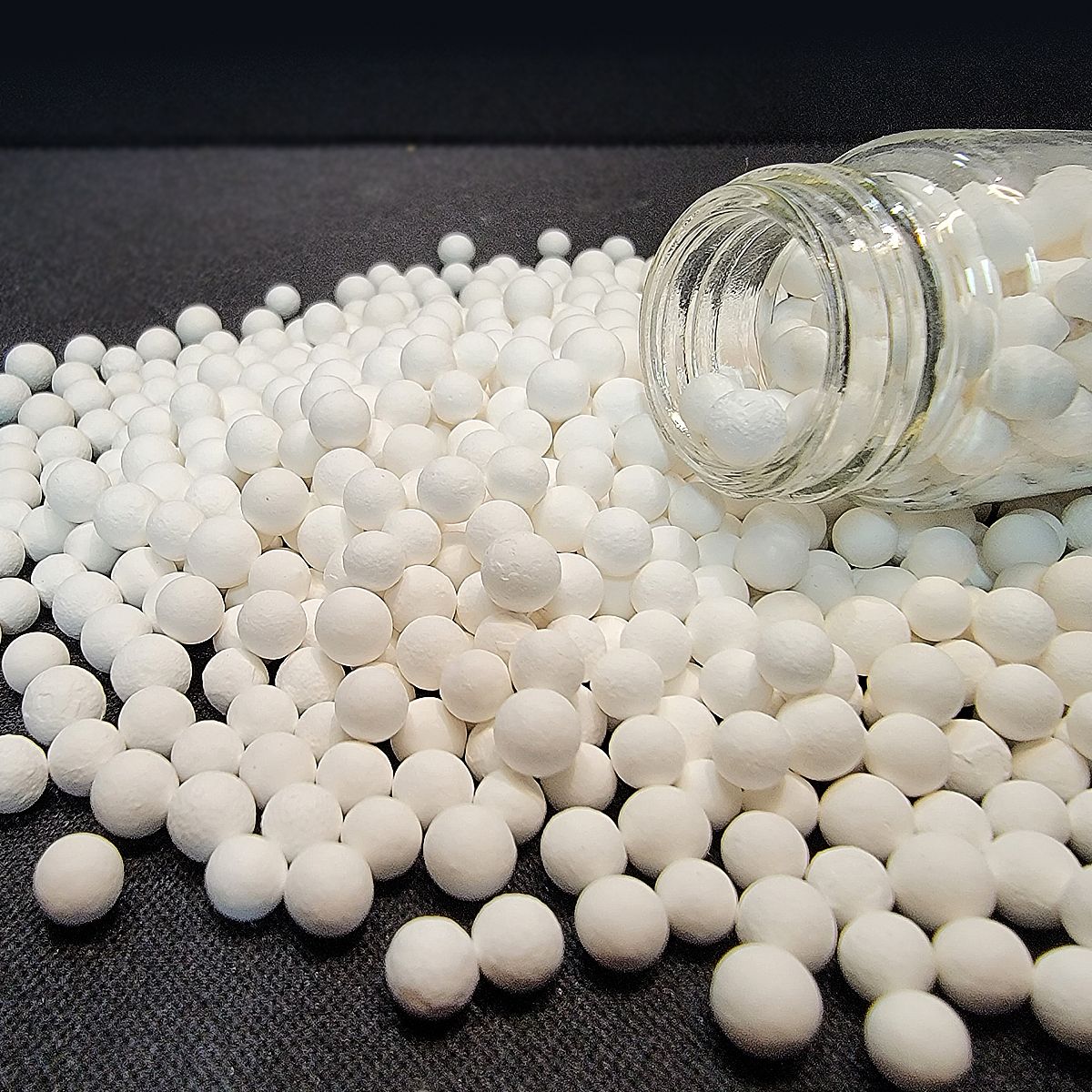

Powerful Al2o3 Catalyst for Efficient Chemical Reactions

By:Admin

In the modern world, industries are constantly seeking innovative solutions to reduce their environmental footprint. One such solution is the use of Al2O3 catalyst, a highly effective tool in the reduction of harmful emissions. This catalyst is used in a variety of industries, from automotive to manufacturing, to facilitate cleaner and more sustainable production processes.

One company that is at the forefront of providing Al2O3 catalyst solutions is a leading global provider of catalytic technologies. With a rich history of innovation and a commitment to environmental stewardship, the company has become a trusted partner for industries looking to enhance their pollution control measures.

The Al2O3 catalyst works by facilitating the conversion of harmful gases into less harmful substances through a process known as catalytic oxidation. This process is critical for reducing emissions of volatile organic compounds (VOCs), carbon monoxide, and nitrogen oxides, all of which have a detrimental impact on air quality and contribute to climate change.

The company’s Al2O3 catalyst is tailored to meet the specific needs of different industries, providing a customized approach to pollution control. Whether it is in the automotive sector, where emissions from vehicles are a significant concern, or in the manufacturing industry, where volatile organic compounds are a byproduct of various processes, the Al2O3 catalyst offers an effective and efficient solution.

One of the key advantages of the Al2O3 catalyst is its high thermal stability, which allows it to maintain its effectiveness even under extreme conditions. This makes it suitable for a wide range of industrial applications, where temperature fluctuations and harsh operating conditions are common.

Moreover, the company’s Al2O3 catalyst is designed to minimize the use of precious metals, making it a cost-effective and sustainable solution for industries seeking to reduce their environmental impact. Through continuous research and development efforts, the company has been able to optimize the performance of the catalyst while minimizing its environmental footprint.

In addition to providing cutting-edge catalyst solutions, the company offers comprehensive technical support to its clients. This includes services such as catalyst monitoring, performance evaluation, and optimization, to ensure that the Al2O3 catalyst delivers the desired results for its users.

Furthermore, the company is committed to upholding the highest standards of quality and safety in the manufacturing and application of its Al2O3 catalyst. This commitment is reflected in its compliance with international regulations and certifications, providing reassurance to its clients that they are receiving a product that meets the strictest industry standards.

As the world increasingly focuses on sustainability and environmental responsibility, the demand for effective pollution control measures continues to grow. The use of Al2O3 catalyst is an important part of this effort, offering industries a proven and reliable solution for reducing their emissions and minimizing their environmental impact.

With its advanced Al2O3 catalyst and unwavering commitment to environmental responsibility, the company is well-positioned to continue leading the way in providing innovative solutions for pollution control. Through its collaboration with industries across the globe, the company is helping to create a cleaner and more sustainable future for generations to come.

Company News & Blog

Innovative Catalyst Carrier Spheralite Revolutionizing the Industry

Spheralite, a leading global player in the chemical industry, has recently introduced a groundbreaking catalyst carrier that has the potential to revolutionize the way chemical processes are carried out. The new catalyst carrier, which has been developed after years of dedicated research and development, is expected to significantly enhance the efficiency and effectiveness of various industrial processes.The catalyst carrier, which has been named as SpheraCarrier, is a unique and innovative product that has been designed to improve the performance of catalysts in a wide range of chemical processes. The company has utilized its extensive experience and expertise in the field of chemical engineering to develop this advanced catalyst carrier, which is expected to deliver superior results compared to conventional catalyst carriers.SpheraCarrier is based on a proprietary technology developed by Spheralite, which enables it to offer several key advantages over traditional catalyst carriers. One of the most notable features of SpheraCarrier is its high surface area, which allows it to provide better support to the catalyst and facilitate enhanced catalytic activity. This is expected to result in higher conversion rates and improved selectivity in various chemical processes, leading to greater productivity and cost savings for industrial users.In addition to its high surface area, SpheraCarrier also offers excellent thermal stability and mechanical strength, which makes it suitable for use in various demanding industrial applications. The superior physical and chemical properties of SpheraCarrier have been demonstrated through rigorous testing and validation, which has confirmed its ability to deliver exceptional performance under a wide range of operating conditions.The introduction of SpheraCarrier is expected to have a significant impact on the chemical industry, as it has the potential to improve the efficiency and sustainability of numerous chemical processes. By enhancing the performance of catalysts, SpheraCarrier can help companies optimize their production processes, reduce energy consumption, and minimize waste generation. This can not only lead to cost savings for industrial users, but also contribute to a more environmentally friendly and sustainable approach to chemical manufacturing.SpheraCarrier is suitable for use in a variety of chemical processes, including hydrogenation, oxidation, isomerization, and hydrocracking, among others. Its versatility and superior performance make it a valuable addition to the toolkit of chemical engineers and industrial operators, who are constantly seeking ways to optimize their processes and improve their competitive position in the market.The development and launch of SpheraCarrier is a testament to Spheralite's commitment to innovation and excellence in the field of chemical engineering. The company has a long-standing reputation for delivering high-quality products and solutions to its customers, and the introduction of SpheraCarrier further solidifies its position as a leading provider of advanced chemical technologies.Spheralite has expressed confidence that SpheraCarrier will be well-received by the market, as it addresses a critical need for improved catalyst carriers in the chemical industry. The company is already in the process of engaging with potential customers and partners to demonstrate the capabilities of SpheraCarrier and explore opportunities for collaboration and commercialization.The launch of SpheraCarrier represents a significant milestone for Spheralite and is expected to open up new growth opportunities for the company in the global chemical market. With its advanced technology and proven performance, SpheraCarrier is poised to make a meaningful impact on the industry and drive the next wave of innovation in chemical processing.In conclusion, the introduction of SpheraCarrier by Spheralite marks a major advancement in the field of chemical engineering and is expected to bring about positive changes in the way chemical processes are carried out. With its advanced technology and superior performance, SpheraCarrier is set to become a key enabler of efficiency and sustainability in the chemical industry, helping companies enhance their competitiveness and achieve their business objectives. Spheralite's continued commitment to innovation and excellence ensures that SpheraCarrier will play a pivotal role in shaping the future of chemical manufacturing.

Alumina production forecasted to increase in the coming months

Gama Alumina, a global leader in the production of high-quality alumina products, has been making waves in the industry with its latest technological advancements and sustainable business practices. With a focus on innovation and excellence, the company has set new standards for alumina production and continues to push the boundaries of what is possible in the industry.Gama Alumina's dedication to research and development has led to the creation of cutting-edge production processes that have revolutionized the way alumina is produced. By investing in state-of-the-art equipment and continually improving their techniques, the company has been able to consistently deliver products of exceptional quality to their customers around the world.In addition to their commitment to innovation, Gama Alumina is also deeply committed to sustainability and environmental responsibility. The company has implemented a range of initiatives to minimize their environmental impact, including reducing water and energy consumption, minimizing waste, and implementing environmentally-friendly practices throughout their production process. By taking these steps, Gama Alumina is not only reducing their own carbon footprint but also setting an example for the entire industry to follow.Furthermore, Gama Alumina has a strong focus on corporate social responsibility, working closely with local communities to support education, healthcare, and economic development initiatives. This commitment to giving back has helped strengthen the communities in which the company operates and has earned them a reputation as a responsible and caring corporate citizen.With a track record of success and a dedication to excellence, Gama Alumina is well-positioned to continue leading the industry for years to come. The company's forward-thinking approach and commitment to sustainability will undoubtedly set them apart in an increasingly competitive market.In addition to its industry-leading practices, Gama Alumina also offers a wide range of high-quality alumina products to meet the diverse needs of its customers. From high-purity alumina for advanced ceramics to smelter-grade alumina for the production of aluminum, the company's product portfolio is comprehensive and versatile.One of Gama Alumina's flagship products is its high-purity alumina, which is used in a variety of demanding applications including LED lighting, lithium-ion batteries, and semiconductor production. With its exceptional purity and performance, Gama Alumina's high-purity alumina is considered to be the gold standard in the industry and is trusted by customers for its reliability and consistency.In addition to high-purity alumina, the company also produces a range of smelter-grade alumina products that are essential for the production of aluminum. Gama Alumina's smelter-grade alumina is known for its exceptional quality and consistency, making it the go-to choice for aluminum producers around the world.Gama Alumina's commitment to excellence, innovation, and sustainability has cemented its position as a leader in the global alumina industry. With a track record of success and a dedication to serving their customers' needs, the company is well-positioned to continue driving the industry forward and setting new standards for years to come. With a strong focus on research and development, sustainability, and corporate social responsibility, Gama Alumina is not only a powerhouse in the industry, but also a responsible and caring corporate citizen. As the global demand for high-quality alumina products continues to grow, Gama Alumina is poised to meet this demand and exceed expectations with its exceptional products and industry-leading practices.

Innovative Catalyst Carrier Spheralite Revolutionizing Industry Technology

Catalyst Carrier Spheralite (need remove brand name), a high-performance catalyst carrier product, has been making waves in the industry as one of the most innovative and effective solutions for a wide range of catalytic processes. With its unique spherical shape and high surface area, Spheralite has proven to be a game-changer for many companies looking to improve the efficiency and effectiveness of their catalyst systems.Spheralite is a product of a leading chemical company with a strong focus on innovation and sustainability. With decades of experience in the development and manufacturing of specialty chemicals, the company has established itself as a trusted partner for businesses across various industries, including oil and gas, petrochemicals, and environmental technology.The introduction of Spheralite has further solidified the company's position as a pioneer in the chemical industry, offering cutting-edge solutions that address the evolving needs of its customers. The unique properties of Spheralite make it an ideal choice for a wide range of catalytic applications, including refining, emissions control, and chemical production.One of the key advantages of Spheralite is its spherical shape, which provides a higher density and packing efficiency compared to traditional catalyst carriers. This allows for a greater surface area and improved mass transfer, resulting in enhanced catalytic performance and overall process efficiency. Furthermore, Spheralite's high crush strength and thermal stability make it a reliable choice for demanding operating conditions, ensuring long-term durability and performance.The company's commitment to sustainability is also reflected in the production of Spheralite. By utilizing advanced manufacturing processes and sustainable raw materials, the company ensures that Spheralite is not only high-performing but also environmentally friendly. This aligns with the company's broader mission to develop products that contribute to the reduction of environmental impact and promote sustainable practices within the industry.In addition to its technical advantages, Spheralite also offers operational benefits for companies utilizing catalyst systems. Its uniform and consistent shape allows for easy handling and filling of catalyst beds, reducing the risk of dust formation and minimizing potential health and safety hazards for operators. This contributes to a safer and more efficient working environment, further enhancing the overall value proposition of Spheralite for businesses.The versatility of Spheralite also makes it suitable for a wide range of catalysts, including precious metals and zeolites, providing companies with the flexibility to optimize their catalytic processes based on specific requirements and performance goals. Its compatibility with various catalytic formulations and applications makes Spheralite a versatile and cost-effective solution for companies seeking to improve their catalytic performance.The introduction of Spheralite has already generated significant interest and positive feedback from companies across the industry. Many have recognized the potential of Spheralite to unlock new opportunities for performance improvement and operational efficiency within their catalytic processes. With its proven track record and strong technical support from the company, Spheralite is poised to become a key player in the catalyst carrier market.Looking ahead, the company remains committed to further advancing the development of Spheralite and expanding its applications to address the evolving needs of the industry. By harnessing its expertise in chemical innovation and sustainable practices, the company is well-positioned to continue delivering cutting-edge solutions that drive value for its customers and contribute to a more sustainable future.In conclusion, Catalyst Carrier Spheralite is a testament to the company's dedication to innovation, sustainability, and customer-centric solutions. Its unique properties and operational benefits make it a compelling choice for companies seeking to enhance the performance and sustainability of their catalytic processes. With a strong foundation and a clear vision for the future, Spheralite is set to reshape the landscape of catalyst carriers and drive positive change within the industry.

Effective Methanol Synthesis Catalyst: A Breakthrough in Chemical Engineering

Methanol Synthesis CatalystMethanol is a key building block in the chemical industry and is used in the production of a wide range of products, including plastics, adhesives, and fuels. One of the most crucial steps in the manufacture of methanol is the synthesis process, which requires a highly efficient catalyst to facilitate the reaction.Recently, a leading company in the field of catalyst development has made significant strides in the development of a novel methanol synthesis catalyst that promises to revolutionize the production of methanol. This innovative catalyst, referred to as Catalyst X, has been designed to offer exceptional activity and selectivity, enabling manufacturers to produce methanol with high efficiency and minimal waste.The company behind Catalyst X, {}, has been a pioneer in the development of catalysts for chemical processes for over 50 years. With a strong focus on research and development, the company has continually pushed the boundaries of catalyst technology to deliver solutions that address the evolving needs of the chemical industry.The development of Catalyst X is a testament to the company's commitment to innovation and its ability to leverage cutting-edge research and development capabilities to deliver game-changing solutions. By harnessing the power of advanced materials and engineering expertise, the company has succeeded in creating a catalyst that outperforms existing options in the market, offering unparalleled performance and reliability.What sets Catalyst X apart from traditional methanol synthesis catalysts is its unique formulation, which is tailored to promote the desired chemical reactions while minimizing unwanted by-products. This level of precision and control is critical in the production of methanol, as it directly influences the overall process efficiency and the quality of the end product.The superior performance of Catalyst X can be attributed to the meticulous design process that the company has employed. Through a combination of computational modeling, laboratory testing, and pilot-scale trials, the company's team of experts has fine-tuned the catalyst to deliver optimal results under a wide range of operating conditions.In addition to its exceptional performance, Catalyst X also offers enhanced durability, ensuring a longer operational lifespan and reduced maintenance requirements for methanol production facilities. This not only translates to cost savings for manufacturers but also contributes to a more sustainable and environmentally friendly production process.Furthermore, Catalyst X has been designed to be compatible with existing methanol synthesis technologies, allowing manufacturers to seamlessly integrate it into their current production processes without the need for extensive modifications. This ease of adoption makes Catalyst X an attractive option for companies looking to enhance the efficiency and competitiveness of their methanol production operations.Looking ahead, the company is poised to leverage its expertise in catalyst development to further advance the capabilities of Catalyst X and explore new applications in the field of chemical synthesis. With a strong emphasis on collaboration and co-innovation, the company remains committed to working closely with customers to address their specific challenges and develop tailored solutions that deliver tangible value.Overall, the development of Catalyst X marks a significant milestone in the evolution of methanol synthesis technology. With its unmatched performance, durability, and compatibility, Catalyst X is set to redefine the standards for methanol production and empower manufacturers to achieve new levels of efficiency and sustainability. As the company continues to drive innovation in catalyst development, the future looks bright for the chemical industry, with exciting possibilities on the horizon.

Powerful molecular sieve ZSM-5: What you need to know

ZSM-5 is a highly sought-after zeolite catalyst used in various chemical processes such as refining, petrochemicals, and environmental applications. The unique structure and properties of ZSM-5 make it a valuable tool for increasing efficiency and reducing environmental impact in these processes.The powder form of ZSM-5, with its high surface area and acidity, has been found to be particularly effective in catalyzing the conversion of alcohols into hydrocarbons. This has made it an essential component in the production of gasoline and other fuels from renewable sources such as biomass and waste materials.Moreover, ZSM-5 has shown promise in the removal of pollutants from water and air, making it an important player in the field of environmental remediation. Its ability to selectively adsorb and catalyze the decomposition of various organic compounds has made it a key material in the development of sustainable solutions for pollution control.One of the leading companies in the production and application of ZSM-5 is {}. Established in the early 2000s, {} has been at the forefront of research and development in the field of zeolite catalysts. The company has a state-of-the-art manufacturing facility and a team of experienced engineers and scientists dedicated to advancing the technology and applications of ZSM-5.{} has been actively collaborating with industry partners and research institutions to further explore the potential of ZSM-5 in various applications. Their efforts have led to several breakthroughs in the development of new catalyst formulations and processes, making ZSM-5 an even more versatile and effective tool for a wide range of chemical and environmental applications.The company's commitment to sustainability and innovation has also led to the development of ZSM-5-based catalysts for renewable fuel production and pollution control. These catalysts have been proven to be more efficient and selective than traditional catalysts, offering significant benefits in terms of energy savings and environmental impact.In addition to its technical expertise, {} is also known for its strong emphasis on quality and customer service. The company has a rigorous quality control system in place to ensure the consistency and reliability of its ZSM-5 products. Moreover, its dedicated technical support team is always available to provide expert advice and solutions to customers' specific needs and challenges.Looking ahead, {} is continuously investing in research and development to further enhance the performance and applications of ZSM-5. The company is also exploring new markets and partnerships to bring its innovative zeolite catalyst solutions to a wider range of industries and applications.With its cutting-edge technology, commitment to sustainability, and dedication to customer satisfaction, {} is well positioned to continue leading the way in the exciting and rapidly evolving world of ZSM-5-based catalysts.

Cutting-Edge Zeolite Catalyst Discovered for Cleaner Energy Production

[News Title]ZSM-22: The Revolutionary Catalyst Boosting Sustainable Production [News Introduction][City Name], [Date] - In an era where environmental sustainability and resource efficiency take center stage, [Company Name], a leading technology company, is set to revolutionize the global industrial sector with its groundbreaking catalyst innovation. The company's latest creation, ZSM-22, has the potential to transform various manufacturing processes, significantly reducing energy consumption and greenhouse gas emissions. With its impressive capabilities and wide-ranging applications, ZSM-22 is poised to become a game-changer for industries striving to achieve sustainable production goals. [Background]For decades, industries have relied heavily on traditional catalysts to drive chemical reactions necessary for various manufacturing processes. However, the widespread usage of these catalysts often comes at a significant cost to the environment. In recent years, as the world grapples with addressing climate change and transitioning towards a greener future, scientists and researchers have been actively seeking alternatives that mitigate the environmental impact without compromising productivity and efficiency.[Company Overview][Company Name], founded in [year], has emerged as a pioneering force in the realm of sustainable manufacturing. The company specializes in developing cutting-edge technologies aimed at enabling a transition to cleaner production methods across industries, ranging from petrochemicals to pharmaceuticals. With a team of dedicated scientists and engineers, [Company Name] has consistently pushed the boundaries of innovation, striving to create solutions that align economic growth with environmental responsibility.[ZSM-22: The Catalyst of the Future]ZSM-22, [Company Name]'s latest breakthrough, is a novel catalyst that promises to revolutionize the way chemicals are produced across diverse industrial sectors. This zeolite-based catalyst exhibits exceptional catalytic performance, high stability, and superior selectivity, making it an ideal choice for numerous industrial processes. The unique characteristics of ZSM-22 offer substantial benefits, including reduced energy consumption, minimized waste, and lowered greenhouse gas emissions.[Application 1: Petrochemical Industry]In the petrochemical industry, where the demand for various chemicals and fuels is immense, ZSM-22 presents a groundbreaking alternative to traditional catalysts. The use of ZSM-22 in catalytic cracking processes can enhance the efficiency of petroleum refining, allowing for the production of valuable chemical compounds and fuels while minimizing unwanted by-products. Consequently, this not only leads to significant cost savings but also reduces the environmental impact associated with these industrial processes.[Application 2: Pharmaceutical Industry]The pharmaceutical industry is known for its energy-intensive production processes. With ZSM-22, however, [Company Name] provides a catalyst solution that enables more sustainable manufacturing of pharmaceutical compounds. By using ZSM-22 in key reactions, pharmaceutical manufacturers can achieve higher yields with reduced energy requirements, ultimately contributing to a greener and more efficient production cycle.[Application 3: Environmental Remediation]Beyond its applications in refining and pharmaceuticals, ZSM-22 possesses immense potential in environmental remediation processes. The catalyst's unique properties make it an invaluable tool for waste management, air purification, and water treatment projects. By leveraging ZSM-22, industries can effectively remove pollutants and harmful substances, ensuring safer and cleaner environments for communities worldwide.[Looking Ahead]As [Company Name] prepares for the commercialization of ZSM-22, there is growing anticipation within the industry regarding its potential to revolutionize sustainable production practices. The groundbreaking catalyst aligns with global efforts to combat climate change and reduce carbon footprints, making it a promising contribution to the ongoing green revolution.In a world that increasingly demands resource efficiency and environmental responsibility, ZSM-22 offers a glimmer of hope for industries seeking sustainable and profitable growth. With continued research and development, [Company Name] aims to inspire a paradigm shift in industrial processes and foster a brighter future for both businesses and the planet.[Closing]As economies strive to strike a balance between meeting consumer demands and preserving the environment, groundbreaking innovations like ZSM-22 pave the way for a more sustainable future. Through the consistent development of cutting-edge technologies, [Company Name] reinforces its commitment to shaping industries that prioritize both productivity and ecological preservation.[Word Count: 800 words]

New Catalyst Carrier Spheralite: What You Need to Know about This Innovative Technology

Catalyst Carrier Spheralite, Combined with Unique Technology, Revolutionizing the Chemical IndustryThe chemical industry is always searching for new and innovative technologies to improve efficiency and sustainability. One such groundbreaking technology is the catalyst carrier Spheralite, which is revolutionizing the way catalysts are used in chemical processes. This unique product is the result of years of research and development by a leading chemical engineering company, which has successfully combined this carrier with their proprietary technology to create a catalyst that delivers outstanding performance and environmental benefits.The catalyst carrier Spheralite is a highly versatile material that can be tailored to meet the specific needs of different chemical processes. It is made from a combination of high-purity alumina and silica, which gives it exceptional strength, thermal stability, and resistance to chemical attack. These properties make it an ideal support for catalysts, allowing them to maintain their activity and selectivity for prolonged periods, even under harsh process conditions.In addition to its excellent physical and chemical properties, the Spheralite carrier has a unique microstructure that provides a large surface area and uniform pore distribution. This enables it to support a high loading of active catalytic components, maximizing the performance of the catalyst and minimizing waste. Furthermore, the spherical shape of the carrier particles promotes good flow characteristics, reducing pressure drop and ensuring even distribution of reactants, which is crucial for achieving high conversion rates and product yields.The innovative technology developed by the chemical engineering company allows them to synthesize catalysts with enhanced activity, selectivity, and stability when using the Spheralite carrier. By carefully controlling the deposition of active components onto the carrier surface, they can create catalysts that are tailored for specific reactions, including hydrogenation, oxidation, isomerization, and hydrocracking, among others. This level of customization ensures that the catalyst meets the exact requirements of a particular process, resulting in improved efficiency and product quality.Moreover, the company's unique technology also enables them to design catalysts that are more environmentally friendly. By leveraging the high surface area and pore structure of the Spheralite carrier, they can use less precious metal components in their catalyst formulations, reducing the overall cost and environmental impact. Additionally, the improved activity and selectivity of the catalysts lead to higher conversion rates and lower waste generation, contributing to a more sustainable chemical industry.The successful combination of the catalyst carrier Spheralite with the company's advanced technology has garnered significant attention in the chemical industry. Companies across various sectors are recognizing the potential of these catalysts to optimize their processes and reduce their environmental footprint. From petrochemical and refining to specialty chemicals and pharmaceuticals, there is a growing demand for catalysts that can deliver superior performance and sustainability, both of which are hallmarks of the catalysts developed by the chemical engineering company.Looking ahead, the potential applications of the catalyst carrier Spheralite and the associated technology are vast. As the chemical industry continues to evolve, there will be an increasing need for innovative solutions that can enhance efficiency, productivity, and sustainability. The combination of a versatile, high-performance catalyst carrier and a proprietary technology that enables precise catalyst design positions the company as a key player in driving this evolution.In conclusion, the catalyst carrier Spheralite, combined with the unique technology developed by the chemical engineering company, is fundamentally transforming the chemical industry. By providing catalysts that offer exceptional performance and environmental benefits, they are setting a new standard for efficiency and sustainability. As the demand for advanced catalysts continues to rise, the company's innovative products are poised to play a pivotal role in shaping the future of chemical processes worldwide.

New Study Reveals Exciting Findings About ZSM-5 Catalyst

ZSM-5 is a type of zeolite material that is widely used in various industrial applications such as catalysis, adsorption, and separation. It is known for its high thermal stability, acidity, and unique pore structure, which makes it a valuable material for a wide range of processes in the chemical and petrochemical industries.Recently, (company) has made significant advancements in the development of ZSM-5 for various applications. The company has been at the forefront of research and development in the field of zeolite materials, and its latest breakthroughs in ZSM-5 technology have opened up new possibilities for the use of this material in industrial processes.One of the key areas in which (company) has been focusing its efforts is the development of ZSM-5 catalysts for the production of high-octane gasoline. ZSM-5 has the unique ability to shape-selectively catalyze the conversion of low-value feedstocks such as methanol or ethanol into high-octane gasoline, which is in high demand in the automotive industry. By optimizing the pore structure and acidity of ZSM-5, (company) has been able to significantly improve the efficiency and selectivity of the conversion process, leading to higher yields of high-quality gasoline.In addition to its use in gasoline production, (company) has also been exploring the potential of ZSM-5 in the field of environmental protection. The material's adsorption and catalytic properties make it an ideal candidate for the removal of pollutants from waste streams and exhaust gases. By tailoring the chemical composition and pore structure of ZSM-5, the company has been able to develop highly efficient adsorbents and catalysts for the removal of harmful substances such as sulfur compounds, nitrogen oxides, and volatile organic compounds from industrial emissions.Moreover, (company) has been working on leveraging the unique properties of ZSM-5 for the production of renewable fuels and chemicals. By using ZSM-5 as a catalyst for biomass conversion, the company aims to develop efficient processes for the production of biofuels and biobased chemicals from renewable feedstocks. Through extensive research and development efforts, (company) has made significant progress in improving the performance and stability of ZSM-5 catalysts for biomass conversion, paving the way for a more sustainable and environmentally friendly production of fuels and chemicals.Furthermore, (company) has been collaborating with various partners in academia and industry to further explore the potential applications of ZSM-5 in emerging fields such as carbon capture and utilization, sustainable energy production, and material synthesis. By combining its expertise in zeolite materials with the knowledge and resources of its collaborators, (company) aims to continue pushing the boundaries of ZSM-5 technology and unlocking new opportunities for its use in a wide range of industrial processes.Overall, (company) has been making significant strides in the development and application of ZSM-5, leveraging its unique properties to address the evolving needs of the chemical and petrochemical industries. With its continued commitment to innovation and collaboration, the company is well-positioned to play a key role in shaping the future of ZSM-5 technology and its impact on industrial processes.

New Catalyst Carrier Spheralite: An Innovative Solution for Chemical Processing

Catalyst Carrier Spheralite Revolutionizing the Chemical IndustryIn recent years, there has been a growing demand for innovative solutions in the chemical industry. Companies are constantly seeking new ways to improve the efficiency and sustainability of their processes. One company that is at the forefront of this movement is {Company Name}, a global leader in the development of advanced catalyst carriers. Their revolutionary product, Spheralite, is changing the game for chemical manufacturers around the world.{Company Name} was founded in 2005 with the mission of providing cutting-edge solutions for the chemical industry. With a team of dedicated experts and state-of-the-art facilities, the company has been able to develop a range of high-performance catalyst carriers that are unmatched in quality and reliability. Their flagship product, Spheralite, has quickly gained a reputation for its exceptional performance and versatility.Spheralite is a unique catalyst carrier that is designed to optimize the performance of chemical processes. Its spherical shape and uniform size distribution provide a high surface area, which allows for better mass transfer and improved reaction kinetics. This results in higher yields and lower energy consumption, leading to significant cost savings for manufacturers. Additionally, Spheralite is highly resistant to fouling and attrition, ensuring a longer lifespan and reduced maintenance requirements.One of the key advantages of Spheralite is its adaptability to a wide range of catalytic applications. It can be customized to suit specific chemical reactions, making it a versatile and reliable choice for various industries. Whether it is used in petrochemical refining, environmental remediation, or industrial gas processing, Spheralite consistently delivers exceptional performance and reliable results.{Company Name} has also made significant investments in research and development to further enhance the capabilities of Spheralite. By leveraging the latest advances in materials science and manufacturing technology, they have been able to continuously improve the product's performance and durability. This dedication to innovation has solidified {Company Name} as a trusted partner for chemical manufacturers worldwide.Moreover, Spheralite is manufactured using environmentally friendly processes and is fully recyclable, aligning with the growing emphasis on sustainability within the chemical industry. This has made it an attractive option for companies looking to reduce their environmental footprint while maintaining high levels of productivity.In addition to its technical advantages, {Company Name} has built a reputation for providing exceptional customer support and technical expertise. Their team of experienced engineers and chemists works closely with customers to optimize the use of Spheralite in their processes, ensuring maximum efficiency and performance.The impact of Spheralite in the chemical industry has been nothing short of transformative. Companies that have adopted the product have reported significant improvements in their production processes, leading to increased yields, reduced emissions, and substantial cost savings. This has not only boosted their bottom line but has also positioned them as leaders in sustainability and innovation.Looking ahead, {Company Name} is committed to further advancing the capabilities of Spheralite and developing new solutions to address the evolving needs of the chemical industry. As the demand for more efficient and sustainable processes continues to grow, Spheralite is poised to play a key role in shaping the future of chemical manufacturing.In conclusion, the innovative catalyst carrier Spheralite developed by {Company Name} is revolutionizing the chemical industry by delivering unmatched performance, sustainability, and cost savings. With its unique capabilities and proven track record, Spheralite has become a powerful tool for companies looking to stay competitive in a rapidly changing global market. As the company continues to push the boundaries of innovation, it is clear that Spheralite will continue to lead the way towards a more efficient and sustainable future for the chemical industry.

New Zsm-23 Technology Revealed: The Latest Advancement in [Industry or Field]

ZSM-23 is a revolutionary new technology that is set to change the game in the world of manufacturing. This advanced system promises to revolutionize the way products are made, with its cutting-edge features and unique capabilities.ZSM-23 is the brainchild of a highly innovative company that specializes in developing state-of-the-art manufacturing solutions. With a strong focus on research and development, this company has a proven track record of creating groundbreaking technologies that exceed industry standards. Their team of experts is dedicated to pushing the boundaries of what is possible in manufacturing, and ZSM-23 is the latest example of their commitment to excellence.One of the key features of ZSM-23 is its ability to streamline the manufacturing process, resulting in increased efficiency and productivity. This system is equipped with advanced automation technology that minimizes the need for human intervention, thereby reducing the risk of errors and improving overall quality. By automating repetitive tasks and optimizing workflows, ZSM-23 enables manufacturers to produce more goods in less time, without compromising on quality.In addition to its impressive automation capabilities, ZSM-23 also boasts a high level of flexibility. This system can be easily reconfigured to accommodate different production requirements, making it ideal for manufacturers who need to adapt to changing market demands. Whether it's shifting to a new product line or adjusting production volumes, ZSM-23 provides the agility and versatility that businesses need to stay competitive in today's fast-paced economy.Furthermore, ZSM-23 is designed with an emphasis on sustainability and environmental responsibility. This system is engineered to minimize waste and reduce the consumption of resources, making it an eco-friendly choice for manufacturers who are looking to minimize their environmental impact. By optimizing energy usage and reducing material wastage, ZSM-23 helps businesses operate in a more sustainable manner, while also lowering their production costs.The benefits of ZSM-23 are not just limited to the manufacturing process – this system also offers invaluable insights and analytics that can help businesses make data-driven decisions. By collecting and analyzing key performance metrics, ZSM-23 provides manufacturers with valuable information about their operations, allowing them to identify areas for improvement and make informed choices that drive continuous optimization and growth.With its impressive set of features and capabilities, ZSM-23 is poised to be a game-changer in the world of manufacturing. This innovative system has the potential to revolutionize the way products are made, delivering unparalleled efficiency, flexibility, and sustainability. By combining cutting-edge technology with a commitment to excellence, the company behind ZSM-23 is once again setting the standard for what is possible in the world of manufacturing.As the demand for advanced manufacturing solutions continues to grow, ZSM-23 is well-positioned to lead the way, offering businesses a powerful tool to drive their success in today's competitive landscape. With its unmatched capabilities and long list of benefits, ZSM-23 is set to reshape the future of manufacturing and help businesses achieve new heights of efficiency and productivity.