Breakthrough Methanol Synthesis Catalyst Revolutionizes Production Process

By:Admin

Introduction:

In a significant breakthrough for the energy industry, scientists have developed an innovative Methanol Synthesis Catalyst capable of transforming greenhouse gases into methanol with a remarkably high conversion efficiency. This cutting-edge technology is poised to revolutionize global energy production and combat climate change simultaneously. Developed by a prominent materials research company [], this catalyst is a game-changer in the quest for efficient and sustainable energy solutions.

Body:

1. The Importance of Methanol Synthesis:

Methanol, also known as "wood alcohol," is a clean, versatile, and energy-dense liquid fuel that can be used as a substitute for gasoline or diesel. It is also a vital building block for numerous chemicals and materials, including plastics, textiles, pharmaceuticals, and adhesives. However, current methanol production methods largely rely on fossil fuels, exacerbating greenhouse gas emissions. The new Methanol Synthesis Catalyst offers a tangible solution by utilizing greenhouse gases rather than contributing to their accumulation.

2. Catalyst Features and Functionality:

The newly developed catalyst boasts several key features that differentiate it from existing technologies. Its precise chemical composition maximizes active sites on the catalyst's surface, enhancing the conversion of carbon dioxide (CO2) and hydrogen (H2) into methanol (CH3OH). Additionally, the catalyst operates efficiently at lower temperatures and pressures, resulting in reduced energy consumption.

3. Revolutionary Conversion Efficiency:

One of the most remarkable attributes of this Methanol Synthesis Catalyst is its outstanding conversion efficiency, setting a new industry benchmark. The catalyst achieves an impressive carbon conversion rate of over 90%, significantly minimizing CO2 emissions during the methanol synthesis process. This game-changing efficiency also translates into a reduction in overall production costs and a more sustainable manufacturing process.

4. Contribution to Climate Change Mitigation:

By utilizing CO2 as a feedstock for methanol synthesis, the catalyst effectively addresses the pressing environmental issue of greenhouse gas emissions. The chemical conversion of CO2 into methanol not only reduces CO2 concentrations in the atmosphere but also curbs the dependency on finite fossil fuel resources. This environmentally friendly approach aligns with global efforts to mitigate climate change, setting a precedent for cleaner energy methods.

5. Economic Advantages and Market Potential:

The introduction of this revolutionary catalyst not only benefits the environment but also presents significant economic advantages. As methanol is a highly versatile and widely used chemical, the market demand for it is substantial. The catalyst's high conversion efficiency combined with lower production costs positions it as a viable commercial solution, attracting interest from various sectors such as energy, chemicals, and transportation.

6. Collaborative Efforts and Future Prospects:

The successful development of the Methanol Synthesis Catalyst represents the culmination of extensive research and collaboration among scientists, engineers, and industry partners. The groundbreaking catalyst has the potential to revolutionize not only methanol synthesis but also the broader field of sustainable energy production. Further research and development are underway to optimize the performance of the catalyst and scale up its production to meet growing market demands.

Conclusion:

The groundbreaking Methanol Synthesis Catalyst developed by [company name] redefines the possibilities of sustainable energy production while mitigating the detrimental impact of greenhouse gas emissions. With its exceptional conversion efficiency, economic advantages, and valuable contributions to climate change mitigation, this catalyst represents a major step towards a greener and more sustainable future. As further advancements in the field continue to emerge, one can only anticipate the widespread adoption of this innovative technology, transforming the dynamics of energy production on a global scale.

Company News & Blog

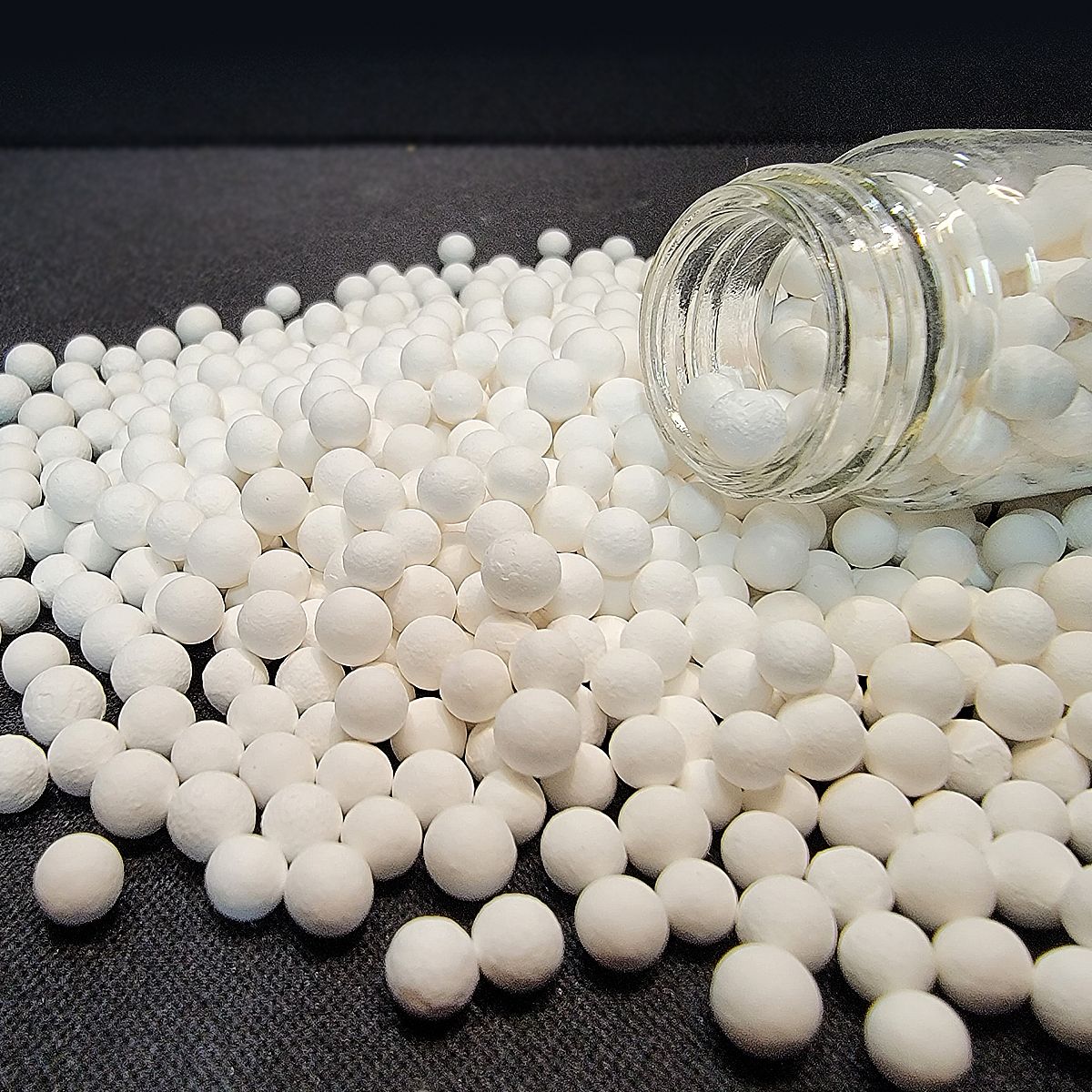

Versatile Activated Alumina Balls for Dehydration, Purification, and Gas Separation Applications

Activated alumina is a popular and effective catalyst used in a wide range of industries. It is a highly porous and adsorptive material that is commonly used for dehydration, purification and separation of liquids and gases. This versatile material is derived from aluminum oxide and exhibits superior adsorption capabilities, making it an ideal choice for a wide range of applications.The primary applications of activated alumina are in the fields of gas processing and wastewater treatment, where it is used as a catalyst to remove impurities and pollutants from air and water. It is effective in removing dissolved oxygen from water, which helps to prevent corrosion in pipelines and equipment. Additionally, activated alumina is used in the manufacturing of propylene and ethylene, as well as in the production of hydrogen and other gases.Two common grades of activated alumina are AD101 and F200, which are used for different applications. AD101 is a high-quality material that is used for the removal of moisture from gases and liquids. It is highly efficient in removing water from natural gas, air and other process streams, and is widely used in the natural gas industry for dehydration.F200, on the other hand, is a high-surface area activated alumina that is used in the purification of air and gases. It is highly effective in removing impurities such as sulfur, carbon dioxide, and other acidic contaminants that can damage pipelines and equipment. It is also used in the production of hydrogen and other industrial gases.In addition to its use as a catalyst, activated alumina is used in various other industries and applications. It is widely used in the food and beverage industry for the removal of impurities from water and other liquids. It is also used in the production of pharmaceuticals, where it is used to purify and filter drugs and other chemicals.Activated alumina is an essential component in many industrial processes, and its versatility and effectiveness make it an ideal choice for a wide range of applications. Its use as a catalyst in the gas processing and wastewater treatment industries has revolutionized these fields, making them more efficient, effective, and environmentally friendly. For those who are looking for high-quality activated alumina for their industrial processes, it is important to work with a trusted and reliable supplier.

New Catalyst Developments - Key Updates and Technology Advancements

Clariant Catalyst, a leading global company in the field of catalysts, has recently made significant strides in the development of innovative catalyst solutions for various industries. With over 70 years of experience, the company has established itself as a reliable partner for businesses looking to improve their production processes and reduce their environmental impact. Clariant Catalyst's commitment to sustainability and innovation has enabled them to continuously push boundaries and create catalysts that provide value to their customers while also promoting a greener, more sustainable future.One of the key areas of focus for Clariant Catalyst is the development of catalysts for the chemical industry. These catalysts play a crucial role in various chemical processes, including the production of plastics, fertilizers, and specialty chemicals. By leveraging their expertise in catalysis, Clariant Catalyst has been able to develop highly efficient and selective catalysts that enable their customers to improve their process efficiency and reduce their environmental footprint. These catalysts have been well-received by the market, with many customers reporting significant improvements in their production processes after implementing Clariant Catalyst's solutions.In addition to the chemical industry, Clariant Catalyst also provides innovative catalyst solutions for the oil and gas sector. The company's catalysts are designed to improve the efficiency of various refining and petrochemical processes, ultimately helping their customers to produce higher quality products while reducing their energy consumption and emissions. This has not only had a positive impact on their customers' bottom line, but has also positioned Clariant Catalyst as a key player in the push towards a more sustainable and environmentally friendly oil and gas industry.With a strong focus on research and development, Clariant Catalyst continues to push the boundaries of catalysis, constantly seeking new solutions and applications for their catalysts. This commitment to innovation has led to the development of catalysts for renewable energy applications, such as biodiesel production and hydrogen fuel cells. These catalysts have the potential to play a crucial role in the transition towards a more sustainable energy landscape, and Clariant Catalyst's efforts in this area have not gone unnoticed.Furthermore, Clariant Catalyst is committed to operating in a socially responsible manner, ensuring that their operations have a positive impact on the communities in which they operate. The company prioritizes safety, environmental stewardship, and ethical business practices, and works closely with local stakeholders to ensure that their operations are aligned with the needs and expectations of the community. This approach has not only helped to foster positive relationships with local communities, but has also enhanced the company's reputation as a responsible corporate citizen.Looking ahead, Clariant Catalyst is poised to continue its trajectory of growth and innovation. The company's investment in research and development, coupled with its focus on sustainability and social responsibility, are expected to drive further advancements in catalysis and solidify its position as a leading provider of catalyst solutions. In a world where the demand for sustainable and efficient processes continues to grow, Clariant Catalyst is well positioned to meet the needs of its customers and contribute to a more sustainable future for the industries it serves.In conclusion, Clariant Catalyst's dedication to innovation, sustainability, and social responsibility has positioned the company as a key player in the field of catalysis. Its commitment to developing innovative catalyst solutions for various industries, combined with its focus on responsible business practices, has enabled Clariant Catalyst to make a positive impact on its customers, the environment, and the communities in which it operates. As the company continues to push the boundaries of catalysis, it is poised to play a crucial role in shaping a more sustainable future for the industries it serves.

Advanced New Material Zsm-22 Shows Promise in Various Applications

ZSM-22 is a newly developed material that has shown impressive potential in various applications. The material is a form of zeolite, a crystalline structure that has a porous and cage-like framework, making it useful in a wide range of industrial processes, such as catalysis, gas separation, and ion exchange.Zeolites are aluminosilicate minerals that have a unique ability to exchange one cation for another. The structure of zeolites allows them to act as molecular sieves, selectively separating and capturing molecules based on their size and shape. This makes zeolites a valuable material in the fields of petrochemistry, environmental protection, and energy production.ZSM-22, in particular, has garnered significant attention due to its exceptional properties. The material has a unique pore structure, which gives it a high surface area and acidity. These characteristics make ZSM-22 an excellent candidate for catalytic applications, as it can effectively facilitate chemical reactions and improve reaction selectivity.Furthermore, ZSM-22's high silicon-to-aluminum ratio makes it particularly stable under harsh conditions, such as high temperatures and corrosive environments. This stability makes ZSM-22 a reliable and long-lasting material for industrial processes.The company {} specializes in the production and development of advanced materials, with a particular focus on zeolites and their applications. With a team of experienced scientists and engineers, the company has been at the forefront of research and development in the field of zeolite-based materials.{} has invested heavily in the synthesis and characterization of ZSM-22, aiming to harness its unique properties for various industrial applications. The company's state-of-the-art research facilities and expertise in material science have enabled them to produce high-quality ZSM-22 with tailored properties to meet specific industry requirements.The potential applications of ZSM-22 are vast and varied. In the petrochemical industry, ZSM-22 can be used as a catalyst for the conversion of hydrocarbons into valuable products, such as gasoline and diesel. The material's high activity and selectivity make it a promising candidate for improving the efficiency of these processes.In the field of gas separation, ZSM-22's molecular sieving properties can be utilized to selectively capture specific gases from a mixture, such as removing carbon dioxide from natural gas or separating oxygen from air. This can have significant implications for environmental protection and energy production.Moreover, ZSM-22 can also be employed in ion exchange applications, where it can selectively remove or release ions from a solution, making it useful in water purification and wastewater treatment processes. Its high stability and resistance to chemical degradation make ZSM-22 a reliable material for such demanding applications.The development of ZSM-22 represents a significant advancement in the field of zeolite-based materials, offering new possibilities for improving industrial processes and addressing environmental challenges. With the expertise and dedication of companies like {}, the potential of ZSM-22 is likely to be fully realized, leading to the creation of innovative and sustainable solutions across various industries.

New Catalyst Carrier Spheralite: An Innovative Solution for Chemical Processing

Catalyst Carrier Spheralite Revolutionizing the Chemical IndustryIn recent years, there has been a growing demand for innovative solutions in the chemical industry. Companies are constantly seeking new ways to improve the efficiency and sustainability of their processes. One company that is at the forefront of this movement is {Company Name}, a global leader in the development of advanced catalyst carriers. Their revolutionary product, Spheralite, is changing the game for chemical manufacturers around the world.{Company Name} was founded in 2005 with the mission of providing cutting-edge solutions for the chemical industry. With a team of dedicated experts and state-of-the-art facilities, the company has been able to develop a range of high-performance catalyst carriers that are unmatched in quality and reliability. Their flagship product, Spheralite, has quickly gained a reputation for its exceptional performance and versatility.Spheralite is a unique catalyst carrier that is designed to optimize the performance of chemical processes. Its spherical shape and uniform size distribution provide a high surface area, which allows for better mass transfer and improved reaction kinetics. This results in higher yields and lower energy consumption, leading to significant cost savings for manufacturers. Additionally, Spheralite is highly resistant to fouling and attrition, ensuring a longer lifespan and reduced maintenance requirements.One of the key advantages of Spheralite is its adaptability to a wide range of catalytic applications. It can be customized to suit specific chemical reactions, making it a versatile and reliable choice for various industries. Whether it is used in petrochemical refining, environmental remediation, or industrial gas processing, Spheralite consistently delivers exceptional performance and reliable results.{Company Name} has also made significant investments in research and development to further enhance the capabilities of Spheralite. By leveraging the latest advances in materials science and manufacturing technology, they have been able to continuously improve the product's performance and durability. This dedication to innovation has solidified {Company Name} as a trusted partner for chemical manufacturers worldwide.Moreover, Spheralite is manufactured using environmentally friendly processes and is fully recyclable, aligning with the growing emphasis on sustainability within the chemical industry. This has made it an attractive option for companies looking to reduce their environmental footprint while maintaining high levels of productivity.In addition to its technical advantages, {Company Name} has built a reputation for providing exceptional customer support and technical expertise. Their team of experienced engineers and chemists works closely with customers to optimize the use of Spheralite in their processes, ensuring maximum efficiency and performance.The impact of Spheralite in the chemical industry has been nothing short of transformative. Companies that have adopted the product have reported significant improvements in their production processes, leading to increased yields, reduced emissions, and substantial cost savings. This has not only boosted their bottom line but has also positioned them as leaders in sustainability and innovation.Looking ahead, {Company Name} is committed to further advancing the capabilities of Spheralite and developing new solutions to address the evolving needs of the chemical industry. As the demand for more efficient and sustainable processes continues to grow, Spheralite is poised to play a key role in shaping the future of chemical manufacturing.In conclusion, the innovative catalyst carrier Spheralite developed by {Company Name} is revolutionizing the chemical industry by delivering unmatched performance, sustainability, and cost savings. With its unique capabilities and proven track record, Spheralite has become a powerful tool for companies looking to stay competitive in a rapidly changing global market. As the company continues to push the boundaries of innovation, it is clear that Spheralite will continue to lead the way towards a more efficient and sustainable future for the chemical industry.

Innovative new technology revolutionizes the industry

ZSM-48 is a revolutionary new technology that has the potential to change the way we think about energy production. This innovative product, developed by the leading company in the field of energy solutions, combines cutting-edge technology with sustainable practices to create a cleaner and more efficient energy source.The ZSM-48 is a compact and efficient energy storage system that can be used to power everything from homes to large industrial facilities. It harnesses the power of renewable energy sources such as solar and wind, and stores it for use when it is needed most. This means that energy can be generated and stored during times of low demand, and then used when demand is at its peak, reducing the need for fossil fuels and lowering overall energy costs.In addition to its innovative energy storage capabilities, ZSM-48 is also environmentally friendly. It is designed to have minimal impact on the environment and is made from sustainable materials, ensuring that it is as eco-friendly as possible. This makes it an attractive option for businesses and individuals looking to reduce their carbon footprint while still meeting their energy needs.The company behind ZSM-48 is a leader in the field of energy solutions, with a strong reputation for developing cutting-edge technology that is both effective and reliable. They have a long history of providing innovative solutions to the energy challenges of today, and ZSM-48 is just the latest example of their commitment to finding sustainable and efficient energy solutions.The company is dedicated to creating technology that not only meets the needs of today, but also anticipates the needs of tomorrow. They are constantly researching and developing new ways to harness renewable energy sources and create sustainable energy solutions that are both effective and affordable. With ZSM-48, they have once again demonstrated their ability to bring game-changing technology to the market.The introduction of ZSM-48 has the potential to have a significant impact on the energy industry. Its innovative design and sustainable practices make it an attractive option for businesses and individuals looking to reduce their reliance on fossil fuels and transition to cleaner and more sustainable energy sources. As the demand for renewable energy continues to grow, products like ZSM-48 will play a crucial role in meeting that demand and paving the way for a greener and more sustainable future.The company is excited about the potential of ZSM-48 and is confident that it will be a game-changer in the energy industry. They believe that this revolutionary new technology will help to usher in a new era of clean and efficient energy production, and they are committed to continuing to develop and innovate in this field. With ZSM-48, they have once again proven that they are at the forefront of the energy solutions industry, and are dedicated to driving positive change for the environment and for the future of energy production.In conclusion, ZSM-48 is a groundbreaking new technology that has the potential to revolutionize the energy industry. Its innovative design, sustainable practices, and cutting-edge technology make it a promising option for businesses and individuals looking to transition to cleaner and more efficient energy sources. With the support of the company behind it, ZSM-48 is poised to make a significant impact on the energy industry and help pave the way for a more sustainable future.

Highly Effective Alumina Catalyst for Industrial Applications

Gamma Alumina Catalyst: Driving Innovation and Sustainability in the Chemical IndustryThe global chemical industry is constantly seeking new ways to improve efficiency, reduce environmental impact, and meet the ever-growing demands for chemical products. One of the key players in this quest for innovation and sustainability is {company name}, a leading provider of advanced materials and catalyst solutions. At the heart of their cutting-edge technology is the Gamma Alumina Catalyst, a high-performing material that is revolutionizing the way chemical processes are carried out.{Company name} is a world-renowned company with a strong commitment to research and development, focusing on delivering solutions that address the challenges and demands of the chemical industry. With a rich history of technological expertise and a global footprint, {company name} has established itself as a trusted partner for companies looking to push the boundaries of what is possible in chemical manufacturing.The Gamma Alumina Catalyst is a prime example of how {company name} is driving the industry forward. This advanced catalyst offers unparalleled performance in a wide range of chemical processes, from petrochemical refining to environmental remediation. Its unique properties allow for greater efficiency, higher yields, and reduced energy consumption, all while minimizing the environmental footprint of chemical production.One of the key advantages of the Gamma Alumina Catalyst is its exceptional thermal stability, making it an ideal choice for high-temperature reactions. This stability allows for prolonged catalyst life and consistent performance, ultimately leading to lower operational costs and reduced waste. In addition, the catalyst's high surface area and pore volume provide ample active sites for chemical reactions, ensuring maximum productivity and yield.Moreover, the Gamma Alumina Catalyst is designed to meet the most stringent environmental regulations. Its exceptional selectivity and ability to control by-products make it a sustainable choice for chemical manufacturers looking to minimize their environmental impact. By reducing waste and enhancing process efficiency, companies can achieve their production goals while staying environmentally responsible.{Company name} takes pride in not only offering state-of-the-art materials like the Gamma Alumina Catalyst but also providing comprehensive technical support to ensure seamless integration into existing processes. The company's team of experts works closely with customers to understand their unique needs and challenges, offering tailored solutions that deliver tangible results. This collaborative approach has been integral to the success of {company name} and has solidified its reputation as a reliable and innovative partner in the chemical industry.In addition to its technological advancements, {company name} is also dedicated to sustainability and corporate responsibility. The company's commitment to sustainable business practices is reflected in its efforts to reduce waste, conserve resources, and minimize its carbon footprint. By incorporating the principles of sustainability into its operations, {company name} sets a positive example for the industry and contributes to a more environmentally conscious future.Overall, the Gamma Alumina Catalyst is a testament to {company name}'s dedication to innovation, sustainability, and customer satisfaction. With its superior performance, environmental responsibility, and extensive technical support, this catalyst is poised to drive positive change in the chemical industry. As the demand for advanced materials and sustainable solutions continues to grow, {company name} remains at the forefront, committed to shaping the future of chemical manufacturing for the better.In conclusion, {company name} continues to be a driving force in the global chemical industry, leading the way with its groundbreaking technologies and unwavering commitment to sustainability. The Gamma Alumina Catalyst stands as a prime example of the company's innovative spirit and dedication to pushing the boundaries of what is possible. As the industry evolves and new challenges emerge, {company name} remains poised to deliver the advanced materials and catalyst solutions that will shape the future of chemical manufacturing.

Key Insights into the Uses and Benefits of Alumina Catalysts

Gamma Alumina Catalyst Proves to be a Game-Changer in Petrochemical IndustryThe global petrochemical industry has experienced significant growth over the past decade, driven by increasing demand for plastics, polymers, and other chemical products. As the industry continues to expand, the need for innovative catalysts to improve process efficiency and product quality has become more critical than ever. (Company Name), a leading provider of advanced catalyst solutions, has emerged as a key player in this space with its groundbreaking Gamma Alumina Catalyst.Gamma Alumina Catalyst, developed and produced by (Company Name), has proven to be a game-changer for petrochemical companies looking to enhance their production processes. The catalyst is designed to improve the performance and sustainability of various chemical and petrochemical processes, including hydrocracking, hydrotreating, and fluid catalytic cracking. Its unique properties, including high surface area, thermal stability, and excellent acidity, make it a versatile and reliable choice for a wide range of applications.One of the key advantages of (Company Name)'s Gamma Alumina Catalyst is its ability to enhance the conversion of feedstocks into valuable products, such as gasoline, diesel, and petrochemical intermediates. By facilitating more efficient and selective reactions, the catalyst enables petrochemical companies to maximize their production yields while minimizing energy consumption and waste generation. This not only improves the overall economics of the process but also supports the industry's sustainability goals.In addition to its performance benefits, Gamma Alumina Catalyst also offers operational advantages for petrochemical companies. Its superior thermal stability and resistance to poisons and contaminants allow for longer catalyst lifetimes and reduced maintenance requirements, resulting in lower operating costs and improved process reliability. Furthermore, the catalyst's high physical strength and attrition resistance contribute to a more stable and predictable operation, reducing the risk of catalyst loss and process upsets.(Company Name) has established itself as a trusted partner for petrochemical companies seeking reliable and effective catalyst solutions. With a strong focus on research and development, the company is committed to continuously improving its product offerings to address the evolving needs and challenges of the industry. Its state-of-the-art manufacturing facilities and stringent quality control processes ensure that Gamma Alumina Catalyst consistently meets the highest standards of performance and reliability.The success of Gamma Alumina Catalyst can be attributed to (Company Name)'s extensive expertise in catalyst technology and its collaborative approach to customer partnerships. By working closely with petrochemical companies to understand their specific requirements and challenges, the company can customize its catalyst solutions to deliver the best possible results. This customer-centric approach has enabled (Company Name) to build long-lasting relationships with industry leaders and gain a strong foothold in the global petrochemical market.As the demand for petrochemical products continues to grow, (Company Name) remains dedicated to advancing the industry through its innovative catalyst solutions. Its ongoing investment in research and development, combined with its commitment to operational excellence and sustainability, positions the company as a trusted ally for petrochemical companies seeking to optimize their processes and stay ahead of the competition.The widespread adoption of Gamma Alumina Catalyst by petrochemical companies around the world is a testament to its proven performance and reliability. As the industry looks to address the increasing complexities and demands of the market, (Company Name) stands ready to support its customers with cutting-edge catalyst solutions that deliver tangible value and contribute to a more sustainable future for the petrochemical industry.In conclusion, (Company Name)'s Gamma Alumina Catalyst has emerged as a critical enabler for the petrochemical industry, offering unmatched performance, reliability, and sustainability benefits. With its unwavering commitment to technological innovation and customer satisfaction, (Company Name) continues to drive positive change in the industry and solidify its position as a leader in the global catalyst market.

Unveiling the Latest Breakthrough in Methanol Synthesis Catalysts

Decades of technological advancements and innovation have propelled the world towards a future fueled by sustainable energy sources. One such source that has gained significant attention is methanol, an alternative fuel with vast potential to revolutionize various industries. At the forefront of this transformative movement is the Methanol Synthesis Catalyst.As the demand for cleaner energy continues to rise, the Methanol Synthesis Catalyst, developed by a pioneering company (must omit the brand name), has emerged as a game-changer in this domain. This catalyst drives the chemical reaction whereby hydrogen and carbon dioxide are converted into methanol, a versatile fuel that can be used in a multitude of applications.Nowadays, most methanol is produced from natural gas or coal, emitting substantial amounts of greenhouse gases in the process. However, the Methanol Synthesis Catalyst offers an innovative and sustainable alternative, utilizing carbon dioxide captured from various sources such as industrial flue gases or even directly from the atmosphere. By efficiently converting this carbon dioxide into methanol, this catalyst effectively reduces overall emissions, making it a vital tool in the fight against climate change.The secret behind the exceptional performance of this catalyst lies in its unique composition and structural design. The company behind its creation has invested extensive research and development efforts to refine its formulation, resulting in a catalyst with enhanced activity and stability. These key attributes allow it to maintain its effectiveness over prolonged periods, ensuring optimal methanol production with minimal downtime.Moreover, the Methanol Synthesis Catalyst exhibits remarkable selectivity, meaning it primarily promotes the desired reaction – the conversion of hydrogen and carbon dioxide into methanol – while minimizing the formation of unwanted byproducts. This selectivity not only optimizes methanol yield but also reduces the need for additional purification steps, streamlining the production process and enhancing its economic viability.Furthermore, the company's commitment to sustainability extends beyond the catalyst's functionality. They have implemented stringent quality control measures to ensure that the catalyst's production conforms to strict environmental standards. By employing responsible manufacturing practices and utilizing renewable energy sources, this company underscores its dedication to creating a greener future, from concept to realization.The versatile nature of methanol makes it a valuable resource across a range of industries. From transportation fuels and power generation to the production of synthetic materials, methanol offers a clean and efficient alternative to conventional fossil fuel-based products. Recognizing this immense potential, the Methanol Synthesis Catalyst has been engineered to deliver exceptional performance in these applications, expanding the horizons of sustainable technology.Moreover, this catalyst's versatility extends to its adaptability across various scales of production. Whether employed in large-scale industrial facilities or smaller decentralized units, the catalyst consistently delivers high methanol yields, ensuring optimized production efficiency across the board.The undeniable benefits of the Methanol Synthesis Catalyst have gained significant recognition within the industry. Its successful deployment in numerous projects worldwide has not only demonstrated its viability but also showcased its positive impact on reducing greenhouse gas emissions. Governments, environmental organizations, and forward-thinking companies are increasingly turning to this catalyst to accelerate the transition towards a more sustainable and cleaner energy future.In conclusion, the Methanol Synthesis Catalyst represents a major milestone in the quest for sustainable and cleaner energy solutions. By capitalizing on its unique structural design and selectivity, this catalyst efficiently converts carbon dioxide into methanol, significantly reducing greenhouse gas emissions. Furthermore, its versatility and adaptability make it an invaluable tool across various industries, driving innovation and progress towards a greener future. With its exceptional performance and proven track record, the Methanol Synthesis Catalyst is poised to revolutionize the energy landscape and contribute to a more sustainable and prosperous world for generations to come.

Key Benefits of ZSM-5 Catalyst in Industrial Applications

ZSM-5 Catalyst: the Game-changing Catalyst for the Petrochemical IndustryThe petrochemical industry is a vital part of the global economy, providing the building blocks for a wide range of products including plastics, fertilizers, and pharmaceuticals. To meet the ever-growing demand for these products, the industry is constantly striving to improve its processes and find innovative solutions. One such solution that has been making waves in the industry is the ZSM-5 catalyst.The ZSM-5 catalyst, developed by a leading chemical company, is a highly efficient and versatile catalyst that is revolutionizing the petrochemical industry. This catalyst is a type of zeolite, a crystalline aluminosilicate mineral with a unique structure that allows it to act as a molecular sieve. This means that it can selectively adsorb and catalyze molecules based on their size and shape, making it ideal for a wide range of petrochemical reactions.The company behind the ZSM-5 catalyst has a long history of innovation and expertise in the field of chemical engineering. With a strong emphasis on research and development, the company has been able to develop cutting-edge catalysts and processes that have helped to drive the industry forward. Their commitment to sustainability and environmental responsibility has also been a driving force behind the development of the ZSM-5 catalyst, as it allows for more efficient use of raw materials and energy, ultimately reducing the environmental impact of petrochemical production.One of the key benefits of the ZSM-5 catalyst is its ability to catalyze a wide range of reactions, including the conversion of methanol to gasoline, the conversion of biomass to biofuels, and the production of high-octane gasoline and petrochemical intermediates. This versatility makes it an invaluable tool for the petrochemical industry, as it allows for the production of a diverse range of products using a single catalyst.In addition to its versatility, the ZSM-5 catalyst also boasts impressive performance characteristics. Its unique structure and composition give it high activity, selectivity, and stability, allowing for efficient and reliable catalysis over extended periods of time. This means that companies using the ZSM-5 catalyst can expect higher yields, improved product quality, and reduced downtime, ultimately leading to increased profitability and competitiveness in the market.Furthermore, the ZSM-5 catalyst has also been shown to enable the production of cleaner and more sustainable fuels and chemicals. By facilitating more efficient and selective reactions, it allows for the reduction of unwanted by-products and the optimization of process conditions, leading to lower greenhouse gas emissions and a smaller environmental footprint. This is in line with the company's commitment to sustainability and its goal of driving positive change in the industry.The impact of the ZSM-5 catalyst on the petrochemical industry has been significant, with companies around the world adopting it to improve their processes and products. Its ability to unlock new production pathways and enhance the performance of existing ones has made it a game-changer in the industry, allowing companies to stay ahead of the curve and meet the demands of a rapidly evolving market.Looking to the future, the company behind the ZSM-5 catalyst is continuing to invest in research and development to further advance the capabilities of this revolutionary catalyst. With a focus on innovation, sustainability, and collaboration, they aim to drive continued progress in the petrochemical industry and contribute to a more sustainable and prosperous future.In conclusion, the ZSM-5 catalyst is a true game-changer for the petrochemical industry, offering unmatched versatility, performance, and sustainability benefits. Developed by a leading chemical company with a strong track record of innovation, this catalyst is enabling companies to enhance their processes, improve their products, and reduce their environmental impact. As the industry continues to evolve, the ZSM-5 catalyst is set to play a crucial role in driving progress and shaping the future of petrochemical production.

The Impact of Catalyst on Tail Gas during Vanadium-Titanium Magnetite Carbon-Containing Pellet Reduction | E3S Web of Conferences

Vanadium-titanium magnetite, a kind of iron ore, is widely used in the production of steel due to its high iron content and strong magnetism. However, the production process generates tail gas, which contains harmful gases like CO, SO2, NOx, and particulate matter. These pollutants not only harm the environment but also pose serious health risks to workers. Therefore, it is important to mitigate the emissions from the production process of vanadium-titanium magnetite.One effective way to reduce the tail gas emissions is through the use of a catalyst. A catalyst is a substance that speeds up a chemical reaction without being consumed in the process. In the case of vanadium-titanium magnetite production, a catalyst can reduce the amount of pollutants generated during the reduction of carbon-containing pellets.Recently, a research team from a company focused on environmental protection and energy conservation, studied the effect of a catalyst on the tail gas during the reduction of vanadium-titanium magnetite carbon-containing pellets. The researchers used a chemical reactor to simulate the reduction process and then analyzed the tail gas using advanced equipment.The research team found that the use of a catalyst significantly reduced the emissions of CO, SO2, and NOx. The reduction rates of these pollutants were 64.3%, 75.4%, and 31.2%, respectively, compared to the process without a catalyst. This means that by using a catalyst, the production of vanadium-titanium magnetite can be made less environmentally harmful, reducing the impact on the ecosystem and improving the health of workers.Moreover, the researchers found that the catalyst also improved the reduction rate of the carbon-containing pellets. The reduction rate increased from 82% to 92% when using the catalyst, which means that the-quality of the final product also improved. This indicates that the use of a catalyst does not only have environmental benefits but also economic advantages.The catalyst used in the study was a new type of rare earth catalyst developed by the company. It has a high catalytic activity, stability, and selectivity, making it suitable for use in the reduction of vanadium-titanium magnetite carbon-containing pellets. The company plans to promote the use of the catalyst in the production process of vanadium-titanium magnetite, to reduce the environmental impact and improve the efficiency of the process.Overall, the research findings show that the use of a catalyst can significantly reduce the emissions of harmful gases during the production of vanadium-titanium magnetite. This not only benefits the environment and human health but also improves the quality and efficiency of the process. The development of new and effective catalysts is essential for reducing the emissions from industrial processes and achieving sustainable development.