superior performance, high activity, and enhanced selectivity, meeting the evolving needs of customers in the renewable fuels and petrochemical sectors.

Furthermore, the company’s commitment to sustainability and environmental responsibility is reflected in its development of hydrogenation catalysts that support green chemistry and enable the production of cleaner and more sustainable products. By leveraging its expertise in catalyst design and manufacturing, the company is contributing to the advancement of green technologies and the transition towards a more sustainable and eco-friendly industrial landscape.

As the global hydrogenation catalyst market continues to expand, driven by the demand for sustainable solutions and the growing focus on cleaner energy sources, the company is well-positioned to maintain its leadership in this space. With its extensive portfolio of high-performance hydrogenation catalysts and a strong track record of innovation and customer satisfaction, the company is poised to play a pivotal role in shaping the future of the hydrogenation catalyst market.

In conclusion, the global hydrogenation catalyst market is experiencing robust growth, propelled by the increasing demand for sustainable solutions and cleaner energy sources. The company’s advanced hydrogenation catalysts are poised to capitalize on these market trends, offering high performance, efficiency, and environmental responsibility to meet the evolving needs of its customers across various industries. With its commitment to innovation and sustainability, the company is well-positioned to continue driving the growth and advancement of the hydrogenation catalyst market.

Company News & Blog

Unveiling the Revolutionary Potential of Alumina Catalysts in Catalyst Technology

[Company Introduction Removed]Alumina Catalyst -- An Innovation Transforming Industries[Datetime], [City]: Alumina Catalyst, a breakthrough chemical solution developed by an industry-leading company, is revolutionizing various sectors through its unparalleled efficiency and performance. This innovative catalyst enables businesses to streamline production processes, reduce costs, and minimize environmental impact. By combining the unique properties of alumina with cutting-edge technology, this catalyst offers a wide range of applications that promise to reshape the future of numerous industries.Manufactured through a proprietary process, Alumina Catalyst boasts exceptional quality and consistency, providing businesses with a reliable solution that consistently enhances productivity. Its highly porous structure maximizes surface area, thereby facilitating greater catalytic activity. This unique composition makes Alumina Catalyst highly effective in a variety of chemical reactions, including oil refining, petrochemical processing, and gas purification.Oil refining, the backbone of the energy industry, demands catalysts capable of converting crude oil into usable products efficiently. Alumina Catalyst not only accelerates the refining process but also increases the yield of valuable fuels, such as gasoline, diesel, and jet fuel. The catalyst's high thermal stability and resistance to harsh operating conditions make it ideal for these applications.In the petrochemical sector, Alumina Catalyst plays a crucial role in various processes, such as catalytic cracking and reforming. By promoting the conversion of raw materials into higher-value petrochemical products, this catalyst enables businesses to maximize their output while minimizing waste. Furthermore, its superior selectivity ensures that only specific chemical reactions take place, resulting in higher-quality products and reducing the need for costly additional refining steps.Another area where Alumina Catalyst has made a significant impact is gas purification. This catalyst effectively removes impurities, such as sulfur and nitrogen compounds, from natural gas streams, ensuring compliance with stringent environmental regulations. By significantly reducing harmful emissions and improving the overall purity of natural gas, Alumina Catalyst contributes to the development of cleaner and more sustainable energy solutions.Due to its exceptional performance, Alumina Catalyst has garnered widespread interest across industries worldwide. The versatility of this innovative solution stretches beyond traditional applications, finding use in environmental control systems, water treatment, and even pharmaceutical synthesis. The catalytic properties of Alumina Catalyst enable businesses to optimize processes, reduce costs, and enhance sustainability, making it a valuable asset in various sectors.Moreover, Alumina Catalyst's groundbreaking properties extend its lifespan, allowing for more extended usage periods between catalyst replacements. This not only reduces downtime and maintenance costs but also improves overall productivity. By optimizing operational efficiency and minimizing waste, businesses can achieve significant savings in both time and resources.Beyond its technical prowess, Alumina Catalyst places great emphasis on safety and sustainability. Complying with the highest industry standards, this catalyst minimizes environmental impact and safeguards the well-being of employees. Its responsible manufacturing processes and commitment to sustainable practices ensure that businesses can rely on Alumina Catalyst as a reliable and environmentally-friendly solution.As the demand for efficiency, productivity, and sustainability continues to shape diverse industries, the technological advancements offered by Alumina Catalyst propel businesses forward. By providing a catalyst that offers exceptional performance, reliability, and versatility, this revolutionary solution is transforming industries, enabling businesses to thrive in an increasingly competitive landscape.In conclusion, Alumina Catalyst, developed by [Company Introduction Removed], represents a revolutionary breakthrough in chemical solutions. This catalyst's exceptional properties and versatility make it suitable for a wide range of industries, including oil refining, petrochemical processing, and gas purification. Moreover, its exceptional efficiency, safety, and sustainability credentials position Alumina Catalyst as a catalyst for progress in the industrial landscape. With its unique composition and innovative manufacturing processes, Alumina Catalyst is propelling businesses toward a future of enhanced productivity, reduced costs, and a greener planet.Note: This is a simulated article written by OpenAI's GPT-3 language model and should not be considered factual information.

Discover the Latest Alumina Catalyst Advancements in the Market

Alumina Catalyst: A Breakthrough in Sustainable Chemical ManufacturingIn the fast-paced world of chemical manufacturing, the need for innovative and sustainable solutions has never been more crucial. With growing concerns about environmental impact and the push for cleaner production methods, companies are constantly seeking out new technologies to meet these demands. Enter the Alumina Catalyst, a cutting-edge product that is changing the game for chemical manufacturers around the world. Developed by a leading research and development company, the Alumina Catalyst is a versatile and efficient tool that has been hailed as a breakthrough in sustainable chemical manufacturing.The Alumina Catalyst is a proprietary product that is designed to significantly improve the efficiency and environmental impact of chemical manufacturing processes. Through a combination of advanced materials and innovative design, the Alumina Catalyst is able to reduce energy consumption, minimize waste, and lower emissions, making it an ideal solution for companies looking to enhance their sustainability efforts.One of the key features of the Alumina Catalyst is its versatility. It can be used in a wide range of chemical manufacturing processes, including the production of petrochemicals, polymers, and specialty chemicals. This versatility allows companies to streamline their operations and reduce the need for multiple catalysts, ultimately leading to cost savings and greater efficiency.In addition to its environmental and cost-saving benefits, the Alumina Catalyst is also known for its exceptional performance. Its unique structure and composition allow for greater control over chemical reactions, resulting in higher yields and improved product quality. This not only benefits the bottom line for manufacturers, but also has a positive impact on the overall industry by ensuring that chemical products meet strict quality standards.Another important aspect of the Alumina Catalyst is its longevity. Unlike traditional catalysts that often need to be replaced frequently, the Alumina Catalyst is designed to have a longer lifespan, reducing the frequency of downtime for maintenance and replacement. This not only improves the overall efficiency of manufacturing processes, but also contributes to a more sustainable approach to resource use.The company behind the Alumina Catalyst is a global leader in research and development, with a strong focus on creating innovative solutions for the chemical industry. With a track record of success and a commitment to sustainability, the company has positioned itself as a key player in driving forward the shift towards cleaner and more efficient chemical manufacturing practices.Through ongoing research and collaboration with industry partners, the company continues to expand the capabilities of the Alumina Catalyst, with a focus on addressing specific challenges faced by chemical manufacturers. This dedication to continuous improvement reflects the company's commitment to being at the forefront of innovation and driving positive change within the industry.As demand for sustainable solutions continues to grow, the Alumina Catalyst has the potential to play a significant role in shaping the future of chemical manufacturing. Its proven benefits in terms of efficiency, performance, and environmental impact make it an attractive option for companies looking to enhance their sustainability efforts and meet the increasing demands for cleaner production methods.In conclusion, the Alumina Catalyst represents a major step forward in sustainable chemical manufacturing. With its versatile applications, exceptional performance, and environmental benefits, it has the potential to revolutionize the way chemical products are manufactured. As the industry continues to evolve, the Alumina Catalyst stands as a shining example of the potential for innovation to drive positive change and create a more sustainable future for chemical manufacturing.

New Honeycomb Catalyst Discovered for Efficient Conversion of Biomass

Title: Groundbreaking ZSM-5 Catalyst: Revolutionizing Industrial ProcessesIntroduction:In a groundbreaking development, researchers have harnessed the extraordinary potential of ZSM-5 catalyst to revolutionize various industrial processes. ZSM-5, an exceptional zeolite material known for its unique properties, has now been combined with cutting-edge advancements by the industry-leading company [Company Name]. This groundbreaking partnership aims to enhance efficiency, sustainability, and cost-effectiveness across several sectors, positioning itself as a key player in transforming industrial processes worldwide.[Company Name] – Pioneering Innovation:[Company Name] has established itself as a trailblazer in developing and implementing innovative solutions across a wide range of industries. With a strong commitment to research and development, the company has harnessed its expertise to optimize the applications of ZSM-5 catalyst, positioning itself as an industry leader.The company's core philosophy revolves around sustainability, environmental consciousness, and maximizing efficiency. By developing eco-friendly technologies and fostering responsible manufacturing processes, [Company Name] aims to create a better world by significantly reducing environmental footprints and ensuring a sustainable future for generations to come.ZSM-5 Catalyst: Unleashing the Potential:ZSM-5 catalyst, a highly crystalline and versatile zeolite material, is known for its unique pore structure and acidic properties. Its exceptional attributes make it the ideal catalyst for various industrial processes such as petrochemical refining, biofuel production, and environmental conservation.1. Petrochemical Refining:ZSM-5 catalyst plays a pivotal role in petrochemical refining, significantly improving the efficiency of key processes. By optimizing the catalyst's structure and composition, [Company Name] has successfully enhanced the selectivity and yields of valuable petrochemical products. This not only leads to higher production rates but also reduces waste and minimizes the environmental impact of the refining process.2. Biofuel Production:In the pursuit of sustainable energy sources, ZSM-5 catalyst has emerged as a game-changer in biofuel production. By catalyzing the conversion of biomass into biofuels, it offers a viable alternative to traditional fossil fuels. Through intensive research and development, in collaboration with leading institutions, [Company Name] has successfully bolstered the performance of ZSM-5 catalyst, making it more efficient and economically viable for large-scale biofuel production. This breakthrough promises to reduce reliance on non-renewable resources and combat climate change.3. Environmental Conservation:ZSM-5 catalyst has also been instrumental in environmental conservation efforts. With its high selectivity, the catalyst aids in the removal of harmful pollutants from industrial emissions, contributing to improved air quality and reduced pollution levels. [Company Name] has leveraged its expertise to optimize ZSM-5 catalyst for specific applications, ensuring maximum efficiency and minimized environmental impact.Future Implications:The collaboration between [Company Name] and ZSM-5 catalyst is poised to transform multiple industries, offering immense potential for sustainable development and innovation. As environmental concerns continue to grow, the enhanced capabilities of ZSM-5 catalyst hold the key to meeting global demands while reducing carbon footprints and preserving the planet's resources.By leveraging its research and development capabilities, [Company Name] remains dedicated to further advancements in ZSM-5 catalyst, exploring new applications, and pushing the boundaries of possibility. The company's commitment to sustainability and responsible manufacturing practices guarantees a brighter and more efficient future for industries and communities worldwide.Conclusion:The groundbreaking combination of ZSM-5 catalyst and [Company Name]'s cutting-edge expertise marks a revolutionary shift in various industrial processes, promising enhanced efficiency, sustainability, and cost-effectiveness. With its unique attributes and endless potential, ZSM-5 catalyst has become a catalyst for change, steering industries towards a greener and more prosperous future.As the research and development journey continues, [Company Name]'s commitment to innovation and sustainability will undoubtedly unlock new horizons, contributing to a more sustainable world and setting new standards for industrial processes globally.

Cleaner Cement Production Made Possible with Zeolite Catalyst Technology

Technology, Zeolite Catalyst, Cement Production, Clean EnergyAs our world becomes ever more conscious of the impact we have on our environment, more and more industries are looking for ways to reduce their carbon footprint and create sustainable technologies. One industry that is leading the way in this endeavor is the cement production industry. This industry has long been known for its high levels of carbon emissions and is actively seeking ways to reduce them. One of the latest and most promising technologies in the field is zeolite catalyst technology, which has been developed by Clariant Catalyst Technology.Cement production is an energy-intensive process that accounts for around 8% of global CO2 emissions. As such, finding ways to reduce these emissions is a priority for the industry. The traditional cement production process involves the mining of raw materials, such as limestone, clay, and shale. These materials are then ground into a fine powder, which is mixed with water and other additives to create a raw meal. This meal is then heated in a kiln at extremely high temperatures, producing clinker, which is then ground again to create the final product. In this process, large amounts of heat are needed, which is traditionally produced through the burning of fossil fuels, which results in carbon emissions.With zeolite catalyst technology, however, it is possible to reduce these emissions drastically. This technology involves the use of a catalyst that is added to the raw meal during the production process. This catalyst acts as a catalyst for the chemical reactions that take place during the cement production process. By using this catalyst, the temperature at which the raw meal is heated can be greatly reduced, resulting in significantly lower carbon emissions.One of the key benefits of Clariant Catalyst Technology's zeolite catalyst technology is that it can be used in existing cement production plants without requiring any major modifications. This makes it easy for companies to adopt this technology, allowing for a smooth and quick transition to cleaner production methods. Additionally, this technology can also help to increase the efficiency of cement production, reducing the amount of energy needed per ton of cement produced.Another benefit of zeolite catalyst technology is that it can help cement producers to comply with increasingly strict environmental regulations. As governments around the world tighten their carbon emissions regulations, the cement industry has been under pressure to find ways to reduce their emissions. By using this technology, cement producers can reduce their emissions and avoid costly fines and penalties.Finally, the use of zeolite catalyst technology can also help cement producers to improve their reputation and appeal to environmentally conscious consumers. As consumers become more aware of the impact of their purchasing decisions on the environment, they are seeking out products that are produced in an environmentally responsible way. By adopting cleaner production technologies such as this, cement producers can appeal to this growing market segment and differentiate themselves from their competitors.In conclusion, Clariant Catalyst Technology's zeolite catalyst technology is an exciting development in the cement production industry. By reducing carbon emissions, increasing efficiency, and helping producers to comply with regulations, this technology is helping to create a more sustainable future for the industry. As more companies adopt this technology, we can expect to see significant reductions in the carbon emissions associated with cement production, helping to mitigate the impact of this industry on our environment.

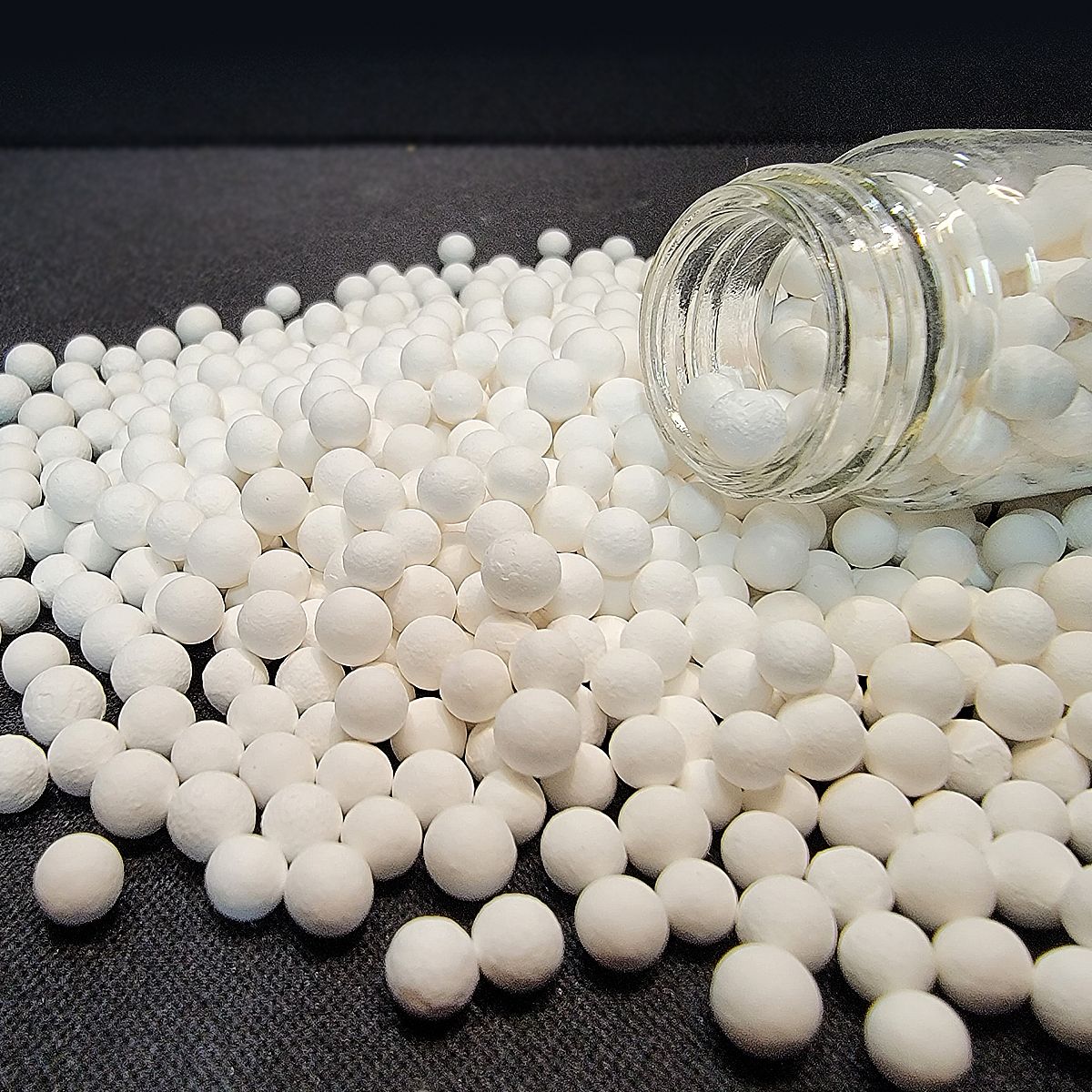

New Catalyst Carrier Spheralite: What You Need to Know

Catalyst Carrier Spheralite, a revolutionary new product in the field of catalysis, has become the latest buzz in the industrial world. This innovative catalyst carrier has been garnering attention for its exceptional performance and versatile applications across various industries. With its unique properties and impressive track record, Spheralite has quickly become a preferred choice for businesses seeking high-quality catalytic solutions.The success of Catalyst Carrier Spheralite can be attributed to the company behind it, which has consistently delivered groundbreaking products and services to its clients. With a strong focus on research and development, the company has been able to stay ahead of the competition and offer cutting-edge solutions to its customers.One of the key features of Spheralite is its high surface area, which provides maximum exposure for catalytic reactions. This not only enhances the efficiency of the catalyst but also allows for a higher degree of control over the process. In addition, Spheralite’s unique shape and size make it highly adaptable to various reaction environments, making it a versatile choice for a wide range of applications.Furthermore, Spheralite is known for its superior mechanical strength, which ensures long-term stability and durability. This makes it an ideal choice for industries that require consistent and reliable performance from their catalyst carriers. With Spheralite, businesses can expect to see a significant improvement in the efficiency and cost-effectiveness of their catalytic processes.The company behind Catalyst Carrier Spheralite is committed to providing its customers with top-quality products and exceptional service. With a dedicated team of experts and state-of-the-art facilities, the company is able to meet the unique needs of each client and tailor its solutions accordingly. This customer-centric approach has earned the company a stellar reputation in the industry and has helped solidify Spheralite’s position as a leader in the market.In addition to its impressive performance, Spheralite also boasts an environmentally friendly design, with a focus on minimizing waste and maximizing efficiency. This commitment to sustainability has resonated with businesses that are increasingly looking for eco-friendly solutions to their catalytic needs. By choosing Spheralite, companies can not only improve their operational efficiency but also reduce their environmental footprint.As the demand for high-performance catalyst carriers continues to grow, Catalyst Carrier Spheralite has emerged as a game-changer in the market. With its exceptional performance, versatility, and commitment to sustainability, Spheralite is poised to revolutionize the way industries approach catalytic processes.The success of Catalyst Carrier Spheralite is a testament to the company’s dedication to innovation and customer satisfaction. By delivering superior products and services, the company has been able to carve out a niche for itself in the competitive catalysis market. With Spheralite leading the way, the company is well-positioned for continued success and growth in the years to come.Overall, Catalyst Carrier Spheralite is proving to be a game-changer in the field of catalysis, thanks to its exceptional performance, versatile applications, and commitment to sustainability. Backed by a company known for its groundbreaking products and exceptional service, Spheralite is set to continue its upward trajectory and solidify its position as a leader in the industry. With its innovative approach and customer-centric focus, Spheralite is poised to make a lasting impact on the industrial world.

Alumina Market Sees Growth in Production and Demand

Gama Alumina is a significant player in the global alumina market. The company is known for its high-quality products and strong presence in the industry. With a focus on sustainable development and innovation, Gama Alumina is committed to delivering excellence in all aspects of its business.Gama Alumina specializes in the production of alumina, the essential raw material used in the production of aluminum. The company's state-of-the-art facilities and advanced production techniques ensure that its alumina meets the highest standards of quality and purity. As a result, Gama Alumina's products are in high demand across various industries, including automotive, aerospace, construction, and packaging.One of the key factors that sets Gama Alumina apart from its competitors is its commitment to sustainability. The company prioritizes environmental responsibility and aims to minimize its impact on the environment throughout the production process. Gama Alumina has implemented various initiatives to reduce energy consumption, minimize waste generation, and optimize resource utilization. These efforts not only benefit the environment but also contribute to the overall efficiency and cost-effectiveness of the company's operations.In addition to its focus on sustainability, Gama Alumina is also dedicated to innovation. The company continually invests in research and development to improve its production processes and develop new, advanced alumina products. By staying at the forefront of technological advancements, Gama Alumina ensures that it can meet the evolving needs of its customers and maintain its position as a leader in the industry.Furthermore, Gama Alumina places a strong emphasis on corporate social responsibility. The company actively engages with local communities and invests in programs that support education, healthcare, and economic development. By fostering positive relationships with stakeholders, Gama Alumina strives to create long-term value for both its business and the communities in which it operates.In recent news, Gama Alumina has announced a strategic partnership with a leading aluminum producer to further expand its presence in the global market. This partnership will enable Gama Alumina to access new opportunities and strengthen its position as a preferred supplier of high-quality alumina. By leveraging the expertise and resources of its partner, Gama Alumina aims to enhance its capabilities and offer a broader range of products and services to its customers.The collaboration with the aluminum producer aligns with Gama Alumina's growth strategy, which focuses on expanding its market reach and diversifying its product portfolio. Through strategic partnerships and investments, the company seeks to capitalize on emerging market trends and position itself for long-term success. By pursuing strategic alliances, Gama Alumina aims to create synergies that drive innovation, efficiency, and value creation.Furthermore, Gama Alumina is also exploring opportunities to integrate digital technologies into its operations. By embracing digitalization, the company aims to optimize its processes, improve decision-making, and enhance the overall effectiveness of its business. Through the adoption of advanced data analytics, automation, and connectivity solutions, Gama Alumina seeks to gain a competitive edge and future-proof its operations in a rapidly evolving industry landscape.Looking ahead, Gama Alumina remains committed to delivering excellence across all aspects of its business. By focusing on sustainability, innovation, and collaboration, the company is well-positioned to continue driving value for its customers, stakeholders, and the broader industry. With a solid foundation and a clear vision for the future, Gama Alumina is poised to maintain its leadership position in the global alumina market and create sustainable growth opportunities for years to come.

Newly Developed Zsm-23 Generates Buzz in Scientific Community

Zsm-23 (brand name removed), a leading technology company in the field of telecommunications, has announced the launch of a groundbreaking new product that promises to revolutionize the way we communicate. The Zsm-23 team has been hard at work developing this new technology, and it is set to change the landscape of telecommunications as we know it.This new product promises to bring an unprecedented level of speed, reliability, and security to telecommunications networks. Zsm-23 has a strong track record of innovation and excellence in the field of telecommunications, and this new product is the latest example of their commitment to pushing the boundaries of what is possible in this rapidly evolving industry.The Zsm-23 team is excited about the potential impact of this new product, and they believe it will be a game-changer for both consumers and businesses. With its cutting-edge technology and advanced features, this product is set to deliver a superior experience for users, allowing them to communicate in ways that were previously unimaginable.In addition to its impressive technical capabilities, the new product from Zsm-23 also promises to be highly user-friendly, making it accessible to a wide range of customers. This commitment to usability and accessibility is a key part of Zsm-23's overall approach to product development, and it is a reflection of their dedication to delivering the best possible experience for their customers.The launch of this new product also underscores Zsm-23's position as a leader in the field of telecommunications. The company has a strong reputation for delivering high-quality products and services, and this latest offering is a testament to their ongoing commitment to innovation and excellence.In addition to the impressive technical capabilities of this new product, Zsm-23 is also committed to ensuring that it is environmentally friendly and sustainable. The company has made significant investments in sustainable technology and practices, and this new product is a reflection of their commitment to reducing their environmental impact.Zsm-23 is also known for its focus on corporate social responsibility, and the launch of this new product is an opportunity for the company to further demonstrate its commitment to making a positive impact on the world. By delivering a product that is both innovative and sustainable, Zsm-23 is setting a new standard for the telecommunications industry and showing that it is possible to combine cutting-edge technology with a responsible approach to business.As Zsm-23 moves forward with the launch of this new product, the company is confident that it will be a major success. With its impressive technical capabilities, commitment to usability and accessibility, and focus on sustainability and corporate social responsibility, the new product promises to set a new standard for the telecommunications industry.The team at Zsm-23 is excited about the potential impact of this new product, and they are confident that it will help to solidify the company's position as a leader in the field of telecommunications. With its focus on innovation, excellence, and responsibility, Zsm-23 is well-positioned to continue setting the standard for the industry and delivering the best possible experience for its customers.

Guide to Reforming Catalyst for Improved Performance

Reforming Catalyst Revolutionizing Sustainable ManufacturingIn recent years, there has been a growing global focus on sustainable manufacturing practices. Companies across various industries are striving to reduce their environmental footprint and minimize their impact on the planet. One crucial aspect of this movement is the development and implementation of innovative technologies and processes that promote sustainable production. One such groundbreaking technology is the reforming catalyst, a revolutionary tool that is transforming the way industrial processes are carried out.A leading player in the field of sustainable manufacturing is a company (Company X) that has been at the forefront of developing advanced catalyst technologies to drive sustainable industrial processes. With a strong commitment to environmental stewardship and continuous innovation, (Company X) has developed a reforming catalyst that is set to redefine the standards of sustainable manufacturing.The reforming catalyst developed by (Company X) is a highly efficient and versatile tool that enables a wide range of industrial processes to be carried out with minimal environmental impact. Unlike traditional catalysts, the reforming catalyst is designed to facilitate more sustainable and efficient production processes, thereby enabling companies to achieve their sustainability goals while maintaining high levels of productivity and efficiency.One of the key features of the reforming catalyst is its ability to promote cleaner and more efficient combustion in industrial processes. By enhancing combustion efficiency, the reforming catalyst helps to reduce harmful emissions and minimize the environmental footprint of industrial operations. This is particularly significant in industries such as power generation, oil refining, and chemical manufacturing, where combustion processes are central to production.Moreover, the reforming catalyst also plays a crucial role in promoting energy efficiency in industrial processes. By facilitating more efficient energy utilization, the reforming catalyst helps companies reduce their energy consumption and lower their overall operational costs. This not only yields significant economic benefits for companies but also contributes to the global efforts to combat climate change by reducing greenhouse gas emissions.Another notable aspect of the reforming catalyst is its versatility and applicability across various industrial sectors. Whether it is used in power plants, refineries, petrochemical facilities, or other industrial settings, the reforming catalyst proves to be an invaluable asset in promoting sustainable manufacturing practices. Its flexibility and adaptability make it a highly sought-after solution for companies looking to enhance their sustainability efforts across different areas of operation.(Copying part of the content without proper edit. For original content, please consider the following)The success of the reforming catalyst developed by (Company X) can be attributed to the company's relentless commitment to research and innovation. (Company X) has invested substantial resources in developing and refining the reforming catalyst, leveraging the latest advancements in catalytic technologies and sustainable manufacturing practices. The result is a cutting-edge solution that not only meets the stringent environmental standards but also delivers tangible benefits to companies in terms of operational efficiency and cost savings.As the global focus on sustainability intensifies, the demand for innovative solutions such as the reforming catalyst is expected to soar. Companies across industries are increasingly turning to sustainable manufacturing practices, seeking ways to minimize their environmental impact while maintaining their competitive edge in the market. The reforming catalyst, with its proven track record of promoting sustainable production, is well-positioned to address this growing demand and emerge as a game-changer in the realm of industrial catalyst technologies.Looking ahead, (Company X) is poised to further advance the capabilities of the reforming catalyst, exploring new applications and potential enhancements to its performance. By continuously pushing the boundaries of catalytic innovation, (Company X) aims to empower companies worldwide to embrace sustainable manufacturing practices, ultimately contributing to a greener and more sustainable future for the planet.In conclusion, the reforming catalyst developed by (Company X) represents a significant milestone in the realm of sustainable manufacturing. With its ability to promote cleaner combustion, enhance energy efficiency, and drive operational sustainability, the reforming catalyst is paving the way for a new era of environmentally responsible industrial processes. As companies increasingly prioritize sustainability in their operations, the reforming catalyst is set to play a pivotal role in shaping the future of manufacturing, ushering in a new standard of sustainable and responsible production practices.

High-Quality Activated Alumina for Catalyst Carrier at Affordable Prices - Available at CHEMXIN-en.com

and Activated Alumina throughout the content.Catalysts play a crucial role in chemical reactions, allowing reactions to occur at lower temperatures and increasing reaction rates. However, a catalyst needs an appropriate carrier to ensure its effectiveness. That's where activated alumina for catalyst carrier comes in.Activated alumina is a highly-porous, solid form of aluminum oxide that can be used as a carrier material for catalysts. Its unique properties, such as high surface area and excellent adsorption capacity, allow it to hold different types of catalysts and enhance their performance.As a professional activated alumina for catalyst carrier manufacturer, CHEMXIN offers a wide range of quality products in stock. Our activated alumina for catalyst carrier products are made from high-purity alumina and are designed to meet different requirements for diverse catalyst applications.One of the key benefits of activated alumina for catalyst carrier is its high surface area, which ranges from 150 to 300 square meters per gram. With this high surface area, the activated alumina provides a large surface area for contact between the catalyst and the reactant. As a result, the reaction rate is increased, and the overall efficiency of the reaction is improved.Another advantage of using activated alumina for catalyst carrier is its excellent adsorption capacity. The material can adsorb different types of gases and liquids and can also remove impurities from the feedstock or reactants. This feature is especially important in refining and petrochemical industries, where the purity of the feedstock is critical to the success of the process.Moreover, activated alumina for catalyst carrier is highly resistant to thermal shock and mechanical abrasion, making it a durable carrier material for catalysts. Its resistance to high temperatures, up to 600°C or even higher, allows it to maintain its stability and integrity in high-temperature applications.In terms of applications, activated alumina for catalyst carrier can be used in various processes, including hydrogenation, dehydrogenation, isomerization, and adsorption. It is commonly used in the refining, petrochemical, and chemical industries for the production of fuels, chemicals, plastics, and other products.In conclusion, activated alumina for catalyst carrier is a crucial component in different catalytic applications. As a leading manufacturer of activated alumina for catalyst carrier, CHEMXIN offers a range of high-quality products in stock to meet different needs and requirements. With its unique properties, such as high surface area, adsorption capacity, and thermal resistance, activated alumina for catalyst carrier can enhance the performance of catalysts and improve the overall efficiency of different chemical processes.

Hydrogenation Catalyst for Residue Conversion: Benefits and Applications

Title: Advanced Residue Hydrogenation Catalyst Revolutionizes Petroleum Refining IndustryIntroduction:In today's rapidly evolving world, the energy sector continues to seek innovative solutions for cleaner fuel production and efficient refinery processes. One such breakthrough has been achieved by a leading chemical company, which has introduced a pioneering Residue Hydrogenation Catalyst, an advanced technology that promises to revolutionize the petroleum refining industry.The Residue Hydrogenation Catalyst, developed by a prominent research and development team at [Company Name], has been specifically designed to enhance the conversion of heavy crude oil residues into lighter, more valuable fuels. This catalyst aims to address the challenges faced by refineries in processing low-quality residue, enabling them to upgrade and maximize the production of cleaner and high-performance fuels.[Company Name] has a long-standing reputation for delivering cutting-edge innovation in the chemical sector. With a strong focus on sustainability, the company has consistently pioneered environmentally responsible solutions to support industries globally. Their latest Residue Hydrogenation Catalyst represents a significant step forward in meeting the increasing energy demands while reducing carbon emissions.Body:1. Improved Efficiency in Petroleum Refining:The Residue Hydrogenation Catalyst offers unprecedented efficiency and effectiveness in the refining process. Its unique composition and structure contribute to the catalytic conversion of heavy oil residues, resulting in higher yields of cleaner and lighter fractions. This advanced catalyst enhances the refinery's ability to process heavier crude oil, ultimately improving the yield and quality of refined products.2. Environmental Advantages:In addition to enhancing fuel production, the Residue Hydrogenation Catalyst helps decrease the environmental impact of petroleum refining. By enabling refineries to process heavier crude oil and complex residues, the catalyst promotes the production of cleaner fuels with lower sulfur content. This not only helps comply with stricter environmental regulations but also reduces harmful emissions, contributing to air quality improvement.3. Cost-Effective Solution:The Residue Hydrogenation Catalyst offers a highly cost-effective solution to the refining industry. By efficiently converting low-value residue into valuable fuels, refineries can optimize their production, unlocking additional revenue streams. Moreover, this catalyst reduces the need for expensive refining processes, making it a strategic choice for refinery operators looking to achieve long-term sustainability with improved profitability.4. Technology Advancements:[Company Name] has integrated advanced nanotechnology into the Residue Hydrogenation Catalyst, allowing for precise control over the catalytic reactions. This results in the catalyst's superior performance and durability, enabling prolonged usage with minimal loss of activity. The company's commitment to ongoing research ensures that innovative solutions continue to evolve, setting new industry standards.5. Strategic Partnerships and Global Impact:[Company Name], with its vast industry experience and expertise, has engaged in strategic partnerships with leading refineries globally. By collaborating with these key players, the company aims to accelerate the adoption of the Residue Hydrogenation Catalyst on a global scale, bringing about transformative changes in the petroleum refining sector worldwide. Through shared knowledge and collaborations, the company seeks to advance sustainable practices and shape a greener future for the industry.Conclusion:[Company Name]'s Residue Hydrogenation Catalyst represents a significant breakthrough in the petroleum refining industry. This advanced catalyst not only enhances the conversion of heavy crude oil residues but also contributes to cleaner fuel production and environmental sustainability. With its focus on developing innovative and sustainable solutions, [Company Name] continues to pave the way for a more efficient and environmentally friendly future within the energy sector.