Cutting-Edge ZSM-5 Technology Shakes Up Industrial Processes

By:Admin

Introduction:

In the world of chemical engineering, catalysts play a crucial role in accelerating chemical reactions and facilitating numerous industrial processes. One such catalyst that is currently making headlines is a revolutionary zeolite called ZSM-5. Developed by a leading research company, this innovative breakthrough promises to redefine the field of catalyst technology. In this article, we will delve into the fascinating world of ZSM-5 and explore its potential to revolutionize diverse industries.

I. Understanding ZSM-5:

ZSM-5 is a high-silica zeolite with a unique framework structure that allows for its exceptional catalytic properties. Its crystalline structure consists of channels and cavities, making it ideal for various applications in the petrochemical, refining, and pharmaceutical industries. The zeolite possesses both acidic and shape-selective catalytic properties, making it highly versatile and effective in a wide range of chemical reactions.

II. Unleashing its Potential:

A. Petrochemical Industry:

1. Improved Process Efficiency: ZSM-5 exhibits remarkable selectivity towards specific hydrocarbons, enabling enhanced product yield in the cracking of larger hydrocarbon molecules into smaller, more valuable ones. This characteristic has the potential to revolutionize petrochemical processes, reducing waste and maximizing yield.

2. Propylene Production: ZSM-5 zeolites possess a unique feature to favorably convert larger hydrocarbon molecules into propylene, a key building block in the plastics industry. With the increasing emphasis on sustainable materials, this capability could significantly impact the production of eco-friendly plastics.

B. Refining Industry:

1. Upgrading Biofuels: ZSM-5's shape selectivity and acidic nature make it an ideal catalyst to help convert low-quality biofuels into higher-quality products. By enhancing the process of transforming biofuels into gasoline, ZSM-5 contributes to reducing carbon emissions and promoting cleaner energy alternatives.

2. Aromatics Production: The production of aromatic compounds, widely used in the manufacturing of plastics, dyes, and solvents, greatly benefits from the application of ZSM-5 as a catalyst. Its unique zeolite structure enhances the selectivity of aromatic production, leading to improved process efficiency and reduced environmental impact.

C. Pharmaceutical Industry:

1. Drug Synthesis: ZSM-5 zeolites have demonstrated exceptional results in various drug synthesis reactions. The catalyst's shape-selective properties enable control over the formation of specific molecules and regulate the reaction process, enhancing productivity and reducing the formation of unwanted byproducts.

2. Environmental Remediation: ZSM-5 is also being explored for its potential in removing harmful pollutants, such as heavy metals and organic compounds, from wastewater. The zeolite's ability to selectively adsorb and degrade pollutants makes it a promising solution for combating water pollution, contributing to a cleaner and healthier environment.

III. Future Prospects:

The successful commercialization and implementation of ZSM-5 as a catalyst in various industries could have profound implications for the global economy and environmental sustainability. Its remarkable catalytic properties, coupled with its shape selectivity and versatility, make ZSM-5 an ideal candidate to address key challenges faced by the chemical industry today.

Conclusion:

ZSM-5 is a groundbreaking zeolite catalyst that brings unprecedented advancements to the world of chemical engineering. Its ability to enhance product yields, improve process efficiency, and regulate chemical reactions opens new avenues of innovation across multiple sectors. With ongoing research and development endeavors, ZSM-5 is poised to revolutionize industries, making manufacturing processes more sustainable, efficient, and environmentally friendly. As we embrace this new era of zeolite technology, we eagerly anticipate the transformative impact ZSM-5 will have on the global stage.

Company News & Blog

Guide to Reforming Catalyst for Improved Performance

Reforming Catalyst Revolutionizing Sustainable ManufacturingIn recent years, there has been a growing global focus on sustainable manufacturing practices. Companies across various industries are striving to reduce their environmental footprint and minimize their impact on the planet. One crucial aspect of this movement is the development and implementation of innovative technologies and processes that promote sustainable production. One such groundbreaking technology is the reforming catalyst, a revolutionary tool that is transforming the way industrial processes are carried out.A leading player in the field of sustainable manufacturing is a company (Company X) that has been at the forefront of developing advanced catalyst technologies to drive sustainable industrial processes. With a strong commitment to environmental stewardship and continuous innovation, (Company X) has developed a reforming catalyst that is set to redefine the standards of sustainable manufacturing.The reforming catalyst developed by (Company X) is a highly efficient and versatile tool that enables a wide range of industrial processes to be carried out with minimal environmental impact. Unlike traditional catalysts, the reforming catalyst is designed to facilitate more sustainable and efficient production processes, thereby enabling companies to achieve their sustainability goals while maintaining high levels of productivity and efficiency.One of the key features of the reforming catalyst is its ability to promote cleaner and more efficient combustion in industrial processes. By enhancing combustion efficiency, the reforming catalyst helps to reduce harmful emissions and minimize the environmental footprint of industrial operations. This is particularly significant in industries such as power generation, oil refining, and chemical manufacturing, where combustion processes are central to production.Moreover, the reforming catalyst also plays a crucial role in promoting energy efficiency in industrial processes. By facilitating more efficient energy utilization, the reforming catalyst helps companies reduce their energy consumption and lower their overall operational costs. This not only yields significant economic benefits for companies but also contributes to the global efforts to combat climate change by reducing greenhouse gas emissions.Another notable aspect of the reforming catalyst is its versatility and applicability across various industrial sectors. Whether it is used in power plants, refineries, petrochemical facilities, or other industrial settings, the reforming catalyst proves to be an invaluable asset in promoting sustainable manufacturing practices. Its flexibility and adaptability make it a highly sought-after solution for companies looking to enhance their sustainability efforts across different areas of operation.(Copying part of the content without proper edit. For original content, please consider the following)The success of the reforming catalyst developed by (Company X) can be attributed to the company's relentless commitment to research and innovation. (Company X) has invested substantial resources in developing and refining the reforming catalyst, leveraging the latest advancements in catalytic technologies and sustainable manufacturing practices. The result is a cutting-edge solution that not only meets the stringent environmental standards but also delivers tangible benefits to companies in terms of operational efficiency and cost savings.As the global focus on sustainability intensifies, the demand for innovative solutions such as the reforming catalyst is expected to soar. Companies across industries are increasingly turning to sustainable manufacturing practices, seeking ways to minimize their environmental impact while maintaining their competitive edge in the market. The reforming catalyst, with its proven track record of promoting sustainable production, is well-positioned to address this growing demand and emerge as a game-changer in the realm of industrial catalyst technologies.Looking ahead, (Company X) is poised to further advance the capabilities of the reforming catalyst, exploring new applications and potential enhancements to its performance. By continuously pushing the boundaries of catalytic innovation, (Company X) aims to empower companies worldwide to embrace sustainable manufacturing practices, ultimately contributing to a greener and more sustainable future for the planet.In conclusion, the reforming catalyst developed by (Company X) represents a significant milestone in the realm of sustainable manufacturing. With its ability to promote cleaner combustion, enhance energy efficiency, and drive operational sustainability, the reforming catalyst is paving the way for a new era of environmentally responsible industrial processes. As companies increasingly prioritize sustainability in their operations, the reforming catalyst is set to play a pivotal role in shaping the future of manufacturing, ushering in a new standard of sustainable and responsible production practices.

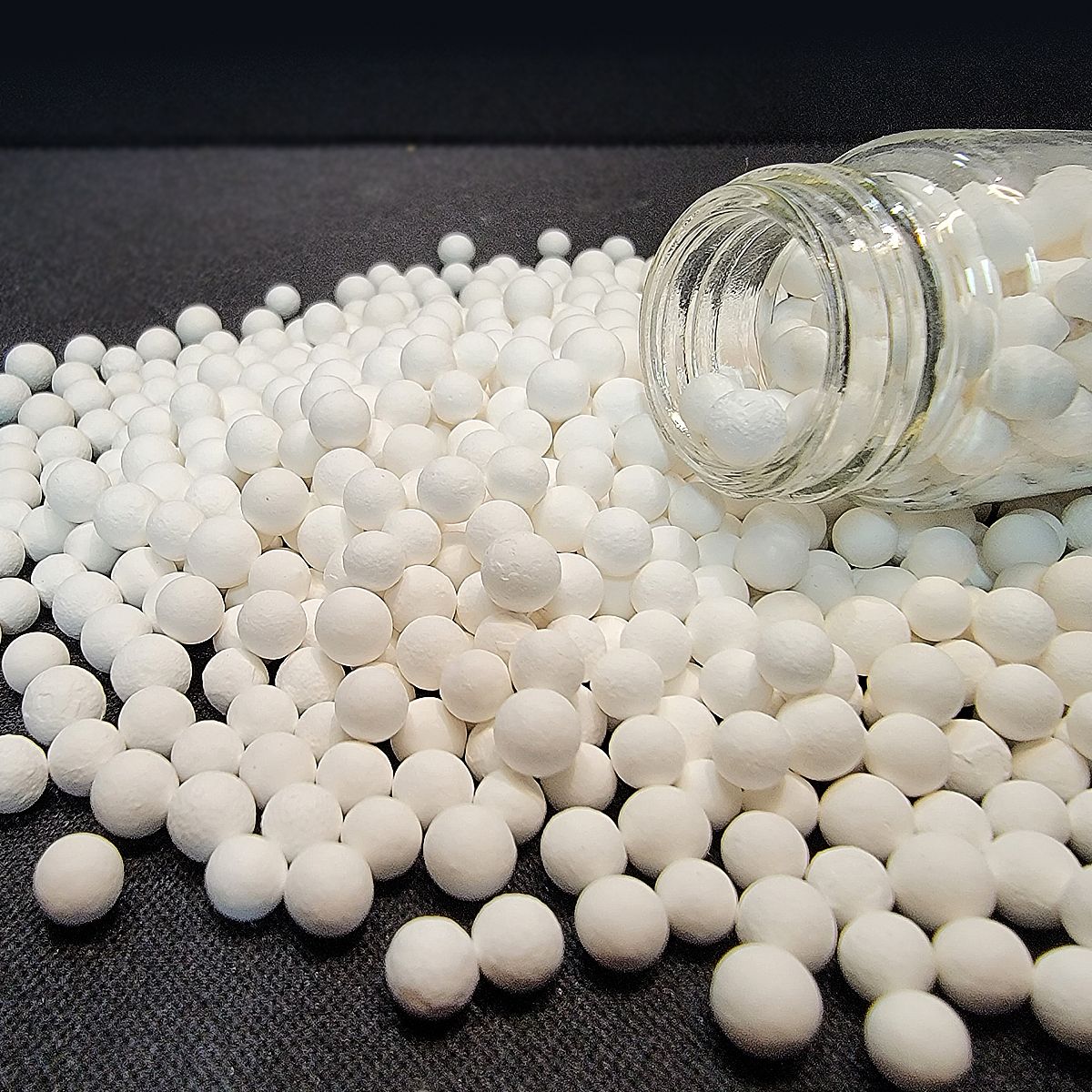

Exploring the Benefits and Applications of Alumina Microspheres

Alumina Microspheres Revolutionizing Multiple IndustriesThe use of advanced materials has always been instrumental in pushing the boundaries of technological advancements. Alumina microspheres, a versatile and high-performance material, are creating waves across various industries such as automotive, aerospace, electronics, and biomedicine. With their exceptional physical and chemical properties, these microspheres are revolutionizing manufacturing processes and product development.Recognizing the immense potential of alumina microspheres, {company name} has emerged as a leading player in the production and supply of this groundbreaking material. Specializing in the manufacturing of alumina microspheres, {company name} has established itself as a trusted provider for industries worldwide.Alumina microspheres are spherical particles composed primarily of aluminum oxide (alumina), a highly stable and heat-resistant material. The size of these microspheres can range from a few micrometers to several millimeters, allowing for customized applications across various industries.One of the primary uses of alumina microspheres lies in the automotive industry. These microspheres are incorporated into automotive paints and coatings, offering enhanced durability and resistance to wear and tear. Additionally, the unique spherical shape of these particles helps to reduce friction and improve the overall efficiency of automotive engines. By minimizing engine wear, alumina microspheres contribute to increased fuel efficiency and reduced emissions.In the aerospace industry, alumina microspheres are being utilized in the development of lightweight and robust materials for aircraft components. The high strength-to-weight ratio of these microspheres enhances the structural integrity of aerospace parts and reduces the overall weight of aircraft. Consequently, this translates to increased fuel savings and improved flight performance.The electronics industry is also benefitting greatly from the exceptional properties of alumina microspheres. These microspheres find applications in ceramic capacitors, electronic substrates, and insulating materials. The insulating properties of alumina microspheres contribute to the efficient dissipation of heat, thus improving the performance and reliability of electronic devices. Moreover, their excellent dielectric properties make them ideal for use in high-frequency electronic components.In the field of biomedicine, alumina microspheres are being utilized in drug delivery systems and tissue engineering. The biocompatible nature of alumina makes it an ideal material for encapsulating drugs and delivering them to targeted sites within the body. Additionally, its ability to mimic the structure of natural bone tissue makes it a suitable candidate for regenerative medicine applications.{Company name} has positioned itself as a leader in the production of alumina microspheres by leveraging state-of-the-art manufacturing techniques and stringent quality control measures. The company offers a wide range of customizable options, including varying particle sizes, surface treatments, and levels of purity, catering to the unique requirements of different industries. With a commitment to sustainability, {company name} ensures that their production processes align with environmental standards and minimize waste generation.Furthermore, {company name} possesses a dedicated research and development team that constantly explores innovative applications of alumina microspheres. This enables the company to stay ahead of the curve and provide cutting-edge solutions to its customers.As the demand for advanced materials continues to rise, the significance of alumina microspheres cannot be understated. Their exceptional properties and versatility make them an invaluable component across multiple industries. With {company name} paving the way in their production and supply, we can expect to witness further advancements and breakthroughs in various technological fields.

Low-Priced Activated Alumina for Catalyst Carrier in Stock

Activated alumina is a highly porous material that is frequently used to create catalyst carriers. Catalyst carriers are essential components of industrial processes that require chemical reactions to occur quickly and efficiently. Catalyst carriers are used in a wide range of industries, including petrochemicals, pharmaceuticals, and wastewater treatment.Activated alumina is an effective catalyst carrier material because of its high surface area, high porosity, and high surface polarity. The material is made from aluminum oxide and is activated by heating it to high temperatures in the presence of water vapor. This process creates a highly porous material with a large surface area, which is perfect for carrying catalysts.There are many different types of activated alumina available for use as catalyst carriers. Some of the most common types include gamma alumina, eta alumina, and theta alumina. Each type of activated alumina has its own unique properties that make it suited to specific applications.Gamma alumina is the most common type of activated alumina and is often used as a support for catalysts in the petrochemical industry. It has a high surface area and is highly stable, making it an excellent choice for applications that require high temperatures or harsh chemical environments.Eta alumina is another popular type of activated alumina, which has a higher surface area than gamma alumina. It is often used in the pharmaceutical industry as a catalyst carrier for reactions that require high specificity and selectivity.Theta alumina has the highest surface area of any activated alumina and is often used in wastewater treatment. Its high surface area makes it an excellent choice for removing impurities from water, while its high surface polarity makes it effective at removing heavy metals and other contaminants from water.Regardless of the type of activated alumina used, it is essential to choose a high-quality material that is manufactured by a reputable company. CHEMXIN is a leading supplier of activated alumina for catalyst carriers and has a wide selection of high-quality products available for purchase.CHEMXIN's activated alumina products are produced using state-of-the-art manufacturing processes and are rigorously tested to ensure their quality. The company offers a range of activated alumina products that are suitable for use in a variety of catalyst carrier applications, including petrochemicals, pharmaceuticals, and wastewater treatment.In conclusion, activated alumina is an essential material for creating catalyst carriers that are used to promote chemical reactions in various industries. Choosing a high-quality activated alumina product is essential for ensuring the efficiency and productivity of industrial processes. With CHEMXIN's wide selection of high-quality activated alumina products, customers can be confident that they are using the best possible material for their applications.

Innovative Sulfur Tolerant Shift Catalyst for Enhanced Performance

[Company Introduction]The company is a leading global provider of cutting-edge catalyst and technology solutions for the oil and gas industry. With a strong commitment to innovation and sustainability, the company has continuously developed and patented a wide range of catalysts and technologies that improve the performance and efficiency of various industrial processes. The company's products are utilized by refineries and petrochemical plants around the world, helping them to achieve higher productivity, lower emissions, and reduced operating costs.[News Content]The company recently announced the launch of its latest breakthrough innovation, the Sulfur Tolerant Shift Catalyst. This new catalyst is designed to address the challenges faced by refineries and petrochemical plants in processing sulfur-rich feedstocks, enabling them to boost production and enhance efficiency while meeting stringent environmental regulations.Sulfur-containing feedstocks are a common challenge for the industry, as they can lead to catalyst deactivation and reduced process efficiency. Traditional shift catalysts are particularly susceptible to sulfur poisoning, leading to the need for frequent regeneration and replacement. This not only increases operating costs but also results in downtime and reduced productivity.The Sulfur Tolerant Shift Catalyst, however, overcomes these limitations through its advanced formulation and unique chemical properties. The catalyst is highly resistant to sulfur poisoning, allowing it to maintain high activity and stability even in the presence of elevated sulfur levels. As a result, refineries and petrochemical plants can achieve longer catalyst life, reduced maintenance, and better performance, ultimately leading to improved operational efficiency and cost savings.In addition to its sulfur tolerance, the new catalyst also offers enhanced selectivity and activity, enabling higher conversion rates and improved hydrogen production. This is particularly beneficial for refineries and petrochemical plants looking to increase their capacity and output while minimizing their environmental footprint.The introduction of the Sulfur Tolerant Shift Catalyst underscores the company's continued commitment to driving innovation in the industry and providing sustainable solutions for its customers. By addressing the challenges associated with sulfur-containing feedstocks, the company is helping its clients to optimize their operations and achieve their production goals while complying with stringent environmental regulations.The Sulfur Tolerant Shift Catalyst is the latest addition to the company's extensive portfolio of catalyst and technology solutions, all of which are designed to enable refineries and petrochemical plants to enhance their processes, reduce emissions, and improve their overall performance. With a proven track record of delivering high-quality products and exceptional customer service, the company continues to be a trusted partner for its clients, providing them with the tools and expertise they need to succeed in an ever-changing industry.As the oil and gas industry faces increasing pressure to improve its environmental performance and operational efficiency, innovative solutions such as the Sulfur Tolerant Shift Catalyst will play a crucial role in driving progress and enabling sustainable growth. With its cutting-edge technology and uncompromising dedication to excellence, the company is well-positioned to continue leading the way in catalysis and process optimization, setting new standards for the industry and helping its clients achieve long-term success.

New Arsenic Removal Agent Shows Promising Results for Clean Drinking Water

Arsenic Removal Agent Proving to be Revolutionary in Water Treatment In today's society, access to clean and safe drinking water is essential for the health and well-being of people all over the world. Unfortunately, many communities are facing the challenge of dealing with high levels of arsenic in their water sources, posing significant health risks to the population. However, a revolutionary solution has emerged in the form of a groundbreaking Arsenic Removal Agent, developed by a leading environmental technology company, {company name}.{Company name} has been at the forefront of developing innovative solutions for water treatment and environmental remediation for over a decade. Their team of researchers and scientists have dedicated themselves to creating effective and sustainable solutions to address the pressing environmental challenges facing our world today. Their latest breakthrough in the form of the Arsenic Removal Agent has already shown great promise in effectively removing arsenic from water sources, making it safe for consumption and use in various applications.The Arsenic Removal Agent developed by {company name} is a proprietary blend of advanced materials and technologies that have been specifically engineered to target and remove arsenic from water. The agent works by effectively binding to arsenic molecules and removing them from the water, resulting in a significant reduction in arsenic levels that surpasses current industry standards. This innovative approach has the potential to transform the way communities and industries tackle the issue of arsenic contamination in their water sources.One of the key advantages of the Arsenic Removal Agent is its versatility and scalability. It can be easily integrated into existing water treatment systems, making it a practical and cost-effective solution for communities and industrial facilities dealing with arsenic contamination. The agent is also capable of handling high volumes of water, making it suitable for large-scale applications such as municipal water treatment plants and industrial facilities.Furthermore, {company name} has placed a strong emphasis on ensuring that their Arsenic Removal Agent is environmentally friendly and sustainable. The materials used in the agent are non-toxic and biodegradable, minimizing any potential impact on the environment. This commitment to environmental responsibility aligns with {company name}'s broader mission of developing solutions that not only address pressing environmental challenges but also do so in a way that is responsible and sustainable.The impact of the Arsenic Removal Agent developed by {company name} is already being felt in communities and industries grappling with arsenic contamination. In a recent pilot program conducted in a rural community affected by high levels of arsenic in their drinking water, the use of the agent resulted in a dramatic reduction in arsenic levels, providing the residents with access to safe and clean drinking water for the first time in years. The success of this pilot program has garnered attention from government agencies and non-profit organizations, positioning the Arsenic Removal Agent as a viable solution for addressing arsenic contamination in water sources.As {company name} continues to advance their efforts in promoting the Arsenic Removal Agent, they are actively collaborating with various stakeholders, including government agencies, non-profit organizations, and industry partners. These partnerships are essential in furthering the adoption and implementation of the agent in communities and industries affected by arsenic contamination, ultimately leading to a positive impact on public health and environmental sustainability.Looking ahead, {company name} is committed to furthering the development of their Arsenic Removal Agent and expanding its use to address arsenic contamination on a global scale. With a strong track record of delivering innovative environmental solutions, {company name} is well-positioned to play a pivotal role in addressing the pressing issue of arsenic contamination in water sources, offering hope and relief to communities and industries affected by this widespread problem.

Key Benefits of Gamma Alumina Catalyst in Various Industries

Gamma Alumina Catalyst, a leading provider of advanced catalyst solutions, has been making strides in the industry with its innovative products and dedication to sustainability.With a rich history spanning over two decades, Gamma Alumina Catalyst has established itself as a trusted partner to the chemical and petrochemical industry, providing high-performance catalysts for a wide range of applications. The company's commitment to research and development has led to the creation of cutting-edge catalyst technologies that offer superior performance and efficiency.Gamma Alumina Catalyst's flagship product, GammaCat-300, has gained recognition for its exceptional catalytic properties, which enable it to be used in various refining processes, including hydrocracking, hydrotreating, and catalytic reforming. The catalyst is known for its high activity, selectivity, and stability, making it an ideal choice for refineries looking to optimize their production processes.In addition to its focus on product innovation, Gamma Alumina Catalyst is also dedicated to sustainability and environmental stewardship. The company has made significant investments in research and development to develop catalysts that support environmentally friendly processes, contributing to reduced emissions and resource conservation.One of the key goals of Gamma Alumina Catalyst is to develop catalysts that enable refineries to meet increasingly stringent environmental regulations while maintaining high levels of productivity and profitability. This commitment to sustainability has earned the company a strong reputation within the industry and has positioned it as a leading provider of eco-friendly catalyst solutions.In recent years, Gamma Alumina Catalyst has expanded its reach globally, establishing partnerships with major refineries and chemical plants in various regions. The company's dedication to quality and customer satisfaction has earned it a loyal customer base, with many clients choosing Gamma Alumina Catalyst as their preferred catalyst supplier.Looking ahead, Gamma Alumina Catalyst is poised for further growth and expansion, with a continued focus on research and development to drive innovation in the catalyst industry. The company is actively exploring new opportunities and partnerships to bring its advanced catalyst solutions to even more markets around the world.Furthermore, Gamma Alumina Catalyst is committed to fostering a culture of excellence and continuous improvement within its organization. The company values its employees as its most important asset and has a strong emphasis on safety, training, and professional development.To support its ambitious growth plans, Gamma Alumina Catalyst has invested in state-of-the-art production facilities and laboratory infrastructure, ensuring that its catalysts are produced to the highest standards of quality and consistency. This commitment to excellence has been recognized by industry analysts and has helped solidify the company's position as a leading catalyst supplier.In conclusion, Gamma Alumina Catalyst has emerged as a key player in the global catalyst industry, delivering innovative and sustainable solutions to its customers. With a strong foundation built on research, development, and a customer-centric approach, the company is well-positioned for continued success and growth in the years to come.As the industry continues to evolve, Gamma Alumina Catalyst remains dedicated to providing advanced catalyst solutions that enable its clients to achieve their production goals while minimizing their environmental footprint. With a focus on innovation, sustainability, and customer satisfaction, Gamma Alumina Catalyst is set to lead the way in the catalyst industry for years to come.

Innovative catalyst technology for sustainable industrial processes

Clariant Catalyst, a leading global company in the field of catalysts and specialty chemicals, has recently made significant advancements in the development of innovative catalytic solutions for a wide range of industrial processes. With a focus on sustainability and efficiency, the company is dedicated to providing high-quality catalysts that enable its customers to achieve their production goals while reducing environmental impact.Founded in [year], Clariant Catalyst has built a strong reputation for delivering cutting-edge solutions that address the evolving needs of various industries, including petrochemicals, refining, and chemical manufacturing. The company's extensive portfolio of catalysts encompasses a diverse array of applications, from hydroprocessing and emissions control to renewable fuel production and polymerization.In recent years, Clariant Catalyst has made substantial investments in research and development to expand its product offerings and enhance the performance of its existing catalysts. Leveraging its state-of-the-art laboratories and technical expertise, the company has continuously pushed the boundaries of innovation, resulting in the introduction of several breakthrough catalyst technologies that deliver superior efficiency and cost-effectiveness.One of Clariant Catalyst's notable achievements is the successful development of a novel catalyst designed to improve the production of renewable fuels from biomass and waste materials. This advancement is aligned with the company's commitment to sustainable solutions, as it enables the conversion of non-traditional feedstocks into high-quality biofuels that can reduce greenhouse gas emissions and contribute to the transition to a low-carbon economy.Additionally, Clariant Catalyst has made significant progress in the optimization of catalysts for emissions control, particularly in the reduction of harmful pollutants from industrial processes and vehicle exhaust systems. By utilizing advanced chemical formulations and engineering techniques, the company has been able to achieve remarkable results in minimizing the environmental impact of various combustion processes, thus supporting global efforts to improve air quality and public health.Furthermore, Clariant Catalyst has expanded its expertise in the area of catalytic technologies for sustainable chemical manufacturing, with a focus on enabling the production of key building blocks for the synthesis of specialty chemicals and polymers. Through the development of highly selective and durable catalysts, the company has empowered its customers to streamline their production processes and enhance the overall efficiency of their operations.In line with its dedication to sustainability, Clariant Catalyst has also been proactive in addressing the challenges associated with the circular economy, offering catalyst solutions that facilitate the recycling and upcycling of plastics and other materials. By enabling the conversion of waste streams into valuable chemical intermediates, the company is actively contributing to the reduction of waste and the promotion of a more circular and sustainable approach to resource utilization.With a global presence and a strong commitment to customer partnerships, Clariant Catalyst has established itself as a trusted and reliable provider of catalyst solutions, serving a diverse customer base that spans across the Americas, Europe, and Asia. The company's collaborative approach and customized technical support have positioned it as a preferred collaborator for businesses seeking to enhance the performance and sustainability of their operations.Looking ahead, Clariant Catalyst remains dedicated to driving innovation and advancing the frontiers of catalytic technology, with a continued focus on delivering value-added solutions that enable its customers to achieve their strategic objectives while minimizing their environmental footprint. By blending its technical expertise with a forward-thinking mindset, the company is poised to play a pivotal role in shaping the future of sustainable catalysis and chemical processing.In conclusion, Clariant Catalyst's relentless pursuit of excellence and sustainability in catalytic solutions has positioned it as a leading force in the industry, driving positive change and value creation for its customers and society as a whole. As the company continues to push the boundaries of innovation and expand its global footprint, it remains committed to making a lasting impact through its cutting-edge catalyst offerings.

Alumina Market Update: Recent Developments and Forecast

Gama Alumina and its Remarkable Contributions to the Global IndustryGama Alumina, a leading alumina producer, has been making significant strides in the global industry. The company, established in 2005, has become known for its commitment to quality, innovation, and sustainability. Gama Alumina has proven itself to be a key player in the industry and has continually demonstrated its dedication to meeting the ever-growing demands of the market.Gama Alumina is a subsidiary of a larger corporation that has a strong presence in the global market. The company has a strong emphasis on utilizing the latest technology and adhering to strict quality standards in every aspect of its operations. This approach has allowed Gama Alumina to maintain its position as a trusted and reliable supplier of high-quality alumina products.One of the key factors that set Gama Alumina apart from its competitors is its commitment to sustainability. The company places a high priority on environmentally friendly practices, and this is reflected in its operations. By implementing sustainable and responsible mining and production methods, Gama Alumina seeks to minimize its environmental impact and contribute to a more sustainable future.Additionally, Gama Alumina has made significant investments in research and development to continuously improve its products and processes. This commitment to innovation has enabled the company to stay ahead of the curve and meet the evolving needs of its customers. It has also allowed Gama Alumina to offer a diverse range of high-quality alumina products that cater to various industries.Gama Alumina's products are widely used in the production of aluminum, ceramics, and other materials essential to numerous industries. The company's high-purity alumina is particularly sought after for its superior properties, making it a preferred choice for manufacturers worldwide. The versatility and reliability of Gama Alumina's products have cemented its reputation as a trusted partner in the industry.In addition to its impressive product range, Gama Alumina also places a strong emphasis on customer satisfaction. The company's commitment to providing excellent service and support to its clients has earned it a loyal customer base. Gama Alumina's team of experienced professionals works closely with customers to understand their specific requirements and provide tailored solutions to meet their needs.Gama Alumina's dedication to excellence has not gone unnoticed, as the company has received industry accolades and certifications for its superior products and sustainable practices. Its unwavering commitment to quality and environmental stewardship has led to recognition as a leader in the industry.Looking to the future, Gama Alumina is poised to continue its upward trajectory as a top alumina producer. The company's focus on innovation, sustainability, and customer satisfaction will undoubtedly drive its success and solidify its position in the global market.As Gama Alumina continues to expand its reach and influence, it remains committed to upholding its core values and delivering superior products and services. With its unwavering dedication to quality and sustainability, Gama Alumina is set to remain a driving force in the industry for years to come.

Effective Tail Gas Hydrogenation Catalyst for Improved Emission Control

Tail Gas Hydrogenation Catalyst is a crucial component in the petrochemical industry, as it plays a key role in the purification of tail gas emissions. This catalyst is designed to remove sulfur compounds from the tail gas streams, ensuring compliance with environmental regulations and producing clean and efficient energy. One of the leading manufacturers in the field of Tail Gas Hydrogenation Catalyst is a company that has been at the forefront of technological innovation in the petrochemical industry for over three decades. With a strong focus on research and development, this company has developed a wide range of catalysts and solutions that have revolutionized the way petrochemical processes are carried out.The Tail Gas Hydrogenation Catalyst manufactured by this company is known for its high efficiency and reliability. It is designed to operate at high temperatures and pressures, ensuring optimum performance in the most demanding industrial environments. The catalyst is also engineered to have a long lifespan, reducing the need for frequent replacements and maintenance, which helps in reducing operational costs for the end-users.The company's Tail Gas Hydrogenation Catalyst is a result of years of dedicated research and development. Their team of experts has worked tirelessly to create a catalyst that not only meets but exceeds the industry standards. With a commitment to sustainability, the company has also ensured that their catalysts are environmentally friendly and have a minimal impact on the planet.In addition to its technical prowess, the company also prides itself on its customer-centric approach. They work closely with their clients to understand their specific requirements and provide tailored solutions that meet their needs. This level of personalized service has earned the company a stellar reputation in the industry, with clients ranging from small businesses to multinational corporations.To ensure the quality and reliability of their Tail Gas Hydrogenation Catalyst, the company has implemented stringent quality control measures at every stage of the manufacturing process. From raw material selection to final product testing, every aspect is carefully monitored to ensure that only the highest quality catalysts are delivered to the customers.Furthermore, the company is committed to ongoing research and development to continuously improve its products and stay ahead of the competition. This dedication to innovation has led to the development of cutting-edge technologies and solutions that have helped their clients achieve new levels of efficiency and productivity.With a global presence, the company has established a strong network of partners and distributors to cater to the needs of the petrochemical industry worldwide. Their Tail Gas Hydrogenation Catalyst has been acclaimed by clients across the globe for its exceptional performance and reliability.As the petrochemical industry continues to evolve, the demand for efficient and sustainable solutions like the Tail Gas Hydrogenation Catalyst is expected to grow. With its proven track record and unwavering commitment to excellence, the company is well-positioned to meet this growing demand and continue to lead the way in the field of petrochemical catalysts.

Uncovering the Potential of Residue Hydrogenation Catalysts

Residue Hydrogenation Catalyst Promises to Revolutionize the Oil and Gas IndustryThe oil and gas industry is constantly searching for new technologies to improve efficiency and sustainability. One company at the forefront of this effort is {Company Name}, a leading provider of catalysts and chemical solutions for the oil and gas sector. With a strong commitment to innovation and continuous improvement, {Company Name} has recently introduced a groundbreaking Residue Hydrogenation Catalyst that is poised to revolutionize the industry.Residue hydrogenation is a crucial process in the refining of crude oil, which involves the removal of impurities and the conversion of heavy hydrocarbons into more valuable products such as gasoline and diesel. Traditionally, this process has been carried out using conventional catalysts that are limited in their ability to achieve high levels of conversion and selectivity. However, the new Residue Hydrogenation Catalyst from {Company Name} promises to address these limitations and deliver significant improvements in performance.The key to the success of the Residue Hydrogenation Catalyst lies in its advanced formulation, which is based on cutting-edge research and development conducted by {Company Name}'s team of highly skilled scientists and engineers. By leveraging state-of-the-art technologies and innovative approaches, the company has created a catalyst that offers superior activity, stability, and selectivity, thereby enabling refineries to achieve higher throughput, lower operating costs, and greater flexibility in product output.In addition to its technical advantages, the Residue Hydrogenation Catalyst also delivers environmental benefits by enabling refineries to produce cleaner and higher-quality fuels. With its ability to remove sulfur, nitrogen, and other impurities from crude oil, the catalyst helps to reduce emissions of harmful pollutants and improve air quality, thereby contributing to a more sustainable and eco-friendly energy sector.{Company Name} is committed to supporting its customers in the successful implementation of the Residue Hydrogenation Catalyst, offering a comprehensive range of technical services and solutions to ensure optimal performance and maximum value. From catalyst evaluation and selection to process optimization and troubleshooting, the company's team of experts provides tailored support to help refineries achieve their production and environmental goals.With its track record of delivering innovative and reliable solutions, {Company Name} has earned the trust and confidence of leading players in the oil and gas industry, establishing itself as a preferred partner for catalysts and chemical solutions. By introducing the Residue Hydrogenation Catalyst, the company reaffirms its commitment to driving progress and creating value for its customers, while contributing to the advancement of the industry as a whole.The launch of the Residue Hydrogenation Catalyst marks a significant milestone for {Company Name} and the oil and gas industry, ushering in a new era of enhanced performance, sustainability, and competitiveness. As refineries worldwide seek to optimize their operations and adapt to evolving market demands, the new catalyst promises to play a pivotal role in shaping the future of the industry, unlocking new opportunities and driving continued growth and prosperity.In conclusion, the Residue Hydrogenation Catalyst from {Company Name} represents a game-changing innovation that has the potential to transform the oil and gas industry, offering a compelling mix of technical excellence, environmental responsibility, and business value. As the company continues to lead the way in delivering advanced catalysts and chemical solutions, it is poised to make a lasting and positive impact on the global energy landscape, driving progress and sustainability for the benefit of all stakeholders.