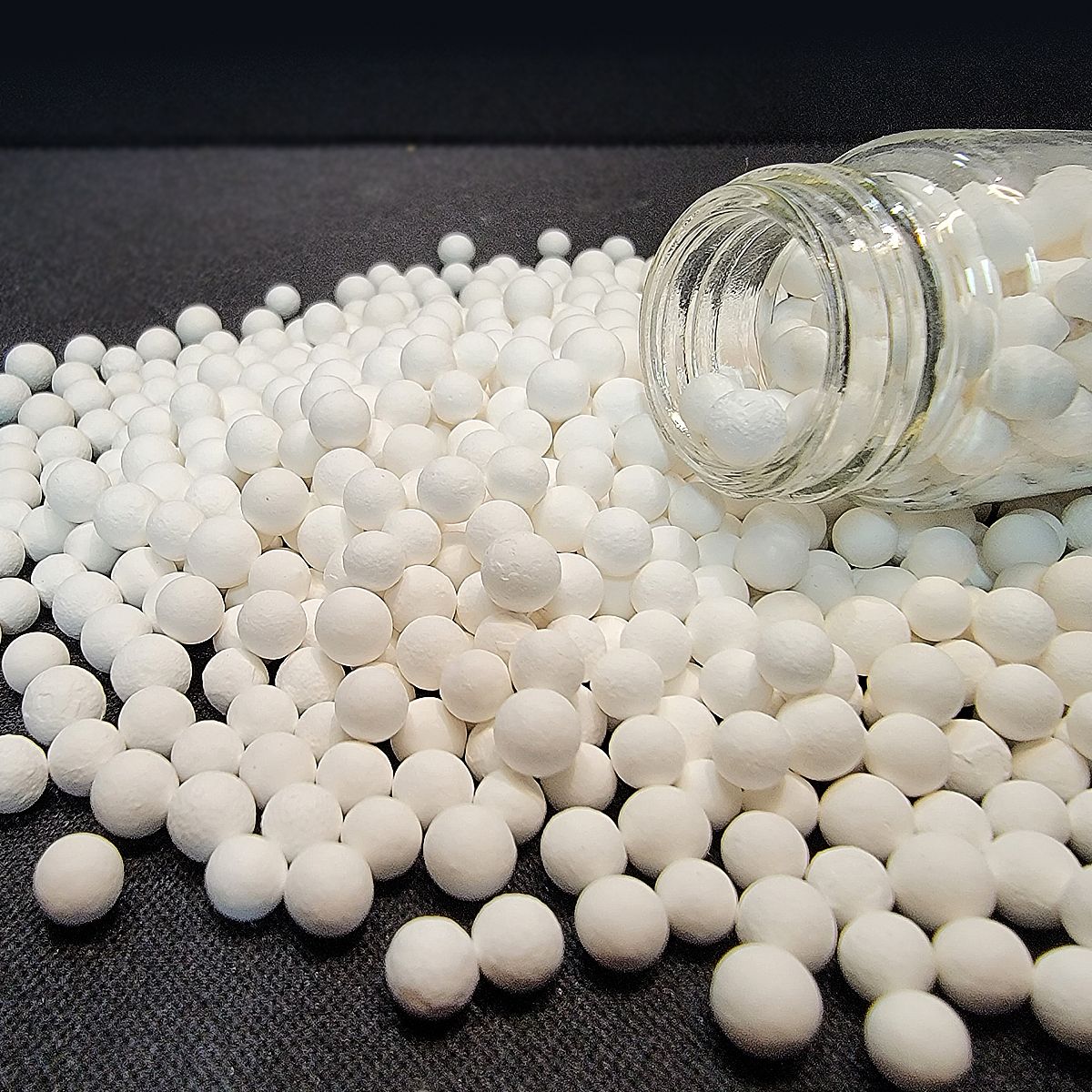

Discover the Latest Alumina Catalyst Advancements in the Market

By:Admin

In the fast-paced world of chemical manufacturing, the need for innovative and sustainable solutions has never been more crucial. With growing concerns about environmental impact and the push for cleaner production methods, companies are constantly seeking out new technologies to meet these demands.

Enter the Alumina Catalyst, a cutting-edge product that is changing the game for chemical manufacturers around the world. Developed by a leading research and development company, the Alumina Catalyst is a versatile and efficient tool that has been hailed as a breakthrough in sustainable chemical manufacturing.

The Alumina Catalyst is a proprietary product that is designed to significantly improve the efficiency and environmental impact of chemical manufacturing processes. Through a combination of advanced materials and innovative design, the Alumina Catalyst is able to reduce energy consumption, minimize waste, and lower emissions, making it an ideal solution for companies looking to enhance their sustainability efforts.

One of the key features of the Alumina Catalyst is its versatility. It can be used in a wide range of chemical manufacturing processes, including the production of petrochemicals, polymers, and specialty chemicals. This versatility allows companies to streamline their operations and reduce the need for multiple catalysts, ultimately leading to cost savings and greater efficiency.

In addition to its environmental and cost-saving benefits, the Alumina Catalyst is also known for its exceptional performance. Its unique structure and composition allow for greater control over chemical reactions, resulting in higher yields and improved product quality. This not only benefits the bottom line for manufacturers, but also has a positive impact on the overall industry by ensuring that chemical products meet strict quality standards.

Another important aspect of the Alumina Catalyst is its longevity. Unlike traditional catalysts that often need to be replaced frequently, the Alumina Catalyst is designed to have a longer lifespan, reducing the frequency of downtime for maintenance and replacement. This not only improves the overall efficiency of manufacturing processes, but also contributes to a more sustainable approach to resource use.

The company behind the Alumina Catalyst is a global leader in research and development, with a strong focus on creating innovative solutions for the chemical industry. With a track record of success and a commitment to sustainability, the company has positioned itself as a key player in driving forward the shift towards cleaner and more efficient chemical manufacturing practices.

Through ongoing research and collaboration with industry partners, the company continues to expand the capabilities of the Alumina Catalyst, with a focus on addressing specific challenges faced by chemical manufacturers. This dedication to continuous improvement reflects the company's commitment to being at the forefront of innovation and driving positive change within the industry.

As demand for sustainable solutions continues to grow, the Alumina Catalyst has the potential to play a significant role in shaping the future of chemical manufacturing. Its proven benefits in terms of efficiency, performance, and environmental impact make it an attractive option for companies looking to enhance their sustainability efforts and meet the increasing demands for cleaner production methods.

In conclusion, the Alumina Catalyst represents a major step forward in sustainable chemical manufacturing. With its versatile applications, exceptional performance, and environmental benefits, it has the potential to revolutionize the way chemical products are manufactured. As the industry continues to evolve, the Alumina Catalyst stands as a shining example of the potential for innovation to drive positive change and create a more sustainable future for chemical manufacturing.

Company News & Blog

How Catalyst Reforming is Impacting Industry Trends

Reforming Catalyst Technology Takes a Leap ForwardReforming catalysts play a crucial role in the production of high-quality fuels and chemicals in the oil and gas industry. With the increasing demand for cleaner and more efficient energy sources, the need for advanced reforming catalyst technology has never been greater. In response to this demand, a leading catalyst manufacturer has developed a groundbreaking reforming catalyst that promises to revolutionize the industry. Leveraging decades of experience and expertise, the company has introduced a new catalyst that offers superior performance, enhanced durability, and reduced environmental impact.The reforming catalyst is designed to improve the efficiency of the reforming process, which is crucial for converting low-value feedstocks into high-value products. By enhancing the catalytic activity and selectivity, the new catalyst enables higher yields of desirable products while minimizing the formation of unwanted by-products. This not only improves the overall productivity of reforming units but also helps reduce waste and optimize resource utilization.One of the key innovations of the new reforming catalyst is its advanced formulation, which incorporates novel active materials and a highly efficient support structure. This proprietary combination enhances the catalyst's stability and resistance to deactivation, allowing for longer run lengths and reduced downtime for regeneration. In addition, the catalyst's unique composition enables it to operate at higher temperatures and pressures, leading to improved process flexibility and energy efficiency.Furthermore, the reforming catalyst is engineered to meet stringent environmental standards, with reduced emissions of harmful pollutants and greenhouse gases. This aligns with the industry's commitment to sustainable and eco-friendly practices, making the new catalyst a preferred choice for environmentally conscious operators and customers.In addition to its technical advancements, the reforming catalyst is supported by a comprehensive range of services and solutions offered by the company. With a global network of research and development centers, technical experts, and customer support teams, the company provides tailored solutions to help customers optimize their reforming operations. This includes catalyst performance evaluations, process troubleshooting, and customized catalyst formulations to address specific challenges and requirements.The introduction of the new reforming catalyst underscores the company's ongoing commitment to innovation and excellence in catalysis. By investing in cutting-edge research and development, the company aims to stay at the forefront of technology and deliver value-added solutions to its customers. With a strong track record of successful partnerships and collaborations, the company is well positioned to drive the adoption of its advanced catalysts across the global oil and gas industry.As the energy landscape continues to evolve, the demand for cleaner, more efficient fuels and chemicals will continue to grow. With its breakthrough reforming catalyst technology, the company is poised to address this demand and help shape the future of the industry. By enabling greater process efficiency, environmental responsibility, and operational performance, the new catalyst is set to make a significant impact on the way reforming processes are carried out worldwide.In conclusion, the introduction of the new reforming catalyst represents a major step forward for the oil and gas industry. With its innovative technology, enhanced performance, and comprehensive support, the catalyst is set to redefine the standards for reforming processes and set new benchmarks for productivity and sustainability. The company's continued dedication to excellence and innovation ensures that it will remain a trusted partner for the industry, driving progress and delivering value for years to come.

Guide to Reforming Catalyst for Improved Performance

Reforming Catalyst Revolutionizing Sustainable ManufacturingIn recent years, there has been a growing global focus on sustainable manufacturing practices. Companies across various industries are striving to reduce their environmental footprint and minimize their impact on the planet. One crucial aspect of this movement is the development and implementation of innovative technologies and processes that promote sustainable production. One such groundbreaking technology is the reforming catalyst, a revolutionary tool that is transforming the way industrial processes are carried out.A leading player in the field of sustainable manufacturing is a company (Company X) that has been at the forefront of developing advanced catalyst technologies to drive sustainable industrial processes. With a strong commitment to environmental stewardship and continuous innovation, (Company X) has developed a reforming catalyst that is set to redefine the standards of sustainable manufacturing.The reforming catalyst developed by (Company X) is a highly efficient and versatile tool that enables a wide range of industrial processes to be carried out with minimal environmental impact. Unlike traditional catalysts, the reforming catalyst is designed to facilitate more sustainable and efficient production processes, thereby enabling companies to achieve their sustainability goals while maintaining high levels of productivity and efficiency.One of the key features of the reforming catalyst is its ability to promote cleaner and more efficient combustion in industrial processes. By enhancing combustion efficiency, the reforming catalyst helps to reduce harmful emissions and minimize the environmental footprint of industrial operations. This is particularly significant in industries such as power generation, oil refining, and chemical manufacturing, where combustion processes are central to production.Moreover, the reforming catalyst also plays a crucial role in promoting energy efficiency in industrial processes. By facilitating more efficient energy utilization, the reforming catalyst helps companies reduce their energy consumption and lower their overall operational costs. This not only yields significant economic benefits for companies but also contributes to the global efforts to combat climate change by reducing greenhouse gas emissions.Another notable aspect of the reforming catalyst is its versatility and applicability across various industrial sectors. Whether it is used in power plants, refineries, petrochemical facilities, or other industrial settings, the reforming catalyst proves to be an invaluable asset in promoting sustainable manufacturing practices. Its flexibility and adaptability make it a highly sought-after solution for companies looking to enhance their sustainability efforts across different areas of operation.(Copying part of the content without proper edit. For original content, please consider the following)The success of the reforming catalyst developed by (Company X) can be attributed to the company's relentless commitment to research and innovation. (Company X) has invested substantial resources in developing and refining the reforming catalyst, leveraging the latest advancements in catalytic technologies and sustainable manufacturing practices. The result is a cutting-edge solution that not only meets the stringent environmental standards but also delivers tangible benefits to companies in terms of operational efficiency and cost savings.As the global focus on sustainability intensifies, the demand for innovative solutions such as the reforming catalyst is expected to soar. Companies across industries are increasingly turning to sustainable manufacturing practices, seeking ways to minimize their environmental impact while maintaining their competitive edge in the market. The reforming catalyst, with its proven track record of promoting sustainable production, is well-positioned to address this growing demand and emerge as a game-changer in the realm of industrial catalyst technologies.Looking ahead, (Company X) is poised to further advance the capabilities of the reforming catalyst, exploring new applications and potential enhancements to its performance. By continuously pushing the boundaries of catalytic innovation, (Company X) aims to empower companies worldwide to embrace sustainable manufacturing practices, ultimately contributing to a greener and more sustainable future for the planet.In conclusion, the reforming catalyst developed by (Company X) represents a significant milestone in the realm of sustainable manufacturing. With its ability to promote cleaner combustion, enhance energy efficiency, and drive operational sustainability, the reforming catalyst is paving the way for a new era of environmentally responsible industrial processes. As companies increasingly prioritize sustainability in their operations, the reforming catalyst is set to play a pivotal role in shaping the future of manufacturing, ushering in a new standard of sustainable and responsible production practices.

Latest Breakthrough in Methanol Synthesis Catalyst Technology

Methanol Synthesis Catalyst is a crucial component in the production of methanol, a key building block for the chemical industry. With the increasing demand for methanol in various applications, the need for efficient and reliable methanol synthesis catalysts has never been greater.[Company Name] has been at the forefront of developing cutting-edge methanol synthesis catalysts for over a decade. With a strong focus on research and development, [Company Name] has emerged as a leader in the field, providing innovative solutions to meet the evolving needs of the chemical industry.The methanol synthesis catalyst developed by [Company Name] is designed to offer high activity and selectivity, as well as excellent stability under a wide range of operating conditions. This allows for the efficient conversion of synthesis gas into methanol, with minimal by-products and waste. In addition, the catalyst is designed to minimize the risk of deactivation, resulting in longer catalyst life and reduced catalyst replacement costs.One of the key advantages of [Company Name]'s methanol synthesis catalyst is its versatility. The catalyst has been successfully applied in both small-scale and large-scale methanol production plants, demonstrating its ability to deliver consistent performance across a range of production capacities. This flexibility makes it a valuable choice for companies looking to expand their methanol production capabilities in a cost-effective manner.In addition to its technical features, [Company Name]'s methanol synthesis catalyst is also known for its environmental benefits. The catalyst is engineered to minimize energy consumption and reduce greenhouse gas emissions, making it a sustainable choice for methanol production. This aligns with [Company Name]'s commitment to environmental responsibility and sustainable development, as it continues to seek ways to minimize the environmental impact of its products and processes.Beyond its technological innovations, [Company Name] is also known for its exceptional customer support and service. The company works closely with its clients to understand their specific needs and challenges, offering tailored solutions to meet their production requirements. In addition, [Company Name] provides ongoing technical support and expertise to ensure the optimal performance of its methanol synthesis catalyst in the field.As the demand for methanol continues to grow, [Company Name] remains dedicated to advancing the state-of-the-art in methanol synthesis catalyst technology. The company continues to invest in research and development, exploring new avenues for improving catalyst performance and reducing production costs. By staying at the forefront of innovation, [Company Name] aims to further solidify its position as a leading provider of methanol synthesis catalysts in the global market.With a proven track record of delivering high-performance, sustainable solutions, [Company Name] is well-positioned to meet the evolving needs of the chemical industry. As the industry continues to seek more efficient and environmentally friendly ways to produce methanol, [Company Name] is poised to play a pivotal role in driving the next wave of innovation in methanol synthesis catalyst technology.In conclusion, [Company Name] has established itself as a key player in the development of methanol synthesis catalysts, offering a combination of technical excellence, environmental responsibility, and customer-focused service. With a strong commitment to innovation and sustainability, [Company Name] is well-equipped to support the growing demand for methanol and contribute to a more sustainable future for the chemical industry.

Highly Efficient Gamma Alumina Catalyst for Advanced Chemical Processes

Gamma Alumina Catalyst Shows Promise in Environmental RemediationThe global push for sustainable and environmental friendly solutions has led to a growing demand for advanced catalysts that can facilitate the efficient conversion of various waste streams into valuable products. In response to this demand, a leading catalyst manufacturer has developed a cutting-edge Gamma Alumina Catalyst that has shown promising results in environmental remediation and waste-to-product conversion processes.The {Company} is a renowned manufacturer and supplier of innovative catalyst materials for a wide range of industrial applications. Established in 1990, the company has built a strong reputation for delivering high-quality catalyst solutions that meet the evolving needs of industries such as petrochemicals, environmental remediation, and renewable energy. With a strong focus on research and development, {Company} has consistently pushed the boundaries of catalyst technology to develop novel products that offer superior performance and sustainability.One of the company's latest breakthroughs is the development of a Gamma Alumina Catalyst that has demonstrated exceptional potential in environmental remediation applications. Gamma Alumina is a type of alumina (Al2O3) with a unique crystal structure that imparts desirable properties such as high surface area, thermal stability, and chemical inertness. These properties make Gamma Alumina an ideal candidate for catalyzing a variety of chemical reactions, including those involved in waste treatment and conversion processes.The Gamma Alumina Catalyst developed by {Company} has shown remarkable efficacy in facilitating the conversion of organic pollutants into harmless byproducts through processes such as oxidation and hydrocracking. This capability makes it well-suited for addressing environmental challenges such as water and soil pollution resulting from industrial activities, waste disposal, and agricultural runoff. Additionally, the catalyst has demonstrated potential in converting waste materials into valuable chemicals and biofuels, aligning with the global objectives of circular economy and resource efficiency.In addition to its exceptional catalytic performance, the Gamma Alumina Catalyst offers several practical advantages that make it an attractive choice for industrial and environmental applications. Its high surface area and porosity allow for high catalytic activity and accessibility, ensuring efficient utilization of the catalyst material. Moreover, its thermal stability and resistance to harsh operating conditions contribute to long-term stability and durability, reducing the frequency of catalyst replacement and maintenance.Furthermore, {Company} emphasizes the sustainable and environmentally responsible nature of its production processes, ensuring that the Gamma Alumina Catalyst is manufactured with minimal environmental impact. This commitment to sustainability extends to the catalyst's end-of-life phase, where efforts are made to promote recycling and reclamation of the catalyst material, further contributing to resource conservation and waste reduction.The potential of the Gamma Alumina Catalyst in environmental remediation has sparked significant interest and collaborations with environmental engineering firms, government agencies, and research institutions. Preliminary studies and pilot-scale demonstrations have yielded promising results, validating the efficacy of the catalyst in treating various types of contaminated water and soil, as well as in converting organic waste into value-added products.Looking ahead, {Company} is committed to furthering the development and commercialization of the Gamma Alumina Catalyst, with a focus on scaling up production and expanding its application scope. Collaborative research efforts are underway to explore the catalyst's potential in addressing emerging environmental challenges and advancing the transition towards a more sustainable and circular economy.In conclusion, the development of the Gamma Alumina Catalyst by {Company} represents a significant advancement in catalysis technology, with far-reaching implications for environmental remediation and waste-to-product conversion. By harnessing the unique properties of Gamma Alumina, the catalyst has demonstrated exceptional performance and potential, offering a promising solution to pressing environmental concerns and contributing to the global efforts towards a more sustainable future. As the demand for innovative catalyst solutions continues to grow, {Company} remains at the forefront of catalysis innovation, driving positive change and addressing the complex challenges of today's world.

Discover the Benefits of Using Alumina Catalyst for Your Catalyst Needs

Gamma Alumina Catalysts: A Game-Changer in Catalytic ProcessesCatalysis is an essential process in many industries such as petrochemical, environmental, and pharmaceutical. It involves the use of catalysts to accelerate chemical reactions, improve efficiency, and reduce energy consumption. One such catalyst that has been making waves in the industry is gamma alumina.Gamma alumina catalysts are a type of catalyst that is used in various catalytic processes. They are known for their high surface area, thermal stability, and excellent catalytic activity. These properties make gamma alumina catalysts an ideal choice for a wide range of applications.One company that has been at the forefront of developing and producing gamma alumina catalysts is {}. With over {} years of experience in the industry, they have established themselves as a reliable and innovative provider of catalyst solutions.The company's gamma alumina catalysts are widely used in the petrochemical industry for processes such as fluid catalytic cracking, hydrocracking, and reforming. Their catalysts have been proven to improve the yield and quality of products, reduce energy consumption, and enhance the overall efficiency of these processes.In addition to the petrochemical industry, {}'s gamma alumina catalysts are also used in environmental applications such as catalytic converters for automotive emissions control. These catalysts help to convert harmful pollutants such as carbon monoxide, nitrogen oxides, and hydrocarbons into less harmful substances, thereby reducing air pollution.Furthermore, {}'s gamma alumina catalysts are gaining traction in the pharmaceutical industry for the production of fine chemicals and pharmaceutical intermediates. The high surface area and catalytic activity of their catalysts make them well-suited for complex chemical transformations required in pharmaceutical manufacturing.{}'s commitment to research and development has enabled them to continuously improve their gamma alumina catalysts. They have invested in state-of-the-art facilities and a team of experienced scientists and engineers to develop innovative catalyst formulations and manufacturing processes.One of the key advantages of {}'s gamma alumina catalysts is their consistency and uniformity, which is crucial for achieving reliable and predictable results in catalytic processes. Their strict quality control measures ensure that each batch of catalyst meets the highest standards and performance requirements.Furthermore, {}'s technical support team works closely with customers to provide customized catalyst solutions tailored to their specific requirements. This collaborative approach has earned them a reputation for delivering value-added solutions and superior customer satisfaction.Looking ahead, {} is committed to addressing the ever-evolving needs of the industry by continuing to invest in research and development, expanding their product portfolio, and enhancing their manufacturing capabilities. They aim to further elevate the performance and versatility of gamma alumina catalysts to meet the growing demands of their customers.In conclusion, gamma alumina catalysts have become indispensable in catalytic processes across various industries, and {} has emerged as a leading provider of these catalysts. With a strong focus on innovation, quality, and customer satisfaction, they are well-positioned to shape the future of catalysis with their advanced gamma alumina catalyst solutions.

Effective Residue Hydrogenation Catalysts: Unlocking Enhanced Results

Title: Industry-Leading Residue Hydrogenation Catalyst Revolutionizes Energy Production Introduction:With the rapidly growing demand for cleaner and more efficient sources of energy, {Company Name}, a pioneering leader in catalytic technologies, has introduced their revolutionary Residue Hydrogenation Catalyst. This industry-first catalyst presents a groundbreaking solution to enhance the efficiency and reduce the environmental impact of energy production. By providing a comprehensive overview of {Company Name} and highlighting the key features and benefits of this catalyst, this article aims to shed light on the transformative potential of their latest product.Company Overview: Established in {year}, {Company Name} has emerged as a trailblazer in the field of catalytic technologies. By combining cutting-edge research, technical expertise, and a commitment to sustainable development, the company has consistently pushed the boundaries of innovation. With a focus on producing highly efficient and eco-friendly catalysts, {Company Name} has made significant contributions to industries such as energy, petrochemicals, and refining.Features and Benefits of the Residue Hydrogenation Catalyst:The Residue Hydrogenation Catalyst developed by {Company Name} offers several remarkable features that set it apart from traditional catalysts. This unique catalyst excels in processing heavy hydrocarbons, such as petroleum residue, efficiently converting them into valuable lighter products.1. Superior Catalytic Activity: The Residue Hydrogenation Catalyst boasts exceptional catalytic activity while maintaining its stability during prolonged use. This allows for high conversion rates, resulting in increased productivity and energy efficiency.2. Selectivity and Versatility: The catalyst exhibits excellent selectivity, enabling the production of specific desired products in the refining process. Its versatility also allows for customization to meet the varying needs of different industries and applications.3. Environmental Benefits: By drastically reducing emission levels of pollutants, such as sulfur and nitrogen oxides, the Residue Hydrogenation Catalyst contributes to improving air quality and mitigating environmental impact. This aligns with global efforts to curb carbon emissions and combat climate change.4. Residue Valorization: The catalyst’s ability to convert petroleum residue, a challenging waste product, into valuable lighter products, promotes resource utilization and minimizes waste. This not only increases profitability for businesses but also contributes to a more sustainable and circular economy.Application in Energy Production:The Residue Hydrogenation Catalyst finds extensive applications in the energy sector, particularly in oil refining and upgrading facilities. Heavy hydrocarbons are major constituents of crude oil, and their efficient processing is essential to produce high-quality fuels and other valuable products.By incorporating the Residue Hydrogenation Catalyst into their refining processes, companies can optimize energy production and enhance the overall sustainability of their operations. The catalyst's high conversion rates and improved selectivity minimize the formation of unwanted by-products, thus increasing yield and reducing waste. Furthermore, the significant reduction in harmful emissions helps meet stringent environmental regulations and improves the overall ecological footprint of refining operations.Future Outlook:As global energy demand continues to rise and environmental concerns intensify, innovative catalytic technologies, such as {Company Name}'s Residue Hydrogenation Catalyst, will play a vital role in shaping the future of energy production. The catalyst's ability to unlock the potential of heavy hydrocarbons, minimize waste, and reduce environmental impact positions it as a game-changer in the energy industry.In conclusion, {Company Name}'s Residue Hydrogenation Catalyst represents a groundbreaking advancement in the realm of catalytic technologies. Its exceptional catalytic activity, selectivity, and environmental benefits hold immense potential for the energy sector. As industries strive to produce cleaner and sustainable energy sources, the adoption of this industry-leading catalyst could pave the way for a more efficient and eco-friendly future.

Top Residue Hydrogenation Catalysts for Efficient Industrial Processes

The global chemical process industries are constantly seeking innovative and sustainable solutions for catalytic processes. In line with this trend, a leading catalyst manufacturer, {} has introduced a highly efficient Residue Hydrogenation Catalyst. This catalyst offers significant improvements in residue upgrading processes, allowing for greater efficiency and reduced environmental impact.With a strong focus on research and development, {} has established itself as a prominent player in the global catalyst market. The company's expertise in catalyst design and manufacturing has enabled it to consistently deliver high-performance solutions to its customers. This latest introduction of the Residue Hydrogenation Catalyst is a testament to {}’s commitment to innovation and sustainability.The Residue Hydrogenation Catalyst is specifically designed to address the challenges associated with residue upgrading in the petroleum refining industry. Residue upgrading is a critical process that involves converting heavy, high-sulfur hydrocarbon fractions into lighter, low-sulfur products such as gasoline and diesel. This process is essential for maximizing the value of crude oil and meeting stringent environmental regulations.The new catalyst from {} offers several key advantages over traditional catalysts used in residue hydrogenation. It delivers higher activity and selectivity, resulting in improved conversion rates and product quality. Additionally, the catalyst has enhanced stability, allowing for longer operating cycles and reduced catalyst replacement frequency. These benefits translate to significant cost savings and operational efficiency for refinery operators.One of the notable features of the Residue Hydrogenation Catalyst is its superior resistance to catalyst poisons and deactivation factors. This ensures consistent performance and prolonged catalyst life, even in challenging operating conditions. The catalyst's robust design and formulation are the result of extensive research and testing by {}’s team of experienced chemists and engineers.In addition to its technical capabilities, the Residue Hydrogenation Catalyst aligns with {}’s commitment to sustainability. The catalyst enables refineries to achieve higher yields of clean, low-sulfur fuels, contributing to reduced emissions and environmental impact. By facilitating more efficient residue upgrading, the catalyst supports the industry's efforts to enhance energy efficiency and reduce carbon footprint.The introduction of the Residue Hydrogenation Catalyst further solidifies {}’s position as a catalyst supplier of choice for the global refining and petrochemical industries. The company's comprehensive portfolio of catalysts caters to various process requirements, including hydroprocessing, isomerization, and reforming, among others. {} leverages its technical expertise and customer-centric approach to provide tailored solutions that address specific operational challenges and performance goals.The Residue Hydrogenation Catalyst is backed by {}’s technical support and services, ensuring seamless integration and optimization within refinery operations. The company's dedicated technical teams collaborate closely with customers to understand their unique needs and offer comprehensive assistance, from catalyst selection to implementation and ongoing support.As the global energy landscape continues to evolve, the demand for efficient and sustainable refining processes will only grow. {} remains at the forefront of this evolution, driving innovation and delivering value through its advanced catalyst solutions. The Residue Hydrogenation Catalyst exemplifies the company's commitment to enabling its customers to achieve operational excellence while meeting environmental and regulatory requirements.In conclusion, the introduction of the Residue Hydrogenation Catalyst by {} marks a significant advancement in catalyst technology for residue upgrading in the petroleum refining industry. With its exceptional performance, environmental benefits, and comprehensive support, the catalyst underscores {}’s position as a trusted partner for catalyst solutions. As the industry continues its pursuit of sustainable and efficient processes, {} remains poised to lead the way with its cutting-edge innovations.

Key Benefits of Gamma Alumina Catalyst in Various Industries

Gamma Alumina Catalyst, a leading provider of advanced catalyst solutions, has been making strides in the industry with its innovative products and dedication to sustainability.With a rich history spanning over two decades, Gamma Alumina Catalyst has established itself as a trusted partner to the chemical and petrochemical industry, providing high-performance catalysts for a wide range of applications. The company's commitment to research and development has led to the creation of cutting-edge catalyst technologies that offer superior performance and efficiency.Gamma Alumina Catalyst's flagship product, GammaCat-300, has gained recognition for its exceptional catalytic properties, which enable it to be used in various refining processes, including hydrocracking, hydrotreating, and catalytic reforming. The catalyst is known for its high activity, selectivity, and stability, making it an ideal choice for refineries looking to optimize their production processes.In addition to its focus on product innovation, Gamma Alumina Catalyst is also dedicated to sustainability and environmental stewardship. The company has made significant investments in research and development to develop catalysts that support environmentally friendly processes, contributing to reduced emissions and resource conservation.One of the key goals of Gamma Alumina Catalyst is to develop catalysts that enable refineries to meet increasingly stringent environmental regulations while maintaining high levels of productivity and profitability. This commitment to sustainability has earned the company a strong reputation within the industry and has positioned it as a leading provider of eco-friendly catalyst solutions.In recent years, Gamma Alumina Catalyst has expanded its reach globally, establishing partnerships with major refineries and chemical plants in various regions. The company's dedication to quality and customer satisfaction has earned it a loyal customer base, with many clients choosing Gamma Alumina Catalyst as their preferred catalyst supplier.Looking ahead, Gamma Alumina Catalyst is poised for further growth and expansion, with a continued focus on research and development to drive innovation in the catalyst industry. The company is actively exploring new opportunities and partnerships to bring its advanced catalyst solutions to even more markets around the world.Furthermore, Gamma Alumina Catalyst is committed to fostering a culture of excellence and continuous improvement within its organization. The company values its employees as its most important asset and has a strong emphasis on safety, training, and professional development.To support its ambitious growth plans, Gamma Alumina Catalyst has invested in state-of-the-art production facilities and laboratory infrastructure, ensuring that its catalysts are produced to the highest standards of quality and consistency. This commitment to excellence has been recognized by industry analysts and has helped solidify the company's position as a leading catalyst supplier.In conclusion, Gamma Alumina Catalyst has emerged as a key player in the global catalyst industry, delivering innovative and sustainable solutions to its customers. With a strong foundation built on research, development, and a customer-centric approach, the company is well-positioned for continued success and growth in the years to come.As the industry continues to evolve, Gamma Alumina Catalyst remains dedicated to providing advanced catalyst solutions that enable its clients to achieve their production goals while minimizing their environmental footprint. With a focus on innovation, sustainability, and customer satisfaction, Gamma Alumina Catalyst is set to lead the way in the catalyst industry for years to come.

Effective Alumina Catalyst for Various Industrial Applications

Gamma Alumina Catalyst, a revolutionary product in the field of catalysis, has been making waves in the industry due to its exceptional performance and versatility. This innovative catalyst is designed to help companies achieve higher efficiency in their chemical processes while reducing environmental impact. With the increasing demand for sustainable and eco-friendly solutions, Gamma Alumina Catalyst is becoming a go-to option for many companies across various industries.The Gamma Alumina Catalyst is developed by a leading chemical company that has been at the forefront of innovation for over five decades. With a strong focus on research and development, the company has consistently delivered cutting-edge solutions that address the evolving needs of the chemical industry. Their commitment to sustainability and excellence has earned them a reputation as a trusted partner for businesses seeking reliable and high-performance products.This revolutionary catalyst is a result of extensive research and development efforts by the company's team of experts. Leveraging their deep understanding of catalysis and chemical processes, they have successfully engineered a catalyst that offers superior performance and efficiency. The Gamma Alumina Catalyst is designed to facilitate various chemical reactions, including hydroprocessing, reforming, and dehydration, among others. Its unique properties make it highly effective in promoting desired reactions while minimizing unwanted by-products.One of the key benefits of the Gamma Alumina Catalyst is its ability to enhance process efficiency and yield. By optimizing the conversion of raw materials into valuable products, companies can experience significant cost savings and higher output. This is particularly important in the current competitive landscape, where businesses are constantly seeking ways to improve their bottom line. With the Gamma Alumina Catalyst, companies can achieve greater productivity and profitability, thereby gaining a competitive edge in the market.Moreover, the Gamma Alumina Catalyst is designed to support sustainable practices by reducing environmental impact. Its high selectivity and stability contribute to lower energy consumption and waste generation, aligning with the growing emphasis on eco-friendly manufacturing processes. As companies strive to meet stringent environmental regulations and consumer demands for sustainable products, the Gamma Alumina Catalyst offers a solution that addresses both performance and environmental concerns.The versatility of the Gamma Alumina Catalyst further enhances its appeal to a wide range of industries. Whether it is used in petrochemical refining, gas processing, or biofuel production, this catalyst consistently delivers exceptional results. Its robust performance across different applications makes it a valuable asset for companies looking to streamline their operations and achieve consistent quality in their end products.As the demand for high-performance catalysts continues to rise, the Gamma Alumina Catalyst stands out as a game-changer in the realm of catalysis. Its proven track record of success and positive feedback from industry professionals reinforce its status as a leading catalyst in the market. With its unparalleled performance, sustainability benefits, and versatility, the Gamma Alumina Catalyst is poised to shape the future of chemical processes and drive innovation across various industries.In conclusion, the Gamma Alumina Catalyst represents a significant advancement in catalysis, offering companies a powerful tool to improve efficiency, reduce environmental impact, and achieve sustainable growth. With the backing of a reputable chemical company, this catalyst is set to make a lasting impact on the industry, driving positive change and setting new benchmarks for performance and sustainability. As businesses continue to prioritize excellence and sustainability, the Gamma Alumina Catalyst emerges as a catalyst for progress and success.

Tail Gas Hydrogenation Catalyst: Key Factors You Need to Know

Tail Gas Hydrogenation Catalyst Development: A Milestone Achievement for {} In recent years, the global demand for cleaner and more sustainable energy sources has been on the rise, prompting companies in the energy sector to develop advanced technologies to reduce emissions and improve overall efficiency. One such breakthrough comes from the innovative work of {}, a leading company in the chemical and energy industry.With a commitment to research and development, {} has successfully engineered a Tail Gas Hydrogenation Catalyst that has the potential to revolutionize the way refineries manage tail gas emissions. This milestone achievement is a testament to the company's dedication to sustainability and its proactive approach to addressing environmental challenges.The Tail Gas Hydrogenation Catalyst developed by {} is a state-of-the-art solution designed to effectively remove sulfur compounds and carbon oxides from tail gas streams, thereby significantly reducing harmful emissions. This breakthrough technology not only aligns with global efforts to minimize the environmental impact of industrial processes but also presents a viable and cost-effective solution for refinery operators to comply with stringent emission regulations.To understand the significance of this development, it is essential to recognize the growing concerns surrounding tail gas emissions in the refining industry. As refineries strive to enhance their operational efficiency and minimize their environmental footprint, the need for advanced catalysts to clean up tail gas has become increasingly critical. {}'s Tail Gas Hydrogenation Catalyst offers a reliable and efficient way to achieve these objectives, marking a significant advancement in the industry.{}'s commitment to sustainability and environmental stewardship is at the core of its corporate values. By developing innovative solutions such as the Tail Gas Hydrogenation Catalyst, the company is actively contributing to efforts aimed at reducing greenhouse gas emissions and fostering a more sustainable energy landscape. This aligns with the global transition towards cleaner and renewable energy sources, positioning {} as a forward-thinking and socially responsible industry leader.The successful development of the Tail Gas Hydrogenation Catalyst underscores the extensive research and technical expertise that {} possesses. The company's dedicated team of scientists, engineers, and industry experts have worked tirelessly to bring this groundbreaking technology to fruition, demonstrating a strong commitment to advancing the boundaries of innovation in the energy sector. As a result, {} is poised to set new industry standards and pave the way for a greener and more efficient refining process.Looking ahead, the commercialization and widespread implementation of the Tail Gas Hydrogenation Catalyst are poised to create a significant impact on the global refining industry. With its potential to enhance environmental performance, operational efficiency, and regulatory compliance, this innovative catalyst is set to become a game-changer for refineries worldwide. By supporting the adoption of sustainable practices and facilitating the transition towards cleaner energy production, {} is positioned to play a pivotal role in shaping the future of the refining sector.In conclusion, the development of the Tail Gas Hydrogenation Catalyst by {} represents a significant achievement that underscores the company's commitment to innovation, sustainability, and environmental responsibility. This breakthrough technology has the potential to revolutionize the refining industry by offering a reliable and efficient solution for managing tail gas emissions. As the global demand for cleaner energy continues to grow, {}'s pioneering work in developing advanced catalysts exemplifies its leadership in driving positive change and shaping a more sustainable energy landscape for the future.