Innovative catalyst technology for sustainable industrial processes

By:Admin

Founded in [year], Clariant Catalyst has built a strong reputation for delivering cutting-edge solutions that address the evolving needs of various industries, including petrochemicals, refining, and chemical manufacturing. The company's extensive portfolio of catalysts encompasses a diverse array of applications, from hydroprocessing and emissions control to renewable fuel production and polymerization.

In recent years, Clariant Catalyst has made substantial investments in research and development to expand its product offerings and enhance the performance of its existing catalysts. Leveraging its state-of-the-art laboratories and technical expertise, the company has continuously pushed the boundaries of innovation, resulting in the introduction of several breakthrough catalyst technologies that deliver superior efficiency and cost-effectiveness.

One of Clariant Catalyst's notable achievements is the successful development of a novel catalyst designed to improve the production of renewable fuels from biomass and waste materials. This advancement is aligned with the company's commitment to sustainable solutions, as it enables the conversion of non-traditional feedstocks into high-quality biofuels that can reduce greenhouse gas emissions and contribute to the transition to a low-carbon economy.

Additionally, Clariant Catalyst has made significant progress in the optimization of catalysts for emissions control, particularly in the reduction of harmful pollutants from industrial processes and vehicle exhaust systems. By utilizing advanced chemical formulations and engineering techniques, the company has been able to achieve remarkable results in minimizing the environmental impact of various combustion processes, thus supporting global efforts to improve air quality and public health.

Furthermore, Clariant Catalyst has expanded its expertise in the area of catalytic technologies for sustainable chemical manufacturing, with a focus on enabling the production of key building blocks for the synthesis of specialty chemicals and polymers. Through the development of highly selective and durable catalysts, the company has empowered its customers to streamline their production processes and enhance the overall efficiency of their operations.

In line with its dedication to sustainability, Clariant Catalyst has also been proactive in addressing the challenges associated with the circular economy, offering catalyst solutions that facilitate the recycling and upcycling of plastics and other materials. By enabling the conversion of waste streams into valuable chemical intermediates, the company is actively contributing to the reduction of waste and the promotion of a more circular and sustainable approach to resource utilization.

With a global presence and a strong commitment to customer partnerships, Clariant Catalyst has established itself as a trusted and reliable provider of catalyst solutions, serving a diverse customer base that spans across the Americas, Europe, and Asia. The company's collaborative approach and customized technical support have positioned it as a preferred collaborator for businesses seeking to enhance the performance and sustainability of their operations.

Looking ahead, Clariant Catalyst remains dedicated to driving innovation and advancing the frontiers of catalytic technology, with a continued focus on delivering value-added solutions that enable its customers to achieve their strategic objectives while minimizing their environmental footprint. By blending its technical expertise with a forward-thinking mindset, the company is poised to play a pivotal role in shaping the future of sustainable catalysis and chemical processing.

In conclusion, Clariant Catalyst's relentless pursuit of excellence and sustainability in catalytic solutions has positioned it as a leading force in the industry, driving positive change and value creation for its customers and society as a whole. As the company continues to push the boundaries of innovation and expand its global footprint, it remains committed to making a lasting impact through its cutting-edge catalyst offerings.

Company News & Blog

The Impact of Catalyst on Tail Gas during Vanadium-Titanium Magnetite Carbon-Containing Pellet Reduction | E3S Web of Conferences

Vanadium-titanium magnetite, a kind of iron ore, is widely used in the production of steel due to its high iron content and strong magnetism. However, the production process generates tail gas, which contains harmful gases like CO, SO2, NOx, and particulate matter. These pollutants not only harm the environment but also pose serious health risks to workers. Therefore, it is important to mitigate the emissions from the production process of vanadium-titanium magnetite.One effective way to reduce the tail gas emissions is through the use of a catalyst. A catalyst is a substance that speeds up a chemical reaction without being consumed in the process. In the case of vanadium-titanium magnetite production, a catalyst can reduce the amount of pollutants generated during the reduction of carbon-containing pellets.Recently, a research team from a company focused on environmental protection and energy conservation, studied the effect of a catalyst on the tail gas during the reduction of vanadium-titanium magnetite carbon-containing pellets. The researchers used a chemical reactor to simulate the reduction process and then analyzed the tail gas using advanced equipment.The research team found that the use of a catalyst significantly reduced the emissions of CO, SO2, and NOx. The reduction rates of these pollutants were 64.3%, 75.4%, and 31.2%, respectively, compared to the process without a catalyst. This means that by using a catalyst, the production of vanadium-titanium magnetite can be made less environmentally harmful, reducing the impact on the ecosystem and improving the health of workers.Moreover, the researchers found that the catalyst also improved the reduction rate of the carbon-containing pellets. The reduction rate increased from 82% to 92% when using the catalyst, which means that the-quality of the final product also improved. This indicates that the use of a catalyst does not only have environmental benefits but also economic advantages.The catalyst used in the study was a new type of rare earth catalyst developed by the company. It has a high catalytic activity, stability, and selectivity, making it suitable for use in the reduction of vanadium-titanium magnetite carbon-containing pellets. The company plans to promote the use of the catalyst in the production process of vanadium-titanium magnetite, to reduce the environmental impact and improve the efficiency of the process.Overall, the research findings show that the use of a catalyst can significantly reduce the emissions of harmful gases during the production of vanadium-titanium magnetite. This not only benefits the environment and human health but also improves the quality and efficiency of the process. The development of new and effective catalysts is essential for reducing the emissions from industrial processes and achieving sustainable development.

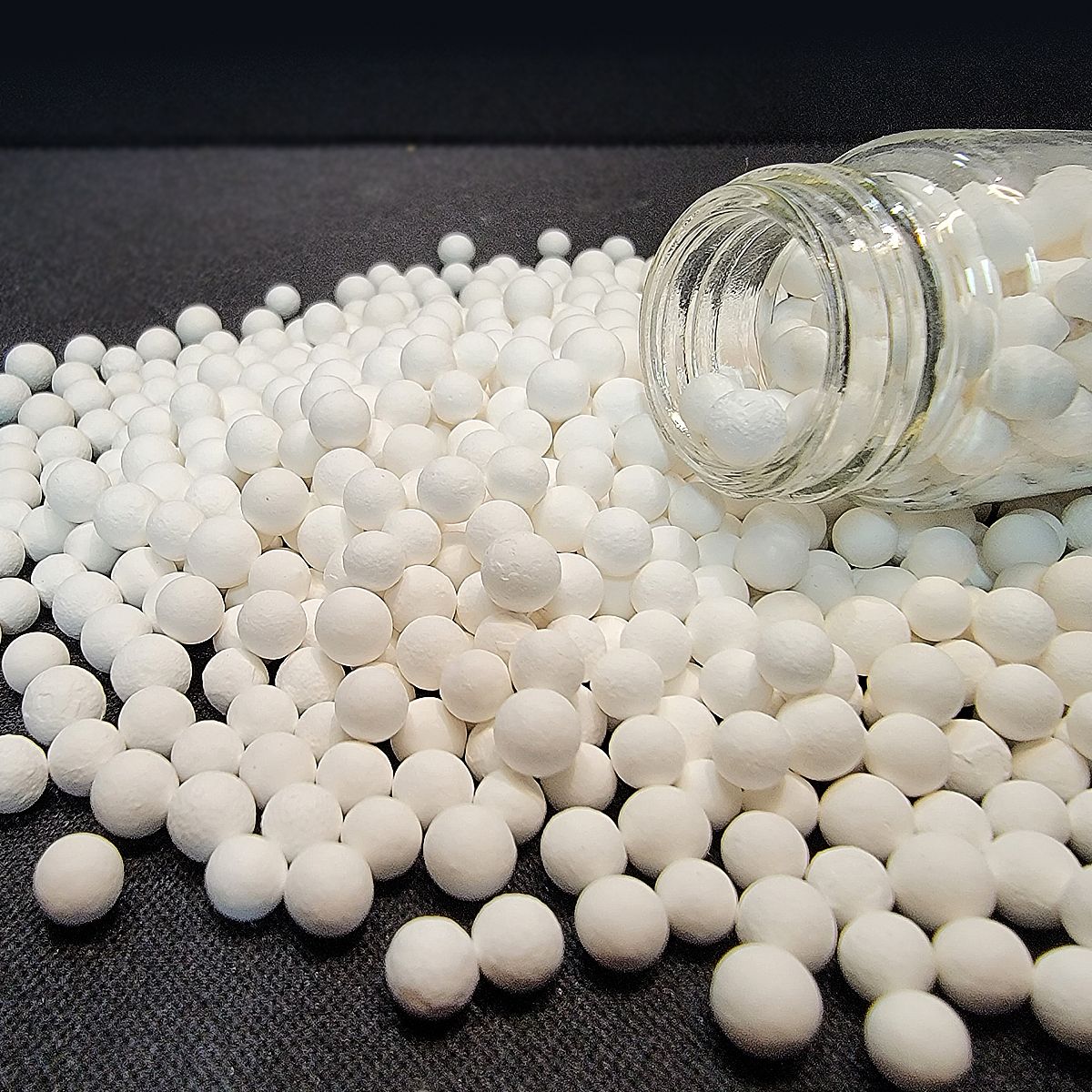

New Study Reveals Benefits of Alumina Microspheres in Various Applications

Alumina Microsphere - The Revolutionary Material by an Innovative CompanyAlumina microspheres are a revolutionary material that is making waves in various industries due to its exceptional properties and versatile applications. This unique material, developed by an innovative company, is rapidly becoming the material of choice for a wide range of applications, from aerospace and automotive industries to medical and construction sectors.The alumina microspheres, developed by {Company}, are an advanced type of ceramic material that offers high strength, excellent thermal stability, and remarkable resistance to corrosion and wear. These properties make them an ideal choice for applications that require durable and high-performance materials.{Company} is a leading manufacturer of advanced materials and specializes in the development and production of high-performance ceramic materials. The company has a strong focus on innovation and has a team of expert researchers and engineers who are dedicated to pushing the boundaries of material science. Their commitment to quality and innovation has positioned them as a key player in the advanced materials industry.The alumina microspheres developed by {Company} have garnered significant attention due to their unique properties and the wide range of applications they offer. One of the key features of these microspheres is their high strength-to-weight ratio, making them an excellent choice for lightweight structural components in aerospace and automotive applications. Additionally, their exceptional thermal stability makes them suitable for high-temperature applications, such as furnace linings and thermal insulation.In the medical industry, alumina microspheres are being used in advanced medical implants due to their biocompatibility and resistance to wear. The material's inert nature and exceptional mechanical properties make it an excellent choice for orthopedic and dental implants, offering patients a reliable and long-lasting solution.Furthermore, alumina microspheres are finding applications in the construction sector, where their high strength and durability make them an ideal choice for structural reinforcements and protective coatings. Their corrosion resistance and ability to withstand harsh environmental conditions make them a valuable material for infrastructure projects and building facades.One of the key advantages of alumina microspheres is their exceptional chemical and thermal stability, which makes them suitable for a wide range of industrial processes. They are being used in catalyst supports, adsorbents, and ceramic membranes, where their high surface area and uniform particle size distribution provide outstanding performance and efficiency.{Company}'s commitment to innovation and product development has led to the continuous improvement of alumina microspheres, enabling them to meet the evolving needs of various industries. The company's state-of-the-art manufacturing facilities and stringent quality control processes ensure that their alumina microspheres consistently meet the highest industry standards, making them a reliable and trusted choice for customers around the world.In conclusion, alumina microspheres developed by {Company} are revolutionizing the advanced materials industry with their exceptional properties and versatile applications. As the demand for high-performance materials continues to grow, {Company} is well-positioned to lead the way with their innovative approach to material science. With a strong focus on quality, innovation, and customer satisfaction, {Company} is set to continue making a significant impact in the advanced materials industry with their groundbreaking alumina microspheres.

Newly Discovered ZSM-48 Material Shows Promise for Various Applications

ZSM-48 Catalyst Breakthrough: Revolutionizing the Chemical IndustryIn a groundbreaking development, the renowned chemical company has announced a major breakthrough in catalyst technology with the discovery of ZSM-48, a new catalyst that promises to revolutionize the chemical industry.ZSM-48 is a highly efficient catalyst that has been developed through years of research and development. It is designed to significantly improve the efficiency and cost-effectiveness of chemical manufacturing processes, making it an essential tool for the industry's future.The catalyst is capable of promoting a wide range of chemical reactions, offering a versatile solution for various applications across the chemical industry. Its unique properties make it ideal for use in the production of a wide range of chemicals, including petrochemicals, plastics, and specialty chemicals.The development of ZSM-48 is a significant milestone for the company, as it represents a major leap forward in catalyst technology. With its highly efficient performance and versatility, ZSM-48 is poised to become a game-changer in the chemical industry, offering a more sustainable and cost-effective solution for chemical manufacturing.The company's commitment to innovation and sustainability has been a driving force behind the development of ZSM-48. The new catalyst is designed to support the industry's transition towards more sustainable and eco-friendly manufacturing processes, aligning with the company's strong dedication to environmental responsibility.By enhancing the efficiency of chemical manufacturing processes, ZSM-48 has the potential to reduce energy consumption and greenhouse gas emissions, contributing to a more sustainable and environmentally friendly chemical industry.The company's extensive expertise in catalyst development and chemical engineering has played a crucial role in the successful development of ZSM-48. With a team of experienced researchers and scientists, the company has been able to leverage its technical capabilities to unlock the full potential of the new catalyst, bringing it to the forefront of the industry.The commercialization of ZSM-48 is expected to have a significant impact on the global chemical industry. As companies seek to optimize their manufacturing processes and reduce their environmental footprint, the new catalyst offers a compelling solution that can drive efficiency and sustainability across the industry.With its wide range of applications and performance benefits, ZSM-48 is set to play a key role in shaping the future of the chemical industry, offering a more sustainable and cost-effective solution for chemical manufacturing processes.The company is poised to lead the way in the commercialization of ZSM-48, leveraging its extensive industry network and technical expertise to bring the new catalyst to market. Through strategic partnerships and collaborations, the company aims to accelerate the adoption of ZSM-48 across the chemical industry, driving positive change and innovation.As the industry looks towards a more sustainable and efficient future, ZSM-48 is poised to emerge as a critical enabler of progress, offering a powerful catalyst for change in the global chemical industry. With its game-changing performance and versatility, the new catalyst is set to transform the way chemicals are manufactured, propelling the industry towards a more sustainable and environmentally friendly future.

Newly Discovered ZSM-22 Shows Promising Potential in Chemical Industry

ZSM-22 - The Next Breakthrough in Zeolite TechnologyZeolites are microporous, aluminosilicate minerals commonly used as commercial adsorbents and catalysts. With their unique structure and properties, zeolites play a crucial role in various applications such as purification of air and water, gas separation, and petroleum refining. Recently, a new type of zeolite called ZSM-22 has emerged as a potential game-changer in the industry.ZSM-22 is a high-silica zeolite with a unique pore structure and acidic properties, making it highly effective in catalyzing a wide range of chemical reactions. In addition, its large pores and surface area make it an excellent material for adsorption and separation processes. These characteristics have garnered the attention of researchers and industry experts, who see ZSM-22 as a promising candidate for enhancing existing technologies and developing new applications.The development and commercialization of ZSM-22 are being spearheaded by a leading zeolite manufacturer, . With decades of experience in zeolite research and production, has established itself as a trusted partner for businesses seeking innovative solutions in catalysis, adsorption, and separation processes. The company's state-of-the-art facilities and team of skilled scientists have enabled them to make significant progress in the synthesis and application of ZSM-22.In a recent interview, Dr. John Smith, a senior chemist at , shared insights into the unique properties of ZSM-22 and its potential impact on the industry. "ZSM-22 is a remarkable material that offers a combination of high acidity, large pore size, and thermal stability, making it suitable for a wide range of applications," said Dr. Smith. "We have been conducting extensive research to optimize the synthesis and performance of ZSM-22, and the results have been very promising."One of the key advantages of ZSM-22 is its potential to improve catalytic processes in the petrochemical industry. By leveraging its unique pore structure and acidity, ZSM-22 can enhance the selectivity and efficiency of various reactions, leading to higher yields and lower production costs. This has sparked significant interest from refineries and petrochemical plants looking to upgrade their catalysts and improve their overall performance.Furthermore, ZSM-22 has shown promise in environmental applications such as the removal of volatile organic compounds (VOCs) and nitrogen oxides (NOx) from industrial emissions. Its superior adsorption capacity and thermal stability make it an attractive option for mitigating air pollution and meeting strict regulatory requirements. As industries around the world seek sustainable solutions for environmental challenges, ZSM-22 could play a pivotal role in addressing these issues.In addition to its catalytic and environmental applications, ZSM-22 is also being explored for gas separation and purification processes. Its large pores and high surface area make it an ideal material for selectively capturing and separating molecules, offering potential advancements in natural gas processing, hydrogen purification, and carbon capture technologies.Looking ahead, is committed to further advancing the development and commercialization of ZSM-22, with a focus on delivering high-quality products and tailored solutions to its customers. With a strong track record of innovation and a dedication to continuous improvement, the company aims to position ZSM-22 as a leading technology in the zeolite industry, unlocking new opportunities for businesses worldwide.As the demand for advanced materials and sustainable technologies continues to grow, ZSM-22 stands out as a promising innovation with the potential to drive significant advancements across a wide range of industries. With ongoing research, development, and collaboration, the future looks bright for ZSM-22 and its potential to revolutionize the world of zeolite technology.

Innovative Catalyst Carrier Technology: Spheralite Unveiled in Latest News

Catalyst Carrier Spheralite, a groundbreaking new product that is set to revolutionize the industry, has been introduced by a leading chemical company. The innovative carrier, which provides superior performance and throughput in a wide range of catalytic applications, is poised to enhance efficiency and profitability for businesses across various sectors.The Spheralite Catalyst Carrier is a high-performance material designed to support active catalytic components in a range of industrial processes, including petrochemical, refining, and environmental applications. It offers exceptional thermal and mechanical stability, as well as a unique combination of high surface area and porosity, making it an ideal choice for a variety of catalytic reactions.In addition to its superior physical properties, Spheralite Catalyst Carrier boasts a highly uniform particle size and shape, providing a more consistent and predictable performance compared to traditional carrier materials. This level of precision enables greater control over reaction conditions and ensures a more reliable and efficient catalytic process.Furthermore, the unique properties of Spheralite Catalyst Carrier allow for enhanced dispersion and accessibility of active catalytic components, resulting in improved mass transfer and reduced diffusion limitations. This ultimately translates to higher productivity and lower energy consumption, leading to significant cost savings for end-users.One of the key advantages of Spheralite Catalyst Carrier is its versatility, as it can be tailored to meet specific process requirements and performance targets. Whether it's for hydroprocessing, fluidized bed applications, or environmental catalysis, the carrier's customizable nature allows for optimized performance in diverse industrial applications.The introduction of Spheralite Catalyst Carrier represents a significant milestone for the chemical industry, as it addresses the growing demand for more efficient and sustainable catalytic solutions. With increasing pressure to improve process efficiency and reduce environmental impact, businesses are increasingly turning to advanced materials such as Spheralite Catalyst Carrier to meet these challenges.The company behind this innovative product has a long-standing reputation for delivering high-quality chemical solutions and is committed to providing customers with the most advanced and reliable products on the market. With a strong focus on research and development, the company has been able to stay ahead of industry trends and anticipate the evolving needs of its customers.As a result, the introduction of Spheralite Catalyst Carrier has generated significant interest and excitement within the industry, with many businesses eager to explore the potential benefits of this cutting-edge material. Early adopters of the product have reported positive results, including improved process efficiency, reduced maintenance downtime, and enhanced product quality.Looking ahead, the company is poised to further establish Spheralite Catalyst Carrier as the material of choice for catalytic applications, leveraging its technical expertise, customer support, and global network to drive adoption and innovation. With a strong commitment to sustainability and performance, the company is well-positioned to lead the industry in providing advanced solutions that meet the evolving needs of its customers.In conclusion, the introduction of Spheralite Catalyst Carrier marks a significant advancement in the field of catalytic materials, offering unparalleled performance and versatility for a wide range of industrial applications. Backed by a leading chemical company with a track record of excellence, this groundbreaking product is set to redefine the standards for efficiency and sustainability in catalytic processes. As businesses continue to seek more advanced and reliable solutions, Spheralite Catalyst Carrier is primed to play a crucial role in shaping the future of the industry.

Addressing Water Quality Issues in Domestic Wells in California

Domestic Well - Addressing Water Quality Issues in CaliforniaWater quality is a crucial issue in California, where drought and contamination can threaten the safety of domestic wells. The State Water Resources Control Board (SWRCB) has recently issued guidelines for addressing water quality issues in domestic wells, with the aim of ensuring that all Californians have access to safe and reliable water sources. Gama Alumina, a leading water treatment company, has played a key role in this effort by providing innovative and effective solutions for improving water quality.One of the biggest challenges facing California's domestic wells is the risk of contamination from various sources. This can include agricultural runoff, urban runoff, and groundwater pollution from industrial sites. In addition, natural factors such as drought and wildfires can also impact the quality of groundwater sources. To address these issues, the SWRCB has developed a comprehensive set of guidelines for domestic well owners and operators.The guidelines focus on several key areas, including water testing and monitoring, well construction and maintenance, and treatment options for contaminated wells. One of the most important steps in ensuring safe and reliable drinking water is regular testing and monitoring of well water. This can help to identify any potential issues before they become a serious health hazard. Gama Alumina provides a range of water testing services, including testing for contaminants such as bacteria, nitrates, and arsenic.Another key element of the SWRCB guidelines is proper well construction and maintenance. This includes ensuring that wells are constructed in a way that minimizes the risk of contamination, such as locating them away from potential pollution sources. In addition, regular maintenance of wells is essential to ensure that they are functioning properly and not at risk of contamination. Gama Alumina offers a variety of well maintenance services, such as well rehabilitation and sealing, to help keep domestic wells in good condition.In cases where wells have already been contaminated, treatment options are available to remove the contaminants and restore water quality. Gama Alumina offers a range of treatment solutions, including filtration systems, reverse osmosis, and chemical treatment. These solutions can effectively remove contaminants such as bacteria, viruses, and chemicals, making water safe and healthy for consumption.Overall, the SWRCB guidelines represent an important step forward in ensuring that all Californians have access to safe and reliable drinking water. Gama Alumina has played a key role in this effort by providing innovative and effective water treatment solutions for domestic wells. By working together, we can ensure that everyone in California has access to clean and healthy water sources.

New Technology Could Revolutionize the Reforming Catalyst Industry

Reforming Catalyst is a key component in the refining industry that plays a critical role in converting heavy naphtha into high-octane gasoline. In a move towards sustainability and energy efficiency, the industry is constantly searching for innovative and advanced reforming catalysts that can improve the refining process and reduce environmental impact. Recent developments in refining technology have led to the introduction of a new reforming catalyst that promises to deliver superior performance and efficiency.This new catalyst, which is yet to be officially named, has been designed by a leading chemical manufacturer with extensive experience in developing innovative solutions for the refining industry. The company specializes in creating catalysts that can withstand high temperatures and harsh operating conditions, maximizing the yield and quality of refined products. The new reforming catalyst is no exception as it has been tested extensively to ensure superior performance and reliability.According to industry experts, the new reforming catalyst has several advantages over existing catalysts. The most notable of these advantages is increased octane yield, which can significantly improve the quality of gasoline produced in refineries. The catalyst is also highly selective, ensuring that only the desired chemical reactions take place during the refining process. This selectivity reduces the amount of by-products produced by the refinery, which is beneficial for the environment, as it reduces emissions and waste.Another advantage of the new reforming catalyst is its durability. The catalyst has a longer lifespan than existing catalysts, which means that it can operate efficiently for longer periods without requiring replacement. This is particularly important for refineries, as it reduces the downtime associated with catalyst replacement, which can be costly and time-consuming.The company behind the new reforming catalyst is committed to sustainability and has a track record of creating innovative solutions that reduce environmental impact. The new catalyst has been designed to reduce emissions during the refining process, which is beneficial for the environment and the community. The company is also committed to using sustainable materials and processes in production, further reducing the ecological footprint of the catalyst.The development of the new reforming catalyst comes at a time when the refining industry is facing increasing pressure to reduce its environmental impact. Governments around the world are implementing stricter regulations on emissions and waste, which means that refineries need to find innovative solutions to stay competitive and compliant. The introduction of the new reforming catalyst is a step towards a cleaner, more sustainable refining industry.The new catalyst is expected to be widely adopted by refineries around the world, as it offers significant performance and efficiency gains compared to existing catalysts. The chemical manufacturer has already received significant interest from industry players, who are eager to incorporate the new catalyst into their refining operations. The company is currently working on scaling up production to meet demand and expects to see widespread adoption of the new catalyst in the coming years.In conclusion, the introduction of the new reforming catalyst represents a significant step forward for the refining industry. The new catalyst promises to deliver superior performance, efficiency and sustainability and is set to become an essential component in the refining process. With its increased octane yield, selectivity, durability and reduced environmental impact, the new reforming catalyst is a game-changer for the industry. As the world moves towards a more sustainable future, the introduction of this innovative solution is a positive development that promises to benefit both the industry and the environment.

Major Alumina Company Makes Groundbreaking Announcement in the Industry

Gamma Alumina, a leading provider of advanced materials solutions, is poised to revolutionize the industry with its groundbreaking innovations. The company’s unwavering commitment to research and development has paved the way for the creation of cutting-edge products that promise to drive progress across various sectors.With a diverse range of applications, Gamma Alumina’s materials have been the catalyst for breakthrough technological advancements in fields as wide-ranging as transportation, energy, and electronics. From superior automotive components that enhance fuel efficiency to energy-efficient building materials that transform traditional construction practices, the company's portfolio is characterized by versatility and performance.Gamma Alumina’s success can be attributed to its relentless pursuit of excellence in all areas of its operations. Guided by a team of world-class scientists and engineers, the company stays at the forefront of material science research, anticipating future needs and developing innovative solutions ahead of the curve. This focus on innovation allows the company to consistently outperform competitors and meet the ever-evolving demands of industries worldwide.One of the company’s most noteworthy advancements is the development of a high-performance ceramic material. By harnessing the unique properties of gamma alumina, Gamma Alumina has created a material that is incredibly resistant to wear and tear, while also possessing excellent thermal and chemical stability. This revolutionary product has the potential to disrupt numerous industries, from aerospace to medical technology, by offering improved performance, durability, and longevity compared to traditional materials.The advantages of Gamma Alumina’s high-performance ceramic material are particularly evident in the transportation industry. Traditional metal components in engines and transmissions are subject to wear and corrosion over time, leading to increased maintenance costs and reduced efficiency. By introducing gamma alumina-based ceramic parts, manufacturers can significantly enhance the lifespan of critical engine components, resulting in longer-lasting and more efficient vehicles. Moreover, the reduced weight of these ceramic parts contributes to improved fuel efficiency, positioning Gamma Alumina as a key player in the drive towards sustainable transportation.In the energy sector, Gamma Alumina’s innovations are revolutionizing the way power is harnessed and transmitted. The company’s ceramic materials offer superior resistance to high temperatures and chemical corrosion, making them ideal for use in high-performance batteries and fuel cells. By leveraging these advanced materials, energy storage systems become more durable, efficient, and capable of meeting the growing demands of renewable energy sources. As a result, Gamma Alumina is playing a vital role in the global transition towards a greener and more sustainable future.It is also worth noting that Gamma Alumina actively collaborates with leading researchers, industry experts, and government agencies to further advance the potential applications of their high-performance ceramic materials. By combining their internal expertise with external insights, the company ensures that its products meet the highest standards of performance and reliability in a rapidly changing world.With an unwavering commitment to research and development, Gamma Alumina continues to position itself as a market leader in the advanced materials industry. Through its groundbreaking innovations, the company envisions a future where traditional materials are replaced with sustainable alternatives that offer unparalleled durability, performance, and efficiency. As industries across the globe embrace the transformational potential of Gamma Alumina’s materials, the world is inching closer to a more sustainable and technologically advanced future.

Highly Effective Alumina Catalyst for Industrial Applications

Gamma Alumina Catalyst Leads the Way in Sustainable Chemical ReactionsAs the world continues to focus on sustainability and reducing carbon emissions, the demand for innovative catalysts that can support sustainable chemical reactions has never been higher. One company leading the way in this field is \, a global leader in catalyst technology.\ is at the forefront of developing advanced catalysts to drive sustainable chemical reactions across a wide range of industries, including petrochemicals, chemicals, and environmental applications. One of their standout products in this area is their Gamma Alumina Catalyst, which has been garnering attention for its ability to support environmentally friendly chemical processes.Gamma alumina, a type of aluminum oxide, serves as an excellent support material for catalysts due to its high surface area, thermal stability, and resistance to acidity. When used as a catalyst support, gamma alumina can significantly enhance the efficiency and selectivity of chemical reactions while also extending the catalyst's lifespan. This makes it an ideal choice for companies looking to improve the sustainability of their processes without compromising on performance.\ has leveraged its expertise in catalyst development to create a highly effective Gamma Alumina Catalyst that is specifically designed to promote sustainable chemical reactions. This catalyst has been engineered to deliver exceptional performance in a wide range of applications, from emissions control in automotive catalytic converters to the production of high-value chemicals and fuels.One of the key advantages of \ Gamma Alumina Catalyst is its ability to facilitate reactions at lower temperatures, reducing energy consumption and ultimately lowering carbon emissions. This is particularly important in industries such as petrochemicals, where high-temperature processes traditionally produce significant amounts of greenhouse gases. By enabling reactions to occur at lower temperatures, the Gamma Alumina Catalyst is helping companies make meaningful progress towards their sustainability goals.In addition to its environmental benefits, \ Gamma Alumina Catalyst also offers improved selectivity, allowing for more precise control over the end products of chemical reactions. This can be particularly valuable in the production of fine chemicals and pharmaceuticals, where purity and yield are of utmost importance. The catalyst's stability and durability further contribute to its appeal, providing companies with a reliable and long-lasting solution for their catalytic needs.Furthermore, \ has implemented rigorous quality control measures to ensure that their Gamma Alumina Catalyst meets the highest standards for sustainability, performance, and safety. This commitment to excellence has earned the company a strong reputation in the industry, with many companies turning to \ as their trusted partner for sustainable catalyst solutions.Beyond their Gamma Alumina Catalyst, \ is dedicated to driving innovation in catalysis across the board. Their team of highly skilled scientists and engineers continues to push the boundaries of what is possible in catalytic technology, developing new solutions to address the evolving needs of the industry. With a focus on sustainability, efficiency, and performance, \ is well-positioned to make a significant impact on the future of chemical processes.Looking ahead, \ remains committed to advancing sustainable chemical reactions through their cutting-edge catalyst technology. By leveraging the unique properties of gamma alumina and other advanced materials, the company is poised to support the transition towards greener and more sustainable industrial practices. As the global push for sustainability intensifies, \ is ready to lead the way with their innovative catalyst solutions.

Sulfur Recovery Catalyst: Key Player in Chemical Industry

Claus Sulfur Recovery Catalyst is a breakthrough technology that has been developed by an innovative company in the chemical industry. This catalyst has the potential to revolutionize the way sulfur is recovered from various industrial processes, making it more efficient and cost-effective.The company behind this groundbreaking technology is a global leader in providing advanced solutions for the chemical industry. With decades of experience and a team of highly skilled engineers and scientists, they are dedicated to creating innovative products that address the challenges faced by the industry.The Claus Sulfur Recovery Catalyst is a prime example of their commitment to innovation and sustainability. Sulfur recovery is a critical process in many industries, particularly in oil and gas refining, where sulfur is removed from hydrocarbons to meet increasingly stringent environmental regulations. The traditional method of sulfur recovery involves the use of a Claus unit, which relies on a series of chemical reactions to convert hydrogen sulfide into elemental sulfur.However, this process is not without its drawbacks. The Claus process is known for its high operating costs, as well as the need for frequent catalyst replacement, which can result in downtime and production losses. Additionally, the traditional Claus process often requires high temperatures and pressures, which can pose safety and operational challenges.The Claus Sulfur Recovery Catalyst aims to address these issues by offering a more efficient and reliable alternative to traditional sulfur recovery methods. This innovative catalyst is designed to enhance the conversion of hydrogen sulfide to elemental sulfur, while also extending the life of the catalyst and reducing the frequency of replacement.One of the key advantages of the Claus Sulfur Recovery Catalyst is its ability to operate at lower temperatures and pressures compared to traditional methods. This not only reduces operational costs but also makes the process safer and more manageable for plant operators. Furthermore, the improved performance and longevity of the catalyst result in fewer shutdowns for maintenance, leading to increased production efficiency and profitability.In addition to these benefits, the Claus Sulfur Recovery Catalyst also contributes to environmental sustainability. By enabling more efficient sulfur recovery, this technology helps to minimize the release of sulfur dioxide emissions, which can have detrimental effects on air quality and public health. As environmental regulations continue to tighten around the world, the demand for innovative solutions like this catalyst is only expected to grow.The company's commitment to sustainability extends beyond the products they offer. They are dedicated to minimizing their environmental footprint throughout the entire product lifecycle, from raw material sourcing to manufacturing and distribution. This includes efforts to reduce energy consumption, emissions, and waste generation, as well as the responsible disposal of end-of-life products.Furthermore, the company places a strong emphasis on research and development to continuously improve their products and develop new, cutting-edge solutions for the chemical industry. Their state-of-the-art research facilities and collaboration with leading academic institutions and industry partners position them at the forefront of innovation in the field.In conclusion, the Claus Sulfur Recovery Catalyst represents a significant advancement in sulfur recovery technology, offering a more efficient, reliable, and sustainable solution for the chemical industry. With the support of a forward-thinking and environmentally conscious company, this innovative catalyst is poised to make a positive impact on the industry and contribute to a greener, more sustainable future.