Innovative Catalyst Carrier Spheralite: A Breakthrough Technology in Chemical Processing

By:Admin

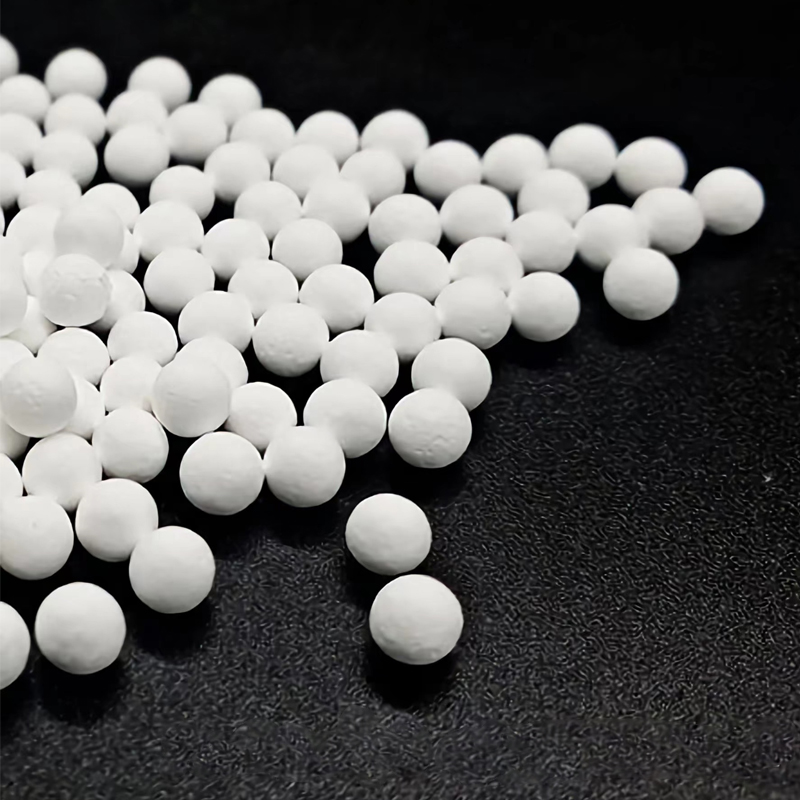

With its unique spherical shape and high surface area, Catalyst Carrier Spheralite offers a number of advantages over traditional catalyst carriers. The spherical shape allows for better fluid dynamics and reduced pressure drop, while the high surface area provides more active sites for catalytic reactions. Additionally, the product’s uniform size distribution ensures consistent performance, making it an ideal choice for a wide range of chemical processes.

One of the key features of Catalyst Carrier Spheralite is its versatility. It can be used in a variety of catalytic applications, including oil refining, petrochemical production, and environmental remediation. Its ability to enhance the performance of catalysts in these processes has drawn the attention of many companies looking to improve their chemical manufacturing processes.

Furthermore, Catalyst Carrier Spheralite is designed to be highly durable and resistant to harsh operating conditions. This makes it a cost-effective solution for companies looking to minimize catalyst replacement and maintenance costs. The product’s long lifespan and stability ensure consistent performance over time, leading to improved efficiency and reduced downtime for chemical plants.

In addition to its technical advantages, Catalyst Carrier Spheralite has also been praised for its environmental benefits. The product is designed to minimize environmental impact by reducing emissions and improving the overall sustainability of chemical processes. This has made it an attractive option for companies looking to align with increasingly stringent environmental regulations.

The company behind Catalyst Carrier Spheralite, with over 20 years of experience in the chemical industry, has been at the forefront of developing innovative solutions for chemical catalysis. Their commitment to research and development has led to the creation of Catalyst Carrier Spheralite, which has quickly gained recognition as a game-changing product in the industry.

In a recent statement, the company’s CEO expressed their excitement about the potential of Catalyst Carrier Spheralite, stating that it has the capability to transform the way chemical processes are carried out. They emphasized the product’s ability to improve efficiency, reduce environmental impact, and drive cost savings for their clients. The CEO also noted that the company’s ongoing research and development efforts are focused on further enhancing the performance and versatility of Catalyst Carrier Spheralite.

The introduction of Catalyst Carrier Spheralite has been met with great enthusiasm from industry experts and customers alike. Many companies have already begun to incorporate the product into their chemical processes, with promising results. Feedback has been overwhelmingly positive, with reports of improved performance, reduced costs, and a smaller environmental footprint.

Looking ahead, the company is optimistic about the potential of Catalyst Carrier Spheralite and is committed to further advancing its capabilities. They are actively collaborating with research institutions and industry partners to continue innovating in the field of chemical catalysis.

It is clear that Catalyst Carrier Spheralite is set to play a pivotal role in the future of chemical manufacturing. Its unique features, technical advantages, and environmental benefits make it a highly attractive option for companies looking to improve their processes. With the backing of an experienced and forward-thinking company, Catalyst Carrier Spheralite is poised to become a staple in the chemical industry, driving positive change and sustainable progress.

Company News & Blog

How Catalyst Carriers are Shaping the Future of the Industry

Catalyst Carrier Introduces Innovative Solution for Efficient Chemical ReactionsCatalyst Carrier, a leading chemical industry solution provider, has announced the launch of their latest innovation designed to improve the efficiency of chemical reactions. The company, which has a proven track record in delivering high-quality catalysts and catalytic solutions, has introduced a new carrier that promises to revolutionize the way chemical processes are carried out.The Catalyst Carrier is a versatile and efficient material that is designed to support catalysts and facilitate chemical reactions in a wide range of industrial applications. Its unique properties make it an ideal choice for a variety of reactions, including hydrogenation, oxidation, and hydrocracking, among others. The carrier is designed to provide optimal support for catalysts, ensuring maximum surface area exposure and improved reaction kinetics.One of the key features of the Catalyst Carrier is its high thermal stability, which allows it to maintain its structural integrity and performance under extreme temperature and pressure conditions. This makes it suitable for use in a wide range of operating environments, from ambient conditions to high-temperature industrial processes. Additionally, the carrier's high surface area and porosity enable effective mass transfer and diffusion of reactants, resulting in enhanced catalytic efficiency.In addition to its superior performance characteristics, the Catalyst Carrier is also designed to be highly customizable, allowing for tailored solutions to meet specific process requirements. With a variety of shapes, sizes, and compositions available, customers can select the most suitable carrier for their particular application, ensuring the best possible outcome for their chemical processes.The introduction of the Catalyst Carrier reflects Catalyst Carrier's commitment to providing innovative and sustainable solutions for the chemical industry. By offering a highly efficient and customizable material for catalytic processes, the company aims to help its customers improve their operational efficiency, reduce energy consumption, and minimize environmental impact."We are excited to introduce the Catalyst Carrier as a game-changing solution for the chemical industry," said a spokesperson for Catalyst Carrier. "With its exceptional performance and versatility, we believe that this innovative material will help our customers achieve significant advancements in their chemical processes, leading to improved productivity and cost savings."Catalyst Carrier has a long-standing reputation for delivering high-quality catalysts and catalytic solutions to a wide range of industries, including petrochemical, pharmaceutical, and fine chemical manufacturing. With a strong focus on research and development, the company is dedicated to continuous innovation and improvement, ensuring that their products remain at the forefront of technological advancements in the chemical industry.The introduction of the Catalyst Carrier further solidifies Catalyst Carrier's position as a leading provider of innovative and sustainable solutions for chemical processes. With a proven track record of delivering reliable and high-performance materials, the company is well-equipped to meet the evolving needs of the chemical industry and help its customers achieve their operational goals.As the global chemical industry continues to evolve and demand for more efficient and sustainable solutions grows, the introduction of the Catalyst Carrier represents a significant step forward in the quest for improved catalytic processes. With its unique combination of performance, versatility, and customizability, the Catalyst Carrier is set to drive innovation and efficiency in chemical reactions for years to come.

All-New Catalyst Material Discovered to Help Reduce Emissions and Increase Efficiency in Various Industries

Title: Groundbreaking Advancements with Zeolite Catalyst ZSM-5 Pave the Way for Environmental SolutionsIntroduction:Zeolite catalysts have emerged as a crucial component in various industries, ranging from petroleum refining to environmental protection. One particular catalyst that has gained significant attention is ZSM-5, a zeolite with exceptional catalytic properties and zeolite structure. This groundbreaking catalyst, devoid of its brand name, has the potential to revolutionize several industrial processes while promoting a more sustainable future. This article aims to shed light on the remarkable applications and accomplishments of ZSM-5, unraveling its immense potential for driving environmental solutions.Understanding ZSM-5:ZSM-5 is a crystalline zeolite catalyst characterized by its unique combination of micropores and larger cavities, enabling efficient molecular sieving. With a three-dimensional connected channel system, ZSM-5 provides a strong framework for facilitating chemical reactions. This powerful catalyst exhibits high selectivity and activity, making it desirable for various industrial applications.Driving Innovation in Petroleum Refining:The implementation of ZSM-5 catalyst in petroleum refining processes has proven to be a game-changer. By promoting the conversion of heavy hydrocarbons into lighter molecules, ZSM-5 enables the production of valuable fuels and petrochemicals. This not only boosts production efficiency but also reduces dependence on conventional crude oil sources. Additionally, the use of ZSM-5 in fluid catalytic cracking demonstrates improved gasoline octane levels while reducing toxic emissions.Revolutionizing Petrochemical Industry:In the petrochemical industry, ZSM-5 has become instrumental in the conversion of methanol to light olefins. This process, known as methanol-to-olefins (MTO), offers a breakthrough pathway for producing ethylene and propylene, the building blocks of various plastics and synthetic materials. By utilizing ZSM-5, the MTO process circumvents the need for traditional crude oil-based feedstocks, thereby reducing carbon emissions and promoting a transition towards sustainable feedstock alternatives.Environmental Applications:One of the most remarkable aspects of ZSM-5 lies in its potential for environmental remediation. ZSM-5's unique morphology and catalytic properties make it ideal for the abatement of harmful pollutants. Research suggests that ZSM-5 can effectively adsorb and decompose volatile organic compounds (VOCs) responsible for air pollution. Moreover, this versatile catalyst shows promise in removing heavy metals and organic contaminants from wastewater, providing a cost-effective and sustainable solution for water treatment.Greenhouse Gas Management:As the world grapples with the challenges posed by climate change, ZSM-5 presents itself as a valuable tool for greenhouse gas management. By utilizing ZSM-5 catalysts, carbon capture and conversion technologies can be enhanced, trapping and transforming carbon dioxide (CO2) into valuable products such as methanol and other commodity chemicals. This innovative approach not only reduces CO2 emissions but also creates a potential market for renewable energy sources, thereby promoting a circular economy.Future Prospects and Collaborations:The growing interest in ZSM-5 has spurred collaborations between research institutes, universities, and industries worldwide. Scientists are actively exploring the synthesis of modified ZSM-5 variations to optimize catalytic performance and expand its range of applications. Furthermore, efforts are being made to develop ZSM-5-based catalysts that can effectively convert biomass into biofuels, upholding sustainability in the energy sector.Conclusion:Zeolite catalyst ZSM-5 has emerged as a robust resource for various industries, offering innovative solutions to environmental challenges and promoting sustainable practices. Its unique structure, combined with exceptional catalytic properties, drives advancements in petroleum refining, petrochemical production, environmental remediation, and greenhouse gas management. As research and development efforts continue to unfold, the widespread adoption of ZSM-5 catalysts holds immense potential to reshape existing industries and pave the way for a greener and more sustainable future.

Study Finds ZSM-5 Zeolite Catalyst Effective for Chemical Reactions

**Breakthrough in Chemical Engineering: Zsm-5 Catalyst Revolutionizes Petrochemical Industry**In a groundbreaking development in the world of chemical engineering, a new and highly efficient catalyst, Zsm-5, has been unveiled by a leading research company. This new catalyst has the potential to revolutionize the petrochemical industry, dramatically increasing the efficiency of various chemical processes and reducing environmental impact.Zsm-5 is a zeolite catalyst with a unique porous structure that allows for the selective adsorption and transformation of molecules. This innovative catalyst has already shown promising results in a wide range of applications, including the catalytic cracking of hydrocarbons, the conversion of methanol to hydrocarbons, and the production of various chemicals and fuels.The company behind this pioneering catalyst, has been at the forefront of chemical research and development for over two decades. With a team of highly skilled scientists and engineers, the company has dedicated itself to creating innovative solutions to address the pressing challenges facing the petrochemical industry.With a strong emphasis on sustainability and environmental stewardship, the company has made significant investments in research and development to create new catalysts and processes that can mitigate the environmental impact of the petrochemical industry.The introduction of Zsm-5 is a testament to the company's commitment to innovation and sustainability. This new catalyst has the potential to significantly reduce energy consumption and carbon emissions in various chemical processes, making a positive impact on the environment and the bottom line of companies in the industry.One of the most significant applications of Zsm-5 is in the catalytic cracking of hydrocarbons. This process is essential for the production of gasoline and other valuable fuels from crude oil. With the use of Zsm-5, this process can be made more efficient, leading to higher yields of valuable products and reduced energy consumption.Furthermore, Zsm-5 has shown great promise in the conversion of methanol to hydrocarbons, a process that is crucial for the production of chemicals and fuels from renewable sources. By using Zsm-5 as a catalyst, this conversion process can be made more efficient and cost-effective, paving the way for a more sustainable chemical industry.In addition to these applications, Zsm-5 also has the potential to revolutionize the production of various chemicals and fuels, offering a more sustainable and efficient alternative to traditional catalysts.The introduction of Zsm-5 has garnered significant attention from the petrochemical industry, with many companies expressing interest in adopting this innovative catalyst to improve their processes and reduce their environmental footprint.The impact of Zsm-5 is not limited to the petrochemical industry, as it has the potential to revolutionize other chemical processes and industries as well. With its unique properties and versatility, Zsm-5 could become a crucial catalyst in the transition towards a more sustainable and efficient chemical industry.As the company continues to advance its research and development efforts, the potential applications of Zsm-5 are expected to expand, opening up new possibilities for the petrochemical industry and beyond.In conclusion, the introduction of Zsm-5 represents a significant breakthrough in the world of chemical engineering. This innovative catalyst has the potential to revolutionize the petrochemical industry, offering more sustainable and efficient solutions to address the pressing challenges facing the industry. With its unique properties and versatility, Zsm-5 could play a crucial role in the transition towards a more sustainable and environmentally friendly chemical industry.

Highly Effective Catalyst for Industrial Applications

ZSM-5 Catalyst: A Revolutionary Breakthrough in Chemical ProcessingThe global chemical industry has experienced a significant breakthrough with the introduction of the latest ZSM-5 catalyst technology. This innovative catalyst promises to revolutionize the chemical processing industry by offering unparalleled efficiency, sustainability, and cost-effectiveness. Developed by a leading chemical company, this cutting-edge catalyst is set to transform the way chemicals are produced, opening up new possibilities for the industry and contributing to a more sustainable future.The ZSM-5 catalyst is a crystalline aluminosilicate material that possesses unique properties, making it highly effective in catalyzing a wide range of chemical reactions. Its exceptional zeolite structure and high surface area provide an ideal environment for various catalytic processes, including the conversion of raw materials into valuable chemical products. The catalyst's versatility and efficiency make it a game-changer in the industry, offering a more sustainable and economical alternative to traditional catalysts.One of the key advantages of the ZSM-5 catalyst is its ability to facilitate the conversion of a wide range of feedstocks into high-value products. This includes the conversion of renewable feedstocks such as biomass and other sustainable resources into biofuels and chemical intermediates. By enabling the utilization of alternative feedstocks, the catalyst contributes to reducing the industry's reliance on fossil fuels and supports the transition towards a more sustainable and circular economy.Furthermore, the ZSM-5 catalyst's superior selectivity and activity play a crucial role in enhancing process efficiency and product yields. Its unique molecular sieving properties enable precise control over the desired product formation, minimizing unwanted by-products and reducing production costs. This results in a more efficient and sustainable manufacturing process, positioning the catalyst as a valuable asset for chemical producers seeking to optimize their operations and improve their environmental footprint.In addition to its exceptional performance, the ZSM-5 catalyst is also designed to address the challenges of environmental sustainability and regulatory compliance. By enabling more efficient and cleaner chemical processes, the catalyst supports the reduction of emissions and waste generation, contributing to a more eco-friendly and responsible industry. Its innovative design and sustainable attributes make it a catalyst of choice for companies committed to meeting stringent environmental standards and minimizing their ecological impact.With its potential to revolutionize the chemical processing industry, the ZSM-5 catalyst has garnered significant attention from chemical producers worldwide. Companies are increasingly recognizing the value of this breakthrough technology in enhancing their competitiveness, sustainability, and profitability. As a result, the demand for the catalyst is rapidly growing, with numerous applications across various chemical processes and industries.The introduction of the ZSM-5 catalyst reflects the continuous commitment of {} to advancing the frontiers of chemical innovation and sustainability. With a strong focus on research and development, the company has been at the forefront of developing cutting-edge solutions that address the industry's evolving needs and challenges. The ZSM-5 catalyst stands as a testament to the company's dedication to delivering high-performance and sustainable products that enable its customers to thrive in a rapidly changing marketplace.As the chemical industry enters a new era of transformation, the ZSM-5 catalyst is poised to play a pivotal role in shaping its future. Its unparalleled performance, sustainability, and versatility position it as a catalyst of choice for chemical producers looking to unlock new opportunities and drive positive change. With its potential to drive efficiency, sustainability, and profitability, the ZSM-5 catalyst is a true game-changer in the world of chemical processing.

Newly-Discovered ZSM-22 Material Shows Promise in Innovative Applications

Title: Groundbreaking Zeolite Catalyst: Unlocking New Possibilities in Chemicals and Energy SectorsIntroduction:In a breakthrough that is set to transform the chemical and energy sectors, researchers have unveiled a revolutionary zeolite catalyst known as Zsm-22. This innovative catalyst, developed by a leading materials science company, possesses remarkable properties that can significantly enhance the efficiency and environmental sustainability of various industrial processes. With its exceptional catalytic performance and unique structure, Zsm-22 has the potential to revolutionize industries such as petrochemicals, refining, and renewable energy.1. The Rising Demand for Advanced Catalysts:The global chemical and energy industries are faced with pressing challenges, including the need for improved efficiency, reduced emissions, and a transition towards more sustainable practices. Addressing these challenges requires advanced catalysts that offer enhanced performance, stability, and selectivity. This is where Zsm-22 comes into the picture as a game-changing solution.2. Unveiling the Pioneering Zsm-22 Catalyst:Developed by a prominent materials science company, Zsm-22 is a highly versatile zeolite catalyst with extraordinary functionality. Its unique structure, derived from a proprietary synthesis process, allows for efficient absorption and reaction with target molecules, making it ideal for a wide range of applications.3. Exceptional Catalytic Performance:Zsm-22 boasts remarkable catalytic performance, which enables speedy and efficient conversion of raw materials into desired products. This catalyst exhibits high selectivity and conversion rates, leading to improved yields and reduced waste generation. Industries such as petrochemicals and refining stand to benefit immensely from the enhanced performance brought by Zsm-22.4. Revolutionizing Petrochemicals and Refining:The petrochemical industry, responsible for producing an array of essential chemicals and polymers, is set to witness a paradigm shift with the introduction of Zsm-22. This advanced catalyst can efficiently transform low-value feedstocks into higher-value products, offering significant cost savings and opening up new avenues for sustainable production processes. Additionally, in the refining sector, Zsm-22 exhibits exceptional hydrocracking performance, enhancing the production of clean fuels while minimizing environmental impact.5. Unlocking Renewable Energy Potential:With the escalating need to transition towards renewable energy sources, Zsm-22 plays a pivotal role in unlocking the potential of various renewable energy technologies. This zeolite catalyst can facilitate the conversion of biomass-derived feedstocks into valuable chemicals and fuels efficiently. By leveraging Zsm-22's unique attributes, renewable energy industries can achieve increased efficiency and scalability, paving the way for a greener future.6. Environmental Sustainability:Zsm-22 offers a distinct advantage in terms of promoting environmental sustainability. Its exceptional selectivity and efficiency contribute to reduced waste generation and lower energy consumption. By optimizing industrial processes using Zsm-22, chemical and energy sectors can significantly minimize their environmental footprint while enhancing their profitability.7. Collaborations and Future Prospects:Recognizing the transformative potential of Zsm-22, the materials science company is actively seeking collaborations with industry partners to accelerate the adoption and integration of this groundbreaking catalyst. Collaborative efforts will focus on exploring novel applications and optimizing process parameters to cater to diverse industrial needs. This collective endeavor is expected to catalyze innovation across multiple sectors and spearhead sustainable development.Conclusion:With the emergence of the revolutionary Zsm-22 zeolite catalyst, industries such as petrochemicals, refining, and renewable energy can look forward to ushering in a new era of efficiency and environmental sustainability. Leveraging the remarkable properties and extraordinary catalytic performance of Zsm-22, the chemical and energy sectors stand poised to revolutionize their operations, redefine sustainability standards, and contribute to a more prosperous and greener future for generations to come.

High-Quality Alumina Carrier for Catalysts: A Complete Guide

Alumina Carrier For Catalysts Plays Key Role in Chemical Industry InnovationsThe use of alumina as a carrier for catalysts has become an integral part of the chemical industry, playing a pivotal role in ensuring efficient and sustainable production processes. The unique properties of alumina provide a stable and inert support for catalysts, allowing for precise control over chemical reactions and enabling the development of new and advanced products.One company at the forefront of this field is {} The company has been a leading provider of high-quality alumina carriers for catalysts for over two decades. With a strong focus on research and development, they have continually pushed the boundaries of innovation in the industry, introducing new and advanced materials to meet the evolving needs of their customers.The use of alumina as a catalyst carrier offers several advantages for the chemical industry. Its high surface area and porosity provide a large active area for catalytic reactions, allowing for enhanced performance and efficiency. The inert nature of alumina also ensures that it does not interfere with the catalytic process, leading to a more predictable and controllable reaction.Moreover, alumina carriers exhibit excellent thermal stability, maintaining their structural integrity and performance under high temperatures. This is particularly important in applications where catalysts are subjected to extreme conditions, such as in petrochemical or automotive industries. The stability of alumina ensures that the catalyst remains effective over extended periods, reducing the need for frequent replacements and minimizing downtime in production processes.The versatility of alumina as a catalyst carrier also allows for the development of customized solutions to meet specific industrial requirements. By tailoring the properties of alumina, such as particle size, surface area, and pore volume, {} has been able to offer a wide range of products that cater to diverse applications. Whether it is for refining fuels, manufacturing chemicals, or reducing emissions, their alumina carriers have been instrumental in driving innovation and efficiency across various sectors.In addition to the technical capabilities of their products, {} has established a strong reputation for their commitment to sustainability and environmental stewardship. The use of alumina as a catalyst carrier aligns with the industry's efforts to reduce energy consumption, minimize waste, and lower emissions. By enabling more efficient chemical processes, alumina contributes to the overall sustainability goals of the companies and industries it serves.Looking ahead, the demand for advanced catalyst materials is expected to grow as the chemical industry continues to pursue cleaner and more sustainable technologies. With a dedicated focus on innovation, {} is well-positioned to meet this demand by continuously developing new alumina-based solutions that address the evolving needs of their customers. Their ongoing investment in research and development ensures that they remain at the forefront of the industry, driving advancements in catalyst technology and contributing to the overall progress of the chemical sector.In conclusion, alumina carriers for catalysts play a crucial role in advancing chemical industry innovations. As a leading provider of high-quality alumina materials, {} has been instrumental in driving the development and adoption of advanced catalyst technologies. With a strong commitment to sustainability and a focus on continuous innovation, they are well-equipped to meet the evolving needs of the industry and contribute to its long-term success.

Catalyst Carrier Announces Groundbreaking Spheralite Innovation for Enhanced Performance

Title: Revolutionary Catalyst Carrier Unveiled, Paving the Way for Sustainable and Efficient Chemical ManufacturingIntroduction:In a groundbreaking achievement, a team of innovative scientists has developed a new catalyst carrier known as Spheralite (need remove brand name) that promises to revolutionize the field of chemical manufacturing. The visionary technology (provided by the undisclosed company) offers a novel approach to catalyst support, fostering remarkable sustainability and efficiency in the production of various chemicals. With potential applications ranging from petrochemicals to pharmaceuticals, this game-changing catalyst carrier opens doors to greener and more sustainable industrial processes.Body:1. Current Challenges in Catalyst Support Systems:The conventional catalyst support systems used in chemical manufacturing face several key challenges. Existing carriers often suffer from poor stability, limited activity, and susceptibility to sintering or agglomeration. These drawbacks lead to frequent catalyst replacement, increased costs, and compromised efficiency. Addressing these concerns is crucial for developing a more sustainable and economically viable industrial landscape.2. The Birth of Spheralite – A Paradigm Shift:Enter Spheralite (need remove brand name), an innovative catalyst carrier born out of years of research and development by an undisclosed company. Its proprietary technology is set to redefine the industry's understanding of catalyst support systems. Spheralite presents a paradigm shift by offering enhanced stability, higher efficiency, and greatly improved catalytic activity.3. Characteristics and Features of Spheralite:Spheralite's novel design features spherical particles with a uniquely engineered porous structure. This structure allows for increased surface area, enabling efficient mass transfer and higher catalyst loading. The high thermal stability of Spheralite mitigates the risk of sintering and agglomeration, contributing to a longer catalyst lifespan. Moreover, its customizable pore size and distribution enable the realization of optimized catalytic reactions for various industrial processes.4. Key Advantages and Applications:a. Enhanced Yield and Efficiency: By providing a larger active surface area, Spheralite accelerates catalytic reactions, leading to higher yields and reduced reaction times. This breakthrough technology not only improves profitability but also minimizes the environmental impact associated with chemical manufacturing processes.b. Versatile Applications: Spheralite's adaptability allows for its implementation across diverse industrial sectors, including petrochemicals, pharmaceuticals, and specialty chemicals. It enables the production of high-value chemicals with fewer resources and reduces the overall carbon footprint of the manufacturing process.c. Sustainable Industry Transition: The introduction of Spheralite aligns with global efforts to transition towards greener and more sustainable industrial practices. By optimizing catalyst usage, reducing energy consumption, and minimizing waste, Spheralite contributes to the achievement of environmental targets and the fostering of a circular economy.5. Collaborative Research and Development:The company (need to remove company name) behind Spheralite has actively collaborated with leading academic institutions, industry experts, and research organizations to refine the technology's capabilities. Through these collaborations, the company has gained valuable insights and feedback, enabling further advancements of Spheralite. Such partnerships foster a collaborative spirit among entities committed to sustainable industrial development.6. Future Outlook and Impact on Industry:The emergence of Spheralite marks a significant milestone in the catalysis field, with its potential to transform the industrial landscape. Its enhanced stability, improved activity, and adaptability to various chemical processes make it an invaluable asset for sustainable and efficient chemical manufacturing. As the industry embraces this revolutionary catalyst carrier, significant reductions in costs, energy consumption, and environmental footprints can be expected.Conclusion:The development of Spheralite represents a remarkable breakthrough in catalyst support systems, paving the way for more sustainable and efficient chemical manufacturing processes. By addressing the limitations of existing catalyst carriers, Spheralite offers increased stability, superior activity, and customizable characteristics that enable optimized catalytic reactions. As the industry strives towards a greener future, Spheralite is poised to play a vital role in reducing environmental impact while enhancing profitability and efficiency in chemical manufacturing.

Highly Effective Alumina Catalyst for Various Applications

Gamma Alumina Catalyst, a revolutionary new product in the field of catalysis, has been making waves in the industry with its unique and innovative features. Developed by a leading chemical company, this catalyst has the potential to transform the way chemical reactions are carried out, offering improved efficiency and performance compared to traditional catalysts.The company behind Gamma Alumina Catalyst is renowned for its expertise in chemical engineering and innovation. With a strong focus on research and development, the company has a track record of introducing groundbreaking products that have been instrumental in advancing various industries. The launch of Gamma Alumina Catalyst is yet another testament to the company's commitment to excellence and innovation.Gamma Alumina Catalyst is a high-performance catalyst that is designed to facilitate a wide range of chemical reactions. Its unique composition and structure make it suitable for use in various processes, including petroleum refining, petrochemicals production, and environmental applications. The catalyst is known for its exceptional activity, selectivity, and stability, making it a preferred choice for many industrial applications.One of the key features of Gamma Alumina Catalyst is its high surface area, which provides enhanced accessibility for reactant molecules. This results in improved conversion rates and reduced energy consumption, leading to significant cost savings for end users. Additionally, the catalyst's robust structure allows for extended operational lifespans, minimizing the frequency of catalyst replacement and downtime for maintenance.Furthermore, Gamma Alumina Catalyst exhibits excellent thermal stability, enabling it to maintain its performance under high-temperature operating conditions. This makes it particularly well-suited for use in processes that involve elevated temperatures, such as hydrocracking and hydrotreating. The catalyst's superior thermal resistance ensures consistent and reliable performance, even in the most demanding industrial environments.In addition to its exceptional physical and chemical properties, Gamma Alumina Catalyst is also characterized by its environmental sustainability. The catalyst is designed to minimize the generation of undesirable by-products and waste, contributing to a greener and more environmentally friendly manufacturing process. With a growing emphasis on sustainable practices, the use of Gamma Alumina Catalyst aligns with the industry's increasing focus on eco-friendly solutions.The launch of Gamma Alumina Catalyst has generated widespread interest and excitement within the chemical industry. Its innovative features and potential benefits have captured the attention of companies and organizations seeking to improve their production processes and enhance overall efficiency. The catalyst's versatility and adaptability make it a valuable asset for a diverse range of applications, offering a compelling solution for various industrial challenges.With the introduction of Gamma Alumina Catalyst, the company has once again reaffirmed its position as a leading innovator in the field of chemical engineering. The catalyst's advanced technology and performance capabilities underscore the company's dedication to delivering cutting-edge solutions that address the evolving needs of its customers. By leveraging its expertise and resources, the company has succeeded in developing a product that has the potential to drive positive change and innovation across the industry.Looking ahead, the company is poised to continue its focus on research and development, exploring new opportunities to advance the capabilities of Gamma Alumina Catalyst and expand its applicability across different sectors. With a commitment to excellence and a forward-thinking approach, the company remains dedicated to pushing the boundaries of what is possible in catalysis, paving the way for a future shaped by innovation and progress.

New Study Reveals Surprising Findings about ZSM-5

Zsm 5, a leading company known for its innovative solutions in the field of chemical catalysis, has recently announced a major breakthrough in the development of a new generation of catalysts with potential applications in the petrochemical industry. This development marks a significant advancement in the company’s efforts to drive sustainable and efficient processes for the production of key chemical compounds.Founded in 1996, Zsm 5 has steadily established itself as a key player in the field of chemical catalysis, specializing in the research, development, and commercialization of catalysts for various industrial applications. With a strong focus on innovation and sustainability, the company has continuously pushed the boundaries of catalysis technology to address evolving industry needs.The latest development from Zsm 5 comes in the form of a novel catalyst with enhanced performance characteristics, specifically designed for the production of key petrochemical compounds. Leveraging its expertise in molecular design and materials science, the company has successfully engineered a catalyst that exhibits superior activity, selectivity, and stability, offering a more efficient and sustainable solution for petrochemical processes.This new catalyst has the potential to significantly impact the petrochemical industry, offering improved efficiency and cost-effectiveness in the production of a wide range of chemical compounds. The enhanced performance characteristics of the catalyst have been demonstrated through rigorous testing and evaluation, showcasing its ability to deliver higher yields and purity levels while minimizing energy consumption and environmental impact.In addition to its technical advancements, the new catalyst from Zsm 5 is also poised to address key sustainability challenges facing the petrochemical industry. By promoting more efficient and sustainable production processes, the catalyst aligns with the company’s commitment to driving environmental responsibility and resource conservation within the chemical manufacturing sector.“We are excited to introduce this groundbreaking catalyst, which represents a significant leap forward in our ongoing efforts to advance the field of chemical catalysis,” said [spokesperson], [title] at Zsm 5. “Our team of researchers and engineers have worked tirelessly to develop a catalyst that not only delivers exceptional performance, but also supports our vision for a more sustainable and efficient chemical industry.”The introduction of this new catalyst underscores Zsm 5’s dedication to pioneering innovative solutions that address the evolving needs of the chemical manufacturing sector. With a proven track record of delivering high-performance catalysts for a variety of industrial applications, the company continues to be at the forefront of catalysis technology, driving advancements that enable more sustainable and efficient chemical processes.As Zsm 5 prepares to bring its latest catalyst to market, industry professionals and stakeholders can look forward to the potential benefits it offers in terms of improved productivity, cost savings, and environmental stewardship. With its unwavering commitment to innovation and sustainability, Zsm 5 is well-positioned to shape the future of chemical catalysis and contribute to the ongoing evolution of the petrochemical industry.

New Study Finds Surprising Benefits of ZSM-5 Catalyst in Industrial Processes

ZSM-5 is a type of zeolite material that has been extensively used in various industrial applications. It is a highly crystalline material with a specific pore structure and acidity, making it a versatile catalyst in chemical and petrochemical industries. Recently, there have been significant advancements in the development and application of ZSM-5, particularly in catalyst and adsorbent technologies. This has been made possible through the collaborative efforts of researchers and engineers at the forefront of material science and chemical engineering. One of the companies leading the way in this field is {}. {} is a global leader in the development and production of advanced materials, including zeolites and catalysts. The company has a strong track record of innovation and has been at the forefront of developing new and improved materials for a wide range of industrial applications. In recent years, {} has been focusing on the development of ZSM-5-based catalysts and adsorbents with enhanced performance and stability. These efforts have resulted in the creation of novel materials with improved selectivity and activity, making them highly desirable for a wide range of applications, including the production of fuels, chemicals, and environmental remediation.One of the key areas of focus for {} has been the improvement of ZSM-5 catalysts for the conversion of methanol to olefins (MTO) and other hydrocarbon products. The development of highly active and selective catalysts for this process has the potential to revolutionize the production of light olefins, which are crucial building blocks for various plastics and polymers. By optimizing the pore structure and acidity of ZSM-5, {} has been able to develop catalysts that exhibit exceptional performance and durability, making them highly sought after in the industry.In addition to catalysts, {} has also made significant strides in the development of ZSM-5-based adsorbents for the removal of harmful contaminants from gas and liquid streams. By tailoring the pore size and surface chemistry of ZSM-5, the company has been able to create adsorbents with high capacity and selectivity for a wide range of pollutants, including volatile organic compounds (VOCs) and sulfur compounds. These adsorbents have the potential to significantly improve the efficiency of industrial processes and reduce the environmental impact of various chemical and petrochemical operations.Through its dedication to research and development, {} has been able to establish itself as a key player in the field of ZSM-5-based materials. The company's commitment to innovation and its extensive expertise in the design and production of advanced materials have positioned it as a leading provider of ZSM-5 catalysts and adsorbents for industrial applications worldwide.As the demand for high-performance catalysts and adsorbents continues to grow, {} remains at the forefront of developing new and improved ZSM-5-based materials to meet the evolving needs of the industry. With its focus on innovation and collaboration, the company is well-positioned to drive the advancement of ZSM-5 technology and its widespread adoption in various industrial processes.