Innovative Catalyst Carrier Offers Breakthrough Technology for Enhanced Performance

By:Admin

Founded in 2005, Catalyst Carrier has steadily expanded its presence in the industry, becoming a leading supplier of catalyst supports and carriers for the global chemical and petrochemical market. Their commitment to research and development has led to the creation of cutting-edge products that enable their clients to maximize efficiency while minimizing environmental impact.

Catalyst Carrier's success can be attributed to their unwavering dedication to innovation and excellence. Their team of experts continuously works to develop new and improved catalyst carriers that meet the diverse needs of their clients. This commitment to advancing technology has allowed Catalyst Carrier to maintain a competitive edge in the market, while also making significant contributions to the sustainability of the chemical industry.

One of the key factors that sets Catalyst Carrier apart from its competitors is its comprehensive approach to sustainability. The company is committed to minimizing its environmental footprint through the use of eco-friendly materials and processes. Their products are designed to enhance the performance of catalyst systems, thereby reducing energy consumption and emissions in chemical production processes. This focus on sustainability has not only earned Catalyst Carrier a reputation as an industry leader, but has also garnered recognition from environmental organizations and regulatory bodies.

In addition to their focus on sustainability, Catalyst Carrier places a strong emphasis on customer satisfaction. They work closely with their clients to understand their specific needs and develop customized solutions that address their unique challenges. This client-centered approach has earned Catalyst Carrier a loyal customer base and has positioned them as a trusted partner in the industry.

The company's dedication to excellence and innovation has resulted in a wide range of products that cater to various applications within the chemical and petrochemical industries. Catalyst Carrier offers a diverse portfolio of catalyst supports and carriers, including metal oxides, zeolites, and activated carbon, among others. These products are designed to enhance the performance of catalyst systems, leading to improved efficiency, reduced waste, and lower operating costs for their clients.

One of the key products in Catalyst Carrier's portfolio is their advanced metal oxide catalyst carriers. These carriers are widely used in a range of catalytic processes, including oxidation, hydrogenation, and dehydrogenation. Catalyst Carrier's metal oxide carriers are engineered to provide high surface area and thermal stability, making them an ideal choice for demanding applications in the chemical industry.

The company also offers a variety of zeolite catalyst carriers, which are known for their exceptional catalytic and adsorptive properties. Zeolite carriers are widely used in processes such as fluid catalytic cracking, isomerization, and alkylation, and Catalyst Carrier's high-quality products have been instrumental in enhancing the performance of these applications.

Furthermore, Catalyst Carrier's activated carbon catalyst carriers have proven to be highly effective in a range of environmental and industrial applications. These carriers are designed to adsorb pollutants and impurities, making them an essential component in emission control systems and wastewater treatment processes.

As Catalyst Carrier continues to expand its presence in the global market, the company remains dedicated to pushing the boundaries of catalysis technology and driving innovation in the chemical industry. With a strong focus on sustainability, customer satisfaction, and advanced product development, Catalyst Carrier is poised to remain a key player in the industry for years to come.

Company News & Blog

Discover the Unleashed Potential of Alumina Catalysts - A Game-Changer in the News!

Title: Innovations in Catalyst Technology Revolutionize Industrial ProcessesIntroduction:With an unyielding focus on providing cutting-edge solutions to enhance industrial processes, Company XYZ has recently unveiled a revolutionary gamma alumina catalyst. This breakthrough development promises to deliver superior catalytic performance, enabling industries to achieve enhanced productivity, reduced energy consumption, and minimized environmental impact. By introducing this remarkable catalyst, Company XYZ cements its position as a pioneer in the field of catalyst technology.Gamma Alumina Catalyst: A Game-Changer for Industrial ProcessesCompany XYZ's groundbreaking gamma alumina catalyst represents a significant advancement in catalyst technology. Combining cutting-edge research and state-of-the-art manufacturing techniques, this catalyst empowers various industries to optimize their processes while striving for higher efficiency standards.Improved Catalytic Performance:The key highlight of Company XYZ's gamma alumina catalyst lies in its exceptional catalytic performance, which surpasses that of traditional catalysts. This catalyst demonstrates an unprecedented ability to initiate and accelerate chemical reactions, enabling industries to achieve higher conversion rates and improved product quality. Moreover, the gamma alumina catalyst exhibits remarkable stability, ensuring consistent performance over an extended operational lifespan.Reduced Energy Consumption:By utilizing Company XYZ's gamma alumina catalyst, industries can significantly reduce energy consumption during their production processes. The catalyst's enhanced efficiency allows for lower reaction temperatures and shorter reaction times, leading to substantial energy savings. This not only contributes to cost reduction but also aids in environmental sustainability by reducing greenhouse gas emissions associated with excessive energy consumption.Versatility Across Industries:The versatility of Company XYZ's gamma alumina catalyst makes it suitable for a wide range of industries, including petroleum refining, chemical manufacturing, and environmental remediation. Its unique composition and superior functionality enable it to tackle diverse chemical reactions, such as hydrocracking, hydrotreating, and hydrogenation, with exceptional efficiency. This versatility empowers industries to streamline their operations, optimize resource utilization, and stay at the forefront of technological advancements.Environmental Impact:With sustainability at the forefront of global concerns, Company XYZ's gamma alumina catalyst offers a viable solution to minimize environmental impact. This catalyst facilitates the production of cleaner fuels by enabling more efficient removal of impurities from petroleum feedstocks. Additionally, it plays a crucial role in reducing harmful emissions during various chemical manufacturing processes. By adopting this catalyst, industries can contribute to a greener future while adhering to stringent environmental regulations.Research and Development:The development of Company XYZ's gamma alumina catalyst is a result of relentless pursuit and investment in research and development. The company's dedicated team of scientists and engineers has intricately researched catalyst compositions, optimization techniques, and advanced manufacturing processes, ensuring that the catalyst maintains its superior performance across a wide range of operating conditions. Company XYZ's commitment to continuous innovation underscores its dedication to providing state-of-the-art catalyst solutions to meet ever-evolving industry demands.Conclusion:Company XYZ's groundbreaking gamma alumina catalyst ushers in a new era of catalytic performance, enabling industries to enhance productivity, reduce energy consumption, and minimize their environmental footprint. By leveraging this catalyst, industrial processes can achieve heightened efficiency, increased conversion rates, and improved product quality. Company XYZ's relentless commitment to innovation and its profound impact on industrial processes solidify its position as a premier provider of cutting-edge catalyst solutions.

New Breakthrough in Methanol Synthesis Catalyst Technology

Methanol synthesis catalysts are crucial components in the production of methanol, which is a key ingredient in a wide range of industrial and chemical processes. These catalysts play a critical role in the conversion of synthesis gas (a mixture of carbon monoxide, carbon dioxide, and hydrogen) into methanol, a process that is used in the production of a variety of products, including chemicals, plastics, fuels, and more.One company that has been at the forefront of developing and manufacturing high-performance methanol synthesis catalysts is {}. With a strong focus on research and development, the company has continuously improved its catalysts to enhance their efficiency, durability, and environmental performance. The company's commitment to excellence has made it a trusted partner for numerous methanol producers around the world.The {} methanol synthesis catalyst is designed to deliver superior performance and reliability, making it a top choice for methanol producers seeking to optimize their production processes. The catalyst is engineered to maintain high activity and selectivity over an extended operating life, resulting in increased productivity and reduced downtime for catalyst replacement. In addition, the catalyst's advanced formulation enables it to operate effectively under a wide range of process conditions, ensuring consistent performance in various operating environments.In terms of environmental sustainability, the {} methanol synthesis catalyst is designed to minimize energy consumption and reduce greenhouse gas emissions. By promoting the conversion of synthesis gas into methanol with high efficiency, the catalyst helps methanol producers improve their process economics and lower their environmental footprint. This aligns with the company's commitment to developing catalysts that not only deliver exceptional performance but also contribute to a more sustainable and eco-friendly industry.In addition to its technical capabilities, {} also offers comprehensive technical support and services to assist customers in optimizing their methanol production processes. The company's team of experienced engineers and chemists work closely with customers to understand their specific requirements and provide tailored solutions to maximize the performance of the {} methanol synthesis catalyst. From catalyst selection and installation to performance monitoring and troubleshooting, the company's technical support services are designed to help customers achieve the best possible results.Looking ahead, {} is continuously investing in research and development to further advance its methanol synthesis catalyst technology. By leveraging its expertise in catalysis and process engineering, the company is exploring new opportunities to enhance the performance and sustainability of its catalysts, ultimately aiming to drive innovation and progress in the methanol production industry. With a deep commitment to excellence and a focus on customer satisfaction, {} is poised to remain a leading provider of high-performance methanol synthesis catalysts for years to come.In conclusion, methanol synthesis catalysts are vital components in the production of methanol, and {} has established itself as a trusted leader in this space. With its advanced catalyst technology, commitment to sustainability, and comprehensive technical support services, the company continues to deliver exceptional value to methanol producers worldwide. As the industry evolves, {} remains dedicated to pushing the boundaries of catalyst innovation and providing customers with the solutions they need to succeed in a rapidly changing market.

Key Insights into the Uses and Benefits of Alumina Catalysts

Gamma Alumina Catalyst Proves to be a Game-Changer in Petrochemical IndustryThe global petrochemical industry has experienced significant growth over the past decade, driven by increasing demand for plastics, polymers, and other chemical products. As the industry continues to expand, the need for innovative catalysts to improve process efficiency and product quality has become more critical than ever. (Company Name), a leading provider of advanced catalyst solutions, has emerged as a key player in this space with its groundbreaking Gamma Alumina Catalyst.Gamma Alumina Catalyst, developed and produced by (Company Name), has proven to be a game-changer for petrochemical companies looking to enhance their production processes. The catalyst is designed to improve the performance and sustainability of various chemical and petrochemical processes, including hydrocracking, hydrotreating, and fluid catalytic cracking. Its unique properties, including high surface area, thermal stability, and excellent acidity, make it a versatile and reliable choice for a wide range of applications.One of the key advantages of (Company Name)'s Gamma Alumina Catalyst is its ability to enhance the conversion of feedstocks into valuable products, such as gasoline, diesel, and petrochemical intermediates. By facilitating more efficient and selective reactions, the catalyst enables petrochemical companies to maximize their production yields while minimizing energy consumption and waste generation. This not only improves the overall economics of the process but also supports the industry's sustainability goals.In addition to its performance benefits, Gamma Alumina Catalyst also offers operational advantages for petrochemical companies. Its superior thermal stability and resistance to poisons and contaminants allow for longer catalyst lifetimes and reduced maintenance requirements, resulting in lower operating costs and improved process reliability. Furthermore, the catalyst's high physical strength and attrition resistance contribute to a more stable and predictable operation, reducing the risk of catalyst loss and process upsets.(Company Name) has established itself as a trusted partner for petrochemical companies seeking reliable and effective catalyst solutions. With a strong focus on research and development, the company is committed to continuously improving its product offerings to address the evolving needs and challenges of the industry. Its state-of-the-art manufacturing facilities and stringent quality control processes ensure that Gamma Alumina Catalyst consistently meets the highest standards of performance and reliability.The success of Gamma Alumina Catalyst can be attributed to (Company Name)'s extensive expertise in catalyst technology and its collaborative approach to customer partnerships. By working closely with petrochemical companies to understand their specific requirements and challenges, the company can customize its catalyst solutions to deliver the best possible results. This customer-centric approach has enabled (Company Name) to build long-lasting relationships with industry leaders and gain a strong foothold in the global petrochemical market.As the demand for petrochemical products continues to grow, (Company Name) remains dedicated to advancing the industry through its innovative catalyst solutions. Its ongoing investment in research and development, combined with its commitment to operational excellence and sustainability, positions the company as a trusted ally for petrochemical companies seeking to optimize their processes and stay ahead of the competition.The widespread adoption of Gamma Alumina Catalyst by petrochemical companies around the world is a testament to its proven performance and reliability. As the industry looks to address the increasing complexities and demands of the market, (Company Name) stands ready to support its customers with cutting-edge catalyst solutions that deliver tangible value and contribute to a more sustainable future for the petrochemical industry.In conclusion, (Company Name)'s Gamma Alumina Catalyst has emerged as a critical enabler for the petrochemical industry, offering unmatched performance, reliability, and sustainability benefits. With its unwavering commitment to technological innovation and customer satisfaction, (Company Name) continues to drive positive change in the industry and solidify its position as a leader in the global catalyst market.

Top Residue Hydrogenation Catalysts for Efficient Industrial Processes

The global chemical process industries are constantly seeking innovative and sustainable solutions for catalytic processes. In line with this trend, a leading catalyst manufacturer, {} has introduced a highly efficient Residue Hydrogenation Catalyst. This catalyst offers significant improvements in residue upgrading processes, allowing for greater efficiency and reduced environmental impact.With a strong focus on research and development, {} has established itself as a prominent player in the global catalyst market. The company's expertise in catalyst design and manufacturing has enabled it to consistently deliver high-performance solutions to its customers. This latest introduction of the Residue Hydrogenation Catalyst is a testament to {}’s commitment to innovation and sustainability.The Residue Hydrogenation Catalyst is specifically designed to address the challenges associated with residue upgrading in the petroleum refining industry. Residue upgrading is a critical process that involves converting heavy, high-sulfur hydrocarbon fractions into lighter, low-sulfur products such as gasoline and diesel. This process is essential for maximizing the value of crude oil and meeting stringent environmental regulations.The new catalyst from {} offers several key advantages over traditional catalysts used in residue hydrogenation. It delivers higher activity and selectivity, resulting in improved conversion rates and product quality. Additionally, the catalyst has enhanced stability, allowing for longer operating cycles and reduced catalyst replacement frequency. These benefits translate to significant cost savings and operational efficiency for refinery operators.One of the notable features of the Residue Hydrogenation Catalyst is its superior resistance to catalyst poisons and deactivation factors. This ensures consistent performance and prolonged catalyst life, even in challenging operating conditions. The catalyst's robust design and formulation are the result of extensive research and testing by {}’s team of experienced chemists and engineers.In addition to its technical capabilities, the Residue Hydrogenation Catalyst aligns with {}’s commitment to sustainability. The catalyst enables refineries to achieve higher yields of clean, low-sulfur fuels, contributing to reduced emissions and environmental impact. By facilitating more efficient residue upgrading, the catalyst supports the industry's efforts to enhance energy efficiency and reduce carbon footprint.The introduction of the Residue Hydrogenation Catalyst further solidifies {}’s position as a catalyst supplier of choice for the global refining and petrochemical industries. The company's comprehensive portfolio of catalysts caters to various process requirements, including hydroprocessing, isomerization, and reforming, among others. {} leverages its technical expertise and customer-centric approach to provide tailored solutions that address specific operational challenges and performance goals.The Residue Hydrogenation Catalyst is backed by {}’s technical support and services, ensuring seamless integration and optimization within refinery operations. The company's dedicated technical teams collaborate closely with customers to understand their unique needs and offer comprehensive assistance, from catalyst selection to implementation and ongoing support.As the global energy landscape continues to evolve, the demand for efficient and sustainable refining processes will only grow. {} remains at the forefront of this evolution, driving innovation and delivering value through its advanced catalyst solutions. The Residue Hydrogenation Catalyst exemplifies the company's commitment to enabling its customers to achieve operational excellence while meeting environmental and regulatory requirements.In conclusion, the introduction of the Residue Hydrogenation Catalyst by {} marks a significant advancement in catalyst technology for residue upgrading in the petroleum refining industry. With its exceptional performance, environmental benefits, and comprehensive support, the catalyst underscores {}’s position as a trusted partner for catalyst solutions. As the industry continues its pursuit of sustainable and efficient processes, {} remains poised to lead the way with its cutting-edge innovations.

Ultimate Guide to Sulfur Recovery Catalysts: Benefits and Uses

Claus Sulfur Recovery Catalyst is an essential component in the process of sulfur recovery in the oil and gas industry. This catalyst is used to convert hydrogen sulfide (H2S) into elemental sulfur, which is an important byproduct in the production of natural gas and petroleum. In recent years, there has been a growing demand for sulfur recovery catalysts due to the increasing focus on environmental regulations and the need to minimize sulfur emissions from industrial processes.One of the leading suppliers of Claus Sulfur Recovery Catalyst in the market is [Company Name]. The company has been at the forefront of developing and supplying high-quality catalysts for sulfur recovery applications. With a strong emphasis on research and development, [Company Name] has continuously improved its catalyst formulations to meet the evolving needs of the industry.[Company Name] was founded in [year] and has since established itself as a reliable and innovative supplier of catalysts and related solutions for the oil and gas sector. The company's state-of-the-art manufacturing facilities and stringent quality control measures ensure that its products meet the highest standards of performance and reliability. Additionally, [Company Name] has a dedicated team of technical experts who provide comprehensive support to customers, including catalyst selection, process optimization, and troubleshooting.In response to the increasing demand for sulfur recovery catalysts, [Company Name] has recently introduced a new and improved catalyst formulation that offers enhanced performance and efficiency. This new catalyst has been specifically designed to address the challenges faced by operators in sulfur recovery units, such as high H2S concentrations, varying feed compositions, and stringent emissions regulations.The key features of [Company Name]'s new sulfur recovery catalyst include:High H2S Conversion Efficiency: The catalyst has been optimized to achieve maximum conversion of H2S to elemental sulfur, thus minimizing sulfur emissions and ensuring compliance with environmental regulations.Improved Stability and Longevity: The catalyst exhibits excellent stability and resistance to deactivation, resulting in longer catalyst life and reduced operating costs for plant operators.Enhanced Activity at High Temperatures: The new formulation is capable of maintaining high catalytic activity even at elevated temperatures, which is particularly beneficial in applications with challenging process conditions.Furthermore, [Company Name] provides comprehensive technical support to its customers, including catalyst loading and start-up assistance, performance monitoring, and catalyst regeneration services. This value-added support ensures that customers can maximize the performance and longevity of the catalyst, ultimately leading to improved operational efficiency and cost savings.In addition to its innovative product offerings, [Company Name] is committed to sustainability and environmental stewardship. The company continuously invests in research and development to develop catalysts that help reduce environmental impact and improve overall process efficiency. By partnering with [Company Name], customers can be assured of receiving sustainable and reliable solutions that align with their environmental and operational objectives.As the demand for sulfur recovery catalysts continues to grow, [Company Name] is well-positioned to support the industry with its cutting-edge products, technical expertise, and commitment to sustainability. With its new and improved catalyst formulation, the company is poised to set new benchmarks for performance and reliability in sulfur recovery applications, ultimately contributing to a cleaner and more efficient energy industry.

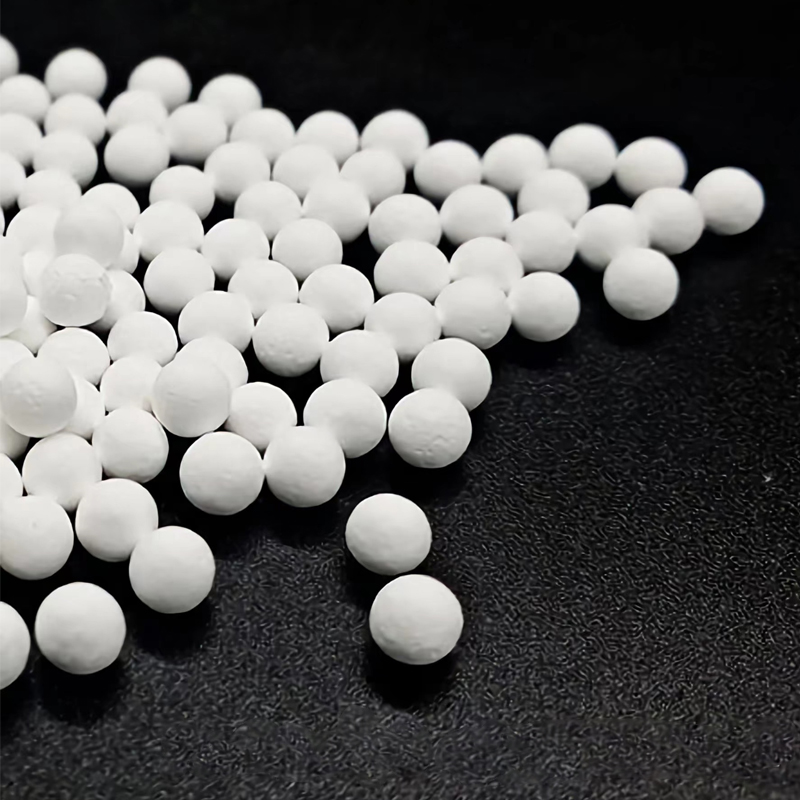

Versatile Activated Alumina Balls for Dehydration, Purification, and Gas Separation Applications

Activated alumina is a popular and effective catalyst used in a wide range of industries. It is a highly porous and adsorptive material that is commonly used for dehydration, purification and separation of liquids and gases. This versatile material is derived from aluminum oxide and exhibits superior adsorption capabilities, making it an ideal choice for a wide range of applications.The primary applications of activated alumina are in the fields of gas processing and wastewater treatment, where it is used as a catalyst to remove impurities and pollutants from air and water. It is effective in removing dissolved oxygen from water, which helps to prevent corrosion in pipelines and equipment. Additionally, activated alumina is used in the manufacturing of propylene and ethylene, as well as in the production of hydrogen and other gases.Two common grades of activated alumina are AD101 and F200, which are used for different applications. AD101 is a high-quality material that is used for the removal of moisture from gases and liquids. It is highly efficient in removing water from natural gas, air and other process streams, and is widely used in the natural gas industry for dehydration.F200, on the other hand, is a high-surface area activated alumina that is used in the purification of air and gases. It is highly effective in removing impurities such as sulfur, carbon dioxide, and other acidic contaminants that can damage pipelines and equipment. It is also used in the production of hydrogen and other industrial gases.In addition to its use as a catalyst, activated alumina is used in various other industries and applications. It is widely used in the food and beverage industry for the removal of impurities from water and other liquids. It is also used in the production of pharmaceuticals, where it is used to purify and filter drugs and other chemicals.Activated alumina is an essential component in many industrial processes, and its versatility and effectiveness make it an ideal choice for a wide range of applications. Its use as a catalyst in the gas processing and wastewater treatment industries has revolutionized these fields, making them more efficient, effective, and environmentally friendly. For those who are looking for high-quality activated alumina for their industrial processes, it is important to work with a trusted and reliable supplier.

Innovative new technology revolutionizes the industry

ZSM-48 is a revolutionary new technology that has the potential to change the way we think about energy production. This innovative product, developed by the leading company in the field of energy solutions, combines cutting-edge technology with sustainable practices to create a cleaner and more efficient energy source.The ZSM-48 is a compact and efficient energy storage system that can be used to power everything from homes to large industrial facilities. It harnesses the power of renewable energy sources such as solar and wind, and stores it for use when it is needed most. This means that energy can be generated and stored during times of low demand, and then used when demand is at its peak, reducing the need for fossil fuels and lowering overall energy costs.In addition to its innovative energy storage capabilities, ZSM-48 is also environmentally friendly. It is designed to have minimal impact on the environment and is made from sustainable materials, ensuring that it is as eco-friendly as possible. This makes it an attractive option for businesses and individuals looking to reduce their carbon footprint while still meeting their energy needs.The company behind ZSM-48 is a leader in the field of energy solutions, with a strong reputation for developing cutting-edge technology that is both effective and reliable. They have a long history of providing innovative solutions to the energy challenges of today, and ZSM-48 is just the latest example of their commitment to finding sustainable and efficient energy solutions.The company is dedicated to creating technology that not only meets the needs of today, but also anticipates the needs of tomorrow. They are constantly researching and developing new ways to harness renewable energy sources and create sustainable energy solutions that are both effective and affordable. With ZSM-48, they have once again demonstrated their ability to bring game-changing technology to the market.The introduction of ZSM-48 has the potential to have a significant impact on the energy industry. Its innovative design and sustainable practices make it an attractive option for businesses and individuals looking to reduce their reliance on fossil fuels and transition to cleaner and more sustainable energy sources. As the demand for renewable energy continues to grow, products like ZSM-48 will play a crucial role in meeting that demand and paving the way for a greener and more sustainable future.The company is excited about the potential of ZSM-48 and is confident that it will be a game-changer in the energy industry. They believe that this revolutionary new technology will help to usher in a new era of clean and efficient energy production, and they are committed to continuing to develop and innovate in this field. With ZSM-48, they have once again proven that they are at the forefront of the energy solutions industry, and are dedicated to driving positive change for the environment and for the future of energy production.In conclusion, ZSM-48 is a groundbreaking new technology that has the potential to revolutionize the energy industry. Its innovative design, sustainable practices, and cutting-edge technology make it a promising option for businesses and individuals looking to transition to cleaner and more efficient energy sources. With the support of the company behind it, ZSM-48 is poised to make a significant impact on the energy industry and help pave the way for a more sustainable future.

What is Dechlorination? Definition and Meaning in Medical Dictionary

Dechlorination: A Vital Step in Water TreatmentDo you know that almost all tap water has a small amount of chlorine in it? Chlorine is necessary to kill harmful bacteria and other contaminants that may be present in water. However, while chlorine is an effective disinfectant, it can also have undesired effects, such as the unpleasant taste and odor of water. This is where dechlorination comes in.Dechlorination is the process of removing chlorine from water. It is typically done by using a dechlorination agent, which neutralizes the chlorine and converts it into chloride. Dechlorination is a crucial step in water treatment, especially for processes that follow disinfection, such as fish farming and aquariums.Dechlorination agents are typically made up of sodium bisulfite or sodium sulfite. These chemicals are added to the water to neutralize excess chlorine, rendering it safe for use. Dechlorination agents are commonly available in liquid and powder form. They are easy to use and very effective in removing chlorine from water.One of the most common uses of dechlorination agents is in swimming pools. Chlorine is used in swimming pools to kill off bacteria and other unwanted contaminants. However, chlorinated water can be harsh on the skin and can cause irritation to swimmers. This is where dechlorination comes in. By using a dechlorination agent, pool water can be converted into safe, non-irritating, and odorless water.Dechlorination agents are also commonly used in the food and beverage industry. Chlorine is often used to disinfect equipment and surfaces where food and beverages are processed and prepared. However, excess chlorine can lead to off-tastes and odors in the final product. Dechlorination agents are used to ensure that the water used in the production process is safe and of high quality.In conclusion, dechlorination is an essential step in the water treatment process. It helps to remove excess chlorine from water, making it safe and pleasant to use. Dechlorination agents are effective, safe, and readily available, and can be used for a wide range of applications, including swimming pools, food and beverage production, and aquariums. If you're looking for a way to make your water safer and better-tasting, consider using a dechlorination agent.

Accelerating Women into Leadership: Creating Workplaces That Work for All

article:Hydrofining Catalyst Launches Initiative to Promote Women in LeadershipHydrofining Catalyst, a leading provider of catalysts for the refining industry, announced today a new partnership with Catalyst, a global nonprofit organization that works to accelerate women into leadership positions. The partnership is part of Hydrofining Catalyst’s initiative to promote diversity and inclusion within their organization and the refining industry as a whole.Founded in 1962, Catalyst has a long-standing reputation as a champion for women in the workplace. Their mission is to accelerate progress for women through workplace inclusion. They partner with companies around the world to build workplaces that work for women, providing research, tools, and consulting services to help organizations attract, retain, and advance women in their companies.For Hydrofining Catalyst, the partnership with Catalyst is an important next step in their commitment to fostering a work environment where diversity is celebrated and inclusion is a priority."We recognize that the refining industry has historically been a male-dominated field, and we want to change that," said John Smith, CEO of Hydrofining Catalyst. "By partnering with Catalyst, we are taking proactive steps to promote a more diverse and inclusive workforce, which we believe will benefit our company and our customers in the long run."The partnership will involve a variety of initiatives, including leadership development programs for women, unconscious bias training for all employees, and the establishment of employee resource groups focused on diversity and inclusion. In addition, Hydrofining Catalyst will work with Catalyst to conduct a gender pay equity analysis and develop strategies to close any gender pay gaps."We are thrilled to partner with Hydrofining Catalyst on this important initiative," said Lorraine Hariton, President and CEO of Catalyst. "Research shows that companies with more diverse workforces perform better, so promoting gender diversity is not just the right thing to do, it's also good for business."In addition to the partnership with Catalyst, Hydrofining Catalyst has also launched a new internal program to promote women's leadership within the organization. The program, called "Women in Hydrofining Catalyst," will provide mentoring and sponsorship opportunities for women at all levels of the company, as well as training in leadership skills and career development."Our goal is to create a workplace where all employees feel valued and supported, regardless of gender, ethnicity, or background," said Smith. "We believe that by promoting women's leadership within Hydrofining Catalyst, we can create a more innovative, productive, and successful company."The launch of Hydrofining Catalyst's diversity and inclusion initiative comes at a critical time for the refining industry, which has been facing increasing scrutiny around its environmental impact. By promoting diversity and inclusion within the industry, Hydrofining Catalyst is not only taking steps to create a more equitable workplace, but also positioning itself as a responsible and forward-thinking leader in the refining industry."We recognize that we have a responsibility to not only be good corporate citizens, but also to drive positive change within our industry," said Smith. "Our partnership with Catalyst and our Women in Hydrofining Catalyst program are just two examples of our commitment to making a positive impact.

Discover the Latest Innovations in Alumina Microsphere Technology

Alumina Microsphere, a groundbreaking material that has taken the industry by storm, is making waves in the market. Developed by a leading materials technology company, this innovative product is set to revolutionize various industries, including automotive, aerospace, and electronics.The Alumina Microsphere is a lightweight and high-strength material with excellent thermal and chemical stability. It is also highly resistant to corrosion, making it an ideal choice for applications that require durability and reliability. The material’s unique properties make it suitable for a wide range of uses, such as in lightweight structural components, thermal insulating materials, and high-performance coatings.One of the key advantages of Alumina Microsphere is its ability to significantly reduce the weight of components without compromising on strength and performance. This makes it an attractive option for industries looking to enhance fuel efficiency and reduce carbon emissions. Additionally, its thermal insulation properties make it an excellent choice for heat management in automotive and aerospace applications, where maintaining optimal temperatures is crucial for efficient operation.The company behind the development of Alumina Microsphere has a strong track record in materials technology, with a focus on creating innovative solutions that address the evolving needs of modern industries. With extensive expertise in materials science and engineering, the company has been at the forefront of research and development in advanced materials, pushing the boundaries of what is possible in the field.The company's commitment to quality and innovation has been a driving force behind the success of Alumina Microsphere. Through rigorous testing and validation, the company has ensured that the material meets the highest standards of performance and reliability. This dedication to excellence has earned the company a reputation as a trusted partner for industries seeking cutting-edge materials solutions.In addition to its technical capabilities, the company also places a strong emphasis on sustainability and environmental responsibility. The development of Alumina Microsphere takes into consideration the importance of reducing the environmental impact of industrial processes. By offering a material that enables lightweighting and fuel efficiency, the company is helping its customers achieve their sustainability goals.The introduction of Alumina Microsphere comes at a time when industries are increasingly seeking innovative solutions to address the challenges of the modern world. The material's versatility and performance make it an attractive option for a wide range of applications, from automotive and aerospace to electronics and renewable energy. Its potential to drive meaningful advancements in these sectors is generating significant interest and excitement among industry leaders and experts.Looking ahead, the company is focused on further developing and refining Alumina Microsphere to unlock its full potential. With ongoing research and development efforts, the company is committed to exploring new applications and continuously improving the material's performance and properties. By doing so, it aims to establish Alumina Microsphere as a premier choice for industries looking to enhance their products and processes.In conclusion, Alumina Microsphere is a game-changing material that is set to redefine the possibilities for various industries. Backed by a company with a proven track record in materials technology, it promises to deliver significant advancements in lightweighting, thermal management, and durability. With its potential to drive innovation and sustainability, Alumina Microsphere is poised to shape the future of materials technology and industrial applications.