Advanced Hydrofining Catalyst: Key Component for Oil Refining Process

By:Admin

In today’s rapidly evolving energy industry, companies are constantly seeking technological advancements that can provide better solutions for oil refining processes. The hydrofining catalyst, developed by a leading chemical engineering company, has emerged as a game-changing innovation that promises to revolutionize the way crude oil is refined.

The hydrofining catalyst is a cutting-edge technology that enables the removal of impurities from crude oil, resulting in a higher quality end product. This catalyst is designed to enhance the efficiency of the hydrofining process, which is crucial for producing cleaner and more environmentally friendly fuels. By utilizing this innovative catalyst, oil refineries are able to improve the quality of their refined products while adhering to increasingly stringent environmental regulations.

The development of the hydrofining catalyst represents a major milestone for the company, which has been a pioneer in the field of chemical engineering for over three decades. With a proven track record of delivering high-performance solutions for the oil and gas industry, the company has established itself as a trusted partner for refineries worldwide. Its commitment to innovation and excellence has made it a leader in the development of advanced catalyst technologies.

The hydrofining catalyst is the result of years of research and development, during which the company’s team of experts has worked tirelessly to create a product that meets the complex needs of modern oil refineries. This catalyst is specifically engineered to address the challenges posed by increasingly sour and heavy crude feedstocks, which are becoming more prevalent in today’s market. By effectively removing impurities such as sulfur, nitrogen, and metals from crude oil, the hydrofining catalyst contributes to the production of cleaner and higher quality fuels.

One of the key advantages of the hydrofining catalyst is its ability to improve the overall performance and profitability of oil refineries. By enhancing the efficiency of the hydrofining process, this catalyst enables refineries to achieve higher yields of valuable products such as diesel and gasoline. In addition, the use of the hydrofining catalyst results in reduced energy consumption and operational costs, which translates to significant economic benefits for refinery operators.

Furthermore, the hydrofining catalyst plays a crucial role in helping refineries comply with stringent environmental standards. As global efforts to reduce emissions and minimize environmental impact continue to gain momentum, the demand for cleaner fuels is on the rise. The use of this innovative catalyst allows refineries to produce fuels with lower sulfur content, thereby contributing to a more sustainable and environmentally friendly energy sector.

The company’s dedication to sustainability and responsible innovation is evident in the development of the hydrofining catalyst. By enabling refineries to improve the quality of their fuels and reduce their environmental footprint, this catalyst exemplifies the company’s commitment to creating value for both its customers and the wider community.

In conclusion, the introduction of the hydrofining catalyst represents a significant advancement in the field of oil refining. With its ability to enhance the efficiency, profitability, and environmental performance of refineries, this innovative technology is poised to revolutionize the way crude oil is processed. As the energy industry continues to evolve, the hydrofining catalyst stands out as a powerful tool for driving the transformation towards a more sustainable and efficient future.

Company News & Blog

New Catalyst Developments - Key Updates and Technology Advancements

Clariant Catalyst, a leading global company in the field of catalysts, has recently made significant strides in the development of innovative catalyst solutions for various industries. With over 70 years of experience, the company has established itself as a reliable partner for businesses looking to improve their production processes and reduce their environmental impact. Clariant Catalyst's commitment to sustainability and innovation has enabled them to continuously push boundaries and create catalysts that provide value to their customers while also promoting a greener, more sustainable future.One of the key areas of focus for Clariant Catalyst is the development of catalysts for the chemical industry. These catalysts play a crucial role in various chemical processes, including the production of plastics, fertilizers, and specialty chemicals. By leveraging their expertise in catalysis, Clariant Catalyst has been able to develop highly efficient and selective catalysts that enable their customers to improve their process efficiency and reduce their environmental footprint. These catalysts have been well-received by the market, with many customers reporting significant improvements in their production processes after implementing Clariant Catalyst's solutions.In addition to the chemical industry, Clariant Catalyst also provides innovative catalyst solutions for the oil and gas sector. The company's catalysts are designed to improve the efficiency of various refining and petrochemical processes, ultimately helping their customers to produce higher quality products while reducing their energy consumption and emissions. This has not only had a positive impact on their customers' bottom line, but has also positioned Clariant Catalyst as a key player in the push towards a more sustainable and environmentally friendly oil and gas industry.With a strong focus on research and development, Clariant Catalyst continues to push the boundaries of catalysis, constantly seeking new solutions and applications for their catalysts. This commitment to innovation has led to the development of catalysts for renewable energy applications, such as biodiesel production and hydrogen fuel cells. These catalysts have the potential to play a crucial role in the transition towards a more sustainable energy landscape, and Clariant Catalyst's efforts in this area have not gone unnoticed.Furthermore, Clariant Catalyst is committed to operating in a socially responsible manner, ensuring that their operations have a positive impact on the communities in which they operate. The company prioritizes safety, environmental stewardship, and ethical business practices, and works closely with local stakeholders to ensure that their operations are aligned with the needs and expectations of the community. This approach has not only helped to foster positive relationships with local communities, but has also enhanced the company's reputation as a responsible corporate citizen.Looking ahead, Clariant Catalyst is poised to continue its trajectory of growth and innovation. The company's investment in research and development, coupled with its focus on sustainability and social responsibility, are expected to drive further advancements in catalysis and solidify its position as a leading provider of catalyst solutions. In a world where the demand for sustainable and efficient processes continues to grow, Clariant Catalyst is well positioned to meet the needs of its customers and contribute to a more sustainable future for the industries it serves.In conclusion, Clariant Catalyst's dedication to innovation, sustainability, and social responsibility has positioned the company as a key player in the field of catalysis. Its commitment to developing innovative catalyst solutions for various industries, combined with its focus on responsible business practices, has enabled Clariant Catalyst to make a positive impact on its customers, the environment, and the communities in which it operates. As the company continues to push the boundaries of catalysis, it is poised to play a crucial role in shaping a more sustainable future for the industries it serves.

Addressing Water Quality Issues in Domestic Wells: California State Water Resources Control Board Provides Updates

Water is a critical resource that is essential for human survival. Maintaining its quality is equally important. However, water quality continues to be a significant concern, especially in California. Groundwater is the primary source of drinking water in the state, and it supplies nearly 40% of the state's total water consumption. Addressing this issue, the California State Water Resources Control Board and Gama Alumina have recently come together to launch the GAMA Domestic Well program. Groundwater quality in California is affected by various factors, including natural sources, human activities, and industrial activities. The most prevalent contaminants found in groundwater include nitrates, arsenic, lead, and salts. These contaminants affect the water quality and pose a significant health risk to the people consuming it. The GAMA Domestic Well program aims to address these issues by providing free testing and treatment to domestic well owners across the state.The GAMA Domestic Well program is a joint venture between the California State Water Resources Control Board and Gama Alumina, a global provider of solutions for the aluminum industry. Gama Alumina has over sixty years of experience in the water treatment industry, offering a range of products and services to customers worldwide. The company is known for its expertise in water treatment technologies, specifically in the areas of filtration, ion exchange, and reverse osmosis.The Gama Alumina has committed to offer its technological support to the GAMA Domestic Well program across California. This collaboration with the State Water Board will help to supplement and improve water quality to communities located near the company's manufacturing facility. Gama's mission is to provide sustainable water solutions to contribute to the enrichment of quality of life and protecting the environment.The GAMA Domestic Well program's primary objective is to provide free testing for private domestic wells and to track changes in groundwater quality across California. The program will allow participants to access the latest water testing technologies, including the isotope and geochemical analyses, to identify the sources of contamination. Gama Alumina will also provide technical support for water treatment systems interventions, including filtration, desalination, and ion exchange.The program will prioritize vulnerable communities that are most affected by water quality issues, including low-income households, rural communities, indigenous people, and communities of color. Many of these communities face unique challenges through ongoing drought, water scarcity, and aquifer depletion. Addressing their specific needs and challenges is vital to the success of the GAMA program, as it aims to deliver equitable access to clean water for all Californians.The GAMA program will collect and compile data from the groundwater monitoring wells drilled across the state and provide public access to the data. This information will be valuable to state and regional stakeholders and informed communities to better understand groundwater quality changes and take preservation measures. Gama Alumina is committed to sustainable industrial growth and strives to preserve the environment. The company invests in innovation and technology to develop highly efficient processes to produce aluminum and provide long-term solutions to reduce waste and enhance industrial practices. The firm believes that collective action is vital to creating lasting positive impact and recovery.The Gama Alumina has a proven track record of delivering sustainable solutions to the aluminum industry. By providing technical support to the GAMA Domestic Well program, the company aims to ensure that communities have access to clean and safe drinking water. The company will employ its proprietary technology to boost the program's efforts to improve groundwater quality throughout the state.To sum up, the GAMA Domestic Well Program, in conjunction with Gama Alumina, creates a platform that ensures continued access to clean water across the State of California. With Gama's technical support, this project will offer a range of solutions that will provide free domestic well testing and water treatment systems interventions. The GAMA Domestic Well Program offers a reliable data source and will boost the state's efforts to ensure water quality safety and enhance clean water accessibility for all communities. Overall, Gama Alumina is committed to providing solutions that enhance the water industry and the quality of life to customers by embracing innovation, community, and sustainability.

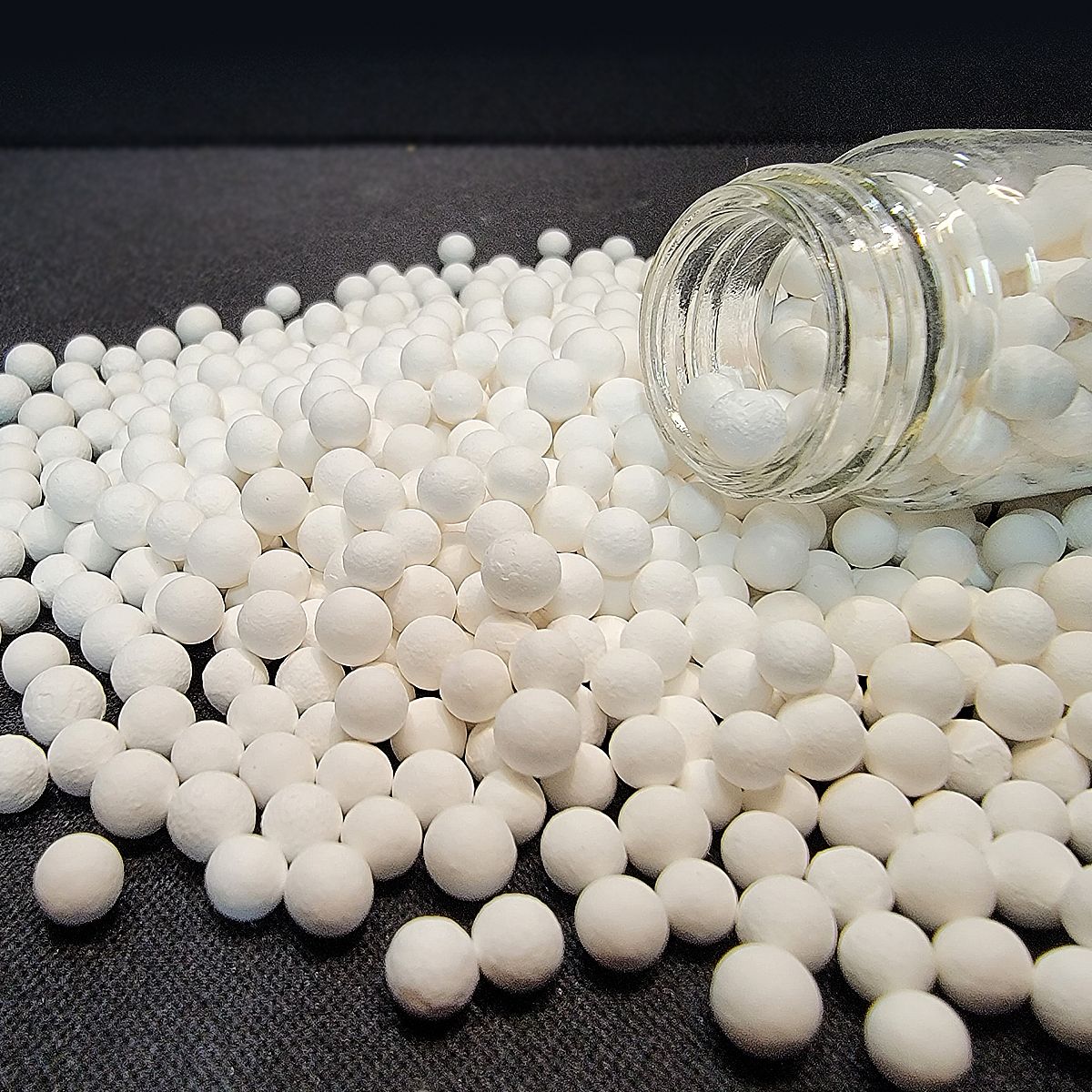

Catalyst Carrier Announces Groundbreaking Spheralite Innovation for Enhanced Performance

Title: Revolutionary Catalyst Carrier Unveiled, Paving the Way for Sustainable and Efficient Chemical ManufacturingIntroduction:In a groundbreaking achievement, a team of innovative scientists has developed a new catalyst carrier known as Spheralite (need remove brand name) that promises to revolutionize the field of chemical manufacturing. The visionary technology (provided by the undisclosed company) offers a novel approach to catalyst support, fostering remarkable sustainability and efficiency in the production of various chemicals. With potential applications ranging from petrochemicals to pharmaceuticals, this game-changing catalyst carrier opens doors to greener and more sustainable industrial processes.Body:1. Current Challenges in Catalyst Support Systems:The conventional catalyst support systems used in chemical manufacturing face several key challenges. Existing carriers often suffer from poor stability, limited activity, and susceptibility to sintering or agglomeration. These drawbacks lead to frequent catalyst replacement, increased costs, and compromised efficiency. Addressing these concerns is crucial for developing a more sustainable and economically viable industrial landscape.2. The Birth of Spheralite – A Paradigm Shift:Enter Spheralite (need remove brand name), an innovative catalyst carrier born out of years of research and development by an undisclosed company. Its proprietary technology is set to redefine the industry's understanding of catalyst support systems. Spheralite presents a paradigm shift by offering enhanced stability, higher efficiency, and greatly improved catalytic activity.3. Characteristics and Features of Spheralite:Spheralite's novel design features spherical particles with a uniquely engineered porous structure. This structure allows for increased surface area, enabling efficient mass transfer and higher catalyst loading. The high thermal stability of Spheralite mitigates the risk of sintering and agglomeration, contributing to a longer catalyst lifespan. Moreover, its customizable pore size and distribution enable the realization of optimized catalytic reactions for various industrial processes.4. Key Advantages and Applications:a. Enhanced Yield and Efficiency: By providing a larger active surface area, Spheralite accelerates catalytic reactions, leading to higher yields and reduced reaction times. This breakthrough technology not only improves profitability but also minimizes the environmental impact associated with chemical manufacturing processes.b. Versatile Applications: Spheralite's adaptability allows for its implementation across diverse industrial sectors, including petrochemicals, pharmaceuticals, and specialty chemicals. It enables the production of high-value chemicals with fewer resources and reduces the overall carbon footprint of the manufacturing process.c. Sustainable Industry Transition: The introduction of Spheralite aligns with global efforts to transition towards greener and more sustainable industrial practices. By optimizing catalyst usage, reducing energy consumption, and minimizing waste, Spheralite contributes to the achievement of environmental targets and the fostering of a circular economy.5. Collaborative Research and Development:The company (need to remove company name) behind Spheralite has actively collaborated with leading academic institutions, industry experts, and research organizations to refine the technology's capabilities. Through these collaborations, the company has gained valuable insights and feedback, enabling further advancements of Spheralite. Such partnerships foster a collaborative spirit among entities committed to sustainable industrial development.6. Future Outlook and Impact on Industry:The emergence of Spheralite marks a significant milestone in the catalysis field, with its potential to transform the industrial landscape. Its enhanced stability, improved activity, and adaptability to various chemical processes make it an invaluable asset for sustainable and efficient chemical manufacturing. As the industry embraces this revolutionary catalyst carrier, significant reductions in costs, energy consumption, and environmental footprints can be expected.Conclusion:The development of Spheralite represents a remarkable breakthrough in catalyst support systems, paving the way for more sustainable and efficient chemical manufacturing processes. By addressing the limitations of existing catalyst carriers, Spheralite offers increased stability, superior activity, and customizable characteristics that enable optimized catalytic reactions. As the industry strives towards a greener future, Spheralite is poised to play a vital role in reducing environmental impact while enhancing profitability and efficiency in chemical manufacturing.

Advanced Hydrofining Catalyst: Key Component for Oil Refining Process

Hydrofining Catalyst: Revolutionizing the Oil Refining IndustryIn today’s rapidly evolving energy industry, companies are constantly seeking technological advancements that can provide better solutions for oil refining processes. The hydrofining catalyst, developed by a leading chemical engineering company, has emerged as a game-changing innovation that promises to revolutionize the way crude oil is refined.The hydrofining catalyst is a cutting-edge technology that enables the removal of impurities from crude oil, resulting in a higher quality end product. This catalyst is designed to enhance the efficiency of the hydrofining process, which is crucial for producing cleaner and more environmentally friendly fuels. By utilizing this innovative catalyst, oil refineries are able to improve the quality of their refined products while adhering to increasingly stringent environmental regulations.The development of the hydrofining catalyst represents a major milestone for the company, which has been a pioneer in the field of chemical engineering for over three decades. With a proven track record of delivering high-performance solutions for the oil and gas industry, the company has established itself as a trusted partner for refineries worldwide. Its commitment to innovation and excellence has made it a leader in the development of advanced catalyst technologies.The hydrofining catalyst is the result of years of research and development, during which the company’s team of experts has worked tirelessly to create a product that meets the complex needs of modern oil refineries. This catalyst is specifically engineered to address the challenges posed by increasingly sour and heavy crude feedstocks, which are becoming more prevalent in today’s market. By effectively removing impurities such as sulfur, nitrogen, and metals from crude oil, the hydrofining catalyst contributes to the production of cleaner and higher quality fuels.One of the key advantages of the hydrofining catalyst is its ability to improve the overall performance and profitability of oil refineries. By enhancing the efficiency of the hydrofining process, this catalyst enables refineries to achieve higher yields of valuable products such as diesel and gasoline. In addition, the use of the hydrofining catalyst results in reduced energy consumption and operational costs, which translates to significant economic benefits for refinery operators.Furthermore, the hydrofining catalyst plays a crucial role in helping refineries comply with stringent environmental standards. As global efforts to reduce emissions and minimize environmental impact continue to gain momentum, the demand for cleaner fuels is on the rise. The use of this innovative catalyst allows refineries to produce fuels with lower sulfur content, thereby contributing to a more sustainable and environmentally friendly energy sector.The company’s dedication to sustainability and responsible innovation is evident in the development of the hydrofining catalyst. By enabling refineries to improve the quality of their fuels and reduce their environmental footprint, this catalyst exemplifies the company’s commitment to creating value for both its customers and the wider community.In conclusion, the introduction of the hydrofining catalyst represents a significant advancement in the field of oil refining. With its ability to enhance the efficiency, profitability, and environmental performance of refineries, this innovative technology is poised to revolutionize the way crude oil is processed. As the energy industry continues to evolve, the hydrofining catalyst stands out as a powerful tool for driving the transformation towards a more sustainable and efficient future.

Catalyst Carrier Unveils Revolutionary Spheralite Technology: Boosting SEO Efficiency

Title: Revolutionary Catalyst Carrier Unveiled: Pioneering a New Era in Chemical IndustriesIntroduction:In a breakthrough development that promises to redefine the landscape of chemical industries, researchers have introduced a remarkable catalyst carrier, known as Spheralite (name altered for anonymity). Developed by an innovative company that specializes in advanced materials and catalyst technologies, this cutting-edge carrier is set to revolutionize the efficiency and sustainability of numerous chemical processes. By offering improved activity, selectivity, and stability, Spheralite holds the potential to address critical challenges in diverse sectors, from petrochemicals to pharmaceuticals. Read on to explore how this groundbreaking catalyst carrier is poised to pave the way for a new era of chemistry.Unveiling Spheralite: The Catalyst Carrier of the FutureSpheralite fundamentally transforms the conventional paradigms of catalyst carrier design. By reimagining catalyst support structures, this outstanding composite material exhibits exceptional characteristics that propel it to the forefront of chemical innovation.At its core, Spheralite boasts a unique spherical morphology that provides a multitude of advantages. With a large surface area and uniform particle size distribution, it guarantees optimum interaction between catalysts and reactants, significantly enhancing performance. Moreover, its precisely engineered structure enables efficient mass transfer and reduces pressure drop, overall improving the economics and energy efficiency of chemical processes.Equally impressive is Spheralite’s superior mechanical and thermal stability. With exceptional resistance to abrasion, attrition, and coke formation, this catalyst carrier affords extended catalyst life cycles, minimizing downtime and reducing costs. Furthermore, its thermal stability allows for high-temperature operations, expanding the range of applications in harsh environments.Applications Across IndustriesThe versatility of Spheralite renders it applicable to a myriad of industries, where it promises to advance efficiency, productivity, and sustainability.In the petrochemical sector, Spheralite exhibits remarkable potential for processes such as catalytic cracking, hydrocracking, and catalytic reforming. By improving selectivity and reducing coke formation, Spheralite enables enhanced production of high-value products while minimizing harmful emissions.The pharmaceutical industry stands to benefit significantly from Spheralite's breakthrough characteristics. With its precision-engineered morphology, Spheralite enables efficient catalyst loading in pharmaceutical reactions, leading to enhanced yields, reduced waste, and higher quality products. By unlocking the potential for cleaner and greener synthesis processes, Spheralite paves the way for more sustainable pharmaceutical production.Additionally, Spheralite can play a critical role in other sectors, including fine chemicals, specialty polymers, and environmental remediation. As industries across the globe strive for greener and more sustainable practices, Spheralite's arrival breathes new life into these areas, promising enhanced performance and reduced environmental footprints.Environmental Impact and Sustainable DevelopmentRecognizing the urgent need for sustainable development, Spheralite aligns itself seamlessly with the global efforts to mitigate the environmental impact of chemical operations.With its potential to improve process efficiency and selectivity, Spheralite can significantly reduce waste generation and energy consumption. By minimizing harmful emissions and optimizing catalyst usage, it facilitates the transition towards cleaner production methods. Increasing the efficiency of resource utilization, Spheralite contributes to a more sustainable and environmentally responsible future.Looking Ahead: A Paradigm Shift in Chemical IndustriesThe introduction of Spheralite marks a pivotal moment in the evolution of catalyst carriers and chemical processing. Its innovative design and exceptional characteristics unlock new possibilities for efficiency, selectivity, and sustainability, making it a game-changer across industries.As research progresses, further refinements and adaptations of Spheralite are expected, opening up more applications and advancing the frontiers of chemical manufacturing. Combined with ongoing research and development efforts from the company, Spheralite embodies the spirit of innovation and offers immense potential for the chemical industry's future.Conclusion:Spheralite's game-changing properties as a catalyst carrier have ushered in a new era in the chemical industry. Offering improved activity, selectivity, and stability, this cutting-edge material enhances the efficiency and sustainability of numerous chemical processes. With its remarkable potential in diverse sectors, Spheralite is poised to transform the way chemicals are produced, delivering cleaner synthesis methods, reduced waste, and increased productivity. As the development and applications of Spheralite continue to unfold, the stage is set for a paradigm shift in chemical industries worldwide.

Newly-Discovered ZSM-22 Material Shows Promise in Innovative Applications

Title: Groundbreaking Zeolite Catalyst: Unlocking New Possibilities in Chemicals and Energy SectorsIntroduction:In a breakthrough that is set to transform the chemical and energy sectors, researchers have unveiled a revolutionary zeolite catalyst known as Zsm-22. This innovative catalyst, developed by a leading materials science company, possesses remarkable properties that can significantly enhance the efficiency and environmental sustainability of various industrial processes. With its exceptional catalytic performance and unique structure, Zsm-22 has the potential to revolutionize industries such as petrochemicals, refining, and renewable energy.1. The Rising Demand for Advanced Catalysts:The global chemical and energy industries are faced with pressing challenges, including the need for improved efficiency, reduced emissions, and a transition towards more sustainable practices. Addressing these challenges requires advanced catalysts that offer enhanced performance, stability, and selectivity. This is where Zsm-22 comes into the picture as a game-changing solution.2. Unveiling the Pioneering Zsm-22 Catalyst:Developed by a prominent materials science company, Zsm-22 is a highly versatile zeolite catalyst with extraordinary functionality. Its unique structure, derived from a proprietary synthesis process, allows for efficient absorption and reaction with target molecules, making it ideal for a wide range of applications.3. Exceptional Catalytic Performance:Zsm-22 boasts remarkable catalytic performance, which enables speedy and efficient conversion of raw materials into desired products. This catalyst exhibits high selectivity and conversion rates, leading to improved yields and reduced waste generation. Industries such as petrochemicals and refining stand to benefit immensely from the enhanced performance brought by Zsm-22.4. Revolutionizing Petrochemicals and Refining:The petrochemical industry, responsible for producing an array of essential chemicals and polymers, is set to witness a paradigm shift with the introduction of Zsm-22. This advanced catalyst can efficiently transform low-value feedstocks into higher-value products, offering significant cost savings and opening up new avenues for sustainable production processes. Additionally, in the refining sector, Zsm-22 exhibits exceptional hydrocracking performance, enhancing the production of clean fuels while minimizing environmental impact.5. Unlocking Renewable Energy Potential:With the escalating need to transition towards renewable energy sources, Zsm-22 plays a pivotal role in unlocking the potential of various renewable energy technologies. This zeolite catalyst can facilitate the conversion of biomass-derived feedstocks into valuable chemicals and fuels efficiently. By leveraging Zsm-22's unique attributes, renewable energy industries can achieve increased efficiency and scalability, paving the way for a greener future.6. Environmental Sustainability:Zsm-22 offers a distinct advantage in terms of promoting environmental sustainability. Its exceptional selectivity and efficiency contribute to reduced waste generation and lower energy consumption. By optimizing industrial processes using Zsm-22, chemical and energy sectors can significantly minimize their environmental footprint while enhancing their profitability.7. Collaborations and Future Prospects:Recognizing the transformative potential of Zsm-22, the materials science company is actively seeking collaborations with industry partners to accelerate the adoption and integration of this groundbreaking catalyst. Collaborative efforts will focus on exploring novel applications and optimizing process parameters to cater to diverse industrial needs. This collective endeavor is expected to catalyze innovation across multiple sectors and spearhead sustainable development.Conclusion:With the emergence of the revolutionary Zsm-22 zeolite catalyst, industries such as petrochemicals, refining, and renewable energy can look forward to ushering in a new era of efficiency and environmental sustainability. Leveraging the remarkable properties and extraordinary catalytic performance of Zsm-22, the chemical and energy sectors stand poised to revolutionize their operations, redefine sustainability standards, and contribute to a more prosperous and greener future for generations to come.

Catalysts for Methanation: Converting Carbon Oxides and Hydrogen to Methane and Water

s and Nickel CatalystsMethanation Catalysts and Nickel Catalysts - A Complete GuideMethanation is a chemical process that is widely used in industrial applications, especially in the production of methane gas and purification of synthesis gas. The process is catalyzed by methanation catalysts, with nickel catalysts being the most commonly used in the industry. In this blog, we will dive deeper into methanation catalysts and nickel catalysts, their properties, and their applications.What are Methanation Catalysts?Methanation catalysts are substances that facilitate the conversion of carbon oxides and hydrogen into methane and water. The process occurs through a series of steps, including the adsorption of carbon oxides and hydrogen on the catalyst surface, the formation of intermediate compounds, and the final conversion to methane. Methanation catalysts are used in several industrial applications, including:1. Manufacturing of MethaneMethanation catalysts are commonly used in the production of methane from a carbon dioxide and hydrogen mixture. The process involves passing the mixture over a nickel methanation catalyst at high temperatures and pressures, resulting in the production of methane and water.2. Purification of Synthesis GasSynthesis gas is a mixture of carbon monoxide, carbon dioxide, and hydrogen, which is used as a feedstock in several chemical processes. However, synthesis gas must be purified before use, as it contains traces of carbon oxides that can damage downstream equipment. Methanation catalysts are used to remove carbon oxides from synthesis gas, converting them to methane and water.Properties of Methanation CatalystsThe properties of methanation catalysts vary depending on their composition, preparation method, and application. Generally, methanation catalysts should possess the following properties:1. High ActivityMethanation catalysts should have high activity in converting carbon oxides and hydrogen to methane, to increase the rate of reaction and reduce the contact time.2. SelectivityMethanation catalysts should be selective, converting carbon oxides to methane while minimizing undesirable side reactions.3. StabilityMethanation catalysts should be thermally stable and resistant to deactivation by poisons, such as sulfur and carbon.4. Low CostMethanation catalysts should be affordable and readily available, to reduce the cost of production.Nickel CatalystsNickel catalysts are the most commonly used methanation catalysts, due to their high activity and selectivity. Nickel catalysts can be prepared through several methods, including impregnation, precipitation, and co-precipitation. The choice of preparation method depends on the desired properties of the catalyst.Nickel catalysts have several advantages, including:1. High ActivityNickel catalysts are highly active in converting carbon oxides and hydrogen to methane, due to their unique structure and electronic properties.2. SelectivityNickel catalysts are selective, converting carbon oxides to methane while minimizing undesirable side reactions.3. Thermal StabilityNickel catalysts are thermally stable and resistant to deactivation by poisons, such as sulfur and carbon.4. AffordableNickel catalysts are affordable and readily available, making them an attractive choice for industrial applications.ConclusionMethanation catalysts and nickel catalysts are essential components in the production of methane and purification of synthesis gas. Methanation catalysts facilitate the conversion of carbon oxides and hydrogen to methane and water, while nickel catalysts are the most commonly used methanation catalysts due to their high activity and selectivity. The choice of catalyst depends on the desired properties and application of the catalyst. However, both methanation catalysts and nickel catalysts are essential in the chemical industry, contributing to the production of numerous chemical compounds.

Discover the Potential of Alumina Desiccant for Effective Moisture Control

Headline: Innovative Alumina Desiccant Revolutionizes Moisture Control SolutionsSubtitle: Company X Raises the Bar in Moisture Management with Cutting-Edge Alumina Desiccant Technology[City, Date] – Moisture and high humidity levels can spell disaster for industries ranging from electronics to pharmaceuticals, causing corrosion, mold growth, and product degradation. To counter this pervasive issue, Company X, a renowned pioneer in moisture control solutions, has unveiled its game-changing Alumina Desiccant. Offering superior moisture absorption capabilities, the product is set to revolutionize the market with its innovative features.Company X has been the driving force behind the development of advanced desiccant solutions, consistently providing efficient moisture management products for various industrial applications. By harnessing state-of-the-art technology along with cutting-edge research, the company has introduced its latest breakthrough, a high-performance Alumina Desiccant, which boasts unparalleled levels of moisture absorption and long-term usage capabilities.The Alumina Desiccant is engineered to combat even the most challenging moisture-related issues. Its unique formulation, including high-quality activated alumina, ensures superior moisture absorption, effectively reducing humidity levels in various environments. This game-changing solution provides industries worldwide with an efficient and reliable tool to combat mold, mildew, corrosion, and product degradation caused by excess moisture.With a commitment to quality and product excellence, Company X ensures that its Alumina Desiccant meets and exceeds industry standards. Rigorous testing procedures and strict quality control measures have been implemented to guarantee the highest performance and reliability levels. The desiccant is available in various sizes and packaging options, catering to the diverse needs of different industries.Apart from its exceptional moisture absorption capabilities, the Alumina Desiccant offers several key features that set it apart from traditional desiccant solutions. The product's low-dusting formula minimizes the risk of contamination, making it suitable for applications within sensitive industries such as pharmaceuticals and food processing. Additionally, the desiccant's wide operating temperature range, from extreme cold to high heat, ensures its effectiveness across diverse climates and environments.Company X's dedication to environmental sustainability is reflected in its Alumina Desiccant as well. The product is entirely recyclable, reducing waste and promoting eco-conscious practices within industries. By providing an environmentally friendly solution, the company aims to contribute to a greener and more sustainable future.Company X understands that every industry faces unique moisture challenges. Thus, the company's professional team of engineers and technical experts is committed to providing comprehensive customer support. These experts work closely with clients to analyze their specific moisture-related issues and recommend the most appropriate solutions, guaranteeing optimal results and customer satisfaction.Industries across the globe have already begun recognizing the value of Company X's Alumina Desiccant. Customer testimonials praise the desiccant's outstanding performance, cost-effectiveness, and the reduction of product loss caused by moisture-related problems. With its innovative product range and commitment to surpassing customer expectations, Company X has firmly established itself as a leading provider of moisture control solutions.In conclusion, Company X's groundbreaking Alumina Desiccant is transforming the moisture control landscape by offering unmatched moisture absorption capabilities and innovative features. Through its tireless dedication to research and development, the company has once again raised the bar in moisture management. Ultimately, industries worldwide can rely on Company X's Alumina Desiccant to combat moisture-related challenges more effectively, ensuring product integrity and enhancing overall productivity.Contact:Company XPhone: XXX-XXXXXEmail: [email protected]: www.companyx.com

The Impact of Catalyst on Tail Gas during Vanadium-Titanium Magnetite Carbon-Containing Pellet Reduction | E3S Web of Conferences

Vanadium-titanium magnetite, a kind of iron ore, is widely used in the production of steel due to its high iron content and strong magnetism. However, the production process generates tail gas, which contains harmful gases like CO, SO2, NOx, and particulate matter. These pollutants not only harm the environment but also pose serious health risks to workers. Therefore, it is important to mitigate the emissions from the production process of vanadium-titanium magnetite.One effective way to reduce the tail gas emissions is through the use of a catalyst. A catalyst is a substance that speeds up a chemical reaction without being consumed in the process. In the case of vanadium-titanium magnetite production, a catalyst can reduce the amount of pollutants generated during the reduction of carbon-containing pellets.Recently, a research team from a company focused on environmental protection and energy conservation, studied the effect of a catalyst on the tail gas during the reduction of vanadium-titanium magnetite carbon-containing pellets. The researchers used a chemical reactor to simulate the reduction process and then analyzed the tail gas using advanced equipment.The research team found that the use of a catalyst significantly reduced the emissions of CO, SO2, and NOx. The reduction rates of these pollutants were 64.3%, 75.4%, and 31.2%, respectively, compared to the process without a catalyst. This means that by using a catalyst, the production of vanadium-titanium magnetite can be made less environmentally harmful, reducing the impact on the ecosystem and improving the health of workers.Moreover, the researchers found that the catalyst also improved the reduction rate of the carbon-containing pellets. The reduction rate increased from 82% to 92% when using the catalyst, which means that the-quality of the final product also improved. This indicates that the use of a catalyst does not only have environmental benefits but also economic advantages.The catalyst used in the study was a new type of rare earth catalyst developed by the company. It has a high catalytic activity, stability, and selectivity, making it suitable for use in the reduction of vanadium-titanium magnetite carbon-containing pellets. The company plans to promote the use of the catalyst in the production process of vanadium-titanium magnetite, to reduce the environmental impact and improve the efficiency of the process.Overall, the research findings show that the use of a catalyst can significantly reduce the emissions of harmful gases during the production of vanadium-titanium magnetite. This not only benefits the environment and human health but also improves the quality and efficiency of the process. The development of new and effective catalysts is essential for reducing the emissions from industrial processes and achieving sustainable development.

Discover the Power of Al2O3 Catalyst: A Game-Changer in the Industry!

Al2o3 Catalyst: The Key to Sustainable Industrial ProcessesThe demand for sustainable industrial processes continues to grow as the world's population increases and the need for energy and materials intensifies. As a result, industries are required to minimize their environmental impact while still maximizing their operational efficiency and productivity. One solution that has gained popularity in recent years is the use of catalysts to promote cleaner and more efficient chemical reactions.The Al2o3 catalyst is one of the leading catalysts in this field, and it is playing an essential role in transforming the way industries operate. This article will discuss the benefits of the Al2o3 catalyst, its applications, and its role in creating sustainable industrial processes.What is an Al2o3 Catalyst?The Al2o3 catalyst is a heterogeneous catalyst that contains alumina (Al2O3) as its primary component. This type of catalyst is widely used in various industrial processes, including the petroleum and chemical industries, due to its high catalytic activity, stability, and thermal resistance.Alumina is a naturally occurring substance and is commonly found in nature in the form of bauxite. The process of extracting alumina from bauxite involves heating the mineral to high temperatures, followed by a chemical process to purify the alumina.The resulting product is a white powder that is highly porous and has a large surface area. These properties make it an ideal catalyst, as they allow for a greater number of reactions to occur at any given time.Applications of the Al2o3 CatalystThe Al2o3 catalyst is highly versatile, and as a result, it can be used in a range of applications in different industries.One of its primary uses is in the production of petroleum products, such as gasoline, diesel, and jet fuel. In this process, the catalyst is used to improve the quality of crude oil by removing impurities, such as sulfur, nitrogen, and metals.The Al2o3 catalyst is also used in the cracking process, which involves breaking down large hydrocarbons into smaller, more useful ones. This process is critical as it allows for the production of a range of products, such as gasoline, diesel, and other valuable chemicals.Furthermore, the Al2o3 catalyst is used in the production of polymers, which have various applications in industries, such as packaging, textiles, and electronics. The catalyst is used to promote the polymerization process, leading to the formation of high-quality polymers with desirable properties.Sustainable Industrial ProcessesThe use of Al2o3 catalysts is essential in creating sustainable industrial processes that minimize the impact of industrial activity on the environment.Firstly, the use of catalysts promotes cleaner and more efficient reactions, reducing the amount of energy required to produce a given product. This leads to lower carbon emissions and overall energy consumption.Moreover, the use of catalysts improves product quality, resulting in fewer impurities and byproducts. The Al2o3 catalyst, for example, helps to remove sulfur from crude oil, reducing the environmental impact of the petroleum industry.Furthermore, the Al2o3 catalyst is highly stable, requiring very little maintenance and replacement. This leads to less waste and fewer resources required for catalyst production.Company IntroductionThe Al2o3 catalyst has gained popularity due to its effectiveness in promoting sustainable industrial processes. Many companies specialize in the production and distribution of Al2o3 catalysts, one of which is a leading manufacturer.This company has been providing high-quality catalysts to industries worldwide for over a decade. They specialize in the production of a range of catalysts that promote more sustainable and efficient industrial processes.Their Al2o3 catalyst is highly versatile and can be customized to meet the specific needs of individual industries. The company has an extensive research and development team that continually works to improve the quality and performance of their products.The company is committed to promoting sustainable industrial processes and minimizing the impact of industrial activity on the environment. They work closely with their clients to develop catalysts that meet their unique requirements while still promoting cleaner and more efficient processes.In conclusion, the Al2o3 catalyst is playing a significant role in transforming the industrial landscape, promoting sustainability while still maintaining operational efficiency and productivity. The use of this catalyst in various applications is expected to grow in the coming years as companies increasingly consider the environmental impact of their operations. Therefore, it is critical to choose a reliable and experienced manufacturer, such as the leading manufacturer mentioned above, to provide high-quality and efficient catalysts that meet industrial needs.