Advanced New Material Zsm-22 Shows Promise in Various Applications

By:Admin

Zeolites are aluminosilicate minerals that have a unique ability to exchange one cation for another. The structure of zeolites allows them to act as molecular sieves, selectively separating and capturing molecules based on their size and shape. This makes zeolites a valuable material in the fields of petrochemistry, environmental protection, and energy production.

ZSM-22, in particular, has garnered significant attention due to its exceptional properties. The material has a unique pore structure, which gives it a high surface area and acidity. These characteristics make ZSM-22 an excellent candidate for catalytic applications, as it can effectively facilitate chemical reactions and improve reaction selectivity.

Furthermore, ZSM-22's high silicon-to-aluminum ratio makes it particularly stable under harsh conditions, such as high temperatures and corrosive environments. This stability makes ZSM-22 a reliable and long-lasting material for industrial processes.

The company {} specializes in the production and development of advanced materials, with a particular focus on zeolites and their applications. With a team of experienced scientists and engineers, the company has been at the forefront of research and development in the field of zeolite-based materials.

{} has invested heavily in the synthesis and characterization of ZSM-22, aiming to harness its unique properties for various industrial applications. The company's state-of-the-art research facilities and expertise in material science have enabled them to produce high-quality ZSM-22 with tailored properties to meet specific industry requirements.

The potential applications of ZSM-22 are vast and varied. In the petrochemical industry, ZSM-22 can be used as a catalyst for the conversion of hydrocarbons into valuable products, such as gasoline and diesel. The material's high activity and selectivity make it a promising candidate for improving the efficiency of these processes.

In the field of gas separation, ZSM-22's molecular sieving properties can be utilized to selectively capture specific gases from a mixture, such as removing carbon dioxide from natural gas or separating oxygen from air. This can have significant implications for environmental protection and energy production.

Moreover, ZSM-22 can also be employed in ion exchange applications, where it can selectively remove or release ions from a solution, making it useful in water purification and wastewater treatment processes. Its high stability and resistance to chemical degradation make ZSM-22 a reliable material for such demanding applications.

The development of ZSM-22 represents a significant advancement in the field of zeolite-based materials, offering new possibilities for improving industrial processes and addressing environmental challenges. With the expertise and dedication of companies like {}, the potential of ZSM-22 is likely to be fully realized, leading to the creation of innovative and sustainable solutions across various industries.

Company News & Blog

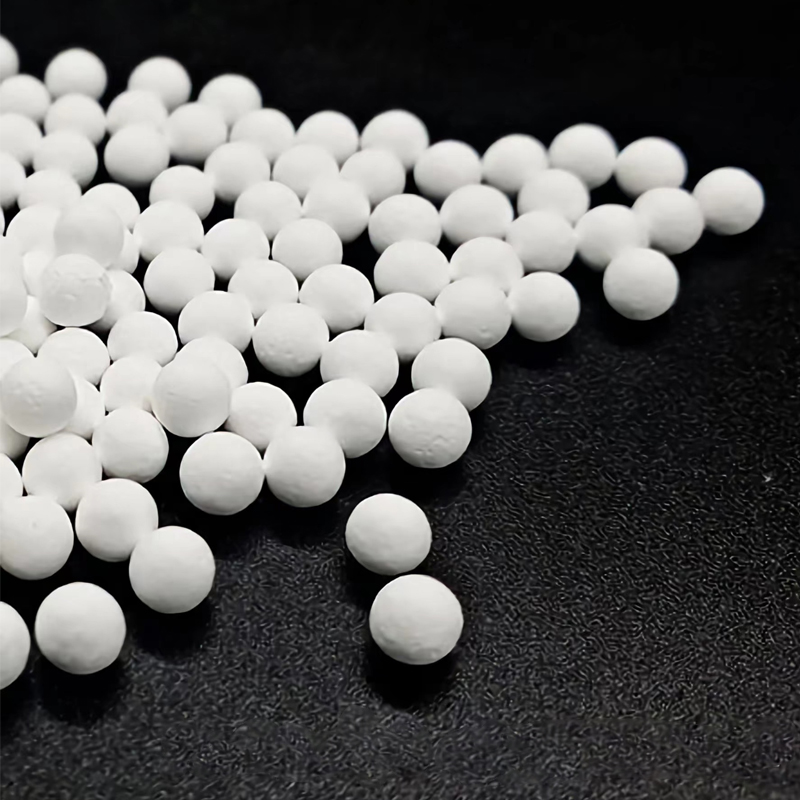

Highly Effective Alumina Catalyst for Various Applications

Alumina Catalyst Enhances Conversion Efficiency in Chemical ProcessesAlumina Catalyst, developed by the leading chemical manufacturing company, has emerged as a game-changer in the chemical industry. This innovative catalyst has enabled companies to significantly enhance their conversion efficiency in various chemical processes, leading to improved productivity and cost savings.The alumina catalyst is a high-performance material that facilitates the conversion of raw materials into valuable chemical products. Its unique properties make it an essential component in numerous industrial applications, including petrochemical, pharmaceutical, and environmental sectors.One of the key features of the alumina catalyst is its ability to promote desirable chemical reactions while minimizing unwanted by-products. This selectivity is crucial in ensuring the high quality and purity of the final products, which is a crucial factor in the chemical industry.Furthermore, the alumina catalyst has proven to be highly resilient, maintaining its catalytic activity under harsh operating conditions. This durability not only extends the catalyst's lifespan but also reduces the frequency of catalyst replacement, resulting in cost reductions for companies utilizing this technology.Another significant advantage of the alumina catalyst is its versatility. It can be tailored to meet the specific requirements of different chemical processes, allowing for customization and optimization of reaction conditions. This flexibility has made it a preferred choice for many chemical manufacturers seeking to enhance their production efficiency.In addition to its technical benefits, the alumina catalyst also aligns with the growing emphasis on sustainability within the chemical industry. By improving conversion efficiency and reducing waste, it contributes to the overall environmental footprint of chemical processes, aligning with regulatory and societal expectations.{Company Name}, the developer of the alumina catalyst, has a strong track record in delivering innovative solutions to the chemical industry. With a focus on research and development, the company has continuously pushed the boundaries of catalytic technology, resulting in the successful commercialization of advanced catalysts that have redefined industry standards.The company's commitment to excellence is reflected in its state-of-the-art manufacturing facilities and a team of highly skilled engineers and scientists. Rigorous quality control measures ensure that the alumina catalyst meets the highest standards, providing customers with a reliable and high-performance product.As the demand for efficient and sustainable chemical processes continues to grow, {Company Name} remains at the forefront of catalytic innovation. Its ongoing investment in research and development, coupled with a deep understanding of industry needs, positions the company as a trusted partner for chemical manufacturers seeking to optimize their operations.Looking ahead, the alumina catalyst is poised to play a pivotal role in the evolution of the chemical industry, driving enhanced productivity, cost savings, and environmental stewardship. With its proven performance and the backing of {Company Name}, this catalyst is set to redefine the benchmarks for conversion efficiency in chemical processes.

Newly Discovered ZSM-48 Mineral Holds Great Promise

Oil and gas exploration and processing have always been challenging and complex tasks. In order to help the industry achieve consistent success, scientists, and engineers have continuously endeavored to develop new materials and better technologies. One of the most promising advances in this area in recent years is the development of Zsm-48. The material is now being used in various applications within the oil and gas industry which has resulted in improved efficiency and profitability.Zsm-48 is a type of zeolite that has shown to have excellent properties for catalysis applications. The material has a unique structure with a high silica to alumina ratio which makes it ideal for selective conversion of hydrocarbons. The increased selectivity and activity of Zsm-48 are due to its unique pore system which creates an ideal environment for chemical reaction. Efficient and effective use of this material is beneficial for the oil and gas industry since it can enhance processing efficiency, increase yield, and significantly reduce the production cost.This innovative material is being employed in various applications in the oil and gas industry. One of the most notable is in crude oil refining, where Zsm-48 is used to remove sulfur compounds. This is a crucial step in the refining process, as sulfur compounds left in crude oil can cause corrosion in downstream equipment and release pollutants into the environment. By using Zsm-48, oil refineries can achieve better-quality fuels while reducing their carbon footprint.Another application of Zsm-48 is in the conversion of heavy oils. Heavy oils are cheaper than light oils, but due to their high viscosity, they are harder to process and refine. To increase the value of heavy oils, they need to be converted into lighter, more valuable products. Zsm-48 has been found to be highly effective in converting heavy oils into high-value products such as gasoline and diesel, making this innovative material an essential part of modern petroleum processing.Zsm-48 has also been used in the development of new catalyst technology for petrochemical processes. The catalysts developed using Zsm-48 are more selective and efficient, leading to higher yields and reduced costs in the production of various chemical products, including plastics, polymers, and fertilizers. Cracking heavy feedstock into lighter gas products using Zsm-48 catalysts are among the most groundbreaking achievements of this material.The use of Zsm-48 is not limited to the oil and gas industry. This innovative material has also been employed in the growing field of environmental remediation. Zsm-48 can effectively remove pollutants and other contaminants from water sources, including heavy metals, pesticides, and pharmaceutical products. Its selectivity and high adsorption capacity make it an ideal choice for water purification.The importance and relevance of Zsm-48 cannot be overstated, as the oil and gas industry continues its search for innovative solutions to improve efficiency and reduce the environmental impact of hydrocarbon operations. The development and application of this innovative material can lead to substantial benefits in various fields related to petroleum processing, leading to increased value and competitive advantage for companies and improving the lives of individuals all over the world.Companies like {Company Name} have become the preferred choice for businesses in the oil and gas industry looking for quality materials like Zsm-48. The company has been providing innovative products and solutions for the oil and gas, petrochemical, and water treatment industries for years. The company specializes in delivering products to customers in over 30 countries worldwide, and they work closely with customers to provide customized solutions that are tailored to meet the specific requirements of each project and application.With their expert knowledge of materials sciences and engineering, {Company Name} is committed to supporting the industry through continuous research and development, innovation, and strategic alliances with other industry leaders and partners. Their team of experts ensures that clients receive quality products and excellent service that reflects the company's values of sustainability, integrity, and excellence.In conclusion, as the oil and gas industry continues its search for innovative solutions that can improve efficiency and reduce environmental impact, Zsm-48 presents a breakthrough material. The application of this innovative zeolite has revolutionized petroleum processing and opened up new avenues for water treatment and environmental remediation. Companies like {Company Name} have been instrumental in providing access to quality Zsm-48 materials and expertise, which are essential for the success of new and existing projects.

Highly Efficient Gamma Alumina Catalyst for Advanced Chemical Processes

Gamma Alumina Catalyst Shows Promise in Environmental RemediationThe global push for sustainable and environmental friendly solutions has led to a growing demand for advanced catalysts that can facilitate the efficient conversion of various waste streams into valuable products. In response to this demand, a leading catalyst manufacturer has developed a cutting-edge Gamma Alumina Catalyst that has shown promising results in environmental remediation and waste-to-product conversion processes.The {Company} is a renowned manufacturer and supplier of innovative catalyst materials for a wide range of industrial applications. Established in 1990, the company has built a strong reputation for delivering high-quality catalyst solutions that meet the evolving needs of industries such as petrochemicals, environmental remediation, and renewable energy. With a strong focus on research and development, {Company} has consistently pushed the boundaries of catalyst technology to develop novel products that offer superior performance and sustainability.One of the company's latest breakthroughs is the development of a Gamma Alumina Catalyst that has demonstrated exceptional potential in environmental remediation applications. Gamma Alumina is a type of alumina (Al2O3) with a unique crystal structure that imparts desirable properties such as high surface area, thermal stability, and chemical inertness. These properties make Gamma Alumina an ideal candidate for catalyzing a variety of chemical reactions, including those involved in waste treatment and conversion processes.The Gamma Alumina Catalyst developed by {Company} has shown remarkable efficacy in facilitating the conversion of organic pollutants into harmless byproducts through processes such as oxidation and hydrocracking. This capability makes it well-suited for addressing environmental challenges such as water and soil pollution resulting from industrial activities, waste disposal, and agricultural runoff. Additionally, the catalyst has demonstrated potential in converting waste materials into valuable chemicals and biofuels, aligning with the global objectives of circular economy and resource efficiency.In addition to its exceptional catalytic performance, the Gamma Alumina Catalyst offers several practical advantages that make it an attractive choice for industrial and environmental applications. Its high surface area and porosity allow for high catalytic activity and accessibility, ensuring efficient utilization of the catalyst material. Moreover, its thermal stability and resistance to harsh operating conditions contribute to long-term stability and durability, reducing the frequency of catalyst replacement and maintenance.Furthermore, {Company} emphasizes the sustainable and environmentally responsible nature of its production processes, ensuring that the Gamma Alumina Catalyst is manufactured with minimal environmental impact. This commitment to sustainability extends to the catalyst's end-of-life phase, where efforts are made to promote recycling and reclamation of the catalyst material, further contributing to resource conservation and waste reduction.The potential of the Gamma Alumina Catalyst in environmental remediation has sparked significant interest and collaborations with environmental engineering firms, government agencies, and research institutions. Preliminary studies and pilot-scale demonstrations have yielded promising results, validating the efficacy of the catalyst in treating various types of contaminated water and soil, as well as in converting organic waste into value-added products.Looking ahead, {Company} is committed to furthering the development and commercialization of the Gamma Alumina Catalyst, with a focus on scaling up production and expanding its application scope. Collaborative research efforts are underway to explore the catalyst's potential in addressing emerging environmental challenges and advancing the transition towards a more sustainable and circular economy.In conclusion, the development of the Gamma Alumina Catalyst by {Company} represents a significant advancement in catalysis technology, with far-reaching implications for environmental remediation and waste-to-product conversion. By harnessing the unique properties of Gamma Alumina, the catalyst has demonstrated exceptional performance and potential, offering a promising solution to pressing environmental concerns and contributing to the global efforts towards a more sustainable future. As the demand for innovative catalyst solutions continues to grow, {Company} remains at the forefront of catalysis innovation, driving positive change and addressing the complex challenges of today's world.

Addressing Water Quality Issues in Domestic Wells: California State Water Resources Control Board Provides Updates

Water is a critical resource that is essential for human survival. Maintaining its quality is equally important. However, water quality continues to be a significant concern, especially in California. Groundwater is the primary source of drinking water in the state, and it supplies nearly 40% of the state's total water consumption. Addressing this issue, the California State Water Resources Control Board and Gama Alumina have recently come together to launch the GAMA Domestic Well program. Groundwater quality in California is affected by various factors, including natural sources, human activities, and industrial activities. The most prevalent contaminants found in groundwater include nitrates, arsenic, lead, and salts. These contaminants affect the water quality and pose a significant health risk to the people consuming it. The GAMA Domestic Well program aims to address these issues by providing free testing and treatment to domestic well owners across the state.The GAMA Domestic Well program is a joint venture between the California State Water Resources Control Board and Gama Alumina, a global provider of solutions for the aluminum industry. Gama Alumina has over sixty years of experience in the water treatment industry, offering a range of products and services to customers worldwide. The company is known for its expertise in water treatment technologies, specifically in the areas of filtration, ion exchange, and reverse osmosis.The Gama Alumina has committed to offer its technological support to the GAMA Domestic Well program across California. This collaboration with the State Water Board will help to supplement and improve water quality to communities located near the company's manufacturing facility. Gama's mission is to provide sustainable water solutions to contribute to the enrichment of quality of life and protecting the environment.The GAMA Domestic Well program's primary objective is to provide free testing for private domestic wells and to track changes in groundwater quality across California. The program will allow participants to access the latest water testing technologies, including the isotope and geochemical analyses, to identify the sources of contamination. Gama Alumina will also provide technical support for water treatment systems interventions, including filtration, desalination, and ion exchange.The program will prioritize vulnerable communities that are most affected by water quality issues, including low-income households, rural communities, indigenous people, and communities of color. Many of these communities face unique challenges through ongoing drought, water scarcity, and aquifer depletion. Addressing their specific needs and challenges is vital to the success of the GAMA program, as it aims to deliver equitable access to clean water for all Californians.The GAMA program will collect and compile data from the groundwater monitoring wells drilled across the state and provide public access to the data. This information will be valuable to state and regional stakeholders and informed communities to better understand groundwater quality changes and take preservation measures. Gama Alumina is committed to sustainable industrial growth and strives to preserve the environment. The company invests in innovation and technology to develop highly efficient processes to produce aluminum and provide long-term solutions to reduce waste and enhance industrial practices. The firm believes that collective action is vital to creating lasting positive impact and recovery.The Gama Alumina has a proven track record of delivering sustainable solutions to the aluminum industry. By providing technical support to the GAMA Domestic Well program, the company aims to ensure that communities have access to clean and safe drinking water. The company will employ its proprietary technology to boost the program's efforts to improve groundwater quality throughout the state.To sum up, the GAMA Domestic Well Program, in conjunction with Gama Alumina, creates a platform that ensures continued access to clean water across the State of California. With Gama's technical support, this project will offer a range of solutions that will provide free domestic well testing and water treatment systems interventions. The GAMA Domestic Well Program offers a reliable data source and will boost the state's efforts to ensure water quality safety and enhance clean water accessibility for all communities. Overall, Gama Alumina is committed to providing solutions that enhance the water industry and the quality of life to customers by embracing innovation, community, and sustainability.

New Study Reveals Exciting Findings About ZSM-5 Catalyst

ZSM-5 is a type of zeolite material that is widely used in various industrial applications such as catalysis, adsorption, and separation. It is known for its high thermal stability, acidity, and unique pore structure, which makes it a valuable material for a wide range of processes in the chemical and petrochemical industries.Recently, (company) has made significant advancements in the development of ZSM-5 for various applications. The company has been at the forefront of research and development in the field of zeolite materials, and its latest breakthroughs in ZSM-5 technology have opened up new possibilities for the use of this material in industrial processes.One of the key areas in which (company) has been focusing its efforts is the development of ZSM-5 catalysts for the production of high-octane gasoline. ZSM-5 has the unique ability to shape-selectively catalyze the conversion of low-value feedstocks such as methanol or ethanol into high-octane gasoline, which is in high demand in the automotive industry. By optimizing the pore structure and acidity of ZSM-5, (company) has been able to significantly improve the efficiency and selectivity of the conversion process, leading to higher yields of high-quality gasoline.In addition to its use in gasoline production, (company) has also been exploring the potential of ZSM-5 in the field of environmental protection. The material's adsorption and catalytic properties make it an ideal candidate for the removal of pollutants from waste streams and exhaust gases. By tailoring the chemical composition and pore structure of ZSM-5, the company has been able to develop highly efficient adsorbents and catalysts for the removal of harmful substances such as sulfur compounds, nitrogen oxides, and volatile organic compounds from industrial emissions.Moreover, (company) has been working on leveraging the unique properties of ZSM-5 for the production of renewable fuels and chemicals. By using ZSM-5 as a catalyst for biomass conversion, the company aims to develop efficient processes for the production of biofuels and biobased chemicals from renewable feedstocks. Through extensive research and development efforts, (company) has made significant progress in improving the performance and stability of ZSM-5 catalysts for biomass conversion, paving the way for a more sustainable and environmentally friendly production of fuels and chemicals.Furthermore, (company) has been collaborating with various partners in academia and industry to further explore the potential applications of ZSM-5 in emerging fields such as carbon capture and utilization, sustainable energy production, and material synthesis. By combining its expertise in zeolite materials with the knowledge and resources of its collaborators, (company) aims to continue pushing the boundaries of ZSM-5 technology and unlocking new opportunities for its use in a wide range of industrial processes.Overall, (company) has been making significant strides in the development and application of ZSM-5, leveraging its unique properties to address the evolving needs of the chemical and petrochemical industries. With its continued commitment to innovation and collaboration, the company is well-positioned to play a key role in shaping the future of ZSM-5 technology and its impact on industrial processes.

Durable Aluminum Oxide Catalyst for Efficient Chemical Reactions

Al2O3 Catalyst Shows Promising Results in Catalyst ApplicationsIn the modern era of industrial and technological advancement, catalysts play a crucial role in enhancing the efficiency and effectiveness of various chemical processes. With the development of new catalyst materials, researchers and manufacturers are constantly seeking innovative ways to improve catalytic performance. Recently, a new Al2O3 catalyst has been making headlines for its promising results in various catalyst applications.A leading company in the catalyst industry, with a strong focus on research and development, has been at the forefront of producing the innovative Al2O3 catalyst. The company, with its state-of-the-art manufacturing facilities and extensive expertise in catalyst technologies, has been successful in creating a catalyst that demonstrates exceptional performance and versatility.The primary function of a catalyst is to accelerate chemical reactions without being consumed in the process, thereby increasing the rate of the reaction and enhancing the yield of the desired product. The unique properties of Al2O3, also known as aluminum oxide, make it an ideal material for catalyst applications. Its high surface area, thermal stability, and resistance to harsh reaction conditions make it a popular choice for a wide range of catalytic processes.One of the key advantages of the Al2O3 catalyst is its ability to promote various reactions, including oxidation, hydrogenation, and dehydration, among others. This versatility makes it a valuable tool for industries such as petrochemicals, pharmaceuticals, and environmental protection, where catalysts play a crucial role in the production of essential chemicals and the treatment of pollutants.Furthermore, the company has conducted extensive research and development to optimize the performance of the Al2O3 catalyst. By fine-tuning the catalyst composition and structure, the company has been able to enhance its catalytic activity, selectivity, and stability, making it a highly efficient and reliable option for industrial applications.The Al2O3 catalyst has also been proven to exhibit excellent resistance to deactivation, a common issue faced by catalysts during prolonged use. This attribute significantly extends the catalyst's lifespan, leading to cost savings and a reduction in downtime for catalyst regeneration or replacement.Moreover, the company has established a strong quality control system to ensure the consistency and reliability of the Al2O3 catalyst production. With strict adherence to industry standards and regulations, the company has earned a reputation for delivering high-quality catalyst materials that meet the stringent requirements of its customers.The successful application of the Al2O3 catalyst in various industrial processes has garnered significant attention and interest from the scientific community and industrial stakeholders. In addition to its outstanding performance, the catalyst has also been lauded for its environmentally friendly nature, as it contributes to the optimization of chemical processes and the reduction of waste and energy consumption.As the demand for efficient and sustainable catalyst materials continues to rise, the Al2O3 catalyst is poised to play a key role in meeting the evolving needs of diverse industries. With ongoing research and innovation, the company is committed to further advancing the capabilities of the Al2O3 catalyst, paving the way for continuous improvements in catalytic technologies.In conclusion, the Al2O3 catalyst has emerged as a game-changing solution for catalyst applications, offering exceptional performance, versatility, and reliability. With the support of a leading company in catalyst technologies, the Al2O3 catalyst is poised to make a lasting impact on the industrial landscape, driving progress and efficiency in chemical processes.

Highly Effective Alumina Catalyst for Industrial Applications

Gamma Alumina Catalyst: Driving Innovation and Sustainability in the Chemical IndustryThe global chemical industry is constantly seeking new ways to improve efficiency, reduce environmental impact, and meet the ever-growing demands for chemical products. One of the key players in this quest for innovation and sustainability is {company name}, a leading provider of advanced materials and catalyst solutions. At the heart of their cutting-edge technology is the Gamma Alumina Catalyst, a high-performing material that is revolutionizing the way chemical processes are carried out.{Company name} is a world-renowned company with a strong commitment to research and development, focusing on delivering solutions that address the challenges and demands of the chemical industry. With a rich history of technological expertise and a global footprint, {company name} has established itself as a trusted partner for companies looking to push the boundaries of what is possible in chemical manufacturing.The Gamma Alumina Catalyst is a prime example of how {company name} is driving the industry forward. This advanced catalyst offers unparalleled performance in a wide range of chemical processes, from petrochemical refining to environmental remediation. Its unique properties allow for greater efficiency, higher yields, and reduced energy consumption, all while minimizing the environmental footprint of chemical production.One of the key advantages of the Gamma Alumina Catalyst is its exceptional thermal stability, making it an ideal choice for high-temperature reactions. This stability allows for prolonged catalyst life and consistent performance, ultimately leading to lower operational costs and reduced waste. In addition, the catalyst's high surface area and pore volume provide ample active sites for chemical reactions, ensuring maximum productivity and yield.Moreover, the Gamma Alumina Catalyst is designed to meet the most stringent environmental regulations. Its exceptional selectivity and ability to control by-products make it a sustainable choice for chemical manufacturers looking to minimize their environmental impact. By reducing waste and enhancing process efficiency, companies can achieve their production goals while staying environmentally responsible.{Company name} takes pride in not only offering state-of-the-art materials like the Gamma Alumina Catalyst but also providing comprehensive technical support to ensure seamless integration into existing processes. The company's team of experts works closely with customers to understand their unique needs and challenges, offering tailored solutions that deliver tangible results. This collaborative approach has been integral to the success of {company name} and has solidified its reputation as a reliable and innovative partner in the chemical industry.In addition to its technological advancements, {company name} is also dedicated to sustainability and corporate responsibility. The company's commitment to sustainable business practices is reflected in its efforts to reduce waste, conserve resources, and minimize its carbon footprint. By incorporating the principles of sustainability into its operations, {company name} sets a positive example for the industry and contributes to a more environmentally conscious future.Overall, the Gamma Alumina Catalyst is a testament to {company name}'s dedication to innovation, sustainability, and customer satisfaction. With its superior performance, environmental responsibility, and extensive technical support, this catalyst is poised to drive positive change in the chemical industry. As the demand for advanced materials and sustainable solutions continues to grow, {company name} remains at the forefront, committed to shaping the future of chemical manufacturing for the better.In conclusion, {company name} continues to be a driving force in the global chemical industry, leading the way with its groundbreaking technologies and unwavering commitment to sustainability. The Gamma Alumina Catalyst stands as a prime example of the company's innovative spirit and dedication to pushing the boundaries of what is possible. As the industry evolves and new challenges emerge, {company name} remains poised to deliver the advanced materials and catalyst solutions that will shape the future of chemical manufacturing.

High-Quality Activated Alumina for Catalyst Carrier at Affordable Prices - Available at CHEMXIN-en.com

and Activated Alumina throughout the content.Catalysts play a crucial role in chemical reactions, allowing reactions to occur at lower temperatures and increasing reaction rates. However, a catalyst needs an appropriate carrier to ensure its effectiveness. That's where activated alumina for catalyst carrier comes in.Activated alumina is a highly-porous, solid form of aluminum oxide that can be used as a carrier material for catalysts. Its unique properties, such as high surface area and excellent adsorption capacity, allow it to hold different types of catalysts and enhance their performance.As a professional activated alumina for catalyst carrier manufacturer, CHEMXIN offers a wide range of quality products in stock. Our activated alumina for catalyst carrier products are made from high-purity alumina and are designed to meet different requirements for diverse catalyst applications.One of the key benefits of activated alumina for catalyst carrier is its high surface area, which ranges from 150 to 300 square meters per gram. With this high surface area, the activated alumina provides a large surface area for contact between the catalyst and the reactant. As a result, the reaction rate is increased, and the overall efficiency of the reaction is improved.Another advantage of using activated alumina for catalyst carrier is its excellent adsorption capacity. The material can adsorb different types of gases and liquids and can also remove impurities from the feedstock or reactants. This feature is especially important in refining and petrochemical industries, where the purity of the feedstock is critical to the success of the process.Moreover, activated alumina for catalyst carrier is highly resistant to thermal shock and mechanical abrasion, making it a durable carrier material for catalysts. Its resistance to high temperatures, up to 600°C or even higher, allows it to maintain its stability and integrity in high-temperature applications.In terms of applications, activated alumina for catalyst carrier can be used in various processes, including hydrogenation, dehydrogenation, isomerization, and adsorption. It is commonly used in the refining, petrochemical, and chemical industries for the production of fuels, chemicals, plastics, and other products.In conclusion, activated alumina for catalyst carrier is a crucial component in different catalytic applications. As a leading manufacturer of activated alumina for catalyst carrier, CHEMXIN offers a range of high-quality products in stock to meet different needs and requirements. With its unique properties, such as high surface area, adsorption capacity, and thermal resistance, activated alumina for catalyst carrier can enhance the performance of catalysts and improve the overall efficiency of different chemical processes.

Highly Effective Alumina Catalyst for Catalyst Applications

Alumina Catalyst Company, a global leader in catalyst manufacturing and solutions, has recently made significant advancements in the field of alumina catalyst technology. With over 40 years of experience in the industry, the company has become a trusted partner for businesses in various sectors, including oil and gas, petrochemicals, and environmental protection.The company's alumina catalysts are known for their high performance and reliability, making them the go-to choice for many companies looking to optimize their operations and reduce their environmental footprint. The recent developments in alumina catalyst technology have further solidified the company's position as a leader in the industry.One of the key advancements made by Alumina Catalyst Company is the development of a new generation of alumina catalysts that offer improved performance and durability. These catalysts are designed to withstand harsh operating conditions, such as high temperatures and pressures, while delivering superior catalytic activity and selectivity. This innovation has been particularly well-received by companies operating in the oil and gas industry, where catalyst performance is crucial to the efficiency of various processes, including refining and petrochemical production.The company's commitment to innovation and continuous improvement has also led to the development of tailored catalyst solutions for specific applications. This includes catalysts designed for hydrocracking, fluid catalytic cracking, and other essential processes in the oil and gas industry. By working closely with their clients, Alumina Catalyst Company is able to customize catalysts to meet their specific requirements, ensuring optimal performance and cost-effectiveness.Furthermore, the company has placed a strong emphasis on sustainability and environmental responsibility in its catalyst manufacturing process. Their alumina catalysts are designed to minimize environmental impact, with a focus on reducing emissions and promoting energy efficiency. This commitment to sustainability has resonated with many companies seeking to enhance their environmental stewardship while maintaining operational excellence.In addition to their cutting-edge catalyst technology, Alumina Catalyst Company also offers comprehensive technical support and services to its clients. This includes catalyst monitoring, optimization, and troubleshooting, as well as on-site support and training. The company's team of experts works closely with clients to ensure that their catalysts are performing at their best and are delivering the expected results.Alumina Catalyst Company's dedication to quality and customer satisfaction has earned them a strong reputation in the industry. Their commitment to excellence, coupled with their ability to deliver tailored catalyst solutions, has made them a trusted partner for leading companies around the world.Looking ahead, the company is poised to continue its trajectory of growth and innovation, with a focus on expanding its product range and enhancing its capabilities. By staying at the forefront of alumina catalyst technology, Alumina Catalyst Company is well-positioned to play a pivotal role in driving the success of its clients and contributing to a sustainable future.In conclusion, Alumina Catalyst Company's recent advancements in alumina catalyst technology demonstrate their unwavering commitment to excellence and innovation. With a strong track record of delivering high-performance catalyst solutions and a dedication to sustainability, the company is well-equipped to meet the evolving needs of its clients and the industry as a whole. As they continue to push the boundaries of catalyst technology, Alumina Catalyst Company is set to shape the future of the industry and drive meaningful change.

Alumina Carrier for Catalysts: What You Need to Know

Alumina Carrier For Catalysts, a leading provider of high-quality alumina products for catalytic applications, has been making waves in the industry with its innovative and customizable solutions for a wide range of catalyst applications. With a focus on superior quality and performance, the company has positioned itself as a key player in the market, offering unmatched expertise and support to its customers.Founded in [year], Alumina Carrier For Catalysts has quickly risen to prominence as a trusted supplier of alumina products for various industries, including petrochemical, environmental, and chemical processing. The company's dedication to continuous improvement and innovation has allowed it to stay ahead of the curve, delivering cutting-edge solutions that meet and exceed the ever-evolving needs of its clients.At the heart of Alumina Carrier For Catalysts is its exceptional product portfolio, which includes a wide range of alumina-based products tailored to meet specific catalyst requirements. From standard alumina carriers to custom-designed formulations, the company's offerings are designed to optimize catalyst performance and longevity, ultimately leading to improved operational efficiency and cost savings for its customers.In addition to its impressive product lineup, Alumina Carrier For Catalysts also prides itself on its unrivaled technical expertise and customer support. The company's team of highly skilled engineers and scientists work closely with clients to understand their unique challenges and develop tailor-made solutions that address their specific needs. Whether it's optimizing an existing catalyst formulation or developing a new product from scratch, the company's technical team is committed to delivering results that exceed expectations.Another key differentiator for Alumina Carrier For Catalysts is its commitment to sustainability and environmental responsibility. The company understands the importance of minimizing its environmental footprint and actively seeks to develop products and processes that align with these values. Through a combination of advanced manufacturing techniques and ongoing research and development, Alumina Carrier For Catalysts continues to drive toward more sustainable and eco-friendly solutions for its customers.As a testament to its commitment to excellence, Alumina Carrier For Catalysts has garnered a strong reputation within the industry and has built long-standing relationships with a diverse array of clients worldwide. From small businesses to multinational corporations, the company's dedication to quality, performance, and customer satisfaction has earned it the trust and loyalty of its customers, further solidifying its position as a leading player in the alumina products market.Looking ahead, Alumina Carrier For Catalysts remains firmly focused on expanding its product offerings and capabilities, with an eye toward continued growth and innovation. The company is actively investing in research and development to further enhance its product portfolio and meet the evolving needs of the market. Additionally, it is exploring new partnerships and collaborations to broaden its reach and deliver its industry-leading solutions to a wider audience.In summary, Alumina Carrier For Catalysts stands out as a top-tier provider of alumina products for catalyst applications, thanks to its unwavering commitment to quality, innovation, and customer satisfaction. With its impressive track record and forward-looking approach, the company is well-positioned to continue driving positive change and delivering value to its clients for years to come.