Innovative new technology revolutionizes the industry

By:Admin

The ZSM-48 is a compact and efficient energy storage system that can be used to power everything from homes to large industrial facilities. It harnesses the power of renewable energy sources such as solar and wind, and stores it for use when it is needed most. This means that energy can be generated and stored during times of low demand, and then used when demand is at its peak, reducing the need for fossil fuels and lowering overall energy costs.

In addition to its innovative energy storage capabilities, ZSM-48 is also environmentally friendly. It is designed to have minimal impact on the environment and is made from sustainable materials, ensuring that it is as eco-friendly as possible. This makes it an attractive option for businesses and individuals looking to reduce their carbon footprint while still meeting their energy needs.

The company behind ZSM-48 is a leader in the field of energy solutions, with a strong reputation for developing cutting-edge technology that is both effective and reliable. They have a long history of providing innovative solutions to the energy challenges of today, and ZSM-48 is just the latest example of their commitment to finding sustainable and efficient energy solutions.

The company is dedicated to creating technology that not only meets the needs of today, but also anticipates the needs of tomorrow. They are constantly researching and developing new ways to harness renewable energy sources and create sustainable energy solutions that are both effective and affordable. With ZSM-48, they have once again demonstrated their ability to bring game-changing technology to the market.

The introduction of ZSM-48 has the potential to have a significant impact on the energy industry. Its innovative design and sustainable practices make it an attractive option for businesses and individuals looking to reduce their reliance on fossil fuels and transition to cleaner and more sustainable energy sources. As the demand for renewable energy continues to grow, products like ZSM-48 will play a crucial role in meeting that demand and paving the way for a greener and more sustainable future.

The company is excited about the potential of ZSM-48 and is confident that it will be a game-changer in the energy industry. They believe that this revolutionary new technology will help to usher in a new era of clean and efficient energy production, and they are committed to continuing to develop and innovate in this field. With ZSM-48, they have once again proven that they are at the forefront of the energy solutions industry, and are dedicated to driving positive change for the environment and for the future of energy production.

In conclusion, ZSM-48 is a groundbreaking new technology that has the potential to revolutionize the energy industry. Its innovative design, sustainable practices, and cutting-edge technology make it a promising option for businesses and individuals looking to transition to cleaner and more efficient energy sources. With the support of the company behind it, ZSM-48 is poised to make a significant impact on the energy industry and help pave the way for a more sustainable future.

Company News & Blog

Newly Discovered ZSM-48 Material Shows Promise for Various Applications

ZSM-48 Catalyst Breakthrough: Revolutionizing the Chemical IndustryIn a groundbreaking development, the renowned chemical company has announced a major breakthrough in catalyst technology with the discovery of ZSM-48, a new catalyst that promises to revolutionize the chemical industry.ZSM-48 is a highly efficient catalyst that has been developed through years of research and development. It is designed to significantly improve the efficiency and cost-effectiveness of chemical manufacturing processes, making it an essential tool for the industry's future.The catalyst is capable of promoting a wide range of chemical reactions, offering a versatile solution for various applications across the chemical industry. Its unique properties make it ideal for use in the production of a wide range of chemicals, including petrochemicals, plastics, and specialty chemicals.The development of ZSM-48 is a significant milestone for the company, as it represents a major leap forward in catalyst technology. With its highly efficient performance and versatility, ZSM-48 is poised to become a game-changer in the chemical industry, offering a more sustainable and cost-effective solution for chemical manufacturing.The company's commitment to innovation and sustainability has been a driving force behind the development of ZSM-48. The new catalyst is designed to support the industry's transition towards more sustainable and eco-friendly manufacturing processes, aligning with the company's strong dedication to environmental responsibility.By enhancing the efficiency of chemical manufacturing processes, ZSM-48 has the potential to reduce energy consumption and greenhouse gas emissions, contributing to a more sustainable and environmentally friendly chemical industry.The company's extensive expertise in catalyst development and chemical engineering has played a crucial role in the successful development of ZSM-48. With a team of experienced researchers and scientists, the company has been able to leverage its technical capabilities to unlock the full potential of the new catalyst, bringing it to the forefront of the industry.The commercialization of ZSM-48 is expected to have a significant impact on the global chemical industry. As companies seek to optimize their manufacturing processes and reduce their environmental footprint, the new catalyst offers a compelling solution that can drive efficiency and sustainability across the industry.With its wide range of applications and performance benefits, ZSM-48 is set to play a key role in shaping the future of the chemical industry, offering a more sustainable and cost-effective solution for chemical manufacturing processes.The company is poised to lead the way in the commercialization of ZSM-48, leveraging its extensive industry network and technical expertise to bring the new catalyst to market. Through strategic partnerships and collaborations, the company aims to accelerate the adoption of ZSM-48 across the chemical industry, driving positive change and innovation.As the industry looks towards a more sustainable and efficient future, ZSM-48 is poised to emerge as a critical enabler of progress, offering a powerful catalyst for change in the global chemical industry. With its game-changing performance and versatility, the new catalyst is set to transform the way chemicals are manufactured, propelling the industry towards a more sustainable and environmentally friendly future.

Enhancing Catalyst Performance: A Step towards Efficient Reforming

Reforming Catalyst Technology: Revolutionizing Industrial ProcessesIndustries around the world are constantly striving to improve efficiency, reduce emissions, and enhance productivity. Now, with the emergence of reforming catalyst technology, a groundbreaking solution is at hand. By streamlining and optimizing industrial processes, this cutting-edge catalyst is poised to revolutionize a wide range of industries, from energy production to automotive manufacturing.Traditionally, industrial processes have been hindered by various challenges, such as high energy consumption, extensive environmental impacts, and limited product yields. In an effort to overcome these obstacles, reforming catalyst technology has become a beacon of hope for many. With its ability to enhance reactions, increase selectivity, and minimize undesirable byproducts, this catalyst has the potential to transform entire industries.Reforming catalyst technology works by promoting the desired reactions while suppressing unwanted side reactions. By doing so, it maximizes the product yield and improves the overall efficiency of the process. This catalyst operates at high temperatures, making it suitable for a wide range of applications, including petrochemical production, ammonia synthesis, and hydrogen generation.One key area where reforming catalyst technology is making a significant impact is in the production of clean energy. Green energy sources, such as solar and wind power, are becoming increasingly popular, but their intermittent nature poses challenges for stable energy supply. This is where reforming catalyst technology comes into play. By utilizing this catalyst in conjunction with renewable energy sources, industries can efficiently convert excess electricity into hydrogen, a versatile and clean fuel. Hydrogen can be stored and used when renewable energy generation is low, ensuring a reliable and sustainable energy supply. Moreover, the byproduct of hydrogen production, water, makes it an eco-friendly alternative to traditional fossil fuels.Another sector poised to benefit greatly from reforming catalyst technology is the automotive industry. As the world transitions towards sustainable transportation, the demand for alternative fuels is on the rise. Reforming catalyst technology presents a viable solution by facilitating the production of hydrogen or synthetic fuels, such as methanol or dimethyl ether, from renewable sources. These fuels emit significantly lower carbon emissions compared to conventional gasoline or diesel, making them essential in curbing global warming and improving air quality.In addition to its applications in the energy and transportation sectors, reforming catalyst technology has the potential to transform the production of valuable chemicals. Many industrial processes rely on the production of high-value chemicals, such as aromatics or olefins. However, these processes often generate large amounts of waste and have significant environmental impacts. By integrating reforming catalyst technology, industries can minimize waste, reduce energy consumption, and increase the selectivity of desired products. This not only enhances the economic viability of these processes but also contributes to a more sustainable future.Reforming catalyst technology goes beyond enhancing industrial processes; it also provides economic advantages. With improved efficiency and higher product yields, companies can optimize their operations, reduce costs, and gain a competitive edge in the market. Moreover, as governments worldwide prioritize sustainability and environmental stewardship, industries that adopt reforming catalyst technology can position themselves as leaders in responsible manufacturing.With its potential to revolutionize various industries, reforming catalyst technology is steadily gaining traction. As the world works towards a sustainable future, this catalyst offers a versatile and practical solution for optimizing industrial processes, reducing emissions, and maximizing productivity. By embracing this technology, companies can not only improve their bottom line but also contribute to a cleaner and greener planet.{Company Introduction}In conclusion, reforming catalyst technology has the potential to revolutionize industrial processes across a wide range of sectors. By improving efficiency, reducing emissions, and increasing selectivity, this catalyst offers a viable solution to the challenges faced by industries worldwide. With its applications in clean energy production, alternative fuels, and valuable chemicals, reforming catalyst technology is paving the way towards a more sustainable future. By adopting this innovative technology, companies can not only enhance their operations but also contribute to global efforts in combating climate change and ensuring a greener planet for future generations.

Innovative new technology revolutionizes the industry

ZSM-48 is a revolutionary new technology that has the potential to change the way we think about energy production. This innovative product, developed by the leading company in the field of energy solutions, combines cutting-edge technology with sustainable practices to create a cleaner and more efficient energy source.The ZSM-48 is a compact and efficient energy storage system that can be used to power everything from homes to large industrial facilities. It harnesses the power of renewable energy sources such as solar and wind, and stores it for use when it is needed most. This means that energy can be generated and stored during times of low demand, and then used when demand is at its peak, reducing the need for fossil fuels and lowering overall energy costs.In addition to its innovative energy storage capabilities, ZSM-48 is also environmentally friendly. It is designed to have minimal impact on the environment and is made from sustainable materials, ensuring that it is as eco-friendly as possible. This makes it an attractive option for businesses and individuals looking to reduce their carbon footprint while still meeting their energy needs.The company behind ZSM-48 is a leader in the field of energy solutions, with a strong reputation for developing cutting-edge technology that is both effective and reliable. They have a long history of providing innovative solutions to the energy challenges of today, and ZSM-48 is just the latest example of their commitment to finding sustainable and efficient energy solutions.The company is dedicated to creating technology that not only meets the needs of today, but also anticipates the needs of tomorrow. They are constantly researching and developing new ways to harness renewable energy sources and create sustainable energy solutions that are both effective and affordable. With ZSM-48, they have once again demonstrated their ability to bring game-changing technology to the market.The introduction of ZSM-48 has the potential to have a significant impact on the energy industry. Its innovative design and sustainable practices make it an attractive option for businesses and individuals looking to reduce their reliance on fossil fuels and transition to cleaner and more sustainable energy sources. As the demand for renewable energy continues to grow, products like ZSM-48 will play a crucial role in meeting that demand and paving the way for a greener and more sustainable future.The company is excited about the potential of ZSM-48 and is confident that it will be a game-changer in the energy industry. They believe that this revolutionary new technology will help to usher in a new era of clean and efficient energy production, and they are committed to continuing to develop and innovate in this field. With ZSM-48, they have once again proven that they are at the forefront of the energy solutions industry, and are dedicated to driving positive change for the environment and for the future of energy production.In conclusion, ZSM-48 is a groundbreaking new technology that has the potential to revolutionize the energy industry. Its innovative design, sustainable practices, and cutting-edge technology make it a promising option for businesses and individuals looking to transition to cleaner and more efficient energy sources. With the support of the company behind it, ZSM-48 is poised to make a significant impact on the energy industry and help pave the way for a more sustainable future.

Mechanistic Insights into DME Conversion over ZSM-5 Catalysts

and Dimethyl Ether (DME)ZSM-5 catalysts play a significant role in the conversion of dimethyl ether (DME) to olefins. This reaction is an important step in the production of valuable chemical compounds. However, the mechanism of this transformation has been elusive due to the complex nature of the reaction. In a recent study, researchers used temperature-programmed surface reaction experiments and microkinetic modelling to decouple the rates of adsorption, desorption, and surface reaction of DME over fresh and working ZSM-5 catalysts with different Si/Al ratios.The study yielded important insights into the reaction mechanism. The researchers discovered that propylene is the major olefin formed during the transformation of DME. They also observed site-specific scaling relations between the activation energies of DME desorption and barriers to the formation of methoxymethyl and methyl propenyl ether. Six ensembles of sites were observed, with a maximum of three adsorption/desorption sites and three adsorption/desorption/reaction sites.Interestingly, the researchers found that barriers were generally higher for working catalysts than fresh catalysts. This could have implications for industrial processes that use ZSM-5 catalysts.The study’s results were obtained by simulating transient reactor performance through the solving of coupled 1D nonlinear partial differential equations. This accounted for elementary steps during the induction period, based on the methoxymethyl mechanism on the zeolite catalyst, and axial dispersion and convection in the reactor. The activation energies of propylene formation were found to be approximately 200 kJ mol1, which corroborated direct mechanistic proposals.Overall, this study provides valuable mechanistic insights into the conversion of DME over ZSM-5 catalysts. The researchers’ use of temperature-programmed surface reaction experiments and microkinetic modelling allowed for decoupling the complex rates of the reaction, providing important information about site-specific mechanisms. This information may prove useful for developing more efficient and effective industrial processes that utilize ZSM-5 catalysts.In conclusion, the study underscores the importance of understanding the mechanistic details of catalytic reactions. By using advanced experimental and modelling techniques, we can gain insights that will allow for the development of more efficient and sustainable industrial processes.

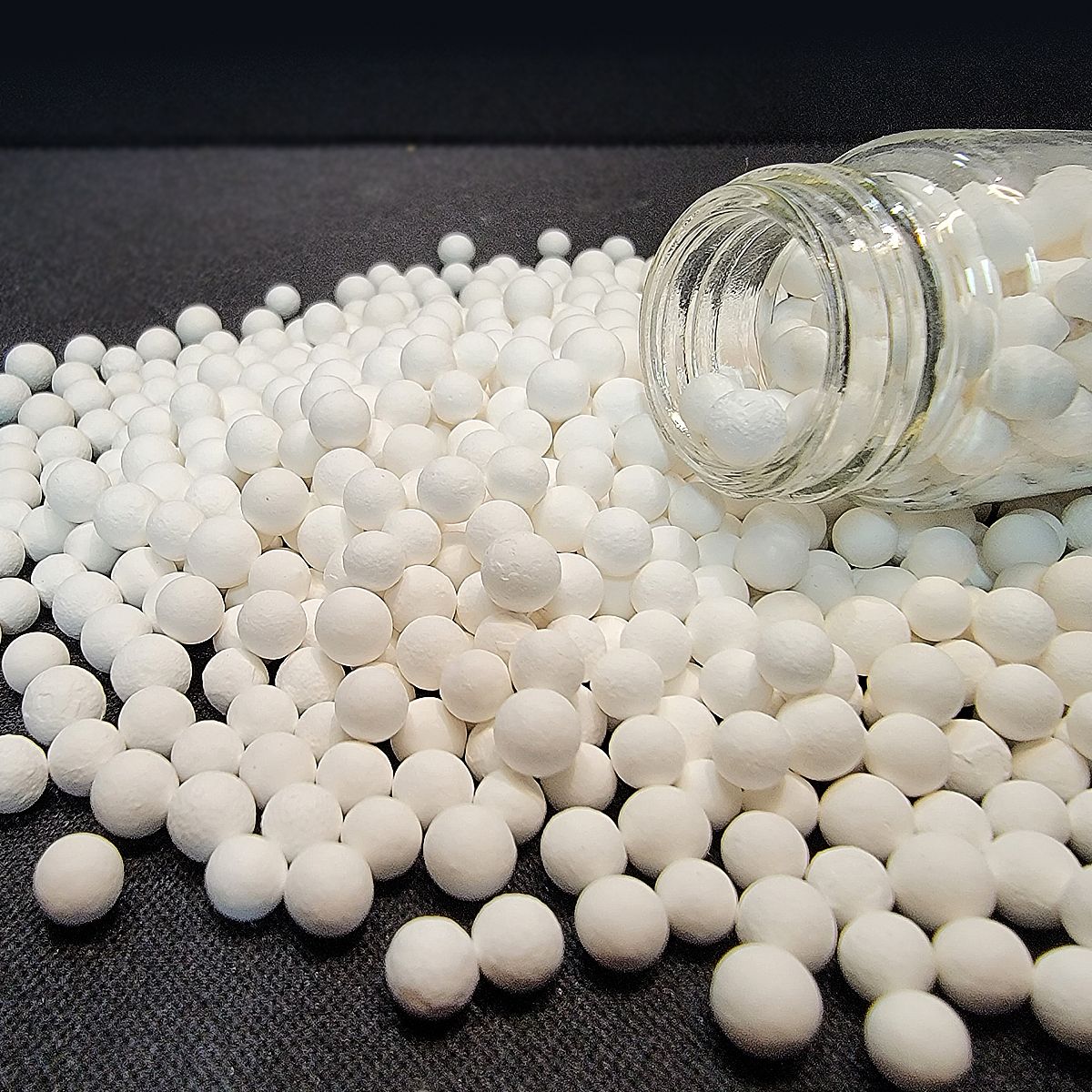

Highly Efficient Gamma Alumina Catalyst for Advanced Chemical Processes

Gamma Alumina Catalyst Shows Promise in Environmental RemediationThe global push for sustainable and environmental friendly solutions has led to a growing demand for advanced catalysts that can facilitate the efficient conversion of various waste streams into valuable products. In response to this demand, a leading catalyst manufacturer has developed a cutting-edge Gamma Alumina Catalyst that has shown promising results in environmental remediation and waste-to-product conversion processes.The {Company} is a renowned manufacturer and supplier of innovative catalyst materials for a wide range of industrial applications. Established in 1990, the company has built a strong reputation for delivering high-quality catalyst solutions that meet the evolving needs of industries such as petrochemicals, environmental remediation, and renewable energy. With a strong focus on research and development, {Company} has consistently pushed the boundaries of catalyst technology to develop novel products that offer superior performance and sustainability.One of the company's latest breakthroughs is the development of a Gamma Alumina Catalyst that has demonstrated exceptional potential in environmental remediation applications. Gamma Alumina is a type of alumina (Al2O3) with a unique crystal structure that imparts desirable properties such as high surface area, thermal stability, and chemical inertness. These properties make Gamma Alumina an ideal candidate for catalyzing a variety of chemical reactions, including those involved in waste treatment and conversion processes.The Gamma Alumina Catalyst developed by {Company} has shown remarkable efficacy in facilitating the conversion of organic pollutants into harmless byproducts through processes such as oxidation and hydrocracking. This capability makes it well-suited for addressing environmental challenges such as water and soil pollution resulting from industrial activities, waste disposal, and agricultural runoff. Additionally, the catalyst has demonstrated potential in converting waste materials into valuable chemicals and biofuels, aligning with the global objectives of circular economy and resource efficiency.In addition to its exceptional catalytic performance, the Gamma Alumina Catalyst offers several practical advantages that make it an attractive choice for industrial and environmental applications. Its high surface area and porosity allow for high catalytic activity and accessibility, ensuring efficient utilization of the catalyst material. Moreover, its thermal stability and resistance to harsh operating conditions contribute to long-term stability and durability, reducing the frequency of catalyst replacement and maintenance.Furthermore, {Company} emphasizes the sustainable and environmentally responsible nature of its production processes, ensuring that the Gamma Alumina Catalyst is manufactured with minimal environmental impact. This commitment to sustainability extends to the catalyst's end-of-life phase, where efforts are made to promote recycling and reclamation of the catalyst material, further contributing to resource conservation and waste reduction.The potential of the Gamma Alumina Catalyst in environmental remediation has sparked significant interest and collaborations with environmental engineering firms, government agencies, and research institutions. Preliminary studies and pilot-scale demonstrations have yielded promising results, validating the efficacy of the catalyst in treating various types of contaminated water and soil, as well as in converting organic waste into value-added products.Looking ahead, {Company} is committed to furthering the development and commercialization of the Gamma Alumina Catalyst, with a focus on scaling up production and expanding its application scope. Collaborative research efforts are underway to explore the catalyst's potential in addressing emerging environmental challenges and advancing the transition towards a more sustainable and circular economy.In conclusion, the development of the Gamma Alumina Catalyst by {Company} represents a significant advancement in catalysis technology, with far-reaching implications for environmental remediation and waste-to-product conversion. By harnessing the unique properties of Gamma Alumina, the catalyst has demonstrated exceptional performance and potential, offering a promising solution to pressing environmental concerns and contributing to the global efforts towards a more sustainable future. As the demand for innovative catalyst solutions continues to grow, {Company} remains at the forefront of catalysis innovation, driving positive change and addressing the complex challenges of today's world.

The Vital Role of Isomerization Catalysts in Chemical Processes

Title: Revolutionary Isomerization Catalyst Enhances Efficiency and Sustainability in Petrochemical IndustryIntroduction:The petrochemical industry has witnessed a major breakthrough with the introduction of a revolutionary Isomerization Catalyst, developed by a leading global innovator. By leveraging state-of-the-art technologies and extensive research, the company has successfully produced a catalyst that promises to enhance efficiency, sustainability, and overall productivity in a variety of petrochemical processes. This breakthrough innovation is expected to revolutionize the industry, enabling manufacturers to meet growing demands while reducing environmental impact.Groundbreaking Technology:The Isomerization Catalyst presents immense potential due to its superior performance in several critical aspects. Engineered to facilitate the isomerization process with extraordinary precision, this catalyst enables petrochemical plants to produce high-quality isomerized products while consuming less energy and raw materials. The catalyst's unique structure and composition allow for enhanced selectivity, reducing unwanted side reactions and minimizing waste byproducts.Furthermore, the catalyst's impressive stability and durability ensure extended operational lifetimes, effectively reducing downtime and maintenance costs. Petrochemical manufacturers can benefit from increased throughput with minimal interruptions, thereby maximizing their operational efficiency and profitability.Sustainable Advantages:Aside from the catalyst's higher performance, its sustainability benefits are a significant achievement in response to a global call for environmentally responsible practices. The Isomerization Catalyst significantly reduces greenhouse gas emissions by optimizing energy consumption during the isomerization process. By minimizing energy wastage, petrochemical plants can markedly reduce their carbon footprint while meeting increased production demands.Additionally, the catalyst's design enables a more efficient use of raw materials, resulting in reduced resource consumption. The ability to maximize the conversion of feedstock into valuable end products ensures optimal resource management while simultaneously maximizing profitability.Impacts on the Industry:The introduction of this game-changing catalyst is expected to result in a paradigm shift within the petrochemical industry. Increased operational efficiency and reduced environmental impact will not only benefit manufacturers but also contribute to sustainable development on a global scale.Petrochemical plants incorporating the Isomerization Catalyst can anticipate improved product quality, meeting the stringent demands of various industries such as automotive, packaging, and consumer goods. This will ultimately enhance customer satisfaction and market competitiveness.Moreover, the catalyst's compatibility with existing infrastructure allows for easy integration into numerous petrochemical processing units globally. The potential for smooth adoption ensures a quicker transition towards sustainable practices without requiring significant capital investments or facility upgrades.Looking Ahead:With the Isomerization Catalyst's commercial availability, the petrochemical industry is poised for lucrative growth opportunities. The catalyst's superior performance, sustainability advantages, and compatibility offer a unique competitive edge to manufacturers who seek to optimize production, minimize costs, and adhere to increasingly stringent environmental regulations.The global innovator behind this breakthrough is dedicated to continuous research and development to further enhance the catalyst's capabilities across various petrochemical processes. Collaborations with industry leaders, research institutions, and regulatory bodies are underway to explore novel applications and expand the scope of sustainable chemical production.Conclusion:The introduction of the Isomerization Catalyst into the petrochemical industry is a groundbreaking achievement. Not only does it deliver superior performance and efficiency, but it also sets new standards for sustainability, ensuring responsible chemical production in line with global environmental objectives. This catalyst is set to revolutionize the industry, enabling manufacturers to meet growing demands while minimizing their ecological footprint. The prospects for greater profitability, customer satisfaction, and environmentally conscious practices make it a game-changer for the future of the petrochemical sector.

New Technology Could Revolutionize the Reforming Catalyst Industry

Reforming Catalyst is a key component in the refining industry that plays a critical role in converting heavy naphtha into high-octane gasoline. In a move towards sustainability and energy efficiency, the industry is constantly searching for innovative and advanced reforming catalysts that can improve the refining process and reduce environmental impact. Recent developments in refining technology have led to the introduction of a new reforming catalyst that promises to deliver superior performance and efficiency.This new catalyst, which is yet to be officially named, has been designed by a leading chemical manufacturer with extensive experience in developing innovative solutions for the refining industry. The company specializes in creating catalysts that can withstand high temperatures and harsh operating conditions, maximizing the yield and quality of refined products. The new reforming catalyst is no exception as it has been tested extensively to ensure superior performance and reliability.According to industry experts, the new reforming catalyst has several advantages over existing catalysts. The most notable of these advantages is increased octane yield, which can significantly improve the quality of gasoline produced in refineries. The catalyst is also highly selective, ensuring that only the desired chemical reactions take place during the refining process. This selectivity reduces the amount of by-products produced by the refinery, which is beneficial for the environment, as it reduces emissions and waste.Another advantage of the new reforming catalyst is its durability. The catalyst has a longer lifespan than existing catalysts, which means that it can operate efficiently for longer periods without requiring replacement. This is particularly important for refineries, as it reduces the downtime associated with catalyst replacement, which can be costly and time-consuming.The company behind the new reforming catalyst is committed to sustainability and has a track record of creating innovative solutions that reduce environmental impact. The new catalyst has been designed to reduce emissions during the refining process, which is beneficial for the environment and the community. The company is also committed to using sustainable materials and processes in production, further reducing the ecological footprint of the catalyst.The development of the new reforming catalyst comes at a time when the refining industry is facing increasing pressure to reduce its environmental impact. Governments around the world are implementing stricter regulations on emissions and waste, which means that refineries need to find innovative solutions to stay competitive and compliant. The introduction of the new reforming catalyst is a step towards a cleaner, more sustainable refining industry.The new catalyst is expected to be widely adopted by refineries around the world, as it offers significant performance and efficiency gains compared to existing catalysts. The chemical manufacturer has already received significant interest from industry players, who are eager to incorporate the new catalyst into their refining operations. The company is currently working on scaling up production to meet demand and expects to see widespread adoption of the new catalyst in the coming years.In conclusion, the introduction of the new reforming catalyst represents a significant step forward for the refining industry. The new catalyst promises to deliver superior performance, efficiency and sustainability and is set to become an essential component in the refining process. With its increased octane yield, selectivity, durability and reduced environmental impact, the new reforming catalyst is a game-changer for the industry. As the world moves towards a more sustainable future, the introduction of this innovative solution is a positive development that promises to benefit both the industry and the environment.

Hydrogenation Catalyst: Key Component in Tail Gas Processing

Tail Gas Hydrogenation Catalyst Successfully Developed by Leading Industrial Technology CompanyIn a significant breakthrough, a leading industrial technology company has successfully developed a Tail Gas Hydrogenation Catalyst that has the potential to revolutionize the process of hydrogenation in the chemical industry. The company, which has a strong reputation for innovation and advanced technological solutions, has made a significant investment in research and development to create this highly efficient catalyst.The Tail Gas Hydrogenation Catalyst is designed to effectively remove impurities and pollutants from the tail gas generated during the hydrogenation process. This not only helps in ensuring compliance with environmental regulations but also enhances the overall efficiency of the hydrogenation process.The company behind this remarkable achievement is known for its expertise in developing advanced catalyst technologies for a wide range of industrial applications. With a strong focus on sustainability and environmental responsibility, the company has been at the forefront of creating innovative solutions that contribute to a cleaner and greener future.The Tail Gas Hydrogenation Catalyst is the latest addition to the company's portfolio of high-performance catalysts, which are widely used in various industries, including petrochemicals, refining, and environmental protection. The new catalyst is designed to deliver superior performance and efficiency, making it an ideal choice for companies looking to optimize their hydrogenation processes while minimizing their environmental footprint.One of the key advantages of the Tail Gas Hydrogenation Catalyst is its ability to effectively remove sulfur compounds, nitrogen compounds, and other pollutants from the tail gas, resulting in a significant reduction in harmful emissions. This is particularly important for industries that are required to adhere to strict emission standards and are looking for cost-effective solutions to meet regulatory requirements.Furthermore, the catalyst is designed to operate at high temperatures and pressures, making it suitable for a wide range of hydrogenation processes. Its robust and versatile nature makes it a valuable asset for companies seeking to enhance the performance and sustainability of their operations.Moreover, the development of the Tail Gas Hydrogenation Catalyst is a testament to the company's commitment to innovation and continuous improvement. By investing in cutting-edge research and development, the company has positioned itself as a leader in the field of catalytic technologies, providing customers with access to the latest advancements in industrial chemistry.With sustainability becoming an increasingly important consideration for businesses across the globe, the introduction of the Tail Gas Hydrogenation Catalyst underscores the company's dedication to delivering solutions that not only meet the needs of its customers but also contribute to a more sustainable and eco-friendly future.Looking ahead, the company is focused on expanding the application of the Tail Gas Hydrogenation Catalyst across various industries, offering businesses a highly efficient and reliable solution for their hydrogenation needs. Through ongoing research and development efforts, the company aims to further enhance the performance and environmental benefits of the catalyst, reinforcing its position as a trusted partner for businesses seeking innovative and sustainable solutions.In conclusion, the successful development of the Tail Gas Hydrogenation Catalyst by the leading industrial technology company represents a significant milestone in the advancement of catalytic technologies. With its exceptional performance, environmental benefits, and potential for widespread application, the catalyst is poised to make a positive impact on the chemical industry, driving greater efficiency and sustainability in hydrogenation processes. As the company continues to explore new possibilities and applications for the catalyst, it is paving the way for a cleaner, greener, and more sustainable future.

Discover the Power of Al2O3 Catalyst: A Game-Changer in the Industry!

Al2o3 Catalyst: The Key to Sustainable Industrial ProcessesThe demand for sustainable industrial processes continues to grow as the world's population increases and the need for energy and materials intensifies. As a result, industries are required to minimize their environmental impact while still maximizing their operational efficiency and productivity. One solution that has gained popularity in recent years is the use of catalysts to promote cleaner and more efficient chemical reactions.The Al2o3 catalyst is one of the leading catalysts in this field, and it is playing an essential role in transforming the way industries operate. This article will discuss the benefits of the Al2o3 catalyst, its applications, and its role in creating sustainable industrial processes.What is an Al2o3 Catalyst?The Al2o3 catalyst is a heterogeneous catalyst that contains alumina (Al2O3) as its primary component. This type of catalyst is widely used in various industrial processes, including the petroleum and chemical industries, due to its high catalytic activity, stability, and thermal resistance.Alumina is a naturally occurring substance and is commonly found in nature in the form of bauxite. The process of extracting alumina from bauxite involves heating the mineral to high temperatures, followed by a chemical process to purify the alumina.The resulting product is a white powder that is highly porous and has a large surface area. These properties make it an ideal catalyst, as they allow for a greater number of reactions to occur at any given time.Applications of the Al2o3 CatalystThe Al2o3 catalyst is highly versatile, and as a result, it can be used in a range of applications in different industries.One of its primary uses is in the production of petroleum products, such as gasoline, diesel, and jet fuel. In this process, the catalyst is used to improve the quality of crude oil by removing impurities, such as sulfur, nitrogen, and metals.The Al2o3 catalyst is also used in the cracking process, which involves breaking down large hydrocarbons into smaller, more useful ones. This process is critical as it allows for the production of a range of products, such as gasoline, diesel, and other valuable chemicals.Furthermore, the Al2o3 catalyst is used in the production of polymers, which have various applications in industries, such as packaging, textiles, and electronics. The catalyst is used to promote the polymerization process, leading to the formation of high-quality polymers with desirable properties.Sustainable Industrial ProcessesThe use of Al2o3 catalysts is essential in creating sustainable industrial processes that minimize the impact of industrial activity on the environment.Firstly, the use of catalysts promotes cleaner and more efficient reactions, reducing the amount of energy required to produce a given product. This leads to lower carbon emissions and overall energy consumption.Moreover, the use of catalysts improves product quality, resulting in fewer impurities and byproducts. The Al2o3 catalyst, for example, helps to remove sulfur from crude oil, reducing the environmental impact of the petroleum industry.Furthermore, the Al2o3 catalyst is highly stable, requiring very little maintenance and replacement. This leads to less waste and fewer resources required for catalyst production.Company IntroductionThe Al2o3 catalyst has gained popularity due to its effectiveness in promoting sustainable industrial processes. Many companies specialize in the production and distribution of Al2o3 catalysts, one of which is a leading manufacturer.This company has been providing high-quality catalysts to industries worldwide for over a decade. They specialize in the production of a range of catalysts that promote more sustainable and efficient industrial processes.Their Al2o3 catalyst is highly versatile and can be customized to meet the specific needs of individual industries. The company has an extensive research and development team that continually works to improve the quality and performance of their products.The company is committed to promoting sustainable industrial processes and minimizing the impact of industrial activity on the environment. They work closely with their clients to develop catalysts that meet their unique requirements while still promoting cleaner and more efficient processes.In conclusion, the Al2o3 catalyst is playing a significant role in transforming the industrial landscape, promoting sustainability while still maintaining operational efficiency and productivity. The use of this catalyst in various applications is expected to grow in the coming years as companies increasingly consider the environmental impact of their operations. Therefore, it is critical to choose a reliable and experienced manufacturer, such as the leading manufacturer mentioned above, to provide high-quality and efficient catalysts that meet industrial needs.

Ultimate Guide to Hydrogenation Catalysts: Types, Uses, and Benefits

Hydrogenation Catalyst Innovations Revolutionize Industrial ProcessesIn recent years, there has been a growing demand for innovative hydrogenation catalysts that can enhance industrial processes, especially in the petrochemical and oil refining industries. The use of hydrogenation catalysts has become essential in these industries to improve the quality of products, increase yield, and reduce environmental impact. One company that has been at the forefront of this innovation is {Company Name}, a global leader in developing advanced catalysts for various industrial applications.{Company Name} has been dedicated to providing highly efficient and sustainable solutions for the petrochemical and oil refining industries for over 30 years. With a strong focus on research and development, they have continually developed cutting-edge technologies to meet the evolving needs of their customers. Their hydrogenation catalysts have played a pivotal role in revolutionizing industrial processes, driving efficiency, and reducing the environmental footprint of many operations.The hydrogenation catalysts developed by {Company Name} are designed to facilitate the addition of hydrogen to various organic compounds, thereby improving the quality of the end products. By using these catalysts, industries can achieve higher conversion rates, reduced energy consumption, and enhanced product properties. Furthermore, the catalysts enable the selective hydrogenation of unsaturated compounds, contributing to the development of cleaner and greener processes.One of the key features of {Company Name}'s hydrogenation catalysts is their superior performance and durability, allowing for extended catalyst life and reduced downtime. This has translated into significant cost savings for their customers, as well as a more sustainable approach to industrial operations. Additionally, the catalysts are designed to be easily integrated into existing processes, minimizing the need for major retooling or investment in new infrastructure.Another crucial aspect of {Company Name}'s catalysts is their ability to support the production of cleaner fuels and chemicals. With the ever-increasing focus on environmental sustainability, the demand for catalysts that can enable the production of low-sulfur fuels and reduce greenhouse gas emissions has been on the rise. {Company Name} has been at the forefront of meeting these demands, with their hydrogenation catalysts playing a vital role in the production of environmentally friendly products.Moreover, {Company Name} has been actively engaged in providing comprehensive technical support and services to their customers, ensuring that the catalysts are optimized for specific applications and operating conditions. Their team of experienced engineers and chemists collaborate closely with clients to understand their requirements and provide tailored solutions that deliver the desired results. This personalized approach has been instrumental in building long-lasting partnerships and driving mutual success.Looking ahead, {Company Name} remains committed to further advancing the capabilities of their hydrogenation catalysts, with a strong emphasis on sustainability and performance. They continue to invest in research and development to bring forth the next generation of catalyst technologies that will push the boundaries of what is achievable in industrial processes. By leveraging their expertise and innovative spirit, {Company Name} is poised to remain a leading force in the field of hydrogenation catalysts, empowering industries to achieve greater efficiency and environmental responsibility.In conclusion, the advancements in hydrogenation catalysts developed by {Company Name} have been instrumental in transforming industrial processes, facilitating the production of higher quality products while reducing environmental impact. With a focus on sustainability, performance, and customer-centric solutions, {Company Name} continues to be a driving force in providing innovative catalyst technologies for the petrochemical and oil refining industries. As the demand for cleaner and more efficient industrial processes continues to grow, {Company Name} is well-positioned to lead the way with their cutting-edge hydrogenation catalysts.