Powerful molecular sieve ZSM-5: What you need to know

By:Admin

The powder form of ZSM-5, with its high surface area and acidity, has been found to be particularly effective in catalyzing the conversion of alcohols into hydrocarbons. This has made it an essential component in the production of gasoline and other fuels from renewable sources such as biomass and waste materials.

Moreover, ZSM-5 has shown promise in the removal of pollutants from water and air, making it an important player in the field of environmental remediation. Its ability to selectively adsorb and catalyze the decomposition of various organic compounds has made it a key material in the development of sustainable solutions for pollution control.

One of the leading companies in the production and application of ZSM-5 is {}. Established in the early 2000s, {} has been at the forefront of research and development in the field of zeolite catalysts. The company has a state-of-the-art manufacturing facility and a team of experienced engineers and scientists dedicated to advancing the technology and applications of ZSM-5.

{} has been actively collaborating with industry partners and research institutions to further explore the potential of ZSM-5 in various applications. Their efforts have led to several breakthroughs in the development of new catalyst formulations and processes, making ZSM-5 an even more versatile and effective tool for a wide range of chemical and environmental applications.

The company's commitment to sustainability and innovation has also led to the development of ZSM-5-based catalysts for renewable fuel production and pollution control. These catalysts have been proven to be more efficient and selective than traditional catalysts, offering significant benefits in terms of energy savings and environmental impact.

In addition to its technical expertise, {} is also known for its strong emphasis on quality and customer service. The company has a rigorous quality control system in place to ensure the consistency and reliability of its ZSM-5 products. Moreover, its dedicated technical support team is always available to provide expert advice and solutions to customers' specific needs and challenges.

Looking ahead, {} is continuously investing in research and development to further enhance the performance and applications of ZSM-5. The company is also exploring new markets and partnerships to bring its innovative zeolite catalyst solutions to a wider range of industries and applications.

With its cutting-edge technology, commitment to sustainability, and dedication to customer satisfaction, {} is well positioned to continue leading the way in the exciting and rapidly evolving world of ZSM-5-based catalysts.

Company News & Blog

The Latest Innovation in Catalyst Carrier Technology

Catalyst Carrier Company, a leading provider of cutting-edge catalyst carrier solutions, has been making waves in the industry with its innovative products and commitment to excellence. The company has been at the forefront of the catalyst carrier industry, providing high-quality solutions to a wide range of clients. With a focus on sustainability and efficiency, Catalyst Carrier Company has positioned itself as a key player in the market.Founded in 2005, Catalyst Carrier Company has quickly gained recognition for its dedication to quality and customer satisfaction. The company's state-of-the-art facilities and advanced technology have enabled it to produce catalyst carriers that meet the highest standards of performance and durability. In addition, Catalyst Carrier Company has a team of experts who are constantly researching and developing new products to meet the evolving needs of the industry.One of the key factors that set Catalyst Carrier Company apart from its competitors is its commitment to sustainability. The company has made significant investments in research and development to ensure that its products are environmentally friendly and energy-efficient. This focus on sustainability has not only helped Catalyst Carrier Company reduce its carbon footprint but has also allowed it to provide clients with solutions that help them meet their own sustainability goals.In recent years, Catalyst Carrier Company has been gaining traction in the market with its cutting-edge products. The company's catalyst carriers have been widely acclaimed for their exceptional performance and reliability. With a wide range of products designed to meet the needs of various industries, Catalyst Carrier Company has been able to cater to a diverse clientele, from automotive manufacturers to petrochemical companies.One of the company's flagship products is its innovative catalyst carrier, which has been specifically designed to maximize the efficiency of catalytic processes. This product has been well-received by clients due to its ability to enhance the performance of catalysts, resulting in improved production processes and reduced emissions. In addition, Catalyst Carrier Company has also been working on developing new catalyst carrier solutions that are tailored to the specific needs of its clients, ensuring that they get the best possible results.Another key strength of Catalyst Carrier Company is its dedication to customer satisfaction. The company takes pride in its ability to provide clients with top-notch service, from the initial consultation to the delivery of products. Catalyst Carrier Company has a team of highly experienced professionals who are committed to understanding the needs of each client and delivering customized solutions that meet their requirements.Looking forward, Catalyst Carrier Company is poised for further growth and success in the industry. The company has ambitious plans to expand its product portfolio and reach new markets. With a strong focus on innovation and sustainability, Catalyst Carrier Company is well-positioned to capitalize on the growing demand for catalyst carrier solutions.In conclusion, Catalyst Carrier Company has established itself as a key player in the catalyst carrier industry, thanks to its dedication to sustainability, innovation, and customer satisfaction. With a strong track record of delivering high-quality products and a focus on meeting the evolving needs of its clients, Catalyst Carrier Company is well-positioned for continued success in the market.

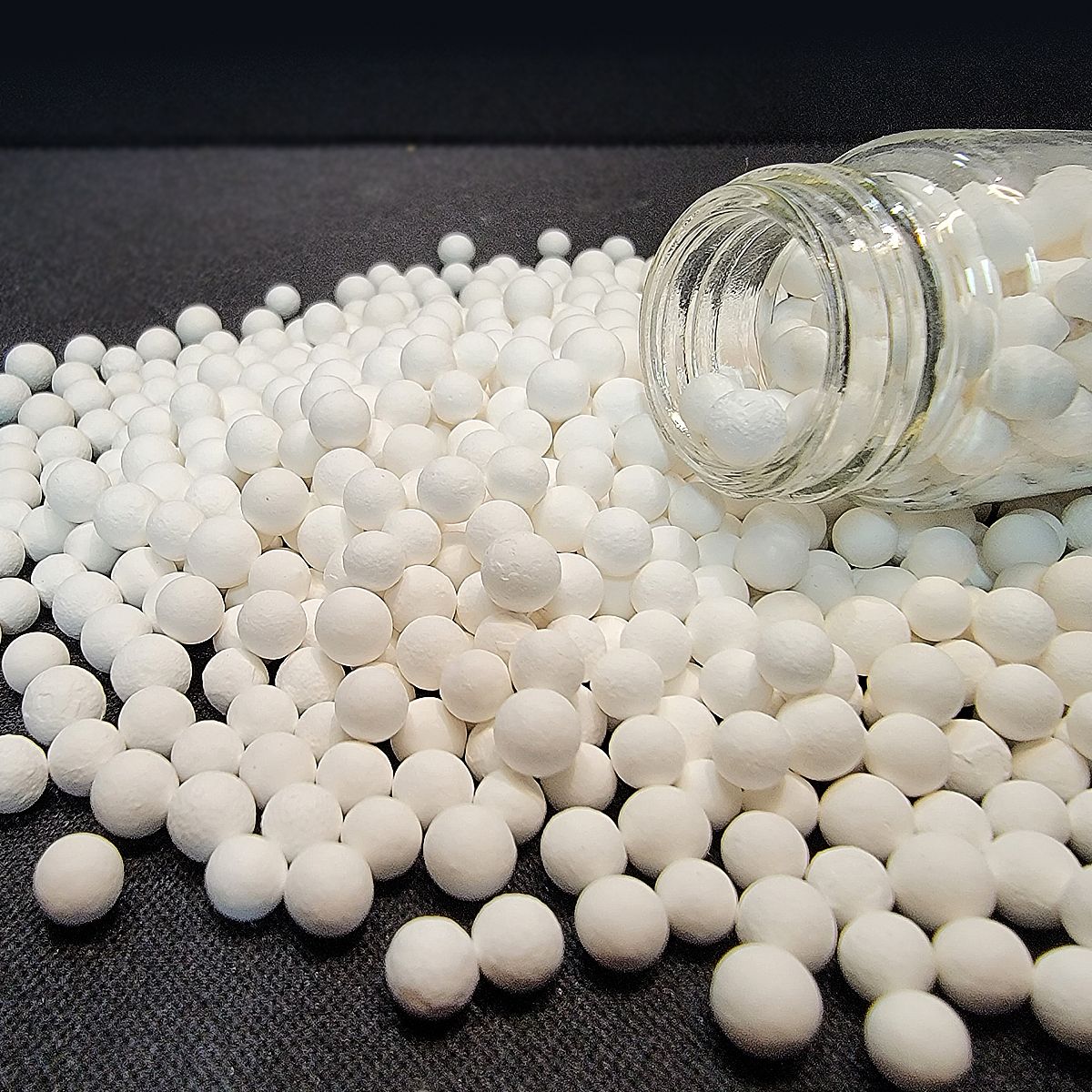

Key Properties and Applications of Gamma Alumina Unveiled in Latest Research

Houston, Texas – Gamma Alumina, a leading provider of high-quality alumina products, has announced the release of a new line of advanced gamma alumina materials. The company, known for its expertise in materials science and chemical engineering, has developed these innovative products to meet the growing demand for high-performance materials in various industrial applications.Gamma Alumina, a subsidiary of a global materials manufacturing company, has been at the forefront of alumina production for over two decades. With a focus on research and development, the company has continuously pushed boundaries in materials innovation, creating products that offer superior performance and reliability.The newly launched line of advanced gamma alumina materials is designed to deliver exceptional thermal and mechanical properties, making them ideal for use in a wide range of industries. These materials are suitable for applications such as catalyst support, adsorbents, and specialty ceramics, where high temperatures, corrosive environments, and mechanical stress are common.The company’s gamma alumina products are manufactured using state-of-the-art technologies and cutting-edge production processes, ensuring consistent quality and performance. Their advanced materials are characterized by high surface area, exceptional pore volume, and superior thermal stability, making them highly sought after by industries requiring reliable and high-performance materials.In addition to their physical properties, the new line of gamma alumina materials also offers excellent chemical stability, low impurity levels, and a highly customizable surface chemistry. This versatility allows the materials to be tailored to specific applications, giving customers the flexibility to optimize their processes and improve overall efficiency.Gamma Alumina’s commitment to sustainability is evident in the development of these advanced materials. The company places a strong emphasis on environmental responsibility, ensuring that their production processes adhere to strict environmental standards and regulations. Their materials are designed to minimize waste and energy consumption while maximizing resource efficiency, supporting the overall sustainability goals of their customers.The release of these innovative gamma alumina materials further solidifies the company’s position as a leader in the materials industry. With a strong focus on research and development, Gamma Alumina continues to invest in cutting-edge technologies and expertise to meet the evolving needs of their customers and stay ahead of industry trends.The company’s dedication to customer satisfaction is reflected in their comprehensive technical support and consulting services, ensuring that customers have access to the knowledge and expertise needed to optimize the performance of their materials. This commitment to excellence has established Gamma Alumina as a trusted partner for businesses seeking high-quality materials for their applications.With the release of their new line of advanced gamma alumina materials, Gamma Alumina is poised to make a significant impact on the materials industry, providing customers with innovative solutions that deliver on performance, reliability, and sustainability. As the demand for high-performance materials continues to grow, Gamma Alumina remains committed to pushing the boundaries of materials science to meet the evolving needs of their customers and contribute to the success of industries worldwide.

Discover the Properties and Applications of Alumina: An Essential Industrial Material

Title: Alumina Supplier Launches Enhanced Gamma Alumina, revolutionizing the IndustryIntroduction:In an impressive breakthrough within the materials industry, a leading alumina supplier has introduced an enhanced version of gamma alumina, promising to revolutionize multiple sectors dependent on this essential material. This groundbreaking innovation brings forth new possibilities in areas such as catalysts, adsorbents, and ceramics, cementing its position as a game-changer within the market.Company Background:(Information about the company) With a long-standing reputation for excellence in manufacturing high-quality alumina products, this company has consistently been at the forefront of driving innovation within the industry. Their expertise in producing advanced materials has earned them a prominent position as a trusted supplier for various sectors globally. Now, with the introduction of their enhanced gamma alumina, the company has yet again proven their commitment to meeting and surpassing market demands.Gamma Alumina - A Vital Catalyst for Diverse Industries:Gamma alumina, a type of alumina with a particular crystal structure, serves as a vital catalyst across a broad range of industries. Catalysts are essential in various chemical processes, facilitating crucial reactions or improving product quality. Gamma alumina's robustness, high surface area, and controlled pore size make it an ideal candidate for numerous catalyst applications.In the petrochemical industry, gamma alumina is commonly employed in the refining and production of various products, including gasoline and polymers. Its immense surface area provides substantial functionality, enhancing chemical reactions and promoting efficiency.Moreover, in the chemical industry, gamma alumina has proven indispensable in manufacturing processes such as hydrogenation and dehydrogenation. These reactions, vital for the production of numerous chemicals, often rely on gamma alumina catalysts to optimize reaction rates and maximize yields.Enhanced Gamma Alumina - Pioneering Advancements:The recent launch of enhanced gamma alumina by our featured supplier brings forth numerous pioneering advancements that will positively impact various sectors:1. Increased Surface Area and Pore Volume: Through advanced manufacturing techniques and proprietary processes, the enhanced gamma alumina offers a significantly increased surface area and pore volume. This improvement translates into enhanced catalytic activity, optimizing reaction kinetics and improving overall process efficiency.2. Enhanced Thermal and Chemical Stability: The enhanced gamma alumina showcases outstanding thermal and chemical stability, allowing it to withstand harsh operating conditions. This stability enables the catalysts to maintain their activity and selectivity, ensuring prolonged catalyst life and reducing downtime for replacements.3. Controlled Pore Structure: The carefully tuned pore structure of the enhanced gamma alumina offers precise control for various applications. This optimal pore size distribution allows for effective diffusion of molecules and efficient access to active sites, ensuring improved reaction selectivity and overall catalyst performance.Applications and Industry Implications:The launch of enhanced gamma alumina opens doors to various possibilities and industry implications:1. Petrochemical Industry: The enhanced gamma alumina will enable more efficient catalysts for refining processes, leading to increased productivity and higher-quality products. This advancement has the potential to significantly impact this vital industry worldwide.2. Environmental Sector: The enhanced gamma alumina's improved catalytic activity can greatly enhance air purification systems, allowing for better pollutant removal and creating a more sustainable environment.3. Industrial Catalysis: The ability of enhanced gamma alumina to withstand robust industrial conditions makes it an excellent choice for catalytic reactions in industrial settings, promoting more efficient and sustainable chemical production.4. Ceramics and Adsorbent Applications: The enhanced gamma alumina's increased surface area and pore volume make it an ideal candidate for various ceramic and adsorbent applications. These developments can result in improved performance in areas such as gas purification, water treatment, and air separation.Conclusion:The introduction of enhanced gamma alumina by our featured supplier marks a significant milestone in the materials industry. This innovation not only showcases the company's commitment to pushing boundaries but also opens up new possibilities for diverse industries. The enhanced gamma alumina's outstanding properties and improved performance will undoubtedly revolutionize catalyst production, leading to more efficient processes and a more sustainable future.

Breaking News: Enhanced Catalyst by Leading Provider Revolutionizes Industry

Clariant Catalyst, a leading innovator in the production of high-performance catalysts, has announced a major breakthrough in the field of catalysis. Their latest product has been developed to deliver greater efficiency, improved sustainability, and enhanced performance to the petrochemical industry.Catalysts are integral components in a variety of chemical reactions and are used to speed up the rate of a reaction or lower the amount of energy required. Clariant Catalysts has been pioneering the field of catalysts for over 70 years and has gained a reputation as a reliable and innovative provider of catalyst solutions.With the petrochemical industry being one of the largest consumers of catalysts, there has been a growing demand for catalysts that can help reduce costs, increase efficiency, and minimize environmental impact. This is where Clariant Catalysts' latest solution comes in.Clariant Catalysts' latest product represents a new class of catalysts that combines two key technologies: high-performance catalysts and sustainability. By incorporating these two technologies, the company has developed a solution that can help petrochemical companies increase efficiency, reduce waste, and ultimately, improve their bottom line.The new catalyst product has been designed to address some of the most pressing problems faced by the petrochemical industry. For instance, the catalyst is capable of converting different types of feedstocks into high-quality products. This is particularly important in the current period when there is an increasing demand for more advanced fuels and other petrochemical products. Furthermore, the new catalyst product can help reduce costs by reducing the amount of energy required to transform feedstocks into products. The result is a more efficient production process that leads to enhanced profitability.Another critical area that the new catalyst product addresses is sustainability. As the world focuses on reducing carbon emissions and transitioning to a greener economy, the petrochemical industry has come under scrutiny for its heavy reliance on fossil fuels. Clariant Catalysts' latest solution is designed to help petrochemical companies reduce their carbon footprint by using renewable feedstocks and reducing energy requirements. By doing so, the new catalyst product can help petrochemical companies meet sustainability goals and comply with regulatory requirements.Clariant Catalysts has always been committed to developing innovative and sustainable catalyst solutions. The company has invested heavily in research and development and has attracted some of the brightest minds in the field of catalysis. Their latest breakthrough represents a significant milestone in the company's history and is a testament to their dedication to sustainability and innovation.The new catalyst product has already generated significant interest from industry players, and its potential impact has been recognized by experts in the field. Andrew Sinclair, Head of Business Unit Catalysts at Clariant said, "We see a growing demand for catalysts that can help the petrochemical industry incorporate sustainability into their production processes. Our latest product is a game-changer in this regard, and we are thrilled to be able to offer it to our customers."The development of the new catalyst product has been a collaborative effort, involving experts from different fields. This multidisciplinary approach has resulted in a product that is truly unique and represents the cutting edge of catalysis.In conclusion, Clariant Catalysts' latest breakthrough represents a major step forward in the field of catalysis. Their new catalyst product offers petrochemical companies a pathway to more sustainable and efficient production processes. With an increasing focus on reducing carbon emissions and transitioning to a greener economy, solutions like Clariant Catalysts' latest product will become increasingly important. The company's commitment to sustainability and innovation is a model for others in the industry to follow.

Discover the latest advancements in Alumina Catalyst technology

Alumina Catalysts: A Game-Changer in Chemical IndustryIn the fast-paced world of chemical manufacturing, efficiency and sustainability are key concerns for companies looking to stay competitive. Enter Alumina Catalysts, a revolutionary new technology that is transforming the way chemical processes are carried out. This innovative catalyst, formulated by a leading chemical company, has been making waves in the industry due to its exceptional performance and environmentally friendly nature.Alumina Catalysts are a type of catalyst used in a wide range of chemical processes, including the production of petrochemicals, polymers, and other specialty chemicals. These catalysts are unique in that they are composed of alumina, a naturally occurring mineral that is renowned for its high surface area and thermal stability. This makes the catalysts highly effective at facilitating chemical reactions and promoting desirable outcomes in various industrial processes.One of the key advantages of Alumina Catalysts is their versatility. These catalysts can be tailored to suit specific chemical reactions, making them ideal for a wide range of applications. Whether it's cracking hydrocarbons in the production of fuels or promoting polymerization in the manufacturing of plastics, Alumina Catalysts have been proven to deliver superior results across the board.Furthermore, the environmental benefits of Alumina Catalysts cannot be overstated. By improving the efficiency of chemical processes, these catalysts help to reduce energy consumption and minimize waste generation. This not only leads to cost savings for companies, but also contributes to a more sustainable and eco-friendly approach to chemical manufacturing.The company behind the development of Alumina Catalysts has a long-standing reputation as a leader in the chemical industry. With decades of experience and a strong commitment to research and development, the company has been at the forefront of creating innovative solutions that address the evolving needs of the market. Their team of experts has worked tirelessly to optimize the performance of Alumina Catalysts, ensuring that they meet the highest standards of quality and reliability.In addition to their technical expertise, the company has also prioritized sustainability as a core value. This is reflected in their dedication to developing products, such as Alumina Catalysts, that contribute to a more sustainable and environmentally conscious chemical industry. By investing in green technologies and promoting responsible practices, the company is making a significant impact on the future of chemical manufacturing.The introduction of Alumina Catalysts has been met with enthusiasm from industry professionals and customers alike. Many companies have already adopted this technology and have reported impressive improvements in their chemical processes. Whether it's enhancing product yields, reducing production costs, or minimizing environmental impact, the benefits of Alumina Catalysts are clear and undeniable.Looking ahead, the prospects for Alumina Catalysts look promising. As the chemical industry continues to evolve and demand for more sustainable solutions grows, the role of these innovative catalysts is expected to become even more prominent. With ongoing research and development efforts, the company is committed to further enhancing the performance and applicability of Alumina Catalysts, solidifying their position as a game-changer in the chemical industry.In conclusion, Alumina Catalysts represent a significant advancement in the field of chemical manufacturing. With their impressive performance, versatility, and eco-friendly attributes, these catalysts have the potential to revolutionize the way chemical processes are carried out. Backed by a reputable and forward-thinking company, Alumina Catalysts are poised to shape a more sustainable and efficient future for the chemical industry.

New Tail Gas Hydrogenation Catalyst Shown to be Effective in Reducing Emissions

Tail Gas Hydrogenation Catalyst: An Innovative Solution for Clean AirWith the growing concern over environmental pollution and the urgent need for sustainable solutions, companies around the world have been constantly innovating to find efficient ways to reduce harmful emissions. One such groundbreaking solution is the Tail Gas Hydrogenation Catalyst, a cutting-edge technology that helps in minimizing air pollution and ensuring cleaner air for all.Tail gas hydrogenation is a process used in the petroleum industry to treat the waste gas produced during the production of sulfuric acid. This gas, commonly known as tail gas, contains high levels of harmful sulfur compounds and must be treated before release into the atmosphere. Failure to address this issue can have severe consequences for both human health and the environment.Enter the Tail Gas Hydrogenation Catalyst, developed by an industry-leading company. This state-of-the-art catalyst is designed to convert noxious sulfur compounds, primarily hydrogen sulfide, into elemental sulfur. By facilitating this conversion, the catalyst significantly reduces the emission of sulfur dioxide (SO2), a major contributor to air pollution and the formation of acid rain.The unique formulation of this catalyst allows it to operate at high temperatures, making it suitable for demanding industrial processes. Furthermore, its exceptional stability and longevity ensure its effectiveness for extended periods, resulting in lower maintenance costs and enhanced operational efficiency.The company behind this revolutionary catalyst has been known for its expertise in the field of catalyst development and its commitment to environmental sustainability. They have invested significant resources into research and development, resulting in a catalyst that not only excels in performance but also meets stringent international environmental regulations.In addition to its remarkable capabilities, the Tail Gas Hydrogenation Catalyst offers numerous benefits for industries looking to reduce their ecological footprint. By effectively eliminating harmful emissions, companies can maintain compliance with environmental regulations, enhance their social responsibility, and improve their reputation among clients and stakeholders.Furthermore, the implementation of this catalyst can lead to substantial cost savings for industries. The reduction in sulfur emissions translates into a lower requirement for expensive desulfurization equipment, resulting in decreased operational expenses. Additionally, the conversion of hydrogen sulfide into elemental sulfur can also generate a valuable byproduct that can be sold or further used in other industries.The Tail Gas Hydrogenation Catalyst has already demonstrated its effectiveness in several industrial applications. Whether in oil refineries, natural gas processing plants, or chemical manufacturing facilities, this catalyst has consistently proven its ability to transform harmful sulfur compounds into elemental sulfur, effectively resulting in cleaner air and a safer environment.As sustainability becomes a centerpiece of corporate strategies worldwide, the Tail Gas Hydrogenation Catalyst stands out as an innovative and reliable solution. Its ability to mitigate air pollution by neutralizing sulfur compounds marks a significant step forward in the quest for a cleaner and healthier planet.In conclusion, the innovative Tail Gas Hydrogenation Catalyst is set to revolutionize the way industries approach the reduction of harmful emissions. With its exceptional performance, environmental benefits, and cost-saving potential, this catalyst is a game-changer for companies striving to create a sustainable future. By embracing this revolutionary technology, industries can take a significant stride towards ensuring cleaner air and a healthier environment for generations to come.

Advanced Hydrofining Catalyst: Key Component for Oil Refining Process

Hydrofining Catalyst: Revolutionizing the Oil Refining IndustryIn today’s rapidly evolving energy industry, companies are constantly seeking technological advancements that can provide better solutions for oil refining processes. The hydrofining catalyst, developed by a leading chemical engineering company, has emerged as a game-changing innovation that promises to revolutionize the way crude oil is refined.The hydrofining catalyst is a cutting-edge technology that enables the removal of impurities from crude oil, resulting in a higher quality end product. This catalyst is designed to enhance the efficiency of the hydrofining process, which is crucial for producing cleaner and more environmentally friendly fuels. By utilizing this innovative catalyst, oil refineries are able to improve the quality of their refined products while adhering to increasingly stringent environmental regulations.The development of the hydrofining catalyst represents a major milestone for the company, which has been a pioneer in the field of chemical engineering for over three decades. With a proven track record of delivering high-performance solutions for the oil and gas industry, the company has established itself as a trusted partner for refineries worldwide. Its commitment to innovation and excellence has made it a leader in the development of advanced catalyst technologies.The hydrofining catalyst is the result of years of research and development, during which the company’s team of experts has worked tirelessly to create a product that meets the complex needs of modern oil refineries. This catalyst is specifically engineered to address the challenges posed by increasingly sour and heavy crude feedstocks, which are becoming more prevalent in today’s market. By effectively removing impurities such as sulfur, nitrogen, and metals from crude oil, the hydrofining catalyst contributes to the production of cleaner and higher quality fuels.One of the key advantages of the hydrofining catalyst is its ability to improve the overall performance and profitability of oil refineries. By enhancing the efficiency of the hydrofining process, this catalyst enables refineries to achieve higher yields of valuable products such as diesel and gasoline. In addition, the use of the hydrofining catalyst results in reduced energy consumption and operational costs, which translates to significant economic benefits for refinery operators.Furthermore, the hydrofining catalyst plays a crucial role in helping refineries comply with stringent environmental standards. As global efforts to reduce emissions and minimize environmental impact continue to gain momentum, the demand for cleaner fuels is on the rise. The use of this innovative catalyst allows refineries to produce fuels with lower sulfur content, thereby contributing to a more sustainable and environmentally friendly energy sector.The company’s dedication to sustainability and responsible innovation is evident in the development of the hydrofining catalyst. By enabling refineries to improve the quality of their fuels and reduce their environmental footprint, this catalyst exemplifies the company’s commitment to creating value for both its customers and the wider community.In conclusion, the introduction of the hydrofining catalyst represents a significant advancement in the field of oil refining. With its ability to enhance the efficiency, profitability, and environmental performance of refineries, this innovative technology is poised to revolutionize the way crude oil is processed. As the energy industry continues to evolve, the hydrofining catalyst stands out as a powerful tool for driving the transformation towards a more sustainable and efficient future.

Latest Breakthrough in Technology: Zsm-23 Makes Waves in the Industry

ZSM-23, a cutting-edge technology developed by a leading global company in the field of engineering and manufacturing, has been making waves in the industry. This innovative technology represents a significant breakthrough in the world of engineering, promising to revolutionize manufacturing processes and enhance productivity across various sectors.The company behind ZSM-23 is renowned for its commitment to excellence and its track record of developing cutting-edge solutions that address the evolving needs of the industry. With a strong emphasis on research and development, the company has consistently pushed the boundaries of what is possible, delivering state-of-the-art solutions that have set new benchmarks for quality, efficiency, and reliability.ZSM-23 is the latest testament to the company's dedication to innovation and its relentless pursuit of excellence. This groundbreaking technology is set to redefine the way manufacturing processes are carried out, offering a range of benefits that will drive efficiency and productivity to new heights.At its core, ZSM-23 is designed to optimize manufacturing processes, enabling companies to streamline production and achieve higher levels of output without compromising on quality. By leveraging cutting-edge algorithms and advanced automation capabilities, ZSM-23 has the potential to revolutionize the way products are manufactured, reducing lead times and costs while maximizing overall efficiency.One of the key features of ZSM-23 is its ability to adapt to the specific needs of different industries and production environments. This versatility makes it an ideal solution for a wide range of manufacturing applications, from automotive and aerospace to electronics and consumer goods. Whether it's precision machining, assembly line operations, or quality control, ZSM-23's capabilities are poised to deliver tangible improvements across the board.Moreover, ZSM-23 is built on a robust and reliable platform, ensuring seamless integration with existing manufacturing systems and equipment. This compatibility is a crucial factor in driving widespread adoption of the technology, as it enables companies to leverage the benefits of ZSM-23 without having to overhaul their entire production infrastructure.In addition to its technical prowess, ZSM-23 is backed by comprehensive support and service offerings from the company, ensuring that customers can maximize the value of the technology while minimizing downtime and disruptions. This commitment to customer satisfaction is a hallmark of the company's ethos, reflecting its dedication to delivering not just cutting-edge solutions, but also a superior overall experience to its clientele.The potential impact of ZSM-23 on the manufacturing industry cannot be overstated. By empowering companies to achieve higher levels of productivity and efficiency, ZSM-23 has the potential to drive significant improvements in cost-effectiveness and competitiveness. This, in turn, will contribute to the advancement of the industry as a whole, creating new opportunities for growth and innovation.As the global manufacturing landscape continues to evolve, the need for transformative technologies like ZSM-23 has never been greater. With its unparalleled capabilities and the backing of a pioneering company, ZSM-23 is poised to lead the charge in reshaping the future of manufacturing, setting new standards for what is possible and inspiring a new era of progress and achievement.

Innovative Catalysts: A Breakthrough in Sustainable Technology

Chemical company Clariant Catalysts recently announced a major breakthrough in the development of a new catalyst that has the potential to significantly improve the efficiency and sustainability of chemical processes. The new catalyst, which has been in development for several years, promises to revolutionize the industry by enabling the production of a wide range of chemicals in a more environmentally friendly and cost-effective manner.The development of the new catalyst is the result of extensive research and development efforts by Clariant Catalysts, a global leader in the field of catalyst technology. The company has a long history of innovation and has been at the forefront of developing cutting-edge solutions for the chemical industry. With a strong focus on sustainability and environmental responsibility, Clariant Catalysts is committed to developing products that not only meet the needs of its customers but also contribute to a more sustainable and environmentally friendly future.The new catalyst represents a significant advancement in the field of chemical catalysis. It is designed to be highly selective, which means that it can promote specific chemical reactions while minimizing the formation of unwanted by-products. This selectivity not only improves the efficiency of chemical processes but also reduces waste and energy consumption, leading to a more sustainable and cost-effective production process.One of the key advantages of the new catalyst is its ability to operate under milder conditions, which can lead to significant energy savings compared to traditional catalysts. This is particularly important in the chemical industry, where energy-intensive processes are common. By enabling reactions to take place at lower temperatures and pressures, the new catalyst has the potential to reduce the environmental impact of chemical production while also lowering operating costs for manufacturers.In addition to its environmental and economic benefits, the new catalyst also has the potential to enable the production of new and innovative chemicals that were previously difficult or impractical to produce. This could open up new opportunities for manufacturers to develop novel products and expand their offerings, ultimately driving innovation and growth in the industry.Clariant Catalysts is currently working with a select group of partners to further develop and commercialize the new catalyst. The company is leveraging its extensive expertise in catalyst development and its global presence to bring this innovative technology to market. By collaborating with industry partners, Clariant Catalysts aims to accelerate the adoption of the new catalyst and ensure that it meets the needs of a wide range of chemical manufacturers.The development of the new catalyst is a testament to Clariant Catalysts' commitment to innovation and sustainability. By investing in research and development and working closely with industry partners, the company is leading the way in developing new technologies that have the potential to transform the chemical industry. As the global demand for sustainable and efficient chemical processes continues to grow, the new catalyst is poised to play a key role in addressing this need and driving the industry forward.In conclusion, the development of the new catalyst by Clariant Catalysts represents a significant milestone in the field of chemical catalysis. With its potential to improve the efficiency, sustainability, and versatility of chemical processes, the new catalyst has the power to revolutionize the industry. By continuing to invest in research and development and collaborating with industry partners, Clariant Catalysts is well-positioned to bring this innovative technology to market and drive positive change in the chemical industry.

Discover the Benefits of Residue Hydrogenation Catalyst for Industrial Use

Residue Hydrogenation Catalyst is revolutionizing the oil and gas industry with its innovative and efficient catalyst technology. The company has been a leader in the field of catalyst development and manufacturing for over 20 years, providing high-quality solutions for a wide range of refining processes. With a strong commitment to research and development, the company has continuously improved its products and services to meet the evolving needs of the energy sector.The Residue Hydrogenation Catalyst is a critical component in the refining process, enabling the conversion of heavy hydrocarbons into more valuable products such as gasoline, diesel, and jet fuel. This process helps to maximize the yield of high-quality fuels from crude oil, while also reducing the environmental impact of refining operations. The catalyst's unique composition and structure enable it to efficiently remove impurities and improve the overall quality of the end products.One of the key advantages of the Residue Hydrogenation Catalyst is its high activity and selectivity, which allows for greater process flexibility and optimization. This results in higher throughput and lower operating costs for refineries, ultimately leading to improved profitability and competitiveness in the market. Additionally, the catalyst's exceptional stability and durability ensure long-term performance and reliability, reducing the frequency of catalyst replacement and maintenance.The company behind the Residue Hydrogenation Catalyst is committed to providing comprehensive technical support and expertise to its customers. Its team of experienced engineers and scientists work closely with refining operators to optimize catalyst performance and address specific challenges in their operations. Through on-site troubleshooting, catalyst monitoring, and performance evaluation, the company helps its clients achieve maximum efficiency and productivity in their refining processes.Furthermore, the company places a strong emphasis on sustainability and environmental responsibility. The Residue Hydrogenation Catalyst is designed to minimize the production of undesirable by-products and emissions, contributing to a cleaner and more sustainable refining industry. By helping refineries comply with stringent environmental regulations and standards, the catalyst supports the industry's transition towards a more eco-friendly and socially responsible future.The Residue Hydrogenation Catalyst has been successfully deployed in numerous refineries around the world, delivering exceptional performance and reliability in a variety of operating conditions and feedstocks. Its proven track record of success has earned the trust and confidence of major oil and gas companies, making it a preferred choice for catalyst solutions in the industry.In conclusion, the Residue Hydrogenation Catalyst is a game-changing technology that is reshaping the refining landscape. With its innovative design, superior performance, and strong support services, the catalyst enables refineries to achieve greater efficiency, profitability, and sustainability in their operations. As the demand for high-quality fuels continues to grow, the Residue Hydrogenation Catalyst will play a pivotal role in ensuring the industry's success and long-term viability.