Advanced Hydrofining Catalyst: Key Component for Oil Refining Process

By:Admin

In today’s rapidly evolving energy industry, companies are constantly seeking technological advancements that can provide better solutions for oil refining processes. The hydrofining catalyst, developed by a leading chemical engineering company, has emerged as a game-changing innovation that promises to revolutionize the way crude oil is refined.

The hydrofining catalyst is a cutting-edge technology that enables the removal of impurities from crude oil, resulting in a higher quality end product. This catalyst is designed to enhance the efficiency of the hydrofining process, which is crucial for producing cleaner and more environmentally friendly fuels. By utilizing this innovative catalyst, oil refineries are able to improve the quality of their refined products while adhering to increasingly stringent environmental regulations.

The development of the hydrofining catalyst represents a major milestone for the company, which has been a pioneer in the field of chemical engineering for over three decades. With a proven track record of delivering high-performance solutions for the oil and gas industry, the company has established itself as a trusted partner for refineries worldwide. Its commitment to innovation and excellence has made it a leader in the development of advanced catalyst technologies.

The hydrofining catalyst is the result of years of research and development, during which the company’s team of experts has worked tirelessly to create a product that meets the complex needs of modern oil refineries. This catalyst is specifically engineered to address the challenges posed by increasingly sour and heavy crude feedstocks, which are becoming more prevalent in today’s market. By effectively removing impurities such as sulfur, nitrogen, and metals from crude oil, the hydrofining catalyst contributes to the production of cleaner and higher quality fuels.

One of the key advantages of the hydrofining catalyst is its ability to improve the overall performance and profitability of oil refineries. By enhancing the efficiency of the hydrofining process, this catalyst enables refineries to achieve higher yields of valuable products such as diesel and gasoline. In addition, the use of the hydrofining catalyst results in reduced energy consumption and operational costs, which translates to significant economic benefits for refinery operators.

Furthermore, the hydrofining catalyst plays a crucial role in helping refineries comply with stringent environmental standards. As global efforts to reduce emissions and minimize environmental impact continue to gain momentum, the demand for cleaner fuels is on the rise. The use of this innovative catalyst allows refineries to produce fuels with lower sulfur content, thereby contributing to a more sustainable and environmentally friendly energy sector.

The company’s dedication to sustainability and responsible innovation is evident in the development of the hydrofining catalyst. By enabling refineries to improve the quality of their fuels and reduce their environmental footprint, this catalyst exemplifies the company’s commitment to creating value for both its customers and the wider community.

In conclusion, the introduction of the hydrofining catalyst represents a significant advancement in the field of oil refining. With its ability to enhance the efficiency, profitability, and environmental performance of refineries, this innovative technology is poised to revolutionize the way crude oil is processed. As the energy industry continues to evolve, the hydrofining catalyst stands out as a powerful tool for driving the transformation towards a more sustainable and efficient future.

Company News & Blog

How Catalyst Reforming is Impacting Industry Trends

Reforming Catalyst Technology Takes a Leap ForwardReforming catalysts play a crucial role in the production of high-quality fuels and chemicals in the oil and gas industry. With the increasing demand for cleaner and more efficient energy sources, the need for advanced reforming catalyst technology has never been greater. In response to this demand, a leading catalyst manufacturer has developed a groundbreaking reforming catalyst that promises to revolutionize the industry. Leveraging decades of experience and expertise, the company has introduced a new catalyst that offers superior performance, enhanced durability, and reduced environmental impact.The reforming catalyst is designed to improve the efficiency of the reforming process, which is crucial for converting low-value feedstocks into high-value products. By enhancing the catalytic activity and selectivity, the new catalyst enables higher yields of desirable products while minimizing the formation of unwanted by-products. This not only improves the overall productivity of reforming units but also helps reduce waste and optimize resource utilization.One of the key innovations of the new reforming catalyst is its advanced formulation, which incorporates novel active materials and a highly efficient support structure. This proprietary combination enhances the catalyst's stability and resistance to deactivation, allowing for longer run lengths and reduced downtime for regeneration. In addition, the catalyst's unique composition enables it to operate at higher temperatures and pressures, leading to improved process flexibility and energy efficiency.Furthermore, the reforming catalyst is engineered to meet stringent environmental standards, with reduced emissions of harmful pollutants and greenhouse gases. This aligns with the industry's commitment to sustainable and eco-friendly practices, making the new catalyst a preferred choice for environmentally conscious operators and customers.In addition to its technical advancements, the reforming catalyst is supported by a comprehensive range of services and solutions offered by the company. With a global network of research and development centers, technical experts, and customer support teams, the company provides tailored solutions to help customers optimize their reforming operations. This includes catalyst performance evaluations, process troubleshooting, and customized catalyst formulations to address specific challenges and requirements.The introduction of the new reforming catalyst underscores the company's ongoing commitment to innovation and excellence in catalysis. By investing in cutting-edge research and development, the company aims to stay at the forefront of technology and deliver value-added solutions to its customers. With a strong track record of successful partnerships and collaborations, the company is well positioned to drive the adoption of its advanced catalysts across the global oil and gas industry.As the energy landscape continues to evolve, the demand for cleaner, more efficient fuels and chemicals will continue to grow. With its breakthrough reforming catalyst technology, the company is poised to address this demand and help shape the future of the industry. By enabling greater process efficiency, environmental responsibility, and operational performance, the new catalyst is set to make a significant impact on the way reforming processes are carried out worldwide.In conclusion, the introduction of the new reforming catalyst represents a major step forward for the oil and gas industry. With its innovative technology, enhanced performance, and comprehensive support, the catalyst is set to redefine the standards for reforming processes and set new benchmarks for productivity and sustainability. The company's continued dedication to excellence and innovation ensures that it will remain a trusted partner for the industry, driving progress and delivering value for years to come.

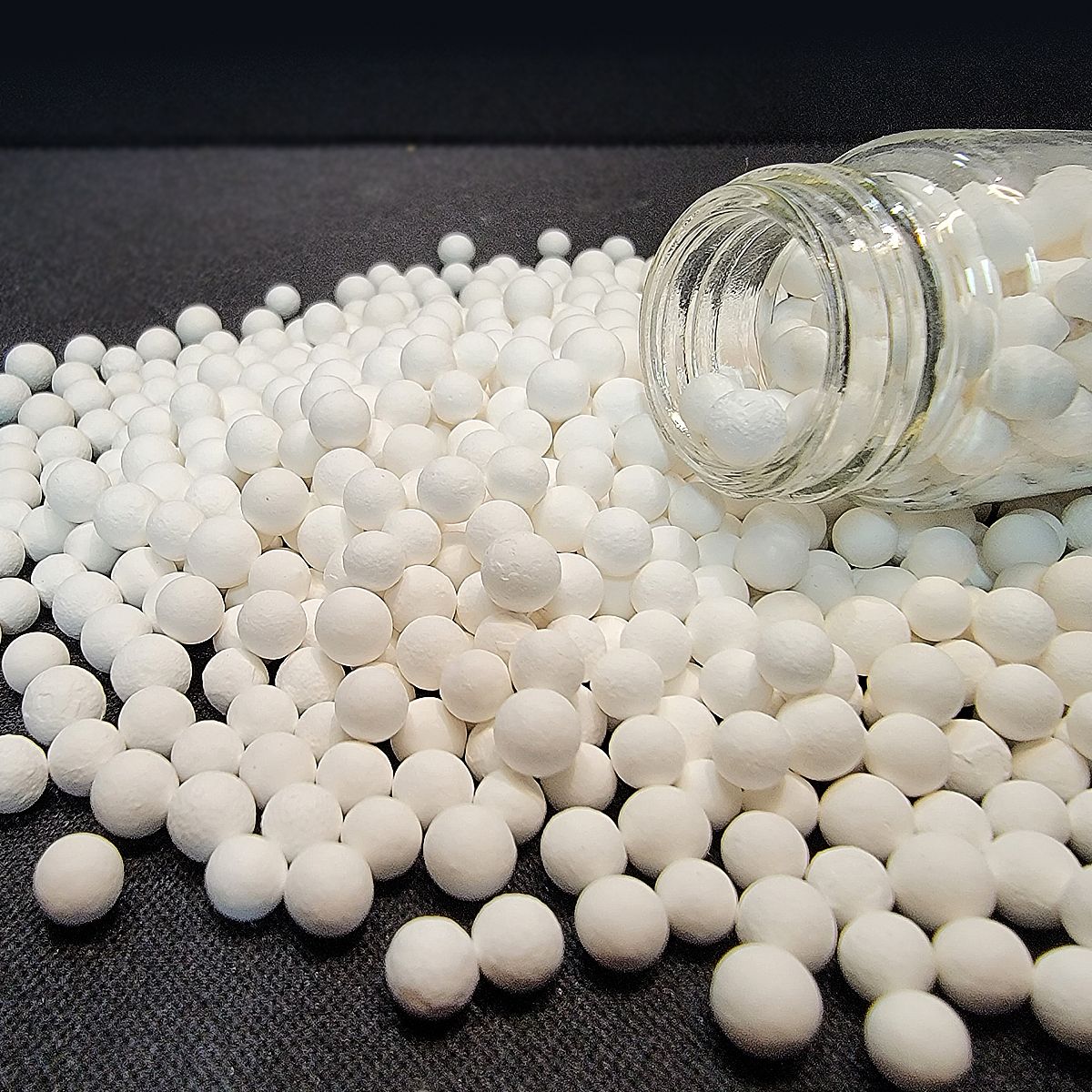

High-Quality Alumina Carrier for Catalysts: What You Need to Know

Recently, the renowned chemical company {} has developed an innovative alumina carrier for catalysts that is set to revolutionize the chemical and petrochemical industries. This new product promises to enhance the efficiency of various chemical processes, ultimately leading to cost savings and environmental benefits.{} has been a leading player in the chemical industry for decades, known for its commitment to research and development of cutting-edge solutions. With a strong focus on sustainability and innovation, the company has consistently pushed the boundaries of what is possible in the field of chemical engineering. This latest development, the alumina carrier for catalysts, is a testament to {}'s dedication to providing high-quality products that meet the evolving needs of its customers.The alumina carrier for catalysts is designed to improve the performance of catalysts used in chemical and petrochemical processes. Catalysts play a crucial role in speeding up chemical reactions, and the effectiveness of the catalyst carrier is vital to the overall efficiency of the process. {}'s new alumina carrier is poised to deliver a range of benefits, including higher catalytic activity, improved resistance to harsh operating conditions, and enhanced stability over time.One of the key advantages of this new alumina carrier is its superior surface area and pore volume. These characteristics are essential for maximizing the exposure of active catalytic sites and facilitating the diffusion of reactants and products. By increasing the accessibility of the active sites, the alumina carrier ensures that a larger proportion of the catalyst is utilized, leading to higher conversion rates and improved yields.Furthermore, the alumina carrier's exceptional thermal stability makes it well-suited for use in processes that operate at high temperatures. This characteristic is particularly important in industries such as oil refining and chemical manufacturing, where extreme thermal conditions are commonplace. With the alumina carrier, catalysts can maintain their performance even in demanding environments, resulting in reduced downtime and maintenance costs for industrial plants.In addition to its technical advantages, {}'s alumina carrier for catalysts also offers environmental benefits. By enhancing the efficiency of chemical processes, the product enables manufacturers to achieve higher yields with lower energy consumption and reduced emissions. This aligns with {}'s commitment to sustainability and its efforts to develop products that contribute to a more environmentally friendly industry.{}'s alumina carrier for catalysts has already generated significant interest among key players in the chemical and petrochemical sectors. Industry experts have recognized the potential of this new product to drive improvements in process efficiency and overall operational performance. As a result, {} has seen a growing demand for the alumina carrier, with several major customers already incorporating it into their operations.The development of the alumina carrier for catalysts is a clear reflection of {}'s leadership in the chemical industry. The company's ongoing investment in research and development, coupled with its deep understanding of market needs, has positioned it at the forefront of innovation. With this new product, {} is poised to set a new standard for catalyst carriers, providing its customers with a competitive edge and contributing to advancements in the chemical and petrochemical fields.Moving forward, {} is committed to further leveraging its expertise to develop advanced solutions that address the evolving needs of the industry. The company's dedication to innovation and sustainability will continue to drive its efforts to bring cutting-edge products to the market, ultimately shaping the future of the chemical and petrochemical sectors.In summary, {}'s alumina carrier for catalysts represents a significant milestone in the company's journey to provide high-performance solutions to its customers. With its exceptional technical capabilities and environmental benefits, the alumina carrier is poised to make a positive impact on the chemical and petrochemical industries, driving efficiency, and sustainability for years to come.

Discover the Latest Advancements in ZSM-23 Technology

Zsm-23: A Revolutionary Addition to the Chemical IndustryThe chemical industry is one of the largest and most dynamic sectors in the world. Chemicals are used in virtually every aspect of our lives, from the food we eat to the clothes we wear, to the medicines we take. As a result, any innovation in this field can have a significant impact on society. One such innovation is Zsm-23 - a new zeolite molecular sieve from a leading chemical company that has the potential to revolutionize the industry.Zeolites are crystalline materials made up of silicon, aluminum, and oxygen. They have a unique structure with ultra-small pore sizes that can trap and separate molecules. This makes zeolites useful in a wide range of applications, including catalysis, adsorption, and ion exchange. However, current zeolites have limitations in terms of their structure and performance.Zsm-23, on the other hand, is a novel zeolite that offers significant advantages over traditional zeolites. It has a higher Si/Al ratio, which gives it a more stable structure and higher thermal stability. It also has larger and more uniform pore sizes, which allow for better selectivity and higher adsorption capacity. These properties make Zsm-23 ideal for use in catalysis, adsorption, and separation applications.The company behind Zsm-23 has a long history in the chemical industry, with a focus on innovation and sustainability. It is committed to developing new products and technologies that meet the needs of its diverse customers while minimizing its environmental impact. The company has a wide range of products, including chemicals, plastics, and specialty materials, serving various industries such as agriculture, electronics, and healthcare.Zsm-23 is the latest addition to the company's portfolio, and it is already generating interest from customers and partners worldwide. Its unique properties enable it to be used in numerous applications, such as catalytic conversion of biomass and waste, selective adsorption of carbon dioxide, and separation of light hydrocarbons from natural gas.In the catalytic conversion of biomass and waste, Zsm-23 offers superior performance compared to traditional zeolites. Its larger pore size allows for better diffusion of the reactants, leading to higher conversion rates and selectivity. Moreover, its higher thermal stability makes it suitable for use in harsh conditions, such as high temperature and pressure.In the selective adsorption of carbon dioxide, Zsm-23 outperforms other materials due to its larger and more uniform pore size. This enables it to selectively capture carbon dioxide while leaving other gases untouched. This property is particularly important in the context of carbon capture and storage, which is becoming an increasingly important technology in the fight against climate change.In the separation of light hydrocarbons from natural gas, Zsm-23 offers excellent selectivity and adsorption capacity. Its larger pores enable it to trap larger hydrocarbons, such as ethane and propane, while allowing smaller ones, such as methane, to pass through. This makes it an ideal material for gas processing plants, where the separation of natural gas components is crucial.With its unique structure and properties, Zsm-23 is set to become a game-changer in the chemical industry. It has the potential to drive innovation and sustainability in various sectors and contribute to a more prosperous and cleaner world. The company behind Zsm-23 is proud to be at the forefront of this development and is committed to working with its customers and partners to unlock its full potential.

The Latest Breakthrough in Alumina Production Unveiled by Researchers

Title: Advanced Alumina-Based Catalyst Developed for Enhanced Industrial ApplicationsIntroduction:In a breakthrough development, a leading materials research company has successfully engineered a novel alumina-based catalyst called Gamma Alumina. This exceptional catalyst possesses unparalleled chemical and physical properties, making it a game-changer across various industrial applications. Developed with cutting-edge innovation and extensive research, Gamma Alumina offers improved catalytic performance, longevity, and versatility, revolutionizing processes and driving operational efficiency.Structure and Properties:Gamma Alumina boasts a remarkable crystalline structure that sets it apart from conventional catalysts. With a high surface area, exceptional porosity, and well-defined pores, it maximizes its catalytic potential by optimizing reactant adsorption and diffusion. This unique structure makes Gamma Alumina highly adaptable for diverse catalytic reactions, ensuring superior performance and selectivity across a wide range of industrial processes.Applications:1. Petrochemical Industry:The petrochemical industry can benefit significantly from the introduction of Gamma Alumina as a catalyst. Its exceptional properties make it an ideal choice for catalytic cracking, which plays a crucial role in the conversion of heavy hydrocarbons into valuable lighter fractions. The catalyst's high thermal stability and superior resistance to coke deposition ensure prolonged usage, reducing downtime and maintenance costs for refineries worldwide.2. Pharmaceutical Manufacturing:Gamma Alumina finds extensive application in pharmaceutical manufacturing processes. Its unique structure and surface properties enable it to act as a highly efficient catalyst in several crucial reactions, such as the production of active pharmaceutical ingredients (APIs) and the synthesis of fine chemicals. The catalyst's remarkable performance, coupled with its excellent control over selectivity, enables pharmaceutical manufacturers to enhance reaction yields while reducing waste and increasing purity.3. Environmental Sector:The environmental sector greatly benefits from the implementation of Gamma Alumina as a catalyst. It finds applications in catalytic converters, the vital components of vehicle exhaust systems. By increasing the conversion efficiency of harmful gases, such as nitrogen oxides (NOx), Gamma Alumina helps minimize their impact on the environment. Additionally, its stable and long-lasting catalytic performance in volatile environments makes it an excellent choice for air purification systems and wastewater treatment processes.4. Energy Sector:In the energy sector, Gamma Alumina plays a pivotal role in enhancing the efficiency of energy storage and conversion systems. This catalyst finds extensive use in fuel cells and electrolyzers, enhancing their performance by facilitating faster and more selective reactions. Gamma Alumina's exceptional stability ensures the longevity and durability of these energy conversion devices, reducing operating costs while promoting sustainable energy usage.Future Prospects:The successful development of Gamma Alumina opens doors for further research and applications in various industries. With ongoing advancements in catalyst engineering and material science, it is anticipated that Gamma Alumina will continue to evolve, providing even greater efficiency, selectivity, and durability. The catalyst's potential application in emerging technologies like carbon capture and utilization demonstrates its adaptability and versatility.Conclusion:The introduction of Gamma Alumina as an alumina-based catalyst is a significant advancement in industrial catalysis. Its exceptional properties and unique structure position it as a catalyst of choice across multiple industries, including petrochemicals, pharmaceutical manufacturing, environmental protection, and the energy sector. As research and development in catalyst innovation continues, Gamma Alumina sets the foundation for a more sustainable and efficient future in industrial processes.

Highly Effective Catalyst ZSM-5 Proven to Boost Chemical Reactions

ZSM-5 Catalyst, a breakthrough technology in the field of catalysis, has recently made waves in the industry with its exceptional performance in various chemical processes. This innovative catalyst, developed by a leading chemical company, has revolutionized the way chemical reactions are carried out, paving the way for more efficient and sustainable production processes.The ZSM-5 Catalyst is a type of zeolite catalyst that is widely used in the petrochemical industry for a range of applications, including the production of gasoline, diesel, and other fuels. What sets this catalyst apart from others is its unique structure, which allows for enhanced selectivity and improved yields in various reactions. This has led to significant improvements in productivity and cost-efficiency for companies that have adopted this technology.One of the key features of the ZSM-5 Catalyst is its ability to perform shape-selective reactions. This means that it can selectively catalyze certain molecules while excluding others, leading to higher yields of desired products. Additionally, this catalyst has shown remarkable stability under harsh reaction conditions, making it a reliable and long-lasting solution for industrial processes.In addition to its applications in the petrochemical industry, the ZSM-5 Catalyst has also shown promise in the field of environmental protection. Its use in the conversion of harmful pollutants into less toxic substances has opened up new possibilities for cleaner and more sustainable industrial practices. This has significant implications for reducing the environmental impact of chemical manufacturing and lowering carbon emissions.The company behind the development of the ZSM-5 Catalyst has a strong track record of innovation and excellence in the chemical industry. With a focus on research and development, they have consistently pushed the boundaries of what is possible in catalysis, paving the way for new and improved processes that benefit both the industry and the environment. Their commitment to sustainability and continuous improvement is reflected in the performance of the ZSM-5 Catalyst, which has set a new standard for catalyst technology.The success of the ZSM-5 Catalyst can be attributed to the company's investment in cutting-edge research and development, as well as its dedication to understanding and meeting the needs of its customers. By actively engaging with industry partners and staying ahead of the curve in terms of technological advancements, the company has been able to develop a catalyst that addresses the most pressing challenges faced by the chemical industry today.Moving forward, the company is committed to further advancing the capabilities of the ZSM-5 Catalyst and exploring new applications for this groundbreaking technology. With ongoing research and development efforts, they aim to continue pushing the boundaries of catalysis and setting new benchmarks for performance and sustainability in the industry.In conclusion, the ZSM-5 Catalyst has emerged as a game-changer in the world of catalysis, offering unprecedented selectivity, stability, and sustainability in chemical processes. Its success is a testament to the innovative spirit and forward-thinking approach of the company behind its development, and it is set to have a lasting impact on the future of chemical manufacturing. As the industry continues to evolve, the ZSM-5 Catalyst stands as a shining example of what is possible through innovation and commitment to excellence.

Sulfur Recovery Catalyst Market Shows Growth Potential in the Coming Years

Claus Sulfur Recovery Catalyst is a crucial component in the oil and gas industry, and it plays a vital role in reducing the environmental impact of sulfur emissions. The catalyst is used in the Claus process, which is a widely used method for converting hydrogen sulfide into elemental sulfur in refineries and natural gas processing plants. This process helps to minimize sulfur dioxide emissions, which is a major contributor to air pollution and acid rain.One of the leading manufacturers of Claus Sulfur Recovery Catalyst is {Company Name}, a global leader in the production of catalysts and specialty materials. With over {number} years of experience in the industry, {Company Name} has developed a solid reputation for delivering high-quality products and innovative solutions to meet the evolving needs of the oil and gas sector.The company's Claus Sulfur Recovery Catalyst is designed to offer exceptional performance and reliability in sulfur recovery applications. It is engineered to provide high activity and selectivity, ensuring maximum sulfur recovery efficiency while minimizing the formation of undesirable by-products. This not only helps companies comply with stringent environmental regulations but also improves overall operational efficiency and reduces operating costs.In addition to its outstanding technical properties, {Company Name}'s Claus Sulfur Recovery Catalyst is backed by a comprehensive technical support and after-sales service. The company's team of experts works closely with customers to understand their specific requirements and provide customized solutions to optimize catalyst performance and extend its service life. This level of commitment to customer satisfaction sets {Company Name} apart as a trusted partner in the oil and gas industry.Moreover, the company is committed to sustainability and environmental responsibility. Its Claus Sulfur Recovery Catalyst is designed to promote sustainable practices by facilitating the efficient and effective removal of sulfur from hydrocarbon feedstocks. By helping refineries and gas processing plants meet and exceed environmental standards, {Company Name} is contributing to the global effort to reduce air pollution and mitigate the impacts of climate change.{Company Name} also invests heavily in research and development to continuously improve its Claus Sulfur Recovery Catalyst and develop new, cutting-edge solutions for the oil and gas industry. The company's state-of-the-art facilities and world-class team of scientists and engineers are dedicated to advancing catalyst technology and pushing the boundaries of innovation to address the industry's challenges and opportunities.With a strong commitment to quality, reliability, and sustainability, {Company Name} is a trusted partner for companies seeking a superior Claus Sulfur Recovery Catalyst. Its unwavering dedication to customer satisfaction, technical excellence, and environmental stewardship makes {Company Name} the provider of choice for catalyst solutions in the oil and gas sector.In conclusion, {Company Name}'s Claus Sulfur Recovery Catalyst is a critical tool in the oil and gas industry, driving environmental compliance and operational efficiency. With its high-performance capabilities, commitment to customer support, and focus on sustainability, {Company Name} continues to set the standard for catalyst solutions in the global market. As the industry evolves, {Company Name} remains at the forefront, delivering innovative and reliable solutions to meet the changing needs of the oil and gas sector.

Innovative Sulfur Tolerant Shift Catalyst for Enhanced Performance

[Company Introduction]The company is a leading global provider of cutting-edge catalyst and technology solutions for the oil and gas industry. With a strong commitment to innovation and sustainability, the company has continuously developed and patented a wide range of catalysts and technologies that improve the performance and efficiency of various industrial processes. The company's products are utilized by refineries and petrochemical plants around the world, helping them to achieve higher productivity, lower emissions, and reduced operating costs.[News Content]The company recently announced the launch of its latest breakthrough innovation, the Sulfur Tolerant Shift Catalyst. This new catalyst is designed to address the challenges faced by refineries and petrochemical plants in processing sulfur-rich feedstocks, enabling them to boost production and enhance efficiency while meeting stringent environmental regulations.Sulfur-containing feedstocks are a common challenge for the industry, as they can lead to catalyst deactivation and reduced process efficiency. Traditional shift catalysts are particularly susceptible to sulfur poisoning, leading to the need for frequent regeneration and replacement. This not only increases operating costs but also results in downtime and reduced productivity.The Sulfur Tolerant Shift Catalyst, however, overcomes these limitations through its advanced formulation and unique chemical properties. The catalyst is highly resistant to sulfur poisoning, allowing it to maintain high activity and stability even in the presence of elevated sulfur levels. As a result, refineries and petrochemical plants can achieve longer catalyst life, reduced maintenance, and better performance, ultimately leading to improved operational efficiency and cost savings.In addition to its sulfur tolerance, the new catalyst also offers enhanced selectivity and activity, enabling higher conversion rates and improved hydrogen production. This is particularly beneficial for refineries and petrochemical plants looking to increase their capacity and output while minimizing their environmental footprint.The introduction of the Sulfur Tolerant Shift Catalyst underscores the company's continued commitment to driving innovation in the industry and providing sustainable solutions for its customers. By addressing the challenges associated with sulfur-containing feedstocks, the company is helping its clients to optimize their operations and achieve their production goals while complying with stringent environmental regulations.The Sulfur Tolerant Shift Catalyst is the latest addition to the company's extensive portfolio of catalyst and technology solutions, all of which are designed to enable refineries and petrochemical plants to enhance their processes, reduce emissions, and improve their overall performance. With a proven track record of delivering high-quality products and exceptional customer service, the company continues to be a trusted partner for its clients, providing them with the tools and expertise they need to succeed in an ever-changing industry.As the oil and gas industry faces increasing pressure to improve its environmental performance and operational efficiency, innovative solutions such as the Sulfur Tolerant Shift Catalyst will play a crucial role in driving progress and enabling sustainable growth. With its cutting-edge technology and uncompromising dedication to excellence, the company is well-positioned to continue leading the way in catalysis and process optimization, setting new standards for the industry and helping its clients achieve long-term success.

New Breakthrough in Methanol Synthesis Catalyst Technology

Methanol synthesis catalysts are crucial components in the production of methanol, which is a key ingredient in a wide range of industrial and chemical processes. These catalysts play a critical role in the conversion of synthesis gas (a mixture of carbon monoxide, carbon dioxide, and hydrogen) into methanol, a process that is used in the production of a variety of products, including chemicals, plastics, fuels, and more.One company that has been at the forefront of developing and manufacturing high-performance methanol synthesis catalysts is {}. With a strong focus on research and development, the company has continuously improved its catalysts to enhance their efficiency, durability, and environmental performance. The company's commitment to excellence has made it a trusted partner for numerous methanol producers around the world.The {} methanol synthesis catalyst is designed to deliver superior performance and reliability, making it a top choice for methanol producers seeking to optimize their production processes. The catalyst is engineered to maintain high activity and selectivity over an extended operating life, resulting in increased productivity and reduced downtime for catalyst replacement. In addition, the catalyst's advanced formulation enables it to operate effectively under a wide range of process conditions, ensuring consistent performance in various operating environments.In terms of environmental sustainability, the {} methanol synthesis catalyst is designed to minimize energy consumption and reduce greenhouse gas emissions. By promoting the conversion of synthesis gas into methanol with high efficiency, the catalyst helps methanol producers improve their process economics and lower their environmental footprint. This aligns with the company's commitment to developing catalysts that not only deliver exceptional performance but also contribute to a more sustainable and eco-friendly industry.In addition to its technical capabilities, {} also offers comprehensive technical support and services to assist customers in optimizing their methanol production processes. The company's team of experienced engineers and chemists work closely with customers to understand their specific requirements and provide tailored solutions to maximize the performance of the {} methanol synthesis catalyst. From catalyst selection and installation to performance monitoring and troubleshooting, the company's technical support services are designed to help customers achieve the best possible results.Looking ahead, {} is continuously investing in research and development to further advance its methanol synthesis catalyst technology. By leveraging its expertise in catalysis and process engineering, the company is exploring new opportunities to enhance the performance and sustainability of its catalysts, ultimately aiming to drive innovation and progress in the methanol production industry. With a deep commitment to excellence and a focus on customer satisfaction, {} is poised to remain a leading provider of high-performance methanol synthesis catalysts for years to come.In conclusion, methanol synthesis catalysts are vital components in the production of methanol, and {} has established itself as a trusted leader in this space. With its advanced catalyst technology, commitment to sustainability, and comprehensive technical support services, the company continues to deliver exceptional value to methanol producers worldwide. As the industry evolves, {} remains dedicated to pushing the boundaries of catalyst innovation and providing customers with the solutions they need to succeed in a rapidly changing market.

Effective Arsenic Removal Agent: Remove Harmful Contaminant Safely

Title: Introducing an Effective Arsenic Removal Agent: Revolutionizing Water PurificationIntroduction:In a world where safe and clean drinking water is becoming increasingly scarce, environmental technology company {} has introduced a groundbreaking solution to combat the presence of arsenic in water sources. With the use of their revolutionary arsenic removal agent, this innovative product promises to address a pressing global issue and ensure the provision of clean water to millions of people worldwide.Understanding the Problem:Arsenic contamination in water sources has become a significant concern, particularly in developing countries where poor infrastructure and limited access to clean water prevail. Regular and prolonged exposure to arsenic-contaminated water can lead to serious health complications such as cancer, cardiovascular diseases, and neurological disorders. It is estimated that around 140 million people worldwide are currently at risk due to excessive arsenic levels in their water supplies.Introducing the Arsenic Removal Agent:The recently developed arsenic removal agent by {} aims to comprehensively tackle this significant issue. This innovative formulation effectively eliminates and neutralizes arsenic levels in water, rendering it safe for consumption. The agent is formulated with cutting-edge technology, meticulously designed to meet the highest international standards for water purification.How Does it Work?The functionality of the arsenic removal agent is based on a complex chemical reaction that occurs when it comes into contact with arsenic present in water. The agent binds to the arsenic atoms, forming a stable compound that can be easily separated from the treated water. This separation process ensures that the water is rendered free from arsenic and safe for human consumption.Advantages of the Arsenic Removal Agent:1. High Efficiency: The agent demonstrates exceptional efficiency, effectively reducing arsenic levels to below the recommended safety limits established by global health organizations.2. Cost-Effective Solution: {}'s arsenic removal agent presents a cost-effective solution to water purification. Its application can be easily integrated into existing water treatment facilities and systems, minimizing the need for extensive infrastructure changes.3. Environmentally Friendly: The formulation of the agent prioritizes environmental sustainability. It does not introduce any harmful chemicals or byproducts into the water, ensuring minimal impact on aquatic life or the ecosystem.4. Scalability: The agent's formulation allows for easy scalability. It can be adapted to fit the needs of small communities as well as large-scale water treatment plants, making it highly versatile.Collaboration for a Global Impact:In an effort to address the urgent need for clean drinking water, {} has been collaborating with international organizations, governments, and non-profit entities in several countries. By partnering with these stakeholders, {} aims to provide long-lasting and sustainable solutions to areas suffering from arsenic contamination in their water supplies.The Future of Water Purification:The introduction of {}'s arsenic removal agent marks a significant stride in the global pursuit of clean water for all. As the company continues to innovate and enhance its range of environmentally friendly solutions, the hope for a future where access to clean water is no longer a luxury but a basic human right becomes increasingly attainable.In conclusion, the development and introduction of {}'s arsenic removal agent provides a beacon of hope for communities affected by arsenic contamination. This revolutionary product has the potential to save countless lives by ensuring the provision of safe drinking water. With continued research and collaborations, we can strive to create a world where every individual has access to clean water, paving the way for a healthier and more sustainable future.

Innovative Catalyst Carrier Spheralite Revolutionizing Industry Technology

Catalyst Carrier Spheralite (need remove brand name), a high-performance catalyst carrier product, has been making waves in the industry as one of the most innovative and effective solutions for a wide range of catalytic processes. With its unique spherical shape and high surface area, Spheralite has proven to be a game-changer for many companies looking to improve the efficiency and effectiveness of their catalyst systems.Spheralite is a product of a leading chemical company with a strong focus on innovation and sustainability. With decades of experience in the development and manufacturing of specialty chemicals, the company has established itself as a trusted partner for businesses across various industries, including oil and gas, petrochemicals, and environmental technology.The introduction of Spheralite has further solidified the company's position as a pioneer in the chemical industry, offering cutting-edge solutions that address the evolving needs of its customers. The unique properties of Spheralite make it an ideal choice for a wide range of catalytic applications, including refining, emissions control, and chemical production.One of the key advantages of Spheralite is its spherical shape, which provides a higher density and packing efficiency compared to traditional catalyst carriers. This allows for a greater surface area and improved mass transfer, resulting in enhanced catalytic performance and overall process efficiency. Furthermore, Spheralite's high crush strength and thermal stability make it a reliable choice for demanding operating conditions, ensuring long-term durability and performance.The company's commitment to sustainability is also reflected in the production of Spheralite. By utilizing advanced manufacturing processes and sustainable raw materials, the company ensures that Spheralite is not only high-performing but also environmentally friendly. This aligns with the company's broader mission to develop products that contribute to the reduction of environmental impact and promote sustainable practices within the industry.In addition to its technical advantages, Spheralite also offers operational benefits for companies utilizing catalyst systems. Its uniform and consistent shape allows for easy handling and filling of catalyst beds, reducing the risk of dust formation and minimizing potential health and safety hazards for operators. This contributes to a safer and more efficient working environment, further enhancing the overall value proposition of Spheralite for businesses.The versatility of Spheralite also makes it suitable for a wide range of catalysts, including precious metals and zeolites, providing companies with the flexibility to optimize their catalytic processes based on specific requirements and performance goals. Its compatibility with various catalytic formulations and applications makes Spheralite a versatile and cost-effective solution for companies seeking to improve their catalytic performance.The introduction of Spheralite has already generated significant interest and positive feedback from companies across the industry. Many have recognized the potential of Spheralite to unlock new opportunities for performance improvement and operational efficiency within their catalytic processes. With its proven track record and strong technical support from the company, Spheralite is poised to become a key player in the catalyst carrier market.Looking ahead, the company remains committed to further advancing the development of Spheralite and expanding its applications to address the evolving needs of the industry. By harnessing its expertise in chemical innovation and sustainable practices, the company is well-positioned to continue delivering cutting-edge solutions that drive value for its customers and contribute to a more sustainable future.In conclusion, Catalyst Carrier Spheralite is a testament to the company's dedication to innovation, sustainability, and customer-centric solutions. Its unique properties and operational benefits make it a compelling choice for companies seeking to enhance the performance and sustainability of their catalytic processes. With a strong foundation and a clear vision for the future, Spheralite is set to reshape the landscape of catalyst carriers and drive positive change within the industry.