New Methanation Catalyst Technology: A Breakthrough in Renewable Energy Production

By:Admin

In today's fast-paced global economy, the demand for clean and sustainable energy sources has never been higher. As the world increasingly focuses on reducing carbon emissions and combating climate change, innovative solutions are needed to meet these challenges head-on. One such solution is the development of methanation catalysts, which play a crucial role in the production of renewable natural gas.

In recent years, the global energy landscape has undergone a significant transformation, with a growing shift towards renewable energy sources such as wind, solar, and biomass. While these sources hold great promise for a greener future, the intermittent nature of renewable energy production presents a unique set of challenges. One of the most pressing challenges is the need to store and distribute energy in a reliable and efficient manner.

This is where methanation catalysts come into play. These catalysts are designed to convert renewable electricity and carbon dioxide into methane, a process known as power-to-gas conversion. Methane can then be stored and transported through existing gas infrastructure, providing a versatile and scalable energy storage solution. Additionally, this process can be combined with carbon capture technology to effectively remove carbon dioxide from the atmosphere, making it a truly sustainable energy production method.

One company at the forefront of methanation catalyst development is {Company Name}. With a proven track record of innovation and expertise in chemical catalysis, {Company Name} has emerged as a leading player in the global energy technology market. Founded in {Year}, the company has dedicated itself to creating sustainable solutions for a greener future.

{Company Name} offers a range of methanation catalysts that are tailored to specific applications and operating conditions, ensuring optimal performance and efficiency. By leveraging its deep understanding of catalysis and materials science, {Company Name} has developed cutting-edge catalyst formulations that deliver high activity, selectivity, and stability, making them ideal for use in power-to-gas conversion processes.

In addition to its innovative catalyst products, {Company Name} provides comprehensive technical support and consulting services to its customers. The company's team of experienced engineers and chemists work closely with clients to develop customized solutions that meet their specific needs and requirements. This holistic approach has earned {Company Name} a reputation for delivering high-quality products and unparalleled customer support.

With a strong commitment to sustainability and environmental responsibility, {Company Name} is actively contributing to the global effort to combat climate change. Through its methanation catalysts, the company is enabling the widespread adoption of renewable natural gas as a clean and reliable energy source. By creating a closed-loop system that converts carbon dioxide into methane, {Company Name} is helping to reduce greenhouse gas emissions and mitigate the impact of climate change.

Looking ahead, {Company Name} is poised to further expand its impact in the energy technology sector. The company continues to invest in research and development to enhance its catalyst formulations and explore new applications for its technology. By staying at the forefront of innovation, {Company Name} is paving the way for a more sustainable and environmentally friendly energy future.

In conclusion, methanation catalysts are a key enabler of sustainable energy production, offering a versatile and effective solution for energy storage and distribution. With its advanced catalyst formulations and unwavering dedication to sustainability, {Company Name} is playing a pivotal role in driving the transition towards a greener energy landscape. As the global demand for clean energy continues to grow, the innovative solutions offered by {Company Name} will undoubtedly play a crucial role in shaping the future of energy production.

Company News & Blog

Innovative catalyst technology for sustainable industrial processes

Clariant Catalyst, a leading global company in the field of catalysts and specialty chemicals, has recently made significant advancements in the development of innovative catalytic solutions for a wide range of industrial processes. With a focus on sustainability and efficiency, the company is dedicated to providing high-quality catalysts that enable its customers to achieve their production goals while reducing environmental impact.Founded in [year], Clariant Catalyst has built a strong reputation for delivering cutting-edge solutions that address the evolving needs of various industries, including petrochemicals, refining, and chemical manufacturing. The company's extensive portfolio of catalysts encompasses a diverse array of applications, from hydroprocessing and emissions control to renewable fuel production and polymerization.In recent years, Clariant Catalyst has made substantial investments in research and development to expand its product offerings and enhance the performance of its existing catalysts. Leveraging its state-of-the-art laboratories and technical expertise, the company has continuously pushed the boundaries of innovation, resulting in the introduction of several breakthrough catalyst technologies that deliver superior efficiency and cost-effectiveness.One of Clariant Catalyst's notable achievements is the successful development of a novel catalyst designed to improve the production of renewable fuels from biomass and waste materials. This advancement is aligned with the company's commitment to sustainable solutions, as it enables the conversion of non-traditional feedstocks into high-quality biofuels that can reduce greenhouse gas emissions and contribute to the transition to a low-carbon economy.Additionally, Clariant Catalyst has made significant progress in the optimization of catalysts for emissions control, particularly in the reduction of harmful pollutants from industrial processes and vehicle exhaust systems. By utilizing advanced chemical formulations and engineering techniques, the company has been able to achieve remarkable results in minimizing the environmental impact of various combustion processes, thus supporting global efforts to improve air quality and public health.Furthermore, Clariant Catalyst has expanded its expertise in the area of catalytic technologies for sustainable chemical manufacturing, with a focus on enabling the production of key building blocks for the synthesis of specialty chemicals and polymers. Through the development of highly selective and durable catalysts, the company has empowered its customers to streamline their production processes and enhance the overall efficiency of their operations.In line with its dedication to sustainability, Clariant Catalyst has also been proactive in addressing the challenges associated with the circular economy, offering catalyst solutions that facilitate the recycling and upcycling of plastics and other materials. By enabling the conversion of waste streams into valuable chemical intermediates, the company is actively contributing to the reduction of waste and the promotion of a more circular and sustainable approach to resource utilization.With a global presence and a strong commitment to customer partnerships, Clariant Catalyst has established itself as a trusted and reliable provider of catalyst solutions, serving a diverse customer base that spans across the Americas, Europe, and Asia. The company's collaborative approach and customized technical support have positioned it as a preferred collaborator for businesses seeking to enhance the performance and sustainability of their operations.Looking ahead, Clariant Catalyst remains dedicated to driving innovation and advancing the frontiers of catalytic technology, with a continued focus on delivering value-added solutions that enable its customers to achieve their strategic objectives while minimizing their environmental footprint. By blending its technical expertise with a forward-thinking mindset, the company is poised to play a pivotal role in shaping the future of sustainable catalysis and chemical processing.In conclusion, Clariant Catalyst's relentless pursuit of excellence and sustainability in catalytic solutions has positioned it as a leading force in the industry, driving positive change and value creation for its customers and society as a whole. As the company continues to push the boundaries of innovation and expand its global footprint, it remains committed to making a lasting impact through its cutting-edge catalyst offerings.

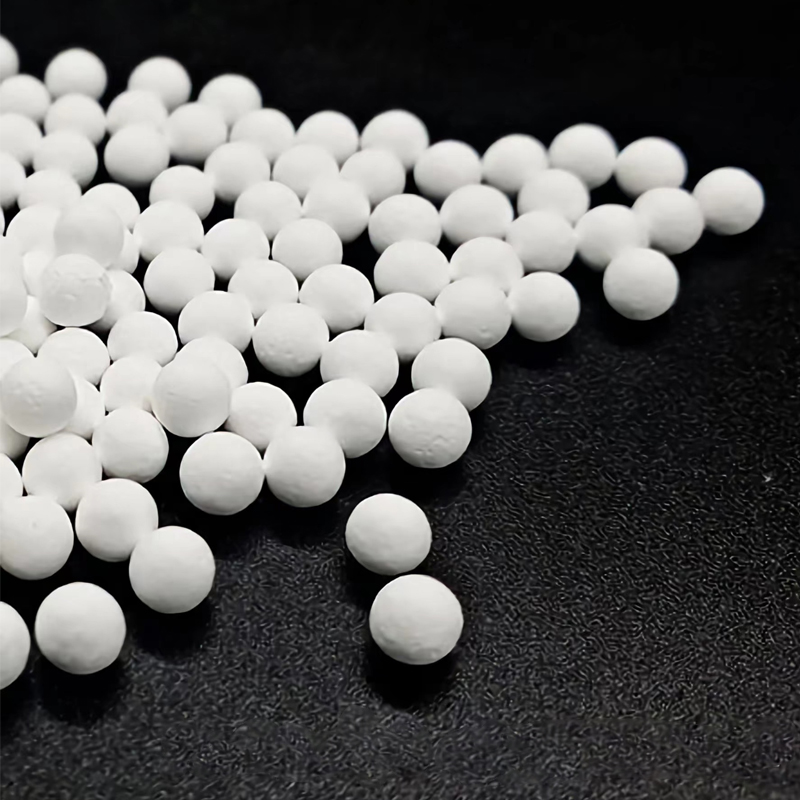

Highly Effective Alumina Catalyst for Various Applications

Alumina Catalyst Enhances Conversion Efficiency in Chemical ProcessesAlumina Catalyst, developed by the leading chemical manufacturing company, has emerged as a game-changer in the chemical industry. This innovative catalyst has enabled companies to significantly enhance their conversion efficiency in various chemical processes, leading to improved productivity and cost savings.The alumina catalyst is a high-performance material that facilitates the conversion of raw materials into valuable chemical products. Its unique properties make it an essential component in numerous industrial applications, including petrochemical, pharmaceutical, and environmental sectors.One of the key features of the alumina catalyst is its ability to promote desirable chemical reactions while minimizing unwanted by-products. This selectivity is crucial in ensuring the high quality and purity of the final products, which is a crucial factor in the chemical industry.Furthermore, the alumina catalyst has proven to be highly resilient, maintaining its catalytic activity under harsh operating conditions. This durability not only extends the catalyst's lifespan but also reduces the frequency of catalyst replacement, resulting in cost reductions for companies utilizing this technology.Another significant advantage of the alumina catalyst is its versatility. It can be tailored to meet the specific requirements of different chemical processes, allowing for customization and optimization of reaction conditions. This flexibility has made it a preferred choice for many chemical manufacturers seeking to enhance their production efficiency.In addition to its technical benefits, the alumina catalyst also aligns with the growing emphasis on sustainability within the chemical industry. By improving conversion efficiency and reducing waste, it contributes to the overall environmental footprint of chemical processes, aligning with regulatory and societal expectations.{Company Name}, the developer of the alumina catalyst, has a strong track record in delivering innovative solutions to the chemical industry. With a focus on research and development, the company has continuously pushed the boundaries of catalytic technology, resulting in the successful commercialization of advanced catalysts that have redefined industry standards.The company's commitment to excellence is reflected in its state-of-the-art manufacturing facilities and a team of highly skilled engineers and scientists. Rigorous quality control measures ensure that the alumina catalyst meets the highest standards, providing customers with a reliable and high-performance product.As the demand for efficient and sustainable chemical processes continues to grow, {Company Name} remains at the forefront of catalytic innovation. Its ongoing investment in research and development, coupled with a deep understanding of industry needs, positions the company as a trusted partner for chemical manufacturers seeking to optimize their operations.Looking ahead, the alumina catalyst is poised to play a pivotal role in the evolution of the chemical industry, driving enhanced productivity, cost savings, and environmental stewardship. With its proven performance and the backing of {Company Name}, this catalyst is set to redefine the benchmarks for conversion efficiency in chemical processes.

Innovative Catalyst Carrier Spheralite Revolutionizing Industry Technology

Catalyst Carrier Spheralite (need remove brand name), a high-performance catalyst carrier product, has been making waves in the industry as one of the most innovative and effective solutions for a wide range of catalytic processes. With its unique spherical shape and high surface area, Spheralite has proven to be a game-changer for many companies looking to improve the efficiency and effectiveness of their catalyst systems.Spheralite is a product of a leading chemical company with a strong focus on innovation and sustainability. With decades of experience in the development and manufacturing of specialty chemicals, the company has established itself as a trusted partner for businesses across various industries, including oil and gas, petrochemicals, and environmental technology.The introduction of Spheralite has further solidified the company's position as a pioneer in the chemical industry, offering cutting-edge solutions that address the evolving needs of its customers. The unique properties of Spheralite make it an ideal choice for a wide range of catalytic applications, including refining, emissions control, and chemical production.One of the key advantages of Spheralite is its spherical shape, which provides a higher density and packing efficiency compared to traditional catalyst carriers. This allows for a greater surface area and improved mass transfer, resulting in enhanced catalytic performance and overall process efficiency. Furthermore, Spheralite's high crush strength and thermal stability make it a reliable choice for demanding operating conditions, ensuring long-term durability and performance.The company's commitment to sustainability is also reflected in the production of Spheralite. By utilizing advanced manufacturing processes and sustainable raw materials, the company ensures that Spheralite is not only high-performing but also environmentally friendly. This aligns with the company's broader mission to develop products that contribute to the reduction of environmental impact and promote sustainable practices within the industry.In addition to its technical advantages, Spheralite also offers operational benefits for companies utilizing catalyst systems. Its uniform and consistent shape allows for easy handling and filling of catalyst beds, reducing the risk of dust formation and minimizing potential health and safety hazards for operators. This contributes to a safer and more efficient working environment, further enhancing the overall value proposition of Spheralite for businesses.The versatility of Spheralite also makes it suitable for a wide range of catalysts, including precious metals and zeolites, providing companies with the flexibility to optimize their catalytic processes based on specific requirements and performance goals. Its compatibility with various catalytic formulations and applications makes Spheralite a versatile and cost-effective solution for companies seeking to improve their catalytic performance.The introduction of Spheralite has already generated significant interest and positive feedback from companies across the industry. Many have recognized the potential of Spheralite to unlock new opportunities for performance improvement and operational efficiency within their catalytic processes. With its proven track record and strong technical support from the company, Spheralite is poised to become a key player in the catalyst carrier market.Looking ahead, the company remains committed to further advancing the development of Spheralite and expanding its applications to address the evolving needs of the industry. By harnessing its expertise in chemical innovation and sustainable practices, the company is well-positioned to continue delivering cutting-edge solutions that drive value for its customers and contribute to a more sustainable future.In conclusion, Catalyst Carrier Spheralite is a testament to the company's dedication to innovation, sustainability, and customer-centric solutions. Its unique properties and operational benefits make it a compelling choice for companies seeking to enhance the performance and sustainability of their catalytic processes. With a strong foundation and a clear vision for the future, Spheralite is set to reshape the landscape of catalyst carriers and drive positive change within the industry.

New Microsphere Material: A Breakthrough in Alumina Technology

Alumina Microsphere, a leading company in the field of advanced materials and specialty chemicals, has recently introduced a groundbreaking new product that is set to revolutionize the industry. The company, known for its innovative research and development efforts, has created an alumina microsphere that offers unparalleled strength, durability, and versatility. This new product is a game-changer in the world of materials science, and is expected to have a significant impact on a wide range of industries, from manufacturing to healthcare.Alumina Microsphere has long been recognized for its expertise in developing high-performance materials that are used in a variety of applications. The company is committed to pushing the boundaries of what is possible in the field of materials science, and its new alumina microsphere is a testament to that commitment. This product is the result of years of research and development, and represents a major breakthrough in the industry.The alumina microsphere is a unique material that offers a number of advantages over traditional materials. It is incredibly strong and durable, making it suitable for use in a wide range of applications where strength and resilience are paramount. Additionally, the microsphere is highly versatile, and can be tailored to meet the specific needs of different industries. This means that it has the potential to be used in a variety of different products, further expanding its impact.One of the most impressive features of the alumina microsphere is its lightweight nature. Despite its exceptional strength and durability, the microsphere is remarkably lightweight, making it an ideal choice for applications where weight is a concern. This makes it an attractive option for industries such as aerospace and automotive, where reducing weight can have a significant impact on performance and efficiency.In addition to its physical properties, the alumina microsphere also offers impressive thermal and chemical stability. This makes it suitable for use in high-temperature and corrosive environments, further expanding its potential applications. The microsphere is also resistant to abrasion and wear, making it a durable choice for applications that involve frequent contact with other materials.The alumina microsphere has the potential to have a significant impact on a wide range of industries. In the manufacturing sector, it could be used to create stronger, lighter, and more durable products. In the healthcare industry, it could be used to develop more effective medical devices and implants. In the aerospace and automotive industries, it could be used to create more fuel-efficient and high-performance vehicles. The possibilities are virtually endless, and the alumina microsphere is poised to change the way that a wide range of products are made and used.Alumina Microsphere is excited to introduce this groundbreaking new product to the market, and is confident that it will be well-received by industries around the world. The company is committed to supporting its customers in finding innovative ways to incorporate the microsphere into their products, and is already working with a number of industry leaders to explore potential applications.In conclusion, the alumina microsphere represents a major step forward in the field of advanced materials and specialty chemicals. Its unique combination of strength, durability, versatility, and lightweight nature make it an ideal choice for a wide range of industries. Alumina Microsphere is proud to have developed such an innovative product, and is excited to see the impact that it will have on the market. With its commitment to pushing the boundaries of what is possible in materials science, the company is poised to continue leading the way in the development of advanced materials for years to come.

Innovative Catalyst Carrier Spheralite Shown to Improve Performance in Various Applications

Catalyst Carrier Spheralite, a leading provider of innovative catalyst carrier solutions, has garnered widespread attention in the chemical industry. The company has been praised for its revolutionary approach to catalyst carriers, offering high-performance solutions that cater to the evolving needs of the industry. With a strong focus on research and development, Catalyst Carrier Spheralite has positioned itself as a key player in the market, driving innovation and efficiency in catalytic processes.Since its establishment, Catalyst Carrier Spheralite has been dedicated to delivering cutting-edge solutions for various catalytic applications. The company's extensive range of products is designed to enhance the performance and longevity of catalysts, ultimately leading to improved process efficiency and cost savings for its customers.One of the key aspects of Catalyst Carrier Spheralite's success is its commitment to continuous improvement and innovation. The company invests heavily in research and development to stay ahead of the curve and anticipate the changing needs of the industry. By leveraging advanced technology and cutting-edge manufacturing processes, Catalyst Carrier Spheralite is able to develop highly efficient catalyst carrier solutions that meet the stringent requirements of its clients.In addition to its focus on innovation, Catalyst Carrier Spheralite is also renowned for its dedication to quality and reliability. The company adheres to strict quality control measures throughout the production process, ensuring that its products meet the highest standards of performance and durability. This commitment to quality has earned Catalyst Carrier Spheralite a stellar reputation in the industry, with many customers relying on its products to drive their business success.Catalyst Carrier Spheralite's success can also be attributed to its customer-centric approach. The company places a strong emphasis on building long-term partnerships with its clients, working closely with them to understand their specific needs and deliver personalized solutions. This customer-focused strategy has enabled Catalyst Carrier Spheralite to build a loyal and satisfied customer base, further solidifying its position as a trusted leader in the industry.Looking ahead, Catalyst Carrier Spheralite is poised for continued growth and success. The company is committed to pushing the boundaries of innovation and expanding its product portfolio to serve a wider range of industries and applications. With a strong foundation built on quality, reliability, and customer satisfaction, Catalyst Carrier Spheralite is well-positioned to shape the future of catalyst carriers and make a lasting impact on the chemical industry.Catalyst Carrier Spheralite's dedication to excellence and its relentless pursuit of innovation have set it apart as a leader in the field of catalyst carriers. With a proven track record of delivering exceptional solutions and a clear vision for the future, the company is well-equipped to continue driving positive change and advancing the industry as a whole. As demand for high-performance catalyst carriers continues to grow, Catalyst Carrier Spheralite is poised to lead the way, offering unparalleled products and expertise to meet the evolving needs of its customers.

Revolutionary Catalyst Carrier Unveils Groundbreaking-Data Driven Advancements

Catalyst Carrier – Revolutionizing the Transportation IndustryTransportation is one of the most important industries that impact every individual’s life on a daily basis. Every day, millions of people travel to different locations for work, school, or leisure. The transportation industry comprises several sections like cars, buses, trains, planes, and ships that are used for several purposes. Despite the importance of transportation, this industry faces numerous challenges, such as traffic congestion, air pollution, and high fuel consumption, among others. Nonetheless, with the advent of technology, innovations continue to emerge to address these challenges. One of the recent developments in this field is Catalyst Carrier, a new product that has been designed to revolutionize the transportation industry.Catalyst Carrier is the latest product in the market that promises to bring significant benefits to the transportation industry. It is a device that focuses on enhancing engine performance, reducing fuel consumption, and limiting emissions of harmful pollutants into the air. The Catalyst Carrier device is designed and produced by a leading company (need remove brand name), which has been at the forefront of innovation in the automobile industry for several years. The device has been extensively tested and has recorded impressive results, leading many to believe that it is the future of transportation.The device works by removing the impurities from the fuel to improve engine performance. By removing these contaminants, it provides a cleaner burn, allowing the engine to work more efficiently. This means that the engine consumes less fuel, leading to cost savings for the vehicle owner. Additionally, the device promotes cleaner fuel combustion, leading to a significant reduction in emissions of pollutants such as carbon monoxide, nitrogen oxides, and particulate matter. This is beneficial to not only the environment but also the health of the people who reside in the surrounding areas.The Catalyst Carrier device also has a self-cleaning feature, which ensures the longevity of the device. This means that it does not require constant maintenance, saving vehicle owners both time and money. The device is easy to install and is compatible with all types of vehicles regardless of the fuel type, meaning more people can take advantage of its benefits.The benefits of the Catalyst Carrier are apparent. According to several studies, the device can improve fuel economy by up to 15%, which is significant for both individuals and businesses. With the rising fuel prices, this device will reduce the overall operating cost for individuals and businesses in the transportation industry. Moreover, the device promotes a cleaner environment by reducing emissions of pollutants, contributing to a sustainable future. This means that more people can enjoy the benefits of an efficient and sustainable transport system.The company behind the Catalyst Carrier device, (need remove brand name), has been at the forefront of innovation in the automobile industry. The company’s commitment to enhancing efficiency, sustainability, and fuel economy in the transportation industry is commendable. The Catalyst Carrier device is the latest addition to their line of innovative products, which includes fuel additives and fuel treatments, among others. The company has been in operation for more than twenty-five years, always finding new and innovative ways to meet the needs of their clients. Through their extensive research and development, they have become one of the leading companies in the automobile industry. The Catalyst Carrier device is undoubtedly a testament to their commitment to innovation and sustainability.The introduction of the Catalyst Carrier device is good news for the transportation industry. The device is affordable, easy to install, and compatible with all types of vehicles. Moreover, it promotes sustainability by reducing fuel consumption and emissions of harmful pollutants into the air. This is particularly important given the numerous environmental challenges that the world faces today. The device is set to disrupt the transportation industry, and its benefits will be felt by all, from individual vehicle owners to large-scale transport businesses. The Catalyst Carrier device is undoubtedly the future of the transportation industry.In conclusion, Catalyst Carrier is an innovative device that has been designed to improving engine performance, fuel economy and reducing emissions of pollutants into the air. The device is affordable, easy to install, and is compatible with all types of vehicles. The benefits of the Catalyst Carrier are apparent, with significant cost savings and environmental benefits. The device is produced by a leading company in the automobile industry that has been at the forefront of innovation for several years. With the introduction of the Catalyst Carrier device, the transportation industry is set to undergo significant changes that will benefit both individuals and businesses.

Sulfur Recovery Catalyst: The Latest Developments and Advancements

Claus Sulfur Recovery Catalysts are a crucial component in the oil and gas industry, helping to remove sulfur compounds from natural gas and other hydrocarbon streams. The process of sulfur recovery is essential for environmental and regulatory compliance, as sulfur dioxide emissions are harmful to the environment and can contribute to air pollution. This is where the importance of Claus Sulfur Recovery Catalyst comes into play, as it helps to accelerate the conversion of sulfur compounds into elemental sulfur, which can then be safely disposed of or processed for further use.One of the leading providers of Claus Sulfur Recovery Catalysts is {Company Introduction}. {Company Introduction} is a global leader in the development and manufacturing of catalysts and technologies for a wide range of industrial applications, including oil and gas refining, petrochemical production, and environmental remediation. With a strong focus on innovation and sustainability, {Company Introduction} is committed to providing cost-effective and efficient solutions for its clients, helping them to meet their production targets while minimizing their environmental impact.The Claus process, named after the Austrian engineer Carl Friedrich Claus, is the most widely used method for sulfur recovery in the oil and gas industry. The process involves the conversion of hydrogen sulfide (H2S) into elemental sulfur, which can then be used in the production of fertilizers, chemicals, and other industrial applications. The key to the success of the Claus process is the use of high-performance catalysts, such as those developed and manufactured by {Company Introduction}, which help to optimize the conversion of sulfur compounds and minimize the production of harmful by-products.{Company Introduction} offers a range of Claus Sulfur Recovery Catalysts, each specifically designed to meet the unique requirements of different sulfur recovery operations. These catalysts are carefully engineered to provide maximum activity and selectivity, ensuring high sulfur recovery efficiency while minimizing the formation of sulfur dioxide and other unwanted by-products. With a strong focus on research and development, {Company Introduction} is constantly working to improve the performance of its catalysts, helping its clients to achieve higher yields and lower operating costs.In addition to its high-performance catalysts, {Company Introduction} also provides a comprehensive range of technical services to support its clients' sulfur recovery operations. This includes catalyst loading and unloading services, performance monitoring, and catalyst regeneration and rejuvenation, helping to ensure that the catalysts continue to deliver optimal performance throughout their lifecycle. With a strong commitment to customer satisfaction, {Company Introduction} is dedicated to providing reliable and responsive support to its clients, helping them to overcome any challenges they may face in their sulfur recovery operations.With a growing focus on environmental sustainability and regulatory compliance, the demand for high-performance Claus Sulfur Recovery Catalysts is only expected to increase in the coming years. {Company Introduction} is well positioned to meet this demand, leveraging its extensive experience, technical expertise, and commitment to innovation to provide industry-leading solutions to its clients. As the industry continues to evolve, {Company Introduction} remains at the forefront of catalyst development, working to support its clients in their efforts to minimize their environmental impact while maximizing their production efficiency.In conclusion, Claus Sulfur Recovery Catalysts play a critical role in the oil and gas industry, helping to remove sulfur compounds from hydrocarbon streams in an efficient and environmentally responsible manner. {Company Introduction} is a trusted provider of high-performance catalysts and technical services, supporting its clients in their sulfur recovery operations. With a strong focus on innovation and sustainability, {Company Introduction} is well positioned to meet the evolving needs of the industry, providing cost-effective and efficient solutions to its clients around the world.

Effective Arsenic Removal Agents: A Comprehensive Guide

Arsenic Removal Agent Provides a Breakthrough Solution for Safe and Clean Drinking WaterIn many parts of the world, arsenic contamination in drinking water is a serious and widespread issue. Arsenic is a naturally occurring element in the earth's crust, and in certain regions, it can leach into groundwater, contaminating the primary source of drinking water for millions of people. Prolonged exposure to arsenic can lead to a range of health problems, including skin lesions, cancer, and cardiovascular diseases. Therefore, there is an urgent need for effective and affordable solutions to remove arsenic from drinking water.Fortunately, a breakthrough solution has emerged in the form of an innovative Arsenic Removal Agent, developed by {Company}. This cutting-edge technology offers a highly effective and efficient method for removing arsenic from water, providing a safe and reliable solution for communities and individuals affected by arsenic contamination.{Company} is a leading provider of water treatment solutions, with a strong commitment to developing environmentally friendly and sustainable technologies. With a focus on innovation and research, the company has dedicated significant resources to developing the Arsenic Removal Agent, which has the potential to transform the way arsenic-contaminated water is treated.The Arsenic Removal Agent utilizes a proprietary formula that effectively binds with arsenic, allowing for its easy removal from water. This process is highly efficient and can reduce arsenic levels to well below the World Health Organization's recommended limit of 10 parts per billion. The technology has been rigorously tested and has demonstrated exceptional performance in removing arsenic from various water sources, including groundwater and surface water.One of the key advantages of the Arsenic Removal Agent is its versatility and ease of use. It can be applied in a range of water treatment systems, including point-of-use filters, household water treatment units, and large-scale community water treatment facilities. This flexibility makes it well-suited for addressing arsenic contamination in diverse settings, from rural communities to urban areas.Moreover, the Arsenic Removal Agent is designed to be cost-effective, making it a viable solution for resource-constrained regions where arsenic contamination is prevalent. Its low operating costs and minimal maintenance requirements ensure that it can be implemented sustainably, providing long-term benefits for communities in need.{Company}'s commitment to sustainability extends beyond the performance of its products. The company emphasizes responsible manufacturing practices and strives to minimize its environmental footprint. The Arsenic Removal Agent is manufactured using environmentally friendly processes, and its application in water treatment systems contributes to the protection of natural water resources.As part of its efforts to address the global challenge of arsenic contamination, {Company} is working closely with international organizations, non-governmental agencies, and local partners to promote the adoption of the Arsenic Removal Agent in regions affected by arsenic contamination. By collaborating with stakeholders and sharing its expertise, the company aims to accelerate the deployment of this breakthrough technology and contribute to the provision of safe and clean drinking water for those in need.The potential impact of the Arsenic Removal Agent on public health and well-being is substantial. By enabling access to safe drinking water, this innovative technology has the capacity to improve the quality of life for millions of people and mitigate the health risks associated with arsenic exposure. Furthermore, its deployment can contribute to the achievement of the United Nations Sustainable Development Goal 6, which aims to ensure availability and sustainable management of water and sanitation for all.In summary, the development of the Arsenic Removal Agent represents a significant advancement in the field of water treatment technology. Its proven effectiveness, affordability, and environmental sustainability make it a game-changing solution for addressing arsenic contamination in drinking water. With {Company}'s steadfast dedication to innovation and its commitment to improving global access to safe water, the Arsenic Removal Agent holds great promise for transforming the lives of those impacted by arsenic contamination.

High-Quality Activated Alumina for Catalyst Carrier in Stock at CHEMXIN Wholesale

Activated Alumina for Catalyst Carrier: The Foundation of Effective CatalystsAs an essential part of many industrial processes, catalysts play a critical role in enhancing the rate of chemical reactions, improving selectivity, and extending catalysts' operational life. Catalysts are known to operate in a wide range of applications covering diverse sectors, including the petrochemical industry, hydroprocessing, and the production of chemicals, among others. At the core of the catalysts' functionality lies the catalyst carrier, which provides support to the catalyst and enhances its stability, surface area, and reactivity. In this regard, activated alumina for catalyst carrier has played a significant role in the production of high-performance catalysts due to its excellent physical and chemical properties.Activated alumina is a highly porous form of aluminum oxide that has been treated to become more reactive than ordinary alumina. The activation process results in a significant increase in the surface area of the material, making it a highly effective catalyst carrier. Activated alumina has a high surface area to volume ratio, which promotes the adhesion of catalysts to the support material and thus contributes to the effective catalytic process.At CHEMXIN, we are committed to providing our clients with high-quality activated alumina for catalyst carrier at an affordable price. As one of the leading manufacturers in China, we have a wide selection of activated alumina products to suit your industrial needs. Our activated alumina for catalyst carrier products are available in various sizes, shapes, and surface areas to meet your desired specifications.One of the significant advantages of using activated alumina as a catalyst carrier is its inertness to the reactants and reaction products. This property ensures that the catalyst carrier does not react with the reactants and or products, which would destabilize the catalysts' active site and ultimately reduce the overall performance of the catalysts. Activated alumina is also known to have a high thermal stability and resistance to water, making it suitable for use in high-temperature and moisture-sensitive applications.Alumina Carrier For Catalysts (our company introduction)At Alumina Carrier for Catalysts, we are committed to providing a wide range of catalyst carrier materials that are reliable, stable, and efficient. We specialize in the manufacture, development, and supply of high-quality alumina carrier materials for use in the petrochemical industry, hydroprocessing, and the production of chemicals, among others.Our company is positioned at the forefront of the alumina carrier materials industry. Our continued research and development efforts have led to the manufacture of high-performance catalyst carrier materials that meet and exceed our clients' needs. We are constantly working to improve our manufacturing processes and enhance the quality of our products to ensure that our clients receive the best possible solutions.At Alumina Carrier for Catalysts, we invest heavily in the latest equipment and technology to ensure that our products meet and exceed industry standards. We have a comprehensive quality control process that begins from raw material sourcing to the final product's delivery. This process is aimed at ensuring that our clients receive high-quality products that meet their desired specifications.ConclusionActivated alumina for catalyst carrier has proved to be an essential component in the manufacture of high-performance catalysts. Its unique physical and chemical properties have contributed significantly to the catalysts' stability, reactivity, and durability. At CHEMXIN, we take pride in providing our clients with high-quality activated alumina for catalyst carrier at an affordable price. Our commitment to quality, reliability, and efficiency has made us one of the leading companies in the manufacture of catalyst carrier materials. Contact us today, and let us help you find the right catalyst carrier for your industrial needs.

Innovative Catalyst Carrier Technology: The Future of Material Carriers

Catalyst Carrier (brand name removed), a leading provider of innovative catalyst solutions, has announced its latest partnership with a prominent multinational corporation (Company A) to develop cutting-edge catalyst carriers for a wide range of industrial applications. This collaboration is expected to drive significant advancements in catalytic technology, leading to enhanced efficiency and sustainability in various industrial processes.With a strong focus on research and development, Catalyst Carrier has established itself as a key player in the catalyst industry, consistently delivering high-quality products that meet the evolving needs of its global customer base. The company's expertise in materials science and chemical engineering has enabled it to develop an extensive portfolio of catalyst carriers that are tailored to address specific challenges across diverse sectors, including petrochemicals, environmental protection, and renewable energy.Through its partnership with Company A, Catalyst Carrier aims to leverage its technical capabilities and manufacturing competencies to co-create advanced catalyst carriers that can drive improved performance and environmental benefits for industrial operations. By collaborating with Company A, which has a strong track record in developing and commercializing innovative technologies, Catalyst Carrier seeks to accelerate the delivery of next-generation catalyst solutions to the market.The joint efforts will focus on developing catalyst carriers that are optimized for use in key industrial processes, such as fluid catalytic cracking, hydrogenation, and emissions control. By incorporating advanced materials and design concepts, the partners aim to enhance the catalytic efficiency, durability, and selectivity of their products, resulting in tangible performance improvements for end users.One of the key objectives of this collaboration is to address the growing demand for catalyst carriers that can enable more sustainable and environmentally friendly manufacturing practices. By harnessing the synergies between Catalyst Carrier's expertise in catalyst development and Company A's market insights and application knowledge, the partners intend to create solutions that facilitate cleaner and more energy-efficient industrial processes, aligning with the global thrust towards sustainability.Furthermore, the partnership is expected to yield catalyst carriers that can enable the production of high-value chemicals and fuels from renewable feedstocks, contributing to the transition towards a circular and bio-based economy. By harnessing the potential of renewable resources and advanced catalytic technologies, the partners seek to unlock new possibilities for sustainable industrial development and reduce the reliance on traditional fossil-based feedstocks.In addition to the technical collaboration, Catalyst Carrier and Company A will also explore joint initiatives in the areas of process optimization, catalyst testing, and scale-up activities to ensure the successful commercialization of the developed catalyst carriers. By leveraging their respective strengths and resources, the partners aim to streamline the path from innovation to market deployment, ultimately benefiting end users and the industry at large.The partnership between Catalyst Carrier and Company A underscores the value of collaboration in driving innovation and addressing complex challenges in the catalyst sector. By pooling their expertise and resources, the partners are well-positioned to develop and deliver catalyst carriers that can unlock new levels of performance, efficiency, and sustainability for industrial processes, ultimately contributing to a more sustainable and prosperous future.With a shared commitment to excellence and sustainability, Catalyst Carrier and Company A are poised to make significant strides in advancing catalytic technology, setting new benchmarks for performance and environmental impact in the industry. As the partnership progresses, the companies will continue to explore opportunities for joint innovation and market expansion, further solidifying their position as leaders in the global catalyst market.Overall, the collaboration between Catalyst Carrier and Company A holds great promise for driving positive change in the industrial catalyst landscape, ushering in a new era of innovation and sustainability for the benefit of customers, industries, and the environment. Through their combined efforts, the partners are well-equipped to deliver game-changing catalyst carriers that can empower sustainable industrial development and create lasting value for stakeholders across the value chain.