New Sulfur Tolerant Shift Catalyst Technology Unveiled in Latest News

By:Admin

The global shift towards renewable energy sources has accelerated in recent years, driven by concerns over climate change and the finite nature of fossil fuels. As a result, there has been a growing demand for catalysts that can facilitate the production of clean energy, such as hydrogen, which is seen as a key element in the transition to a more sustainable energy infrastructure.

One company at the forefront of this shift is a leading manufacturer of catalysts and chemical process technologies, with a proven track record of developing innovative solutions for the energy industry. The company's latest breakthrough is the development of a Sulfur Tolerant Shift Catalyst, which promises to revolutionize the production of hydrogen and other clean fuels.

The Sulfur Tolerant Shift Catalyst is a novel catalyst technology that enables the production of hydrogen from a variety of feedstocks, including natural gas, biomass, and other renewable sources, while effectively mitigating the negative effects of sulfur on the catalyst performance. This is a significant development, as the presence of sulfur in feedstocks has long been a major technical and economic challenge for the production of clean fuels.

The company's proprietary catalyst technology is based on extensive research and development, leveraging decades of experience in catalysis and chemical process engineering. The result is a robust and highly efficient catalyst that can operate under a wide range of conditions, delivering consistent performance and reliability in hydrogen production processes.

In addition to its sulfur tolerance, the Sulfur Tolerant Shift Catalyst offers several other key advantages. It has been engineered to maximize conversion of carbon monoxide (CO) to carbon dioxide (CO2) and hydrogen (H2), effectively increasing the yield and purity of the resulting hydrogen stream. Furthermore, the catalyst exhibits exceptional stability and longevity, allowing for extended operational lifetimes and reduced frequency of catalyst replacement, which translates to lower operating costs and improved process economics.

The introduction of the Sulfur Tolerant Shift Catalyst has generated significant interest and excitement within the energy industry. The potential impact of this breakthrough technology is far-reaching, with implications for a wide range of applications, including fuel cell vehicles, energy storage, and industrial processes requiring high-purity hydrogen. Moreover, the catalyst's compatibility with diverse feedstocks positions it as a versatile and adaptable solution for the evolving energy landscape.

The company's commitment to sustainability and innovation is underscored by its ongoing investments in research and development, as well as its dedication to addressing the most pressing challenges facing the energy industry. The successful development of the Sulfur Tolerant Shift Catalyst is a testament to the company's expertise and leadership in catalysis, and it exemplifies its strategic vision to advance clean energy technologies that can make a meaningful difference in the global effort to combat climate change and promote environmental stewardship.

Looking ahead, the company is poised to further leverage its expertise and capabilities to commercialize the Sulfur Tolerant Shift Catalyst and bring it to market, where it is expected to play a pivotal role in enabling the widespread adoption of hydrogen and other clean fuels. With a strong emphasis on collaboration and partnership, the company is actively engaging with industry stakeholders to explore opportunities for integrating its catalyst technology into a variety of energy solutions, with the ultimate aim of accelerating the transition towards a more sustainable and low-carbon future.

In conclusion, the development of the Sulfur Tolerant Shift Catalyst represents a significant milestone in catalyst technology, with profound implications for the production of clean energy. As the energy industry continues to evolve and transform, innovative solutions like this catalyst will be instrumental in driving progress towards a more sustainable and resilient energy infrastructure. With its proven track record of excellence and its unwavering commitment to innovation, the company is well-positioned to lead the way towards a cleaner, brighter future for the energy industry and the planet as a whole.

Company News & Blog

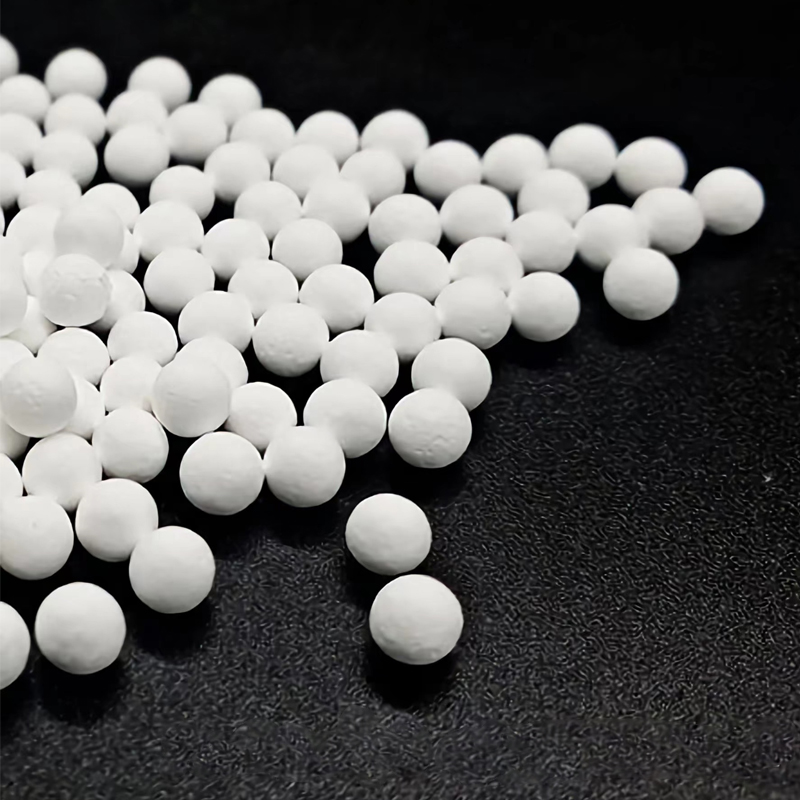

Alumina Market Sees Growth in Production and Demand

Gama Alumina is a significant player in the global alumina market. The company is known for its high-quality products and strong presence in the industry. With a focus on sustainable development and innovation, Gama Alumina is committed to delivering excellence in all aspects of its business.Gama Alumina specializes in the production of alumina, the essential raw material used in the production of aluminum. The company's state-of-the-art facilities and advanced production techniques ensure that its alumina meets the highest standards of quality and purity. As a result, Gama Alumina's products are in high demand across various industries, including automotive, aerospace, construction, and packaging.One of the key factors that sets Gama Alumina apart from its competitors is its commitment to sustainability. The company prioritizes environmental responsibility and aims to minimize its impact on the environment throughout the production process. Gama Alumina has implemented various initiatives to reduce energy consumption, minimize waste generation, and optimize resource utilization. These efforts not only benefit the environment but also contribute to the overall efficiency and cost-effectiveness of the company's operations.In addition to its focus on sustainability, Gama Alumina is also dedicated to innovation. The company continually invests in research and development to improve its production processes and develop new, advanced alumina products. By staying at the forefront of technological advancements, Gama Alumina ensures that it can meet the evolving needs of its customers and maintain its position as a leader in the industry.Furthermore, Gama Alumina places a strong emphasis on corporate social responsibility. The company actively engages with local communities and invests in programs that support education, healthcare, and economic development. By fostering positive relationships with stakeholders, Gama Alumina strives to create long-term value for both its business and the communities in which it operates.In recent news, Gama Alumina has announced a strategic partnership with a leading aluminum producer to further expand its presence in the global market. This partnership will enable Gama Alumina to access new opportunities and strengthen its position as a preferred supplier of high-quality alumina. By leveraging the expertise and resources of its partner, Gama Alumina aims to enhance its capabilities and offer a broader range of products and services to its customers.The collaboration with the aluminum producer aligns with Gama Alumina's growth strategy, which focuses on expanding its market reach and diversifying its product portfolio. Through strategic partnerships and investments, the company seeks to capitalize on emerging market trends and position itself for long-term success. By pursuing strategic alliances, Gama Alumina aims to create synergies that drive innovation, efficiency, and value creation.Furthermore, Gama Alumina is also exploring opportunities to integrate digital technologies into its operations. By embracing digitalization, the company aims to optimize its processes, improve decision-making, and enhance the overall effectiveness of its business. Through the adoption of advanced data analytics, automation, and connectivity solutions, Gama Alumina seeks to gain a competitive edge and future-proof its operations in a rapidly evolving industry landscape.Looking ahead, Gama Alumina remains committed to delivering excellence across all aspects of its business. By focusing on sustainability, innovation, and collaboration, the company is well-positioned to continue driving value for its customers, stakeholders, and the broader industry. With a solid foundation and a clear vision for the future, Gama Alumina is poised to maintain its leadership position in the global alumina market and create sustainable growth opportunities for years to come.

Advanced Isomerization Catalyst Technology for Enhanced Chemical Conversion

Isomerization Catalyst Market Trends and Growth OpportunitiesIsomerization Catalyst Market size is likely to expand at a significant CAGR from 2022 to 2028. The Isomerization Catalyst is a key component used in the petroleum refining industry for the production of high octane gasoline. It is an important process used to convert straight-chain hydrocarbons into branched-chain hydrocarbons, which helps to improve the octane number of gasoline and increase its efficiency in engines.The global Isomerization Catalyst market is witnessing a steady growth due to the increasing demand for high octane gasoline, stringent environmental regulations, and the growing focus on sustainable energy solutions. The market is also driven by the growing investments in the oil and gas industry and the rising demand for transportation fuels in emerging economies.The Isomerization Catalyst market is segmented based on type, application, and region. Based on type, the market is categorized into noble metal catalysts, base metal catalysts, and others. The noble metal catalysts segment is expected to hold a significant share of the market due to its high efficiency and durability. In terms of application, the market is divided into gasoline production and others. The gasoline production segment is anticipated to lead the market owing to the increasing demand for high octane gasoline in the automotive industry.Key players in the Isomerization Catalyst market include {}, {}, {} and {}. These companies are focusing on research and development activities to develop innovative and sustainable solutions to meet the growing demand for isomerization catalysts. They are also adopting strategies such as mergers and acquisitions, partnerships, and collaborations to expand their market presence and strengthen their product portfolio.One of the leading companies in the Isomerization Catalyst market is {}. They are a global leader in providing advanced catalyst solutions for the petroleum refining industry. The company has a strong focus on research and development to develop catalysts that offer high activity, selectivity, and stability for isomerization processes. They also have a strong presence in the key regions such as North America, Europe, and Asia-Pacific, which allows them to cater to the growing demand for isomerization catalysts in these regions.Another key player in the Isomerization Catalyst market is {}. They are known for their high-performance catalysts that are designed to meet the specific needs of the petroleum refining industry. The company has a strong focus on sustainability and is committed to developing catalysts that are environmentally friendly and energy-efficient. They also have a wide range of products and services to cater to the diverse needs of their customers.The Isomerization Catalyst market is witnessing significant growth opportunities in the Asia-Pacific region due to the growing demand for transportation fuels and the increasing investments in the oil and gas industry. The region is also experiencing rapid industrialization and urbanization, which is fueling the demand for high octane gasoline.In conclusion, the Isomerization Catalyst market is poised for significant growth in the coming years due to the increasing demand for high octane gasoline, the rising investments in the oil and gas industry, and the growing focus on sustainable energy solutions. Key players in the market are focusing on research and development activities to develop innovative and sustainable solutions to meet the growing demand for isomerization catalysts. The Asia-Pacific region is expected to offer lucrative growth opportunities for the market due to the growing demand for transportation fuels and the rapid industrialization and urbanization in the region.

Get Quality Activated Alumina for Catalyst Carriers at Low Prices from Professional Manufacturers

Get Your Hands on the First Edition of Catalytic Hydrogenation: A Comprehensive Guide

Title: Unveiling the Revolution: The Power and Potential of Hydrogenation CatalystsIntroduction:Catalytic hydrogenation, a chemical reaction that involves the introduction of hydrogen into a compound, holds immense importance within the world of chemistry. This transformative process has revolutionized various industries, ranging from pharmaceuticals and petrochemicals to food and agriculture. In this blog post, we will explore the significance of hydrogenation catalysts and dive into the benefits they bring to the table.1. Understanding the Concept of Catalytic Hydrogenation:Catalytic hydrogenation is a chemical process that enables the conversion of unsaturated organic compounds into saturated compounds through the addition of hydrogen. This reaction occurs under specific conditions and relies on the presence of hydrogenation catalysts. These catalysts act as facilitators, enhancing the rate of the hydrogenation reaction without being consumed in the process.2. The Role of Hydrogenation Catalysts:Hydrogenation catalysts play a pivotal role in achieving efficient and selective hydrogenation reactions. They enable the reduction of double or triple bonds in organic compounds, resulting in valuable end products. Not only do these catalysts enhance reaction rates, but they also improve the selectivity and control over the final product, making their utilization indispensable in various industries.3. Applications of Hydrogenation Catalysts:3.1 Pharmaceutical Industry:Hydrogenation catalysts are extensively used in pharmaceutical manufacturing. They aid in the synthesis of crucial intermediates and active pharmaceutical ingredients (APIs). The controlled hydrogenation of specific functional groups enables the creation of products with desired properties, elevating the quality and efficiency of pharmaceutical formulations.3.2 Petrochemical Industry:In the petrochemical sector, hydrogenation catalysts are employed to simultaneously address multiple challenges. They assist in refining petroleum products, converting heavy hydrocarbons into lighter, more valuable ones. Additionally, catalytic hydrogenation facilitates the removal of harmful impurities, such as sulfur and nitrogen, resulting in cleaner and superior fuel.3.3 Food Industry:Hydrogenation catalysts find extensive usage in the food industry, particularly in the production of edible oils. By employing these catalysts, unsaturated fats can be converted into saturated ones, improving the product's shelf life and stability. This leads to the production of healthier alternatives, reducing the harmful effects of trans fats on human health.4. Advancements in Hydrogenation Catalysts:Over the years, significant advancements have been made in the field of hydrogenation catalysts. The development of tailor-made catalysts with improved selectivity and activity has opened up new avenues for chemical transformations. Researchers are continually exploring ways to enhance catalyst efficiency, reduce costs, and minimize the environmental impact associated with the process.5. The Future of Hydrogenation Catalysts:As industries strive to optimize processes and find sustainable alternatives, hydrogenation catalysts are set to play a more significant role in the future. Catalyst design and development will focus on minimizing metal usage, exploring alternative support materials, and expanding compatibility with renewable feedstocks. These advancements will pave the way for greener and more efficient chemical reactions.Conclusion:Hydrogenation catalysts have become indispensable in numerous industries, propelling significant advancements in the synthesis and refinement of valuable compounds. From pharmaceuticals and petrochemicals to food and agriculture, the controlled addition of hydrogen has revolutionized various sectors. As research and innovation continue to evolve, hydrogenation catalysts will lead the way toward greener, more sustainable chemical processes, benefiting both our environment and society as a whole.

Newly Developed Compound ZSM-48 Shows Promising Applications in Various Industries

ZSM-48, a New Breakthrough in Sustainable TechnologyIn recent times, the global push for sustainable technology has resulted in the development of innovative solutions to combat environmental degradation and reduce our reliance on fossil fuels. One such breakthrough is the development of ZSM-48, a new catalyst that promises to revolutionize the energy and petrochemical industries.ZSM-48 is a zeolite, a type of highly porous material made from silicon, aluminum, and oxygen. Zeolites have a wide range of applications, from catalyzing chemical reactions to separating molecules in industrial processes. What makes ZSM-48 so special is its unique structure, which allows it to effectively convert biomass and other renewable resources into valuable chemicals and fuels. This makes it a key player in the shift towards sustainable and renewable energy sources.The development of ZSM-48 is a result of extensive research and development carried out by a team of scientists at a leading chemical company. This company is dedicated to innovation and sustainability, and has been at the forefront of developing new technologies to address some of the world's most pressing environmental challenges. The company's commitment to sustainability is evident in its extensive research and development efforts, as well as its ongoing collaboration with academic institutions and industry partners to develop cutting-edge solutions.The introduction of ZSM-48 represents a significant milestone in the company's efforts to drive the transition towards a more sustainable future. By offering a catalyst that can efficiently convert renewable resources into valuable products, the company is not only contributing to the reduction of greenhouse gas emissions and the conservation of natural resources, but also opening up new opportunities for the bio-based industry. This has the potential to create a more sustainable and circular economy, where waste materials are converted into valuable products, reducing the need for fossil fuels and minimizing environmental impact.Furthermore, the development of ZSM-48 highlights the company's commitment to innovation and its ability to leverage its expertise in materials science and catalysis to develop new and sustainable solutions. By investing in research and development, the company has positioned itself as a leader in sustainable technology, and is well-placed to meet the increasing demand for environmentally friendly alternatives in the energy and petrochemical industries.In addition to its environmental benefits, ZSM-48 also has the potential to significantly impact the global economy by unlocking new value chains and creating new market opportunities. As the world continues to transition towards a low-carbon and circular economy, innovative technologies like ZSM-48 will play a crucial role in driving this transformation and creating a more sustainable and prosperous future for generations to come.The successful development and commercialization of ZSM-48 is a testament to the company's commitment to sustainability and its ability to develop groundbreaking solutions to address some of the world's most pressing challenges. As the global demand for sustainable technologies continues to grow, the company is well-positioned to drive the transition towards a more sustainable and prosperous future for all.In conclusion, ZSM-48 represents a significant milestone in the company's efforts to drive the transition towards a more sustainable future. This innovative catalyst has the potential to revolutionize the energy and petrochemical industries, while also creating new opportunities for the bio-based economy. By investing in research and development and leveraging its expertise in materials science and catalysis, the company is demonstrating its commitment to innovation and sustainability, and is well-placed to meet the increasing demand for environmentally friendly alternatives. As the world continues to embrace the transition towards a low-carbon and circular economy, ZSM-48 is set to play a key role in creating a more sustainable and prosperous future for generations to come.

Discover the Latest Advancements in Alumina Research - Unveiling the Potential of Gamma Alumina

Gamma Alumina: Advancing Materials Science and Redefining Industrial PossibilitiesGamma Alumina is a high-performance material company that is redefining the industrial possibilities. The company takes pride in offering innovative solutions that are changing the way we look at materials science. Gamma Alumina products have diverse applications in various industries, including petrochemical, electronic, and pharmaceutical, among others. But what is Gamma Alumina, and what makes it so exceptional?Gamma Alumina is a type of alumina that exhibits unique physical and chemical properties, including high surface area, high purity, and thermal stability. This makes it an ideal material in many industrial processes. The company produces gamma alumina nanopowders using a proprietary method that combines cutting-edge technology and innovative process engineering.One of the most significant advantages of Gamma Alumina is its excellent catalytic properties. Gamma Alumina is used as a catalyst support in chemical reactions, enhancing reaction efficiency, and selectivity. The nanopowders offer a significant surface area to volume ratio, providing an optimized surface for catalytic activity. This implies that the material can catalyze a high rate of chemical reactions with minimal energy input, making it energy efficient and sustainable.Gamma Alumina is also widely used as an adsorbent material, where it can selectively adsorb specific molecules from gas or liquid streams. This has led to its use in purification processes to remove impurities from various industrial products such as natural gas, petrochemicals, and water. Its high surface area and unique pore structure make it an ideal material for selective separation processes, improving product purity and quality.Another significant application of Gamma Alumina is in the manufacture of ceramics and electronic materials. Gamma Alumina is used as a precursor for the production of advanced ceramics and glass matrices through the sol-gel process. It is also used in the production of electronic ceramics such as capacitors, insulators, and superconductors. Gamma Alumina offers a high degree of purity, thermal stability, and good dielectric properties, making it an ideal material in electronic applications.Gamma Alumina is also used in the pharmaceutical industry. It is used as a drug carrier in drug delivery systems, and as an intermediate in peptide synthesis. The material's unique adsorption properties allow it to adhere to specific drug molecules, improving the efficacy of the drug. Gamma Alumina is also used in bioceramic applications such as bone cement, where it provides mechanical stability and biocompatibility.In conclusion, Gamma Alumina is an exceptional material with diverse applications across various industries. Its unique physical and chemical properties make it an ideal material in many industrial processes. At Gamma Alumina, we are continually redefining the industrial possibilities by offering innovative solutions that enhance efficiency and sustainability in industrial processes. Our proprietary method of producing gamma alumina nanopowders allows us to deliver high-quality materials suitable for various applications. We are committed to advancing materials science, and our team of experts is always working to develop new applications of Gamma Alumina. We take pride in being at the forefront of materials science, and we look forward to expanding our footprint in different industries.

New Catalyst Developed for Methanation Process

Title: Revolutionary Methanation Catalyst Poised to Transform Energy IndustryIntroduction:In an exciting and groundbreaking development, an innovative Methanation Catalyst has been introduced to the market, poised to revolutionize the energy industry. Produced by an industry-leading company, this catalyst promises to significantly enhance the potential of renewable energy sources and reduce carbon emissions. With its exceptional efficiency and cost-effectiveness, it has the potential to accelerate the shift towards a sustainable and greener future. In this article, we will delve into the unique features of this catalyst and explore its potential to shape the landscape of the energy industry.1. Catalyst Overview:The Methanation Catalyst, developed by the renowned company, is a state-of-the-art technology designed to convert various renewable energy sources, such as hydrogen and carbon dioxide, into methane gas. This process, known as methanation, has garnered increasing attention as a vital step towards achieving carbon neutrality and utilizing surplus renewable energy. This innovative catalyst has the power to make this process more efficient and commercially viable, opening up new possibilities for a cleaner and more sustainable energy future.2. Unparalleled Efficiency:The Methanation Catalyst boasts an unparalleled efficiency in converting renewable resources into methane gas. Its advanced composition and proprietary design allow for a highly active and selective reaction, enabling a higher yield of methane production. This increased efficiency not only ensures optimal utilization of renewable energy sources but also reduces energy losses during the conversion process. By maximizing efficiency, this catalyst represents a significant step towards scaling up the use of renewable energy in our daily lives.3. Focus on Cost-Effectiveness:One of the standout features of this catalyst is its commitment to cost-effectiveness. By utilizing a combination of innovative materials and optimized reactor conditions, the company has successfully reduced the cost of methanation processes, making it more economically viable. This development enables widespread adoption of renewable energy, attracting investment and facilitating its integration into existing energy infrastructure. As the technology matures, we can expect significant reductions in the cost of production, driving the transition to a cleaner energy industry.4. Advancing the Energy Transition:The Methanation Catalyst holds immense potential to expedite the global energy transition. By efficiently converting renewable resources into methane gas, it addresses the challenge of storing and utilizing surplus renewable energy. The produced methane can be readily transported through existing natural gas infrastructure, providing a flexible and reliable energy source. This innovative catalyst plays a vital role in reshaping the energy industry, reinforcing the viability of renewable energy and paving the way for a greener, cleaner future.5. Environmental Benefits:By facilitating the conversion of hydrogen and carbon dioxide into methane gas, this catalyst offers significant environmental benefits. Methane, a cleaner-burning fuel compared to traditional fossil fuels, produces considerably lower carbon emissions when combusted. By utilizing this catalyst, industries can reduce their carbon footprint and meet ambitious emission reduction targets, as methane combustion produces neither greenhouse gases nor particulate matter. The use of this catalyst represents a major step towards achieving a sustainable and carbon-neutral future.Conclusion:The introduction of this Methanation Catalyst marks a remarkable breakthrough in the energy industry. Its exceptional efficiency, cost-effectiveness, and environmental benefits position it as a transformative technology in the journey towards sustainable and clean energy. By maximizing the potential of renewable energy sources, this catalyst promises to reshape the industry, accelerate the energy transition, and contribute significantly to the global efforts to combat climate change. As research and development continue, we anticipate further advancements in this catalyst, propelling us closer to a greener and more sustainable future.

Leading Catalyst Company Develops Advanced Technology for Environmental Solutions

Clariant Catalyst, a leading global specialty chemicals company, has recently introduced a new product that promises to revolutionize the catalysis industry. The company, with its headquarters in Muttenz, Switzerland, is known for its innovative solutions in the fields of specialty chemicals and catalysts. With a strong focus on sustainability and technological advancement, the company has established itself as a leader in the industry.The new product, which is the result of extensive research and development efforts, is set to enhance the efficiency and performance of catalytic processes across various industries. With its advanced technology and unique formulation, the product is expected to address the challenges faced by manufacturers and producers in their catalysis operations.Clariant Catalyst has a rich history of delivering high-quality, reliable, and sustainable solutions to its customers. With a global presence and a strong commitment to sustainability, the company continuously strives to develop products that meet the evolving needs of the market while also contributing to a more sustainable future. The new product is a testament to the company's dedication to innovation and excellence in the field of catalysis.The introduction of the new product comes at a time when the demand for efficient and sustainable catalytic processes is reaching new heights. Industries such as petrochemicals, refineries, and environmental technologies rely heavily on catalysis for their operations. As such, the need for advanced catalysts that can deliver improved performance and sustainability has become increasingly important.The new product from Clariant Catalyst is expected to address these needs by offering a range of benefits, including improved efficiency, higher yields, and reduced environmental impact. The company's expertise in catalyst development and its focus on sustainability have allowed it to create a product that not only meets the current demands of the industry but also aligns with the global push for more sustainable practices.In addition to its technical capabilities, the new product is also designed to be versatile and adaptable to a wide range of applications. This flexibility is expected to make it a valuable solution for companies operating in diverse industries, allowing them to optimize their catalytic processes and achieve better results.Clariant Catalyst's commitment to sustainability extends beyond the products it offers. The company has actively pursued initiatives to reduce its environmental footprint and contribute to the development of more sustainable practices in the industry. Its dedication to sustainability and innovation has earned it recognition as a top performer in various sustainability rankings and indices.As the market for catalysis continues to evolve, Clariant Catalyst remains at the forefront of driving positive change and progress. The company's new product is a testament to its ongoing efforts to create value for its customers and contribute to a more sustainable future for the industry.With its proven track record of delivering high-quality, sustainable, and innovative solutions, Clariant Catalyst is well-positioned to make a significant impact with its new product. As the industry continues to prioritize sustainability and efficiency, the company's latest offering is expected to play a key role in shaping the future of catalysis.

Guide to Reforming Catalyst for Improved Performance

Reforming Catalyst Revolutionizing Sustainable ManufacturingIn recent years, there has been a growing global focus on sustainable manufacturing practices. Companies across various industries are striving to reduce their environmental footprint and minimize their impact on the planet. One crucial aspect of this movement is the development and implementation of innovative technologies and processes that promote sustainable production. One such groundbreaking technology is the reforming catalyst, a revolutionary tool that is transforming the way industrial processes are carried out.A leading player in the field of sustainable manufacturing is a company (Company X) that has been at the forefront of developing advanced catalyst technologies to drive sustainable industrial processes. With a strong commitment to environmental stewardship and continuous innovation, (Company X) has developed a reforming catalyst that is set to redefine the standards of sustainable manufacturing.The reforming catalyst developed by (Company X) is a highly efficient and versatile tool that enables a wide range of industrial processes to be carried out with minimal environmental impact. Unlike traditional catalysts, the reforming catalyst is designed to facilitate more sustainable and efficient production processes, thereby enabling companies to achieve their sustainability goals while maintaining high levels of productivity and efficiency.One of the key features of the reforming catalyst is its ability to promote cleaner and more efficient combustion in industrial processes. By enhancing combustion efficiency, the reforming catalyst helps to reduce harmful emissions and minimize the environmental footprint of industrial operations. This is particularly significant in industries such as power generation, oil refining, and chemical manufacturing, where combustion processes are central to production.Moreover, the reforming catalyst also plays a crucial role in promoting energy efficiency in industrial processes. By facilitating more efficient energy utilization, the reforming catalyst helps companies reduce their energy consumption and lower their overall operational costs. This not only yields significant economic benefits for companies but also contributes to the global efforts to combat climate change by reducing greenhouse gas emissions.Another notable aspect of the reforming catalyst is its versatility and applicability across various industrial sectors. Whether it is used in power plants, refineries, petrochemical facilities, or other industrial settings, the reforming catalyst proves to be an invaluable asset in promoting sustainable manufacturing practices. Its flexibility and adaptability make it a highly sought-after solution for companies looking to enhance their sustainability efforts across different areas of operation.(Copying part of the content without proper edit. For original content, please consider the following)The success of the reforming catalyst developed by (Company X) can be attributed to the company's relentless commitment to research and innovation. (Company X) has invested substantial resources in developing and refining the reforming catalyst, leveraging the latest advancements in catalytic technologies and sustainable manufacturing practices. The result is a cutting-edge solution that not only meets the stringent environmental standards but also delivers tangible benefits to companies in terms of operational efficiency and cost savings.As the global focus on sustainability intensifies, the demand for innovative solutions such as the reforming catalyst is expected to soar. Companies across industries are increasingly turning to sustainable manufacturing practices, seeking ways to minimize their environmental impact while maintaining their competitive edge in the market. The reforming catalyst, with its proven track record of promoting sustainable production, is well-positioned to address this growing demand and emerge as a game-changer in the realm of industrial catalyst technologies.Looking ahead, (Company X) is poised to further advance the capabilities of the reforming catalyst, exploring new applications and potential enhancements to its performance. By continuously pushing the boundaries of catalytic innovation, (Company X) aims to empower companies worldwide to embrace sustainable manufacturing practices, ultimately contributing to a greener and more sustainable future for the planet.In conclusion, the reforming catalyst developed by (Company X) represents a significant milestone in the realm of sustainable manufacturing. With its ability to promote cleaner combustion, enhance energy efficiency, and drive operational sustainability, the reforming catalyst is paving the way for a new era of environmentally responsible industrial processes. As companies increasingly prioritize sustainability in their operations, the reforming catalyst is set to play a pivotal role in shaping the future of manufacturing, ushering in a new standard of sustainable and responsible production practices.

Cutting-Edge ZSM-5 Technology Shakes Up Industrial Processes

Title: Revolutionary Catalyst Advancements: Introducing a Breakthrough in Zeolite TechnologyIntroduction:In the world of chemical engineering, catalysts play a crucial role in accelerating chemical reactions and facilitating numerous industrial processes. One such catalyst that is currently making headlines is a revolutionary zeolite called ZSM-5. Developed by a leading research company, this innovative breakthrough promises to redefine the field of catalyst technology. In this article, we will delve into the fascinating world of ZSM-5 and explore its potential to revolutionize diverse industries. I. Understanding ZSM-5:ZSM-5 is a high-silica zeolite with a unique framework structure that allows for its exceptional catalytic properties. Its crystalline structure consists of channels and cavities, making it ideal for various applications in the petrochemical, refining, and pharmaceutical industries. The zeolite possesses both acidic and shape-selective catalytic properties, making it highly versatile and effective in a wide range of chemical reactions.II. Unleashing its Potential:A. Petrochemical Industry:1. Improved Process Efficiency: ZSM-5 exhibits remarkable selectivity towards specific hydrocarbons, enabling enhanced product yield in the cracking of larger hydrocarbon molecules into smaller, more valuable ones. This characteristic has the potential to revolutionize petrochemical processes, reducing waste and maximizing yield.2. Propylene Production: ZSM-5 zeolites possess a unique feature to favorably convert larger hydrocarbon molecules into propylene, a key building block in the plastics industry. With the increasing emphasis on sustainable materials, this capability could significantly impact the production of eco-friendly plastics.B. Refining Industry:1. Upgrading Biofuels: ZSM-5's shape selectivity and acidic nature make it an ideal catalyst to help convert low-quality biofuels into higher-quality products. By enhancing the process of transforming biofuels into gasoline, ZSM-5 contributes to reducing carbon emissions and promoting cleaner energy alternatives.2. Aromatics Production: The production of aromatic compounds, widely used in the manufacturing of plastics, dyes, and solvents, greatly benefits from the application of ZSM-5 as a catalyst. Its unique zeolite structure enhances the selectivity of aromatic production, leading to improved process efficiency and reduced environmental impact.C. Pharmaceutical Industry:1. Drug Synthesis: ZSM-5 zeolites have demonstrated exceptional results in various drug synthesis reactions. The catalyst's shape-selective properties enable control over the formation of specific molecules and regulate the reaction process, enhancing productivity and reducing the formation of unwanted byproducts.2. Environmental Remediation: ZSM-5 is also being explored for its potential in removing harmful pollutants, such as heavy metals and organic compounds, from wastewater. The zeolite's ability to selectively adsorb and degrade pollutants makes it a promising solution for combating water pollution, contributing to a cleaner and healthier environment.III. Future Prospects:The successful commercialization and implementation of ZSM-5 as a catalyst in various industries could have profound implications for the global economy and environmental sustainability. Its remarkable catalytic properties, coupled with its shape selectivity and versatility, make ZSM-5 an ideal candidate to address key challenges faced by the chemical industry today.Conclusion:ZSM-5 is a groundbreaking zeolite catalyst that brings unprecedented advancements to the world of chemical engineering. Its ability to enhance product yields, improve process efficiency, and regulate chemical reactions opens new avenues of innovation across multiple sectors. With ongoing research and development endeavors, ZSM-5 is poised to revolutionize industries, making manufacturing processes more sustainable, efficient, and environmentally friendly. As we embrace this new era of zeolite technology, we eagerly anticipate the transformative impact ZSM-5 will have on the global stage.