- Home

- Blog

- Highly Efficient Methanol Synthesis Catalyst Shows Promising Results in Laboratory Testing

Highly Efficient Methanol Synthesis Catalyst Shows Promising Results in Laboratory Testing

By:Admin

The catalyst, which is manufactured using advanced materials and innovative technology, is designed to enhance the methanol synthesis process by increasing the conversion of synthesis gas into methanol. This results in higher yields of methanol and lower energy consumption, making the production process more cost-effective and environmentally friendly.

The company behind this innovative catalyst, has a long history of pioneering research and development in the chemical industry. With a strong focus on sustainability and innovation, the company has continuously worked towards developing products and solutions that not only meet the demands of the industry but also contribute to a more sustainable future.

By leveraging their expertise in chemical manufacturing and their commitment to research and development, the company has successfully developed the Methanol Synthesis Catalyst, which is a testament to their dedication to advancing the industry and addressing key challenges.

The catalyst not only offers improved efficiency and sustainability in methanol production but also provides a significant competitive advantage to the company's customers. By utilizing this advanced catalyst, methanol producers can enhance their production processes, reduce costs, and minimize their environmental footprint, giving them a strong position in the market.

Furthermore, the catalyst's superior performance and reliability ensure consistent and high-quality methanol production, meeting the stringent requirements of the industry and enabling customers to meet the growing demand for methanol around the world.

In addition to its technical capabilities, the company's commitment to customer support and service further enhances the value proposition of the Methanol Synthesis Catalyst. With a global network of technical experts and customer support teams, the company is well-equipped to provide comprehensive assistance and guidance to customers in implementing and optimizing the use of the catalyst in their production facilities.

The introduction of the Methanol Synthesis Catalyst comes at a critical time for the chemical industry, as the demand for methanol continues to grow across various sectors, including energy, transportation, and chemical manufacturing. With its ability to improve the efficiency and sustainability of methanol production, the catalyst is poised to play a crucial role in meeting this increasing demand while also addressing the industry's environmental and economic challenges.

Overall, the launch of the Methanol Synthesis Catalyst represents a significant milestone for the company and the chemical industry as a whole. Not only does it demonstrate the company's leadership in developing innovative solutions, but it also highlights their commitment to advancing the industry and driving positive change.

As the demand for methanol continues to rise, the Methanol Synthesis Catalyst is well-positioned to make a lasting impact on the industry, offering a more sustainable and efficient approach to methanol production while also creating new opportunities for growth and development. With its advanced technology, proven performance, and unwavering commitment to excellence, the catalyst is set to redefine the future of methanol production and solidify the company's position as a trusted leader in the chemical industry.

Company News & Blog

Newly Developed Zsm-5 Shows Promising Results for Advanced Materials

ZSM-5 is a zeolite material used in the catalytic cracking of petroleum for the production of gasoline. It is a highly-effective catalyst due to its uniform pore structure, high surface area, and strong acidity. The use of ZSM-5 has enabled the petroleum industry to produce gasoline with higher octane numbers and better fuel efficiency.In recent years, the demand for ZSM-5 has been steadily increasing as the automotive industry continues to grow. As a result, the production and supply of ZSM-5 have become vital for the petrochemical industry. This has led to the development of new and more efficient methods for producing ZSM-5, such as the innovative process developed by {company name}.{Company name} is a leading manufacturer of zeolite materials and has been at the forefront of ZSM-5 production for many years. The company has developed a proprietary method for producing ZSM-5 that is more cost-effective and environmentally friendly than traditional methods. This has allowed {company name} to become a key supplier of ZSM-5 to the petrochemical industry.The unique production method developed by {company name} involves the use of advanced catalyst synthesis technology and precise control of reaction conditions. This results in the production of ZSM-5 with higher purity and improved performance compared to traditional methods. Furthermore, the process developed by {company name} has significantly reduced energy consumption and waste generation, making it a more sustainable option for ZSM-5 production.The success of {company name} in the production of ZSM-5 has not gone unnoticed. The company has received accolades for its innovative production process and has become a trusted supplier to major petrochemical companies around the world. This has helped {company name} to expand its market share and establish itself as a leader in the zeolite materials industry.In addition to ZSM-5, {company name} also manufactures a wide range of other zeolite materials for various applications, including catalytic cracking, adsorption, and ion exchange. The company's expertise in zeolite materials has allowed it to provide tailored solutions to its customers, addressing their specific needs and requirements.Looking ahead, {company name} is committed to further advancing its production technology and expanding its product offerings. The company continues to invest in research and development to improve the performance and cost-effectiveness of its zeolite materials. Additionally, {company name} is exploring new applications for its zeolite materials, seeking to diversify its product portfolio and capture new market opportunities.As the global demand for gasoline and petrochemical products continues to grow, the need for high-quality zeolite materials such as ZSM-5 will remain crucial. With its innovative production methods and extensive expertise, {company name} is well-positioned to meet this demand and continue to be a leading supplier to the petrochemical industry.In conclusion, ZSM-5 is an essential catalyst for the production of high-quality gasoline, and {company name} is at the forefront of its production. With its innovative production methods and commitment to excellence, {company name} is a trusted supplier of zeolite materials to the petrochemical industry, and is poised for continued success in the years to come.

High-quality Alumina: Important Information You Need to Know

The use of Gamma Alumina in various industrial applications has been on the rise in recent years, and with the increasing demand for high-quality alumina products, {Company} has emerged as a leading provider in the market. From catalyst supports to wear-resistant components, the versatility and durability of Gamma Alumina make it an indispensable material in a wide range of industries.{Company} has been at the forefront of developing and manufacturing high-purity Gamma Alumina products that meet the stringent quality standards of the industry. With a deep understanding of the unique properties and applications of Gamma Alumina, {Company} has been able to provide tailored solutions to its customers, helping them achieve superior performance and efficiency in their processes.Gamma Alumina, also known as γ-alumina, is a stable form of aluminum oxide with a crystalline structure that gives it exceptional thermal and chemical stability. This makes it an ideal material for use in catalyst supports, where it can withstand the harsh conditions of high-temperature chemical reactions. {Company} offers a range of Gamma Alumina-based catalyst supports that are designed to enhance the performance and longevity of catalysts in various industrial processes.In addition to catalyst supports, {Company} also produces high-purity Gamma Alumina powders for use in advanced ceramics and wear-resistant components. The exceptional hardness and abrasion resistance of Gamma Alumina make it an essential material for applications where durability is paramount. By leveraging its expertise in material science and engineering, {Company} has been able to develop innovative Gamma Alumina formulations that deliver superior performance in demanding environments.With a strong focus on research and development, {Company} is committed to advancing the capabilities of Gamma Alumina and exploring new opportunities for its use in cutting-edge technologies. By collaborating with industry partners and academic institutions, {Company} continues to push the boundaries of what is possible with Gamma Alumina, creating new possibilities for its customers in a wide range of industries.The commitment to quality and innovation has earned {Company} a strong reputation as a trusted supplier of high-performance Gamma Alumina products. With a global presence and a dedicated team of experts, {Company} is well-positioned to meet the growing demand for Gamma Alumina and continue to drive advancements in materials science and engineering.As the demand for high-quality alumina products continues to grow, {Company} remains committed to delivering value to its customers through its innovative Gamma Alumina solutions. With a focus on quality, performance, and sustainability, {Company} is poised to lead the way in meeting the evolving needs of the industry and driving new possibilities for the use of Gamma Alumina in the years to come.In conclusion, the increasing demand for high-quality Gamma Alumina products has created new opportunities for innovation and growth in the industry. With its expertise in materials science and engineering, {Company} is well-positioned to meet the evolving needs of its customers and drive advancements in the use of Gamma Alumina across a wide range of industries. By continuing to invest in research and development, {Company} aims to further expand the capabilities of Gamma Alumina and create new possibilities for its use in the future.

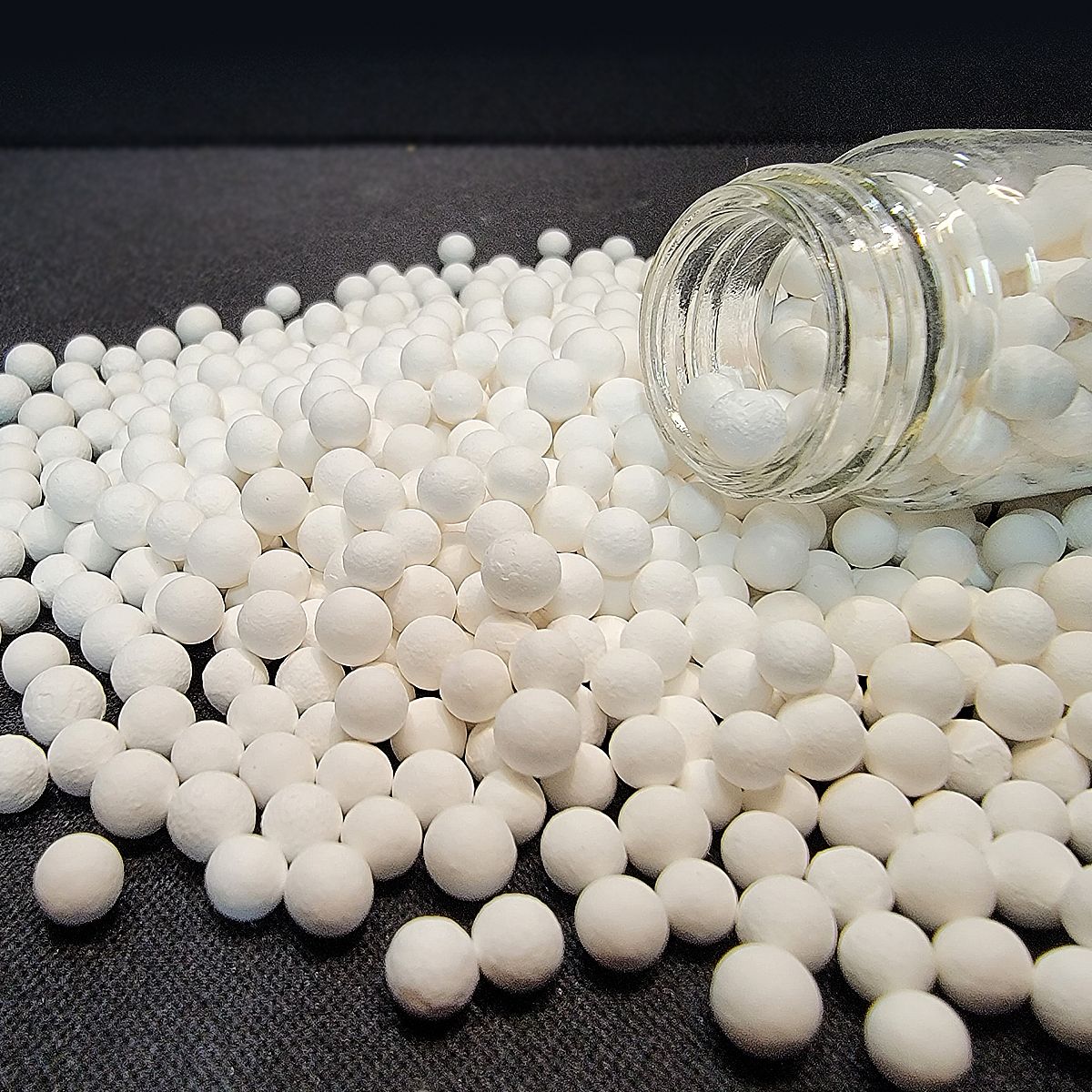

Innovative Catalyst Carrier Spheralite Shown to Improve Performance in Various Applications

Catalyst Carrier Spheralite, a leading provider of innovative catalyst carrier solutions, has garnered widespread attention in the chemical industry. The company has been praised for its revolutionary approach to catalyst carriers, offering high-performance solutions that cater to the evolving needs of the industry. With a strong focus on research and development, Catalyst Carrier Spheralite has positioned itself as a key player in the market, driving innovation and efficiency in catalytic processes.Since its establishment, Catalyst Carrier Spheralite has been dedicated to delivering cutting-edge solutions for various catalytic applications. The company's extensive range of products is designed to enhance the performance and longevity of catalysts, ultimately leading to improved process efficiency and cost savings for its customers.One of the key aspects of Catalyst Carrier Spheralite's success is its commitment to continuous improvement and innovation. The company invests heavily in research and development to stay ahead of the curve and anticipate the changing needs of the industry. By leveraging advanced technology and cutting-edge manufacturing processes, Catalyst Carrier Spheralite is able to develop highly efficient catalyst carrier solutions that meet the stringent requirements of its clients.In addition to its focus on innovation, Catalyst Carrier Spheralite is also renowned for its dedication to quality and reliability. The company adheres to strict quality control measures throughout the production process, ensuring that its products meet the highest standards of performance and durability. This commitment to quality has earned Catalyst Carrier Spheralite a stellar reputation in the industry, with many customers relying on its products to drive their business success.Catalyst Carrier Spheralite's success can also be attributed to its customer-centric approach. The company places a strong emphasis on building long-term partnerships with its clients, working closely with them to understand their specific needs and deliver personalized solutions. This customer-focused strategy has enabled Catalyst Carrier Spheralite to build a loyal and satisfied customer base, further solidifying its position as a trusted leader in the industry.Looking ahead, Catalyst Carrier Spheralite is poised for continued growth and success. The company is committed to pushing the boundaries of innovation and expanding its product portfolio to serve a wider range of industries and applications. With a strong foundation built on quality, reliability, and customer satisfaction, Catalyst Carrier Spheralite is well-positioned to shape the future of catalyst carriers and make a lasting impact on the chemical industry.Catalyst Carrier Spheralite's dedication to excellence and its relentless pursuit of innovation have set it apart as a leader in the field of catalyst carriers. With a proven track record of delivering exceptional solutions and a clear vision for the future, the company is well-equipped to continue driving positive change and advancing the industry as a whole. As demand for high-performance catalyst carriers continues to grow, Catalyst Carrier Spheralite is poised to lead the way, offering unparalleled products and expertise to meet the evolving needs of its customers.

Discover the Benefits of Using Alumina Carrier for Catalysts

Alumina Carrier For Catalysts: A Key Player in the Chemical IndustryWith the ever-increasing demand for environmental-friendly and efficient chemical processes, the use of catalysts has become crucial in various industrial applications. And at the heart of these catalysts lies the alumina carrier, a key component that plays a significant role in enhancing the performance and effectiveness of catalysts. Recognizing the importance of this material, {Company} has emerged as a leading provider of high-quality alumina carriers for catalysts, catering to the needs of the chemical industry worldwide.{Company} has been at the forefront of the chemical industry for over two decades, specializing in the development and production of advanced materials for a wide range of applications. The company's commitment to innovation, quality, and sustainability has earned it a reputation as a trusted partner for businesses seeking cutting-edge solutions for their catalyst needs.One of {Company}'s flagship products is its alumina carrier for catalysts, which is manufactured using state-of-the-art technology and processes to ensure exceptional performance and reliability. The alumina carrier serves as a support material for the active components of catalysts, providing high surface area, thermal stability, and mechanical strength to the catalyst system. This, in turn, enhances the catalyst's ability to facilitate chemical reactions and improve process efficiency.The use of {Company}'s alumina carrier has proven to be instrumental in various chemical processes, including the production of petrochemicals, fine chemicals, and environmental catalysts. The company's commitment to quality and excellence is reflected in its rigorous quality control measures, ensuring that its alumina carriers meet the highest standards of performance and durability.Furthermore, {Company} takes pride in its sustainable approach to manufacturing, prioritizing environmental responsibility and resource efficiency in its operations. The company's dedication to sustainability is evident in its use of eco-friendly production processes and commitment to reducing its environmental footprint. As a result, {Company}'s alumina carrier for catalysts is not only a high-performance material but also a responsible choice for businesses looking to minimize their environmental impact.In addition to its exceptional product quality, {Company} is known for its technical expertise and customer-focused approach. The company's team of experts works closely with clients to understand their specific catalyst requirements and provide tailored solutions that meet their needs. {Company} also offers technical support and consultation services to assist clients in optimizing the performance of their catalyst systems, further solidifying its position as a valuable partner in the chemical industry.Looking ahead, {Company} remains committed to driving innovation and excellence in the development of alumina carriers for catalysts, as well as other advanced materials. The company continues to invest in research and development to push the boundaries of material science and create new opportunities for enhancing chemical processes.As the demand for sustainable and efficient chemical processes continues to grow, {Company} is poised to play a pivotal role in the industry, offering cutting-edge solutions that deliver both performance and environmental responsibility. With its unwavering commitment to quality, sustainability, and innovation, {Company} is set to remain a key player in the chemical industry for years to come.

Discover the Latest Catalyst Carrier Innovations in the Market

Catalyst Carrier is a leading chemical company that has been at the forefront of innovation and research in the field of catalyst carriers for the past several decades. The company specializes in the development and production of high-quality catalyst carriers that are used in a wide range of industrial applications, including petrochemical, refining, and environmental protection industries.Catalyst Carrier's products are known for their exceptional quality, performance, and reliability, and the company has built a strong reputation for providing customized solutions to meet the specific needs of its customers. With a state-of-the-art production facility and a team of highly skilled engineers and researchers, Catalyst Carrier is committed to staying ahead of the curve and continuing to push the boundaries of what is possible in the world of catalyst carriers.One of the key strengths of Catalyst Carrier is its dedication to research and development. The company invests heavily in cutting-edge technologies and scientific advancements to ensure that its products are always at the cutting edge of innovation. By continuously improving and refining its products, Catalyst Carrier can provide its customers with the most advanced and effective catalyst carriers on the market.In addition to its commitment to innovation, Catalyst Carrier also places a strong emphasis on environmental sustainability. The company understands the importance of minimizing its impact on the environment and is dedicated to developing products and processes that are as environmentally friendly as possible. Through the use of advanced technologies and responsible production methods, Catalyst Carrier is able to minimize waste and reduce its carbon footprint while still delivering exceptional quality and performance.Catalyst Carrier's products are used in a wide variety of industrial applications, including refining, petrochemical, and environmental protection industries. The company's catalyst carriers play a crucial role in these industries, helping to facilitate important chemical reactions and processes that are essential for the production of a wide range of products.One of the key advantages of Catalyst Carrier's products is their versatility. The company is able to manufacture catalyst carriers that are tailored to meet the specific needs of its customers, ensuring that they are able to achieve the best possible results in their respective applications. From high-temperature resistance to exceptional durability, Catalyst Carrier's products are designed to excel in a variety of challenging environments.Catalyst Carrier's commitment to quality and innovation has earned it a strong reputation in the industry. The company has established itself as a trusted partner for companies operating in the refining, petrochemical, and environmental protection industries, and its products are known for their exceptional performance and reliability. With a focus on research and development, as well as a dedication to environmental sustainability, Catalyst Carrier is well-positioned to continue leading the way in the field of catalyst carriers for many years to come. In conclusion, Catalyst Carrier is a pioneering chemical company that is dedicated to pushing the boundaries of innovation and research in the field of catalyst carriers. With a strong focus on quality, performance, and environmental sustainability, the company has established itself as a trusted partner for companies operating in a wide range of industrial applications. Through its dedication to research and development, and its commitment to providing customized solutions for its customers, Catalyst Carrier is well-positioned to continue leading the way in the field of catalyst carriers for the foreseeable future.

Highly Effective Al2o3 Catalyst for Various Chemical Reactions

Al2O3 Catalyst: The Key to Sustainable and Efficient Chemical ProcessesIn the world of chemical manufacturing, catalysts play a crucial role in enabling sustainable and efficient processes. Among the various types of catalysts, Al2O3 catalysts have gained immense popularity for their ability to drive a wide range of chemical reactions with high selectivity and efficiency. Today, we will delve into the world of Al2O3 catalysts and explore their significance in the chemical industry.Before we dive into the specifics of Al2O3 catalysts, it is essential to understand the company behind these innovative catalysts. The company, which specializes in the development and production of advanced catalyst materials, has been at the forefront of catalysis technology for over two decades. With a strong focus on innovation and sustainability, the company has continuously pushed the boundaries of catalytic science, leading to the development of cutting-edge catalysts that address the evolving needs of the chemical industry.Al2O3, also known as aluminum oxide, serves as the backbone of the company’s catalyst technology. This versatile material exhibits exceptional thermal stability, high surface area, and acidic or basic properties, making it an ideal candidate for a wide range of catalytic applications. The company has leveraged the unique properties of Al2O3 to develop a portfolio of catalysts that cater to diverse chemical processes, including but not limited to, petrochemical refining, environmental remediation, and specialty chemical synthesis.One of the key strengths of Al2O3 catalysts lies in their ability to facilitate various catalytic reactions with high efficiency and selectivity. Whether it is the conversion of feedstocks into valuable products or the removal of harmful pollutants from industrial effluents, Al2O3 catalysts have demonstrated exceptional performance in driving these reactions while minimizing unwanted by-products. This results in significant cost savings for chemical manufacturers and reduces the environmental footprint of their processes.Furthermore, the company’s Al2O3 catalysts are designed to withstand the extreme operating conditions encountered in many chemical processes. With a focus on durability and longevity, these catalysts offer superior stability under high temperatures, pressures, and corrosive environments, ensuring prolonged catalyst life and consistent performance. This not only translates to cost-effective operations for the end-users but also aligns with the company’s commitment to sustainable and responsible manufacturing practices.In addition to their performance and durability, Al2O3 catalysts from the company are also notable for their versatility. The company offers a range of tailored catalyst formulations based on Al2O3 that are specifically designed to address the unique requirements of different chemical processes. Whether it is a fluidized bed reactor for catalytic cracking or a fixed-bed system for selective oxidation, the company’s Al2O3 catalysts can be customized to deliver optimal performance, thereby maximizing process efficiency and product quality.Looking ahead, the company continues to invest in research and development to further enhance the capabilities of Al2O3 catalysts. With a focus on leveraging advanced materials science and process engineering, the company aims to develop the next generation of Al2O3 catalysts that push the boundaries of catalytic performance and sustainability. These efforts are driven by the company's vision to be a leading provider of advanced catalyst solutions that enable the chemical industry to meet the challenges of tomorrow.In conclusion, Al2O3 catalysts have emerged as vital enablers of sustainable and efficient chemical processes, thanks to their exceptional performance, durability, and versatility. With the company's relentless commitment to innovation and sustainability, Al2O3 catalysts are set to play an even more significant role in shaping the future of the chemical industry. As the demand for cleaner, more sustainable chemical processes continues to grow, Al2O3 catalysts will undoubtedly be at the forefront of this transformative journey.

Top Alumina Carrier for Efficient Material Transportation

Alumina Carrier Unveils Groundbreaking Aluminum Transportation SolutionAlumina Carrier, a leading player in the transportation industry, has recently unveiled a revolutionary new aluminum transportation solution that is set to transform the way aluminum is transported and handled across the globe. The company's innovative approach to aluminum transportation is expected to significantly reduce costs and improve operational efficiency for its clients.The new aluminum transportation solution comes at a time when the aluminum industry is experiencing unprecedented growth, with increasing demand for aluminum products in various sectors including aerospace, automotive, and construction. As a result, the efficient and reliable transportation of aluminum has become more important than ever.Alumina Carrier's new solution has been developed in response to the challenges faced by the aluminum industry, particularly in the transportation and handling of aluminum products. The solution has been designed with a focus on efficiency, reliability, and cost-effectiveness, and is expected to be a game-changer for companies involved in the production and distribution of aluminum products.One of the key features of the new aluminum transportation solution is its advanced technology, which allows for the safe and secure transportation of aluminum products over long distances. The solution includes state-of-the-art transportation containers and handling equipment, as well as advanced tracking and monitoring systems to ensure the safety and security of the aluminum products throughout the transportation process.In addition to its advanced technology, Alumina Carrier's new solution also offers significant cost savings for its clients. The company's streamlined transportation and handling processes are expected to result in lower transportation costs, reduced lead times, and improved overall operational efficiency for clients in the aluminum industry.Furthermore, Alumina Carrier's new aluminum transportation solution is designed to be environmentally friendly, with a focus on reducing carbon emissions and minimizing the environmental impact of aluminum transportation. The company has implemented a number of sustainable practices and initiatives to ensure that its transportation processes are as environmentally friendly as possible.In a statement, the CEO of Alumina Carrier expressed his enthusiasm for the new aluminum transportation solution, stating that it represents a major milestone for the company and the aluminum industry as a whole. He highlighted the company's commitment to innovation and sustainability, and its dedication to providing its clients with the most efficient and cost-effective transportation solutions possible.With its new aluminum transportation solution, Alumina Carrier is well-positioned to meet the growing demand for efficient and reliable transportation of aluminum products. The company's innovative approach to aluminum transportation is expected to set a new standard for the industry, and to provide its clients with a competitive edge in an increasingly demanding market.As the aluminum industry continues to expand, the efficient and reliable transportation of aluminum products will be crucial for companies looking to stay ahead of the competition. With its groundbreaking new solution, Alumina Carrier is poised to lead the way in aluminum transportation and to help shape the future of the industry.In conclusion, Alumina Carrier's new aluminum transportation solution represents a significant advancement for the aluminum industry, offering a range of benefits including improved efficiency, cost savings, and environmental sustainability. The company's innovative approach to aluminum transportation is expected to have a lasting impact on the industry, providing its clients with a competitive advantage in a rapidly evolving market.

Catalyst Carrier Unveils Revolutionary New Technology for Improved Performance

Catalyst Carrier, a leading provider of cutting-edge solutions for the chemical industry, has recently announced a major breakthrough in catalyst technology that is set to revolutionize the way chemical processes are conducted. The company, known for its innovative approach to catalysis, has developed a new carrier material that promises to significantly enhance the performance and efficiency of catalysts used in a wide range of chemical reactions.The new carrier material, which is a proprietary blend of advanced ceramics and metals, has been designed to address the limitations of traditional catalyst carriers. It offers superior thermal stability, mechanical strength, and surface area, making it an ideal platform for catalyst deposition and dispersion. This breakthrough is expected to have a profound impact on the chemical industry, enabling manufacturers to develop more sustainable and cost-effective processes for the production of various chemicals, polymers, and specialty materials.In a recent statement, the company's CEO expressed excitement about the potential of the new carrier material, stating that it represents a major milestone in the company's ongoing commitment to innovation and excellence. "We believe that this breakthrough has the potential to transform the way catalysts are utilized in the chemical industry," the CEO said. "Our new carrier material offers unprecedented performance and durability, opening up new possibilities for a wide range of chemical processes. We are proud to be at the forefront of this exciting development and look forward to working with our partners to unlock its full potential."The development of the new carrier material is a result of extensive research and development efforts at Catalyst Carrier. The company has a long history of innovation in catalyst technology, leveraging its expertise in materials science, chemical engineering, and process design to create novel solutions for the industry. The new carrier material is the latest in a series of successful advancements by the company, which has consistently demonstrated its ability to push the boundaries of what is possible in catalysis.The potential applications of the new carrier material are vast and diverse. It is expected to find use in a wide range of chemical processes, including those related to petrochemicals, pharmaceuticals, fine chemicals, and environmental remediation. The material's high thermal stability and mechanical strength make it well-suited for high-temperature reactions and harsh operating conditions, while its large surface area and optimized pore structure enable efficient catalyst loading and utilization.One of the key benefits of the new carrier material is its potential to improve the sustainability of chemical processes. By enabling more efficient catalyst utilization, it can help reduce the consumption of raw materials and energy, lower the generation of waste and emissions, and ultimately contribute to a more environmentally friendly and economically viable chemical industry. This aligns with Catalyst Carrier's commitment to driving positive change through its innovative solutions, and the company is eager to work with its partners to explore the possibilities of the new material.As the chemical industry continues to evolve, with a growing emphasis on sustainability and efficiency, the development of new catalyst technologies will be crucial. Catalyst Carrier's breakthrough in carrier material represents a significant step forward in this regard, offering a promising avenue for the development of next-generation chemical processes. The company is poised to play a leading role in the commercialization of the new material, collaborating with industry partners to bring its benefits to fruition.In conclusion, Catalyst Carrier's development of a new carrier material for catalysts is a major advancement that holds great promise for the chemical industry. The material's superior performance and versatility position it as a game-changer for a wide range of chemical processes, with far-reaching benefits in terms of sustainability, efficiency, and economics. As the company continues to leverage its expertise and innovation, it is well-positioned to drive positive change in the industry and create lasting value for its partners and customers.

Efficient Isomerization Catalysts for Industrial Applications

New Isomerization Catalyst Set to Revolutionize Petroleum Refining IndustryThe petroleum refining industry is set to undergo a major transformation with the introduction of a groundbreaking new isomerization catalyst by a leading chemical company.The new catalyst, which represents a significant advancement in the field of petroleum refining, is expected to revolutionize the process of converting straight-chain hydrocarbons into their branched-chain isomers, a key step in the production of high-octane gasoline and other fuel products.The catalyst, developed by {}, is the result of years of research and development, and is poised to deliver a quantum leap in performance and efficiency compared to existing catalysts currently in use in the industry.Isomerization is a crucial process in the refining of petroleum, as it allows refiners to convert lower-octane straight-chain hydrocarbons into higher-octane branched-chain isomers, thereby improving the quality of gasoline and other fuel products. This, in turn, leads to increased fuel efficiency and reduced emissions in vehicles.The new catalyst from {} promises to deliver a host of benefits to the petroleum refining industry, including improved product quality, increased production efficiency, and reduced environmental impact. With its superior performance and versatility, the catalyst is expected to become an indispensable tool for refiners looking to optimize their operations and stay ahead of the competition.In addition to its cutting-edge technology, the catalyst also offers cost savings for refiners, thanks to its longer lifespan and lower operating costs compared to traditional catalysts. This is particularly significant at a time when the industry is facing increasing pressure to improve efficiency and reduce costs in order to remain competitive in the market.{} has a strong track record of innovation and technical expertise in the refining and petrochemical industries, making it a trusted partner for refiners seeking to stay at the forefront of technological advancements. With a global network of research and development facilities, as well as a team of highly skilled scientists and engineers, the company is well-positioned to support the industry in adopting and implementing the new catalyst.In addition to its technological capabilities, {} is committed to sustainability and environmental responsibility. The company's new catalyst is designed to help refiners improve their environmental performance by reducing energy consumption and greenhouse gas emissions, while also enabling the production of cleaner, higher-quality fuels.The introduction of the new isomerization catalyst marks a significant milestone for the petroleum refining industry, offering a glimpse into the future of refining technology. With its potential to deliver substantial performance improvements, cost savings, and environmental benefits, the catalyst is poised to make a lasting impact on the industry, demonstrating once again the pivotal role that innovation plays in driving progress and competitiveness in the global energy sector.With its strong reputation for technical excellence, innovation, and commitment to sustainability, {} is well-positioned to lead the industry into a new era of refining technology, and help refiners unlock new levels of performance and efficiency in their operations. As the industry looks to embrace the opportunities and challenges of the future, the new isomerization catalyst from {} is set to play a central role in shaping the next phase of evolution for petroleum refining.

Discover the Latest Innovations in Gamma Alumina Technology

Gamma Alumina, a new product in the market, has been making waves in the industrial sector with its unique properties and wide range of applications. This innovative material has caught the attention of various industries and has been gaining popularity due to its exceptional characteristics.Gamma Alumina, also known as γ-alumina, is a form of aluminum oxide that is highly stable and has a unique crystal structure. It is widely used as a catalyst support in the chemical and petrochemical industries, as well as in the production of various chemicals and plastics. Its high surface area and pore volume make it an ideal material for adsorption and catalysis, making it a versatile and valuable component in a wide range of industrial processes.One of the leading producers of Gamma Alumina is {Company Name}, a renowned company in the field of specialty chemicals and materials. With a strong focus on research and development, {Company Name} has been at the forefront of innovation, constantly pushing the boundaries of what is possible in the industry.{Company Name} has been investing heavily in the development of Gamma Alumina, recognizing its potential to revolutionize various industrial processes. The company has put in extensive resources to create a high-quality product that meets the demanding requirements of its customers. With state-of-the-art manufacturing facilities and a team of highly skilled professionals, {Company Name} has been able to produce Gamma Alumina of exceptional quality and consistency.The unique properties of Gamma Alumina have made it an indispensable material in various applications. Its high surface area and pore volume make it an excellent catalyst support, providing a stable and efficient platform for various chemical reactions. This has led to its widespread use in the production of chemicals, plastics, and other industrial products. Additionally, its superior adsorption capabilities make it a valuable material for the purification and separation of gases and liquids, further expanding its utility in the industry.{Company Name} has been working closely with its customers to understand their specific needs and requirements, and has been able to tailor its Gamma Alumina products to meet their exact specifications. This customer-centric approach has earned {Company Name} a reputation for reliability and excellence in the industry, further solidifying its position as a preferred supplier of Gamma Alumina.In addition to its outstanding technical properties, {Company Name} has also been committed to ensuring that its Gamma Alumina products meet the highest standards of environmental and safety regulations. The company has implemented stringent quality control measures and sustainable manufacturing practices to minimize its environmental impact and ensure the safety of its employees and customers.The success of Gamma Alumina in the market can be attributed to its exceptional properties and the efforts of companies like {Company Name} to develop and supply high-quality products. As the demand for advanced materials continues to grow, Gamma Alumina is poised to play a crucial role in driving innovation and progress in the industrial sector.In conclusion, Gamma Alumina has emerged as a game-changing material in the industrial sector, offering unmatched properties and a wide range of applications. {Company Name} has been instrumental in the development and supply of high-quality Gamma Alumina, showcasing its commitment to innovation, quality, and sustainability. With its exceptional technical properties and versatile applications, Gamma Alumina is set to make a significant impact in various industrial processes, driving progress and efficiency in the industry.