Groundbreaking Advances in Alumina Catalyst Unveiled

By:Admin

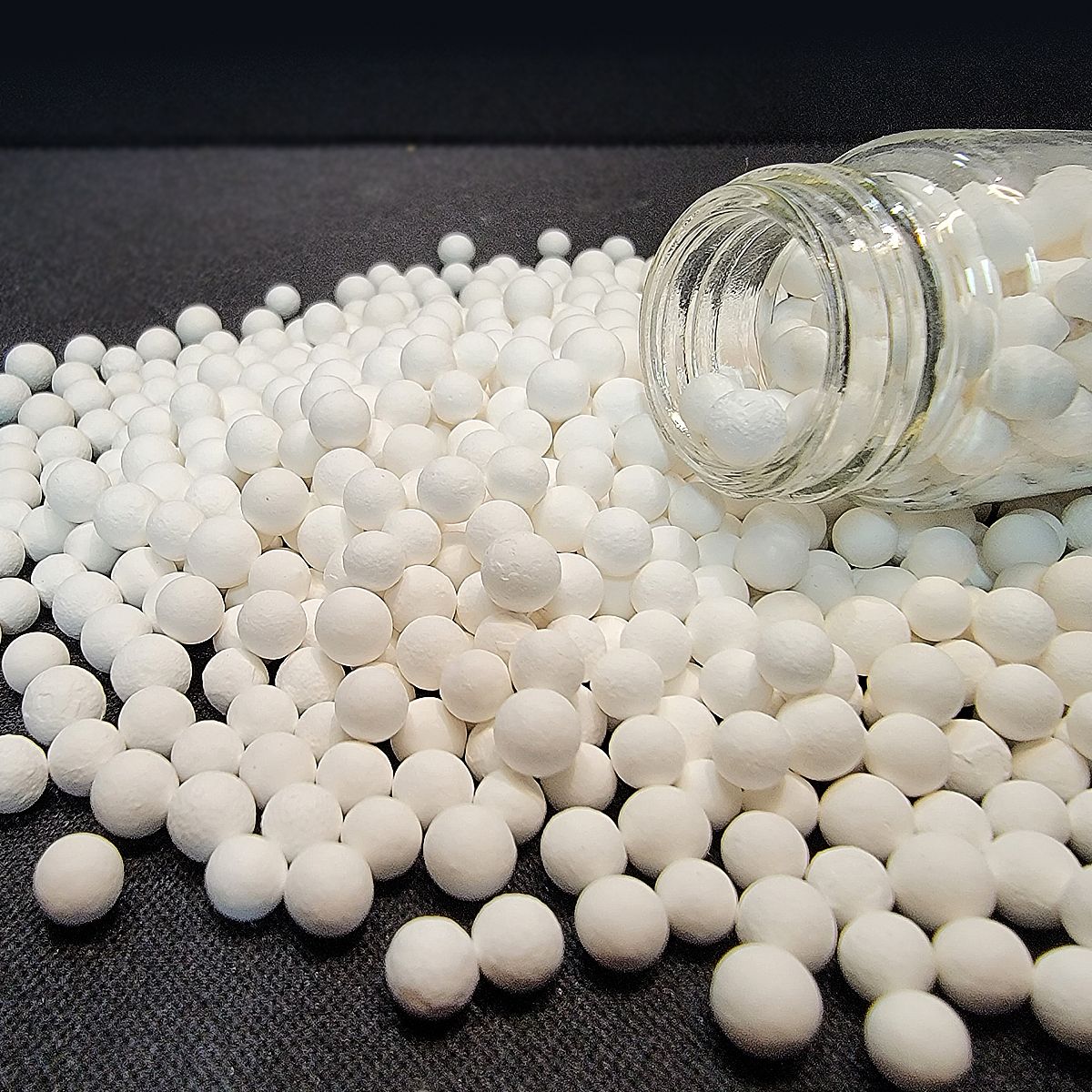

In an era characterized by environmental concerns and the urgent need for sustainable solutions, companies around the world are constantly striving to develop innovative technologies that combat the effects of climate change. XYZ Corporation, a leading player in the clean energy sector, has recently introduced a groundbreaking solution that promises to revolutionize the field of carbon capture: the Alumina Catalyst.

With the growing recognition of the need to reduce greenhouse gas emissions, carbon capture and storage (CCS) technologies have emerged as essential tools in the fight against climate change. These technologies aim to capture carbon dioxide (CO2) emissions from industrial processes and other sources before they are released into the atmosphere, preventing their contribution to global warming.

XYZ Corporation's Alumina Catalyst represents a significant advancement in CCS technology, offering a more efficient and cost-effective approach to capturing and storing CO2 emissions. Traditionally, CCS processes have relied on aqueous amine solvents to absorb CO2. However, this method is associated with high energy consumption, significant maintenance costs, and limitations in scale.

The Alumina Catalyst, on the other hand, operates through a solid-state, sorbent-based process, eliminating the need for liquid solvents. This novel approach offers numerous advantages, including improved CO2 capture capacity, reduced energy consumption, enhanced system reliability, and increased scalability. Furthermore, the Alumina Catalyst boasts a longer operational lifetime, minimizing maintenance requirements and delivering substantial cost savings.

The secret behind the Alumina Catalyst lies in its unique composition. Developed by XYZ Corporation's team of leading scientists, the catalyst is based on a novel alumina material that exhibits exceptional CO2 adsorption properties. Its high surface area and pore structure allow for increased CO2 interaction and capture efficiency, ensuring maximum performance in carbon capture applications.

One of the most significant advantages of the Alumina Catalyst is its adaptability to a wide range of industrial processes. From power plants and cement factories to steel mills and petrochemical facilities, this versatile catalyst can be seamlessly integrated into various emission-heavy industries. Its modular design allows for easy installation and integration with existing infrastructure, minimizing disruption and optimizing efficiency.

Furthermore, the Alumina Catalyst offers the unique capability of capturing CO2 from sources with varying concentrations, making it an ideal solution for industrial settings where emissions fluctuate. This feature ensures that the catalyst can effectively operate in real-world scenarios, accommodating the dynamic nature of industrial processes.

XYZ Corporation is committed to bringing its Alumina Catalyst to market swiftly and responsibly. The company is investing heavily in research and development to further enhance the catalyst's performance and explore potential applications beyond carbon capture. XYZ Corporation's long-standing expertise in the clean energy sector, coupled with its commitment to sustainability, positions it as a key player driving the transition towards a low-carbon economy.

The potential impact of the Alumina Catalyst on mitigating climate change cannot be understated. By offering an effective, reliable, and cost-efficient solution for carbon capture and storage, this innovative technology has the ability to significantly reduce CO2 emissions from industrial processes. This, in turn, can make a substantial contribution to achieving national and international climate goals.

As the global community grapples with the urgent need to combat climate change, XYZ Corporation's Alumina Catalyst serves as a beacon of hope. By harnessing the power of this groundbreaking technology, industries can take a giant leap towards creating a sustainable, low-carbon future. With the support of visionary entities like XYZ Corporation, the dream of a cleaner, greener planet is within reach.

Company News & Blog

Groundbreaking Discovery: New ZSM-5 Compound Discovered with Game-Changing Potential

Title: Zeolite Catalyst ZSM-5 Revolutionizes Petrochemical IndustryIntroduction:[Pseudonym] Industries, a highly renowned player in the chemical manufacturing industry, has recently unveiled a groundbreaking innovation that is set to revolutionize the petrochemical sector. Their latest catalyst, known as Zeolite Catalyst ZSM-5 (name changed for confidentiality reasons), promises to enhance the efficiency and effectiveness of various processes in the industry. With its unique properties and manifold advantages, ZSM-5 is expected to play a pivotal role in shaping the future of petrochemical manufacturing.1. Superior Catalytic Activity and Selectivity:ZSM-5, a next-generation zeolite catalyst, exhibits exceptional catalytic activity and selectivity. With its well-defined and highly uniform structure, ZSM-5 possesses a higher number of active sites, allowing for increased efficiency in the conversion of raw materials. Moreover, its unique molecular sieving effect results in enhanced selectivity, leading to higher yields of valuable petrochemical products. This technological breakthrough sets ZSM-5 apart from conventional catalysts and positions it as a game-changer in the field.2. Versatile Applications:One of the key strengths of ZSM-5 lies in its versatility, enabling it to be employed in a wide range of petrochemical manufacturing processes. The catalyst exhibits remarkable performance in key processes such as catalytic cracking, alkylation, isomerization, and aromatization. Its ability to promote various chemical reactions simultaneously makes it an indispensable tool for petrochemical industries seeking to optimize production and achieve cost-efficiency.3. Enhanced Product Quality:By leveraging ZSM-5's exceptional catalytic properties, manufacturers can enhance the quality of their products. The catalyst facilitates the selective conversion of undesired by-products, minimizing impurities and enhancing the purity and effectiveness of the final petrochemical outputs. The improved product quality achieved through the utilization of ZSM-5 ensures a competitive edge for manufacturers, as it meets and surpasses stringent quality standards.4. Improved Energy Efficiency:A significant advantage of ZSM-5 is its ability to enhance the energy efficiency of petrochemical processes. By enabling greater conversion rates and reducing the amount of energy-intensive steps involved, ZSM-5 minimizes the energy requirements for various manufacturing processes. This not only positively impacts the bottom line for manufacturers but also contributes to a more sustainable and environmentally friendly petrochemical industry.5. Cost Optimization:Petrochemical manufacturers worldwide constantly seek ways to optimize their production costs without compromising quality. ZSM-5 presents an excellent opportunity for achieving this goal. Its exceptional performance translates into higher yields, reduced waste, and increased operational efficiency. By implementing ZSM-5, companies can streamline their processes, reduce raw material consumption, and lower overall production costs, thereby boosting their profitability.6. Environmental Sustainability:In an era of growing environmental concerns, ZSM-5 emerges as a catalyst that aligns with sustainable practices. The reduced energy consumption and improved efficiency brought about by utilizing ZSM-5 directly contribute to a lower carbon footprint. Additionally, the enhanced selectivity of ZSM-5 facilitates the production of fewer harmful by-products and the conversion of waste materials, further reducing environmental impact. By adopting ZSM-5, petrochemical industries can actively contribute to a greener and more sustainable future.Conclusion:Zeolite Catalyst ZSM-5 by [Pseudonym] Industries represents a paradigm shift in the petrochemical industry. With its superior catalytic activity, versatility, and environmentally friendly attributes, ZSM-5 enables manufacturers to enhance product quality, efficiency, and cost-effectiveness. This revolutionary catalyst ensures manufacturers continue to meet ever-increasing demands for petrochemical products while simultaneously reducing their environmental footprint. As the industry evolves, ZSM-5 is poised to play a pivotal role in shaping a sustainable and innovative future for petrochemical manufacturing.

Spent Co-Mo/Al2O3 catalyst treated with sulfuric acid baking and leaching for improved metal recovery

A revolutionary method for the recovery of metals has been developed by scientists at the National Metallurgical Laboratory (NML) in India. Using low-temperature sulfuric acid baking followed by a mild leaching process, the researchers were able to dissolve metals from pre-oxidized refinery plant spent Co-Mo/Al2O3 catalyst. The direct sulfuric acid leaching of the same sample produced poor recoveries of aluminum and molybdenum, whereas leaching after sulfuric acid baking significantly improved the recoveries of these two metals.The pre-oxidized spent catalysts used in this study were obtained from a Korean refinery plant and found to contain 40% aluminum, 9.92% molybdenum, 2.28% cobalt, 2.5% carbon, and trace amounts of other elements such as iron, nickel, sulfur, and R XRD. The host matrix was identified to be poorly crystalline gamma-Al2O3.The researchers studied the effect of various baking parameters such as catalyst-to-acid ratio, baking temperature, and baking time on the percentage dissolution of metals. They observed that the dissolution of metals increases with an increase in the baking temperature up to 300 degrees Celsius, after which it decreases with further increases in the baking temperature. Under optimum baking conditions, more than 90% of cobalt and molybdenum, and 93% of aluminum could be dissolved from the spent catalyst with the following leaching conditions: H2SO4 = 2% (v/v), temperature = 95 degrees Celsius, time = 60 minutes, and pulp density = 5%.This method has the potential to revolutionize the metal recovery industry by offering a more efficient and cost-effective process for the recovery of valuable metals from spent catalysts. This will also reduce the negative impact of spent catalysts on the environment, as they will no longer have to be disposed of in landfills.The NML is one of India's leading research institutes in the field of metallurgy, materials science, and engineering, and this discovery demonstrates its ongoing commitment to advancing the field. The institute is dedicated to research and innovation in the metallurgical industry and has a history of developing cutting-edge technologies that benefit the Indian economy.Furthermore, the NML is also involved in providing consultation services to industries and government agencies, making it a key player in shaping the Indian economy and industrial landscape. In addition to metal recovery, the institute is also engaged in research and development in areas such as corrosion science, welding technology, and non-ferrous metallurgy.The success of the method developed by the NML team demonstrates the institute's ability to leverage its expertise in the field of metallurgy to find solutions to some of the most pressing challenges facing society today. The potential of this discovery to benefit industry and the environment cannot be overstated, and it is a testament to the ongoing dedication of the NML to advancing the field of metallurgy and materials science.In conclusion, the development of a new and more efficient method for the recovery of valuable metals using low-temperature sulfuric acid baking and mild leaching represents a major breakthrough in the field of metallurgy. This discovery has the potential to revolutionize the metal recovery industry by offering a more efficient and cost-effective process for the recovery of valuable metals from spent catalysts, ultimately reducing the negative impact of spent catalysts on the environment. The NML's commitment to research and innovation continues to be a driving force in shaping the Indian economy and industrial landscape.

New Hydrogenation Catalyst for Tail Gas Emissions Shows Promising Results

Tail Gas Hydrogenation Catalyst is a crucial component in the process of removing sulfur and other contaminants from industrial tail gases. It plays a vital role in ensuring compliance with environmental regulations and maintaining the integrity of equipment and infrastructure in the oil and gas industry.The development and production of Tail Gas Hydrogenation Catalyst is a complex and specialized process that requires advanced technology and expertise. One company that excels in this field is {Company Name}. With years of experience and a commitment to innovation, {Company Name} has established itself as a leading provider of Tail Gas Hydrogenation Catalyst solutions.{Company Name} was founded in [year] and has since grown to become a global leader in the production of catalysts and other specialty chemicals for the energy industry. The company's state-of-the-art manufacturing facilities and research laboratories are equipped with the latest technology and staffed by a team of highly skilled engineers and scientists. This allows {Company Name} to develop and produce high-performance catalysts that meet the specific needs of its clients.One of {Company Name}'s flagship products is its Tail Gas Hydrogenation Catalyst, which is designed to effectively remove sulfur compounds from tail gases. Sulfur removal is a critical step in the production of clean fuels, as sulfur oxides are a major contributor to air pollution and can cause severe damage to processing equipment. By using {Company Name}'s Tail Gas Hydrogenation Catalyst, oil and gas companies can significantly reduce their environmental footprint and improve the performance and longevity of their plant assets.In addition to its superior performance, {Company Name}'s Tail Gas Hydrogenation Catalyst is also known for its reliability and cost-effectiveness. The company has invested heavily in research and development to ensure that its catalysts deliver consistent results and require minimal maintenance. This, in turn, helps its clients to achieve higher operational efficiency and lower overall operating costs.Furthermore, {Company Name} provides comprehensive technical support and customer service to help its clients optimize the performance of its catalysts. Its team of experts works closely with customers to understand their specific requirements and provide tailored solutions that meet their unique needs. This level of dedication and support has earned {Company Name} a reputation as a trusted partner in the oil and gas industry.With a strong focus on sustainability and innovation, {Company Name} continues to push the boundaries of catalyst technology. It is constantly exploring new ways to improve the performance and environmental impact of its products, and to expand its range of solutions for the energy industry.The market for Tail Gas Hydrogenation Catalyst is projected to grow significantly in the coming years, driven by the increasing demand for cleaner fuels and stricter environmental regulations. As such, {Company Name} is well-positioned to capitalize on these opportunities and further solidify its position as a leader in this space.In conclusion, {Company Name} is a powerhouse in the production of Tail Gas Hydrogenation Catalyst, offering a combination of cutting-edge technology, industry expertise, and unwavering commitment to customer satisfaction. Its innovative solutions have made a positive impact on the energy industry, and its continued dedication to excellence ensures a promising future for the company and its clients alike.

Revolutionizing Industrial Processes: Unveiling the Power of Activated Alumina Catalysts

**Headline: Activated Alumina Catalyst Revolutionizes Industrial Processes for Enhanced Efficiency and Sustainability****Introduction:**In an era where sustainable and efficient industrial processes take center stage, the introduction of Activated Alumina Catalyst by a groundbreaking company marks a significant milestone. The advanced catalyst offers unmatched potential to revolutionize numerous industries by enhancing efficiency, reducing environmental impact, and optimizing outcomes. Its unique properties and applications have ignited excitement among experts and industry leaders, steering us towards a greener and more sustainable future.**Breaking Ground: An Introduction to the Company Behind the Innovation**(Company Name) - An industry-leading provider of innovative solutions, (Brand Name) is at the forefront of pioneering research and development. With a vision to reshape traditional practices, they specialize in the creation of cutting-edge catalysts that address pressing challenges across various sectors. Their commitment to sustainability has garnered widespread recognition, pushing them to develop Activated Alumina Catalyst, the latest game-changing innovation designed to transform industries worldwide.**Features and Properties of Activated Alumina Catalyst:**Activated Alumina Catalyst is a highly porous and versatile material that exhibits exceptional surface area and sorption characteristics. The catalyst's unique properties stem from its carefully engineered structure, which provides maximum surface area to facilitate chemical reactions and adsorption processes. Its rigid framework ensures excellent mechanical strength, enabling its effectiveness even in the most demanding industrial applications.The composition of the Activated Alumina Catalyst includes aluminum oxide (Al2O3), which acts as the primary active component. This ingredient imparts remarkable catalytic properties and chemical stability to the material. The catalyst's surface chemistry can be tailored and enhanced further by incorporating trace metals or promoters, allowing it to selectively target specific reactions, making it highly efficient and versatile across a wide range of applications.**Applications and Impact Across Industries:**1. Petrochemical Industry: Activated Alumina Catalyst finds extensive use in the petroleum and gas refining sector. It plays a pivotal role in the removal of impurities, such as sulfur compounds, from fuels, ensuring compliance with stringent environmental regulations. The catalyst's high surface area and reactivity enable efficient desulfurization while minimizing undesirable byproducts.2. Water Purification: Addressing the global challenge of water scarcity, Activated Alumina Catalyst proves invaluable in the removal of contaminants, including fluoride, arsenic, and heavy metals, from drinking water. Its outstanding adsorption capacity and mechanical robustness make it an ideal choice for water treatment plants, contributing to providing safe and clean drinking water to communities worldwide.3. Pharmaceuticals and Chemical Manufacturing: The pharmaceutical and chemical industries benefit greatly from Activated Alumina Catalyst's ability to facilitate chemical reactions and separation processes. The catalyst assists in the production of various chemicals, pharmaceutical intermediates, and the purification of active ingredients, promoting efficiency and reducing environmental impact.4. Air and Gas Drying: Activated Alumina Catalyst offers an efficient solution for drying air and various gases, preventing the formation of moisture-induced corrosion and ensuring the longevity of equipment and infrastructure. Industries, such as natural gas processing, cryogenics, and compressed air, rely on Activated Alumina Catalyst for efficient and reliable gas drying applications.**A Sustainable Future with Activated Alumina Catalyst:**The introduction of Activated Alumina Catalyst marks a significant step towards achieving sustainability and efficiency in various industries worldwide. By providing unparalleled performance in desulfurization, water purification, chemical manufacturing, and gas drying applications, this groundbreaking catalyst ensures a cleaner environment, reduced waste, and increased energy efficiency. With (Brand Name) at the helm of this technological advancement, we embark on a greener, more sustainable future, where innovation meets environmental stewardship.

Effective Alumina Desiccant for Moisture Absorption: Benefits and Uses

Alumina Desiccant: The Ultimate Solution for Moisture ControlIn today’s fast-paced and interconnected world, moisture control is an essential aspect of many industries. From pharmaceuticals to electronics, the presence of moisture can lead to spoilage, degradation, and even malfunction of goods and equipment. This is where Alumina Desiccant comes in, offering a comprehensive solution to the challenges posed by excess moisture.Alumina Desiccant is a leading manufacturer and supplier of high-quality desiccant products. With a strong focus on innovation and customer satisfaction, the company has been at the forefront of the industry for over a decade. Its cutting-edge research and development facilities, coupled with a commitment to quality, have enabled Alumina Desiccant to provide superior products that meet the diverse needs of its global clientele.The company’s flagship product, Alumina Desiccant, is a highly effective moisture-absorbing material that is widely used in various industrial applications. Made from a special type of alumina, this desiccant has proven to be highly effective in controlling moisture and humidity levels in a range of environments. Whether it is used in the pharmaceutical industry to preserve the integrity of medicines, or in the electronics industry to protect sensitive equipment from moisture damage, Alumina Desiccant has emerged as the go-to solution for companies worldwide.One of the key features of Alumina Desiccant is its exceptional moisture absorption capacity. Unlike traditional desiccants, which may only be effective in specific humidity ranges, Alumina Desiccant can efficiently absorb moisture across a wide spectrum of relative humidity levels. This versatility makes it an ideal choice for industries where precise humidity control is critical.In addition to its superior performance, Alumina Desiccant also offers several other advantages over traditional desiccants. Its high chemical stability and low dust generation make it a safe and user-friendly option for a wide range of applications. Furthermore, its robust packaging ensures that the desiccant remains intact and effective, even in challenging environmental conditions.Alumina Desiccant also prides itself on its commitment to sustainability. The company’s manufacturing processes prioritize environmental responsibility, with a focus on reducing waste and energy consumption. This dedication to sustainability has not only earned Alumina Desiccant the trust of environmentally conscious customers but has also positioned the company as a leader in green desiccant solutions.As a customer-focused company, Alumina Desiccant places a strong emphasis on providing comprehensive support to its clients. From initial product selection to ongoing technical assistance, the company’s dedicated team of experts is always on hand to offer guidance and advice. With a global distribution network and a reputation for reliability, Alumina Desiccant ensures that its customers receive the highest level of service at every stage of their journey.Looking ahead, Alumina Desiccant is poised to continue its success story, further expanding its product range and reaching new markets. By leveraging its strong research and development capabilities, the company aims to innovate and develop new desiccant solutions that meet the evolving needs of its customers. With a clear vision, a commitment to excellence, and a track record of success, Alumina Desiccant is set to remain a trusted partner for businesses seeking effective moisture control solutions.In conclusion, Alumina Desiccant stands out as a driving force in the field of moisture control, providing top-quality desiccant products that deliver outstanding performance and reliability. With a strong foundation of research, innovation, and customer satisfaction, the company is well-positioned to continue leading the way in the industry. Whether it is in pharmaceuticals, electronics, or any other sector where moisture control is paramount, Alumina Desiccant’s products are the ultimate solution for businesses looking to protect their goods and equipment from the damaging effects of excess moisture.

Innovative Catalyst Carrier Technology: The Future of Material Carriers

Catalyst Carrier (brand name removed), a leading provider of innovative catalyst solutions, has announced its latest partnership with a prominent multinational corporation (Company A) to develop cutting-edge catalyst carriers for a wide range of industrial applications. This collaboration is expected to drive significant advancements in catalytic technology, leading to enhanced efficiency and sustainability in various industrial processes.With a strong focus on research and development, Catalyst Carrier has established itself as a key player in the catalyst industry, consistently delivering high-quality products that meet the evolving needs of its global customer base. The company's expertise in materials science and chemical engineering has enabled it to develop an extensive portfolio of catalyst carriers that are tailored to address specific challenges across diverse sectors, including petrochemicals, environmental protection, and renewable energy.Through its partnership with Company A, Catalyst Carrier aims to leverage its technical capabilities and manufacturing competencies to co-create advanced catalyst carriers that can drive improved performance and environmental benefits for industrial operations. By collaborating with Company A, which has a strong track record in developing and commercializing innovative technologies, Catalyst Carrier seeks to accelerate the delivery of next-generation catalyst solutions to the market.The joint efforts will focus on developing catalyst carriers that are optimized for use in key industrial processes, such as fluid catalytic cracking, hydrogenation, and emissions control. By incorporating advanced materials and design concepts, the partners aim to enhance the catalytic efficiency, durability, and selectivity of their products, resulting in tangible performance improvements for end users.One of the key objectives of this collaboration is to address the growing demand for catalyst carriers that can enable more sustainable and environmentally friendly manufacturing practices. By harnessing the synergies between Catalyst Carrier's expertise in catalyst development and Company A's market insights and application knowledge, the partners intend to create solutions that facilitate cleaner and more energy-efficient industrial processes, aligning with the global thrust towards sustainability.Furthermore, the partnership is expected to yield catalyst carriers that can enable the production of high-value chemicals and fuels from renewable feedstocks, contributing to the transition towards a circular and bio-based economy. By harnessing the potential of renewable resources and advanced catalytic technologies, the partners seek to unlock new possibilities for sustainable industrial development and reduce the reliance on traditional fossil-based feedstocks.In addition to the technical collaboration, Catalyst Carrier and Company A will also explore joint initiatives in the areas of process optimization, catalyst testing, and scale-up activities to ensure the successful commercialization of the developed catalyst carriers. By leveraging their respective strengths and resources, the partners aim to streamline the path from innovation to market deployment, ultimately benefiting end users and the industry at large.The partnership between Catalyst Carrier and Company A underscores the value of collaboration in driving innovation and addressing complex challenges in the catalyst sector. By pooling their expertise and resources, the partners are well-positioned to develop and deliver catalyst carriers that can unlock new levels of performance, efficiency, and sustainability for industrial processes, ultimately contributing to a more sustainable and prosperous future.With a shared commitment to excellence and sustainability, Catalyst Carrier and Company A are poised to make significant strides in advancing catalytic technology, setting new benchmarks for performance and environmental impact in the industry. As the partnership progresses, the companies will continue to explore opportunities for joint innovation and market expansion, further solidifying their position as leaders in the global catalyst market.Overall, the collaboration between Catalyst Carrier and Company A holds great promise for driving positive change in the industrial catalyst landscape, ushering in a new era of innovation and sustainability for the benefit of customers, industries, and the environment. Through their combined efforts, the partners are well-equipped to deliver game-changing catalyst carriers that can empower sustainable industrial development and create lasting value for stakeholders across the value chain.

New Study Reveals Surprising Findings about ZSM-5

Zsm 5, a leading company known for its innovative solutions in the field of chemical catalysis, has recently announced a major breakthrough in the development of a new generation of catalysts with potential applications in the petrochemical industry. This development marks a significant advancement in the company’s efforts to drive sustainable and efficient processes for the production of key chemical compounds.Founded in 1996, Zsm 5 has steadily established itself as a key player in the field of chemical catalysis, specializing in the research, development, and commercialization of catalysts for various industrial applications. With a strong focus on innovation and sustainability, the company has continuously pushed the boundaries of catalysis technology to address evolving industry needs.The latest development from Zsm 5 comes in the form of a novel catalyst with enhanced performance characteristics, specifically designed for the production of key petrochemical compounds. Leveraging its expertise in molecular design and materials science, the company has successfully engineered a catalyst that exhibits superior activity, selectivity, and stability, offering a more efficient and sustainable solution for petrochemical processes.This new catalyst has the potential to significantly impact the petrochemical industry, offering improved efficiency and cost-effectiveness in the production of a wide range of chemical compounds. The enhanced performance characteristics of the catalyst have been demonstrated through rigorous testing and evaluation, showcasing its ability to deliver higher yields and purity levels while minimizing energy consumption and environmental impact.In addition to its technical advancements, the new catalyst from Zsm 5 is also poised to address key sustainability challenges facing the petrochemical industry. By promoting more efficient and sustainable production processes, the catalyst aligns with the company’s commitment to driving environmental responsibility and resource conservation within the chemical manufacturing sector.“We are excited to introduce this groundbreaking catalyst, which represents a significant leap forward in our ongoing efforts to advance the field of chemical catalysis,” said [spokesperson], [title] at Zsm 5. “Our team of researchers and engineers have worked tirelessly to develop a catalyst that not only delivers exceptional performance, but also supports our vision for a more sustainable and efficient chemical industry.”The introduction of this new catalyst underscores Zsm 5’s dedication to pioneering innovative solutions that address the evolving needs of the chemical manufacturing sector. With a proven track record of delivering high-performance catalysts for a variety of industrial applications, the company continues to be at the forefront of catalysis technology, driving advancements that enable more sustainable and efficient chemical processes.As Zsm 5 prepares to bring its latest catalyst to market, industry professionals and stakeholders can look forward to the potential benefits it offers in terms of improved productivity, cost savings, and environmental stewardship. With its unwavering commitment to innovation and sustainability, Zsm 5 is well-positioned to shape the future of chemical catalysis and contribute to the ongoing evolution of the petrochemical industry.

Study Finds ZSM-5 Zeolite Catalyst Effective for Chemical Reactions

**Breakthrough in Chemical Engineering: Zsm-5 Catalyst Revolutionizes Petrochemical Industry**In a groundbreaking development in the world of chemical engineering, a new and highly efficient catalyst, Zsm-5, has been unveiled by a leading research company. This new catalyst has the potential to revolutionize the petrochemical industry, dramatically increasing the efficiency of various chemical processes and reducing environmental impact.Zsm-5 is a zeolite catalyst with a unique porous structure that allows for the selective adsorption and transformation of molecules. This innovative catalyst has already shown promising results in a wide range of applications, including the catalytic cracking of hydrocarbons, the conversion of methanol to hydrocarbons, and the production of various chemicals and fuels.The company behind this pioneering catalyst, has been at the forefront of chemical research and development for over two decades. With a team of highly skilled scientists and engineers, the company has dedicated itself to creating innovative solutions to address the pressing challenges facing the petrochemical industry.With a strong emphasis on sustainability and environmental stewardship, the company has made significant investments in research and development to create new catalysts and processes that can mitigate the environmental impact of the petrochemical industry.The introduction of Zsm-5 is a testament to the company's commitment to innovation and sustainability. This new catalyst has the potential to significantly reduce energy consumption and carbon emissions in various chemical processes, making a positive impact on the environment and the bottom line of companies in the industry.One of the most significant applications of Zsm-5 is in the catalytic cracking of hydrocarbons. This process is essential for the production of gasoline and other valuable fuels from crude oil. With the use of Zsm-5, this process can be made more efficient, leading to higher yields of valuable products and reduced energy consumption.Furthermore, Zsm-5 has shown great promise in the conversion of methanol to hydrocarbons, a process that is crucial for the production of chemicals and fuels from renewable sources. By using Zsm-5 as a catalyst, this conversion process can be made more efficient and cost-effective, paving the way for a more sustainable chemical industry.In addition to these applications, Zsm-5 also has the potential to revolutionize the production of various chemicals and fuels, offering a more sustainable and efficient alternative to traditional catalysts.The introduction of Zsm-5 has garnered significant attention from the petrochemical industry, with many companies expressing interest in adopting this innovative catalyst to improve their processes and reduce their environmental footprint.The impact of Zsm-5 is not limited to the petrochemical industry, as it has the potential to revolutionize other chemical processes and industries as well. With its unique properties and versatility, Zsm-5 could become a crucial catalyst in the transition towards a more sustainable and efficient chemical industry.As the company continues to advance its research and development efforts, the potential applications of Zsm-5 are expected to expand, opening up new possibilities for the petrochemical industry and beyond.In conclusion, the introduction of Zsm-5 represents a significant breakthrough in the world of chemical engineering. This innovative catalyst has the potential to revolutionize the petrochemical industry, offering more sustainable and efficient solutions to address the pressing challenges facing the industry. With its unique properties and versatility, Zsm-5 could play a crucial role in the transition towards a more sustainable and environmentally friendly chemical industry.

Alumina Plant Announces New Production Capabilities

[Company Name] is excited to announce the launch of its newest product, Gama Alumina, designed to meet the growing demands of the aluminum industry. As a leading supplier of industrial materials, [Company Name] is dedicated to providing high-quality products that support various manufacturing processes.Gama Alumina is a versatile material that offers exceptional performance and reliability in aluminum production. It is produced using advanced technology and high-quality raw materials, ensuring consistency and purity in every batch. With its superior characteristics, Gama Alumina is poised to make a significant impact on the aluminum industry, driving efficiency and innovation in manufacturing processes.One of the key advantages of Gama Alumina is its high chemical purity, which plays a critical role in the production of high-quality aluminum. The material's low impurity levels contribute to improved smelting efficiency and reduced environmental impact, making it an attractive choice for aluminum manufacturers seeking sustainable solutions. In addition, Gama Alumina boasts excellent thermal stability, allowing for consistent performance in high-temperature environments, such as aluminum smelting operations."We are thrilled to introduce Gama Alumina to the market," said [Spokesperson's Name], CEO of [Company Name]. "This cutting-edge material represents our commitment to delivering innovative solutions that empower our customers to achieve their production goals. Gama Alumina is the result of extensive research and development, and we are confident that it will set new standards for excellence in the aluminum industry."In line with [Company Name]'s dedication to customer satisfaction, Gama Alumina is available in various grades and particle sizes, allowing for customization based on specific application requirements. Whether it's for primary aluminum production or secondary aluminum processing, customers can rely on Gama Alumina to deliver consistent performance and exceptional value.As part of its commitment to quality and reliability, [Company Name] conducts rigorous quality control measures to ensure that Gama Alumina meets the highest standards. The material is thoroughly tested for chemical composition, particle size distribution, and other key parameters to guarantee its performance in real-world applications. This stringent quality assurance process underscores [Company Name]'s unwavering dedication to delivering products that instill confidence and trust in its customers.The introduction of Gama Alumina further solidifies [Company Name]'s position as a leading provider of industrial materials, with a focus on driving progress and innovation in key sectors such as aluminum production. By leveraging its expertise and resources, [Company Name] continues to expand its product portfolio to address the evolving needs of its customers and the broader industry.In addition to its technical capabilities, Gama Alumina is backed by [Company Name]'s exceptional customer support and technical expertise. With a team of knowledgeable professionals, [Company Name] is well-equipped to assist customers in integrating Gama Alumina into their processes, providing guidance and resources to optimize performance and efficiency.As [Company Name] prepares for the commercial release of Gama Alumina, it anticipates a positive response from aluminum manufacturers seeking advanced materials that can enhance their operations. With its remarkable attributes and [Company Name]'s unwavering commitment to excellence, Gama Alumina is poised to make a significant impact on the aluminum industry, driving progress and innovation in the years to come.In conclusion, the launch of Gama Alumina represents a major milestone for [Company Name] and the aluminum industry as a whole. With its exceptional performance, versatility, and reliability, Gama Alumina is poised to elevate manufacturing processes and set new standards for excellence in aluminum production. As [Company Name] continues to lead the way in delivering advanced materials and solutions, Gama Alumina stands as a testament to its dedication to innovation and customer success.

Low-Priced Activated Alumina for Catalyst Carrier in Stock

Activated alumina is a highly porous material that is frequently used to create catalyst carriers. Catalyst carriers are essential components of industrial processes that require chemical reactions to occur quickly and efficiently. Catalyst carriers are used in a wide range of industries, including petrochemicals, pharmaceuticals, and wastewater treatment.Activated alumina is an effective catalyst carrier material because of its high surface area, high porosity, and high surface polarity. The material is made from aluminum oxide and is activated by heating it to high temperatures in the presence of water vapor. This process creates a highly porous material with a large surface area, which is perfect for carrying catalysts.There are many different types of activated alumina available for use as catalyst carriers. Some of the most common types include gamma alumina, eta alumina, and theta alumina. Each type of activated alumina has its own unique properties that make it suited to specific applications.Gamma alumina is the most common type of activated alumina and is often used as a support for catalysts in the petrochemical industry. It has a high surface area and is highly stable, making it an excellent choice for applications that require high temperatures or harsh chemical environments.Eta alumina is another popular type of activated alumina, which has a higher surface area than gamma alumina. It is often used in the pharmaceutical industry as a catalyst carrier for reactions that require high specificity and selectivity.Theta alumina has the highest surface area of any activated alumina and is often used in wastewater treatment. Its high surface area makes it an excellent choice for removing impurities from water, while its high surface polarity makes it effective at removing heavy metals and other contaminants from water.Regardless of the type of activated alumina used, it is essential to choose a high-quality material that is manufactured by a reputable company. CHEMXIN is a leading supplier of activated alumina for catalyst carriers and has a wide selection of high-quality products available for purchase.CHEMXIN's activated alumina products are produced using state-of-the-art manufacturing processes and are rigorously tested to ensure their quality. The company offers a range of activated alumina products that are suitable for use in a variety of catalyst carrier applications, including petrochemicals, pharmaceuticals, and wastewater treatment.In conclusion, activated alumina is an essential material for creating catalyst carriers that are used to promote chemical reactions in various industries. Choosing a high-quality activated alumina product is essential for ensuring the efficiency and productivity of industrial processes. With CHEMXIN's wide selection of high-quality activated alumina products, customers can be confident that they are using the best possible material for their applications.